engine control NISSAN TIIDA 2011 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 447 of 3787

![NISSAN TIIDA 2011 Service Manual Online AV-50

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000 NISSAN TIIDA 2011 Service Manual Online AV-50

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000](/img/5/57396/w960_57396-446.png)

AV-50

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006412034

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006412035

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 463 of 3787

![NISSAN TIIDA 2011 Service Manual Online AV-66

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

END ON-BOARD DIAGNOSIS

Turn OFF ignition switch.

Noise InspectionINFOID:0000000005931317

The vehicle itself can be a source of noise if noise NISSAN TIIDA 2011 Service Manual Online AV-66

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

END ON-BOARD DIAGNOSIS

Turn OFF ignition switch.

Noise InspectionINFOID:0000000005931317

The vehicle itself can be a source of noise if noise](/img/5/57396/w960_57396-462.png)

AV-66

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

END ON-BOARD DIAGNOSIS

Turn OFF ignition switch.

Noise InspectionINFOID:0000000005931317

The vehicle itself can be a source of noise if noise

prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and determine the cause.

NOTE:

The source of the noise can be found easily by listening to the noise while removing the fuses of electrical

components, one by one.

TYPE OF NOISE AND POSSIBLE CAUSE

Symptom ChartINFOID:0000000006216708

MALFUNCTION WITH NAVIGATION

System configuration • 8 pulses speed

• Clock ON/OFF

• Equalizer setup X11C

• RF tuning

• Antenna type

• Sound system

• Sub Out: Code

• Steering wheel The device is configured by a connect-

ed hardware circuit.

The parameter is

influenced.

Self test •Bluetooth

® module Access Mal-

function

• SD-card Access Malfunction

• Radio-Antenna Circuit Malfunc-

tion

• GPS Antenna Circuit Malfunc-

tion

• Microphone Circuit Malfunction A system self test is executed: the re-

sult is stored into

the error memory

which is shown afterwards as a list of

codes of the detected malfunctions.

Mode

ItemContent

Occurrence condition Possible cause

Occurs only when engine is ON. A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed.

Ignition components

A whistling noise occurs while the engine speed is

high. A booming noise occurs while the engine is

running and the lighting switch is ON. Generator

Noise only occurs when various

electrical components are oper-

ating. A cracking or snapping sound occurs with the op-

eration of various switches.

Relay malfunction, radio malfunction

The noise occurs when various motors are operat-

ing. • Motor case ground

• Motor

The noise occurs constantly, not just under certain conditions. • Rear defogger coil malfunction

• Open circuit in printed heater

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively. • Ground wire of body parts.

• Ground due to improper part installation

• Wiring connections or a short circuit

Symptoms

Check itemsProbable malfunction location / Action to

take

Display does not turn ON. All switches cannot be operated.

AV control unit power supply and ground

circuit. Refer to

AV- 6 9

.

All switches can be operated. AV control unit. Refer to AV- 6 9

.

Revision: May 2010 2011 Versa

Page 464 of 3787

![NISSAN TIIDA 2011 Service Manual Online AUDIOAV-67

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

MALFUNCTION WITH AUDIO

• The majority of the audio malfunctions are the result of outside causes (Malfunct NISSAN TIIDA 2011 Service Manual Online AUDIOAV-67

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

MALFUNCTION WITH AUDIO

• The majority of the audio malfunctions are the result of outside causes (Malfunct](/img/5/57396/w960_57396-463.png)

AUDIOAV-67

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

MALFUNCTION WITH AUDIO

• The majority of the audio malfunctions are the result of outside causes (Malfunction CD, electromagnetic interference, etc.). Check the sympt oms below to diagnose the malfunction.

• The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and oper-

ation of each piece of electrical equipment, and then determine the cause.

NOTE:

• CD-R is not guaranteed to play because they can contain compressed audio (MP3, WMA) or could be incorrectly mastered by the customer on a computer.

• Check if the CDs have the Compact Disc logo. If not, the disc is not mastered to the “red book” Compact

Disc standard and may not play.

All switches cannot be operated. Display does not turn ON.

AV control unit power supply and ground

circuit. Refer to

AV- 6 9.

Display turn ON. AV control unit. Refer to AV- 6 9

.

Only specified switch cannot be

operated. –

AV control unit. Refer to AV- 6 9

.

Voice guidance is not heard. Audio sound is normal. AV control unit. Refer to AV- 6 9

.

Display does not dim. Check “Illumination

Signal” in “SERVICE

SYSTEM STATUS”,

“SERVICE MENU”. “Illumination Signal” reaches

100% when the lighting

switch is ON.

AV control unit. Refer to

AV- 7 3

.

“Illumination Signal” does not

reach 100% when the lighting

switch is ON. Illumination signal circuit. Refer to

LT-

109.

Vehicle icon does not move. Check “Speed Signal”

in “SERVICE SYSTEM

STATUS”, “SERVICE

MENU”. A value of “Speed Signal”

changes according to vehicle

speeds.

AV control unit. Refer to

AV- 7 3

.

A value of “Speed Signal”

does not change according to

vehicle speeds. Vehicle speed signal circuit. Refer to

DI-

16.

Map matching is not complete

GPS icon is not displayed Check “GPS Antenna”

in “SERVICE SYSTEM

SELF TEST”, “SER-

VICE MENU”. “Connected” is displayed for

“GPS Antenna”.

AV control unit. Refer to

AV- 7 3

.

“Connected” is not displayed

for “GPS Antenna”. GPS antenna. Refer to

AV- 9 3

.

Traffic information (XM Traffic) is

not received. Radio broadcasts are received.

AV control unit. Refer to AV- 7 3

.

Radio broadcasts are not received. • Radio antenna. Refer to

AV- 9 1

.

• Antenna feeder. Refer to AV- 9 1

.

Symptoms

Check itemsProbable malfunction location / Action to

take

Symptom Probable malfunction location

Audio system does not work normally. • AV control unit power supply and ground circuit. Refer to

AV- 6 9

.

• AV control unit. Refer to AV- 7 3

.

Audio steering wheel switch does not operate proper-

ly. • Remote control signal circuit between steering switch and AV control unit.

Refer to AV- 6 9

.

• Steering wheel audio control switch. Refer to AV- 7 3

.

• AV control unit. Refer to AV- 7 3

.

No sound can be heard from any speakers. • Speaker circuit shorted to ground. Refer to

AV- 5 6

.

• AV control unit. Refer to AV- 7 3

.

No sound can be heard from front speakers. • Audio signal circuit between AV control unit and front speakers. Refer to

AV- 7 0

.

• Front speaker. Refer to AV- 7 3

.

• Front tweeter. Refer to AV- 7 3

.

• AV control unit. Refer to AV- 7 3

.

Revision: May 2010 2011 Versa

Page 492 of 3787

BCS-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929254

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006413290

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 514 of 3787

BL-4

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929267

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929268

NOTE:

• This procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnec ting both battery cables with the ignition in the ″LOCK ″

position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS /IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 598 of 3787

BL-88

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

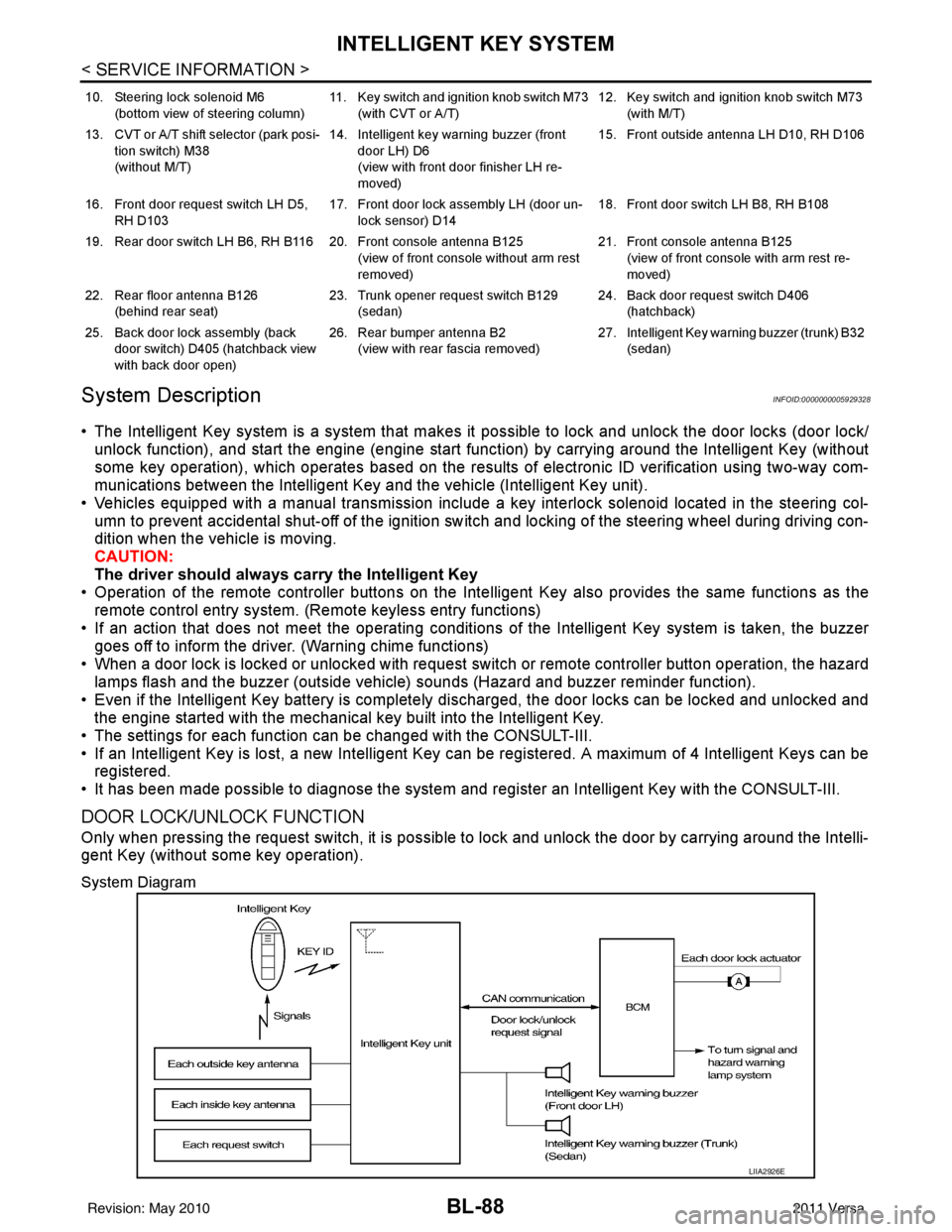

System Description

INFOID:0000000005929328

• The Intelligent Key system is a system that makes it possible to lock and unlock the door locks (door lock/

unlock function), and start the engine (engine start func tion) by carrying around the Intelligent Key (without

some key operation), which operates based on the results of electronic ID verification using two-way com-

munications between the Intelligent Key and the vehicle (Intelligent Key unit).

• Vehicles equipped with a manual transmission include a key interlock solenoid located in the steering col- umn to prevent accidental shut-off of the ignition sw itch and locking of the steering wheel during driving con-

dition when the vehicle is moving.

CAUTION:

The driver should always carry the Intelligent Key

• Operation of the remote controller buttons on the Inte lligent Key also provides the same functions as the

remote control entry system. (Remote keyless entry functions)

• If an action that does not meet the operating conditions of the Intelligent Key system is taken, the buzzer

goes off to inform the driver. (Warning chime functions)

• When a door lock is locked or unlocked with request switch or remote controller button operation, the hazard

lamps flash and the buzzer (outside vehicle) sounds (Hazard and buzzer reminder function).

• Even if the Intelligent Key battery is completely discharged, the door locks can be locked and unlocked and the engine started with the mechanical key built into the Intelligent Key.

• The settings for each function can be changed with the CONSULT-III.

• If an Intelligent Key is lost, a new Intelligent Key can be registered. A maximum of 4 Intelligent Keys can be registered.

• It has been made possible to diagnose the system and r egister an Intelligent Key with the CONSULT-III.

DOOR LOCK/UNLOCK FUNCTION

Only when pressing the request switch, it is possible to lock and unlock the door by carrying around the Intelli-

gent Key (without some key operation).

System Diagram

10. Steering lock solenoid M6

(bottom view of steering column) 11. Key switch and ignition knob switch M73

(with CVT or A/T) 12. Key switch and ignition knob switch M73

(with M/T)

13. CVT or A/T shift selector (park posi- tion switch) M38

(without M/T) 14. Intelligent key warning buzzer (front

door LH) D6

(view with front door finisher LH re-

moved) 15. Front outside antenna LH D10, RH D106

16. Front door request switch LH D5, RH D103 17. Front door lock assembly LH (door un-

lock sensor) D14 18. Front door switch LH B8, RH B108

19. Rear door switch LH B6, RH B116 20. Front console antenna B125 (view of front console without arm rest

removed)21. Front console antenna B125

(view of front console with arm rest re-

moved)

22. Rear floor antenna B126 (behind rear seat) 23. Trunk opener request switch B129

(sedan) 24. Back door request switch D406

(hatchback)

25. Back door lock assembly (back door switch) D405 (hatchback view

with back door open) 26. Rear bumper antenna B2

(view with rear fascia removed) 27. Intelligent Key warn

ing buzzer (trunk) B32

(sedan)

LIIA2926E

Revision: May 2010 2011 Versa

Page 602 of 3787

BL-92

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

The headlamp flashes and the horn sounds intermittently.

The alarm automatically turns off:

• After 25 seconds

• When Intelligent Key unit receives any signal from remote controller of Intelligent Key

• When door request switch is pressed (Intelligent Key is outside vehicle)

Panic alarm function's press and holding time value can be changed in “PANIC ALARM DELAY” mode in

“WORK SUPPORT”. Refer to BL-117, "

CONSULT-III Application Item".

List of Operation Related Parts

Parts marked with × are the parts related to operation.

ENGINE START FUNCTION

When the registered Intelligent Key is carried, the engine can be started without inserting the key.

When ignition knob switch is ON (press ignition switch ), Intelligent Key unit searches Intelligent Key in the

vehicle using inside key antenna.

Then Intelligent Key is inside the vehicle, it performs the following operation.

• Illuminate green “KEY” warning lamp in combination meter.

• Released steering lock and ignition switch can be turned from OFF to ACC, ON or START position.

NOTE:

If Intelligent Key is not registered, “KEY” warning lamp in combination meter illuminates red.

• Intelligent Key sends engine start signal to BCM via CAN communication line.

When ignition switch turns to START position, BCM sends starter request signal to IPDM E/R. Then, engine

starts.

Remote keyless entry functions

Intelligent Key

Key switch

Ignition knob switch

Door request switch

Door switch

Back door lock assembly (back door switch)

Door lock actuator

Intelligent Key warning buzzer

Intelligent Key unit

CAN communication system

BCM

Hazard warning lamp

Horn

IPDM E/R

Head lamp

Door lock/unlock function by Intelligent Key button × ××× ×××

Hazard and buzzer reminder function ×××××

Auto door lock function ×× ××× ×××

Panic alarm function ×××× ××× ×××

WIIA1282E

Revision: May 2010 2011 Versa

Page 629 of 3787

INTELLIGENT KEY SYSTEMBL-119

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

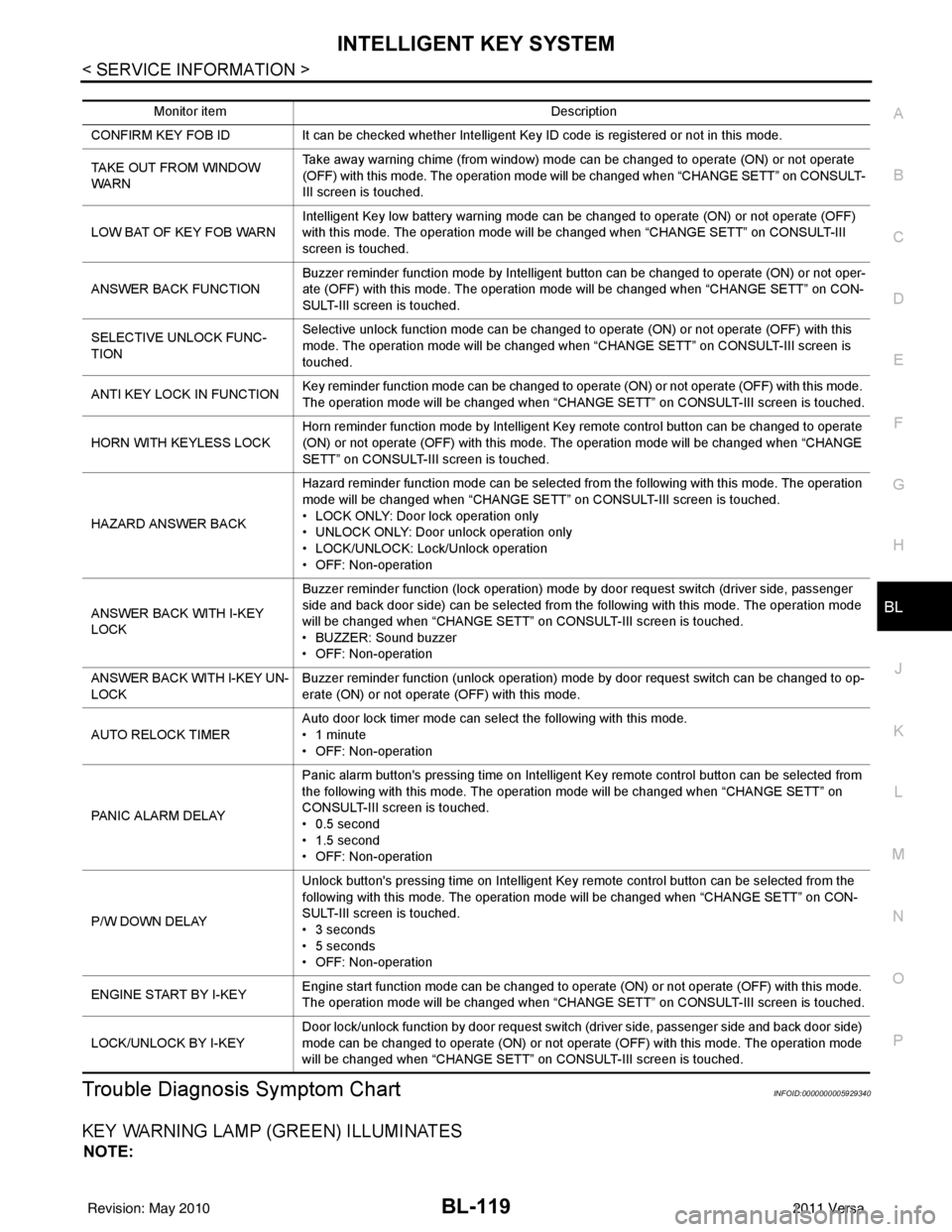

Trouble Diagnosis Symptom ChartINFOID:0000000005929340

KEY WARNING LAMP (GREEN) ILLUMINATES

NOTE:

Monitor item Description

CONFIRM KEY FOB ID It can be checked whether Intelligent Key ID code is registered or not in this mode.

TAKE OUT FROM WINDOW

WARN Take away warning chime (from window) mode can be changed to operate (ON) or not operate

(OFF) with this mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-

III screen is touched.

LOW BAT OF KEY FOB WARN Intelligent Key low battery warning mode can be changed to operate (ON) or not operate (OFF)

with this mode. The operation mode will be changed when “CHANGE

SETT” on CONSULT-III

screen is touched.

ANSWER BACK FUNCTION Buzzer reminder function mode by Intelligent button can be changed to operate (ON) or not oper-

ate (OFF) with this mode. The operation mode will be changed when “CHANGE SETT” on CON-

SULT-III screen is touched.

SELECTIVE UNLOCK FUNC-

TION Selective unlock function mode can be changed to operate (ON) or not operate (OFF) with this

mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is

touched.

ANTI KEY LOCK IN FUNCTION Key reminder function mode can be changed to operate (ON) or not operate (OFF) with this mode.

The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is touched.

HORN WITH KEYLESS LOCK Horn reminder function mode by Intelligent Key remote control button can be changed to operate

(ON) or not operate (OFF) with this mode. The operation mode will be changed when “CHANGE

SETT” on CONSULT-III screen is touched.

HAZARD ANSWER BACK Hazard reminder function mode can be selected from the following with this mode. The operation

mode will be changed when “CHANGE SE

TT” on CONSULT-III screen is touched.

• LOCK ONLY: Door lock operation only

• UNLOCK ONLY: Door unlock operation only

• LOCK/UNLOCK: Lock/Unlock operation

• OFF: Non-operation

ANSWER BACK WITH I-KEY

LOCK Buzzer reminder function (lock operation) mode by door request switch (driver side, passenger

side and back door side) can be selected from the following with this mode. The operation mode

will be changed when “

CHANGE SETT” on CONSULT- III screen is touched.

• BUZZER: Sound buzzer

• OFF: Non-operation

ANSWER BACK WITH I-KEY UN-

LOCK Buzzer reminder function (unlock operation) mode by door request switch can be changed to op-

erate (ON) or not operate (OFF) with this mode.

AUTO RELOCK TIMER Auto door lock timer mode can select the following with this mode.

• 1 minute

• OFF: Non-operation

PANIC ALARM DELAY Panic alarm button's pressing time on Intelligent Key remote control button can be selected from

the following with this mode. The operation mode will be changed when “CHANGE SETT” on

CONSULT-III screen is touched.

• 0.5 second

• 1.5 second

• OFF: Non-operation

P/W DOWN DELAY Unlock button's pressing time on Intelligent Key remote control button can be selected from the

following with this mode. The operation mode will be changed when “CHANGE SETT” on CON-

SULT-III screen is touched.

• 3 seconds

• 5 seconds

• OFF: Non-operation

ENGINE START BY I-KEY Engine start function mode can be changed to operate (ON) or not operate (OFF) with this mode.

The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is touched.

LOCK/UNLOCK BY I-KEY Door lock/unlock function by door request switch (driver side, passenger side and back door side)

mode can be changed to operate (ON) or not operate (OFF) with this mode. The operation mode

will be changed when “

CHANGE SETT” on CONSULT- III screen is touched.

Revision: May 2010 2011 Versa

Page 757 of 3787

NATS (NISSAN ANTI-THEFT SYSTEM)BL-247

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

-BCM

- Mechanical key

• NATS trouble diagnoses, system initialization and additional registration of other NATS mechanical key IDs

must be carried out using CONSULT-III hardware and CONSULT-III NATS software. When NATS initializa-

tion has been completed, the ID of the inserted mechanical key can be displayed.

Regarding the procedures of NATS initialization and mechanical key ID registration, refer to CONSULT-III

operation manual NATS.

SECURITY INDICATOR

• Forewarns that the vehicle is equipped with NATS.

• Security indicator will not blink while the ignition knob is in ON or START state. NOTE:

Because security indicator is highly efficient, the battery is barely affected.

Condition of Secu rity Indicator

• When operating the ignition switch with Intelligent Key, security indicator lamp will turn off at once if ignition

switch is pressed and blinks when ignition switch is released.

• When operating the ignition switch with mechanical key security indicator will turn off at once if mechanical key is inserted into key cylinder and blinks when mechanical key is removed.

(Once the mechanical key is inserted into key cylinder, BCM will only perform the key ID verification with

mechanical key)

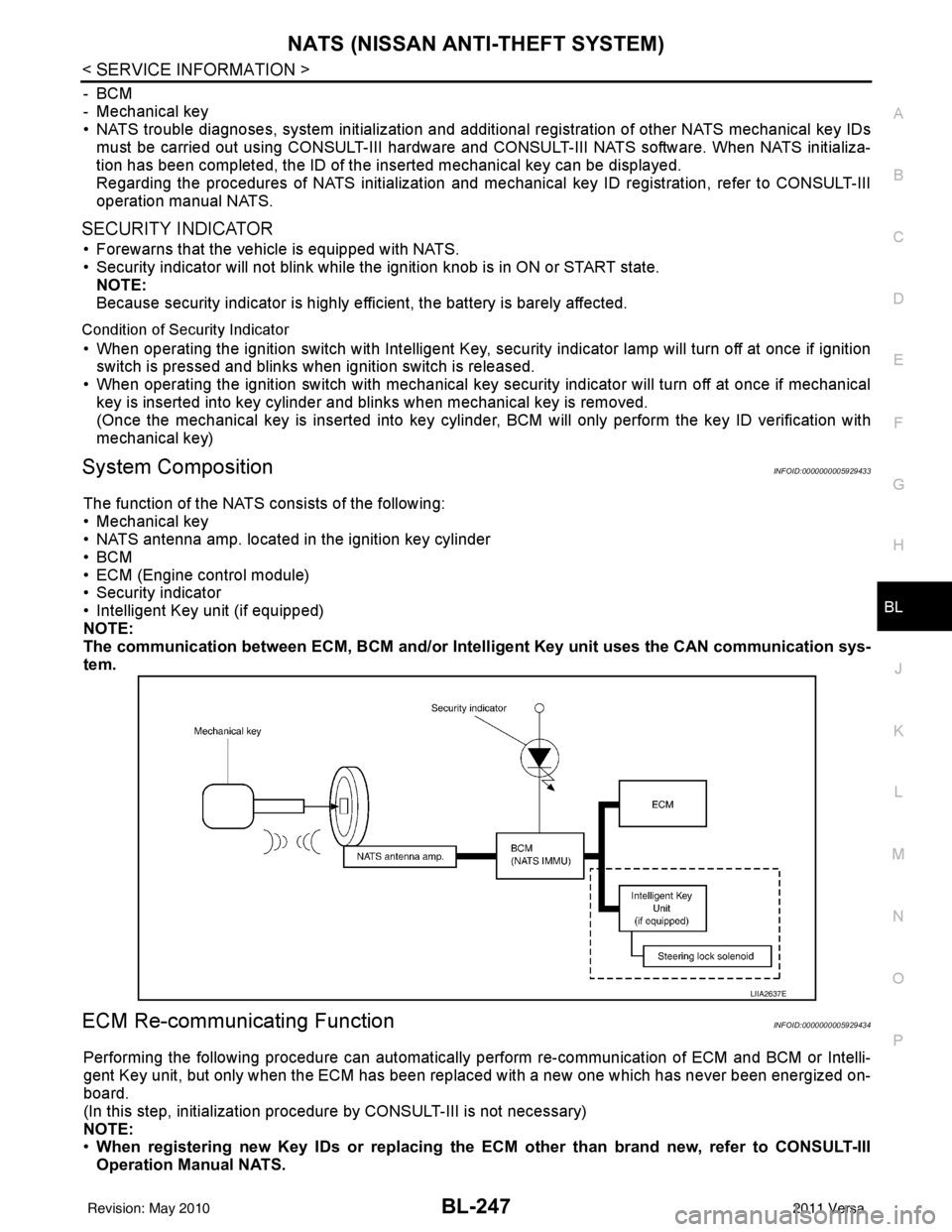

System CompositionINFOID:0000000005929433

The function of the NATS consists of the following:

• Mechanical key

• NATS antenna amp. located in the ignition key cylinder

•BCM

• ECM (Engine control module)

• Security indicator

• Intelligent Key unit (if equipped)

NOTE:

The communication between ECM, BCM and/or Intelligent K ey unit uses the CAN communication sys-

tem.

ECM Re-communicating FunctionINFOID:0000000005929434

Performing the following procedure can automatically perform re-communication of ECM and BCM or Intelli-

gent Key unit, but only when the ECM has been replaced with a new one which has never been energized on-

board.

(In this step, initialization procedur e by CONSULT-III is not necessary)

NOTE:

• When registering new Key IDs or replacing the ECM other than brand new, refer to CONSULT-III

Operation Manual NATS.

LIIA2637E

Revision: May 2010 2011 Versa

Page 758 of 3787

BL-248

< SERVICE INFORMATION >

NATS (NISSAN ANTI-THEFT SYSTEM)

•If multiple keys are attached to the key holder, separate them before work.

• Distinguish keys with unregistered key ID from those with registered ID.

1. Install ECM.

2. Use a registered key (*), turn ignition switch to “ON”. *: To perform this step, use the key that has been used before to perform ECM replacement.

3. Maintain ignition switch in “ON” position for at least 5 seconds.

4. Turn ignition switch to “OFF”.

5. Start engine. If engine can be started, procedure is completed.

If engine cannot be started, refer to CONSULT-III Operation Manual NATS and initialize control unit.

Revision: May 2010 2011 Versa