engine NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3794 of 3833

MA-14

PERIODIC MAINTENANCE

●(4) First replace at 100,000 Km (60,000 miles), then every 60,000Km (36,000 miles). After first replacement, perform "I"

(checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

●(5) If engine power decreases, black exhaust smoke is emitted or engine noise increases, perform this maintenance item.

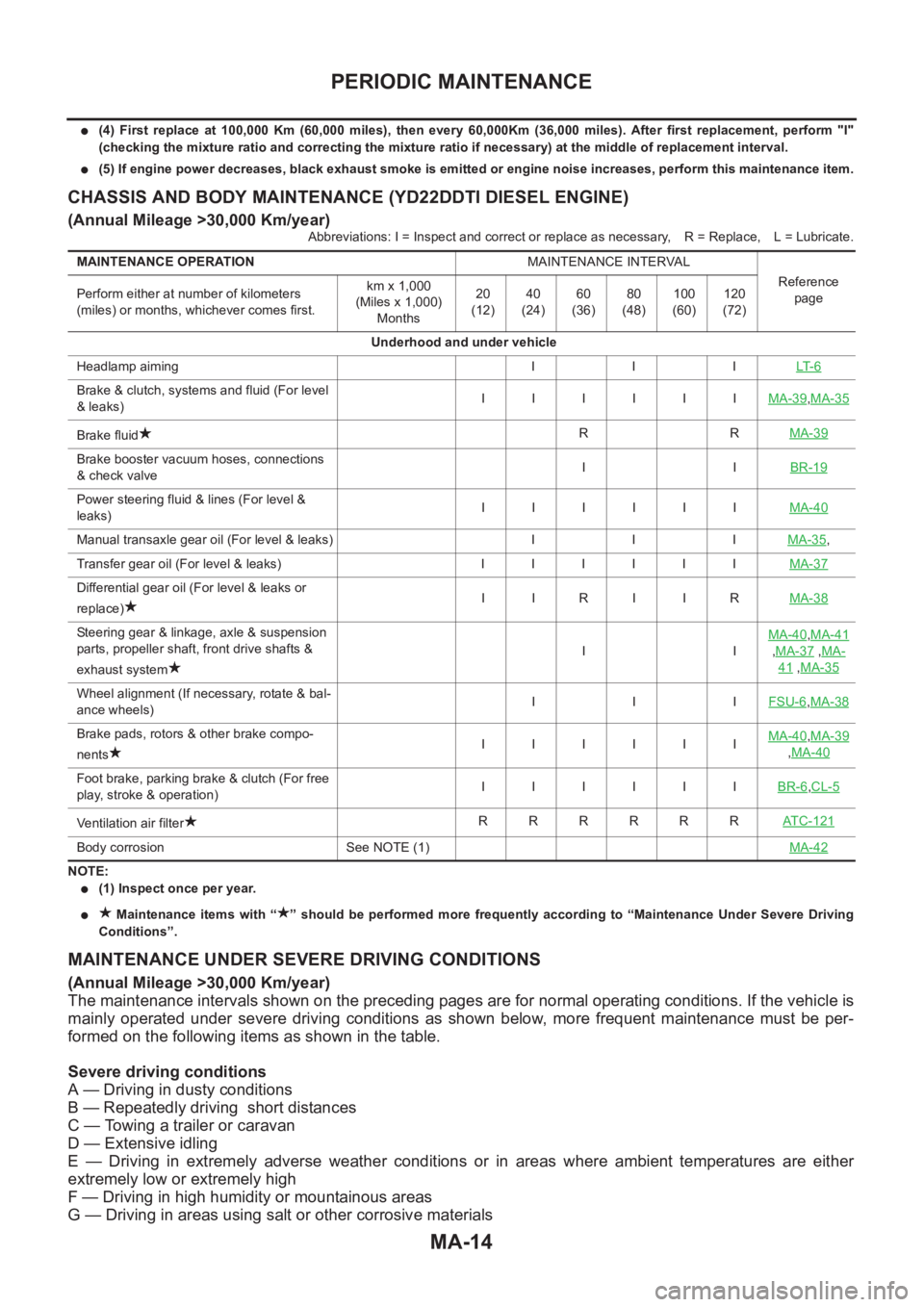

CHASSIS AND BODY MAINTENANCE (YD22DDTI DIESEL ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary,R = Replace, L = Lubricate.

NOTE:

●(1) Inspect once per year.

● Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

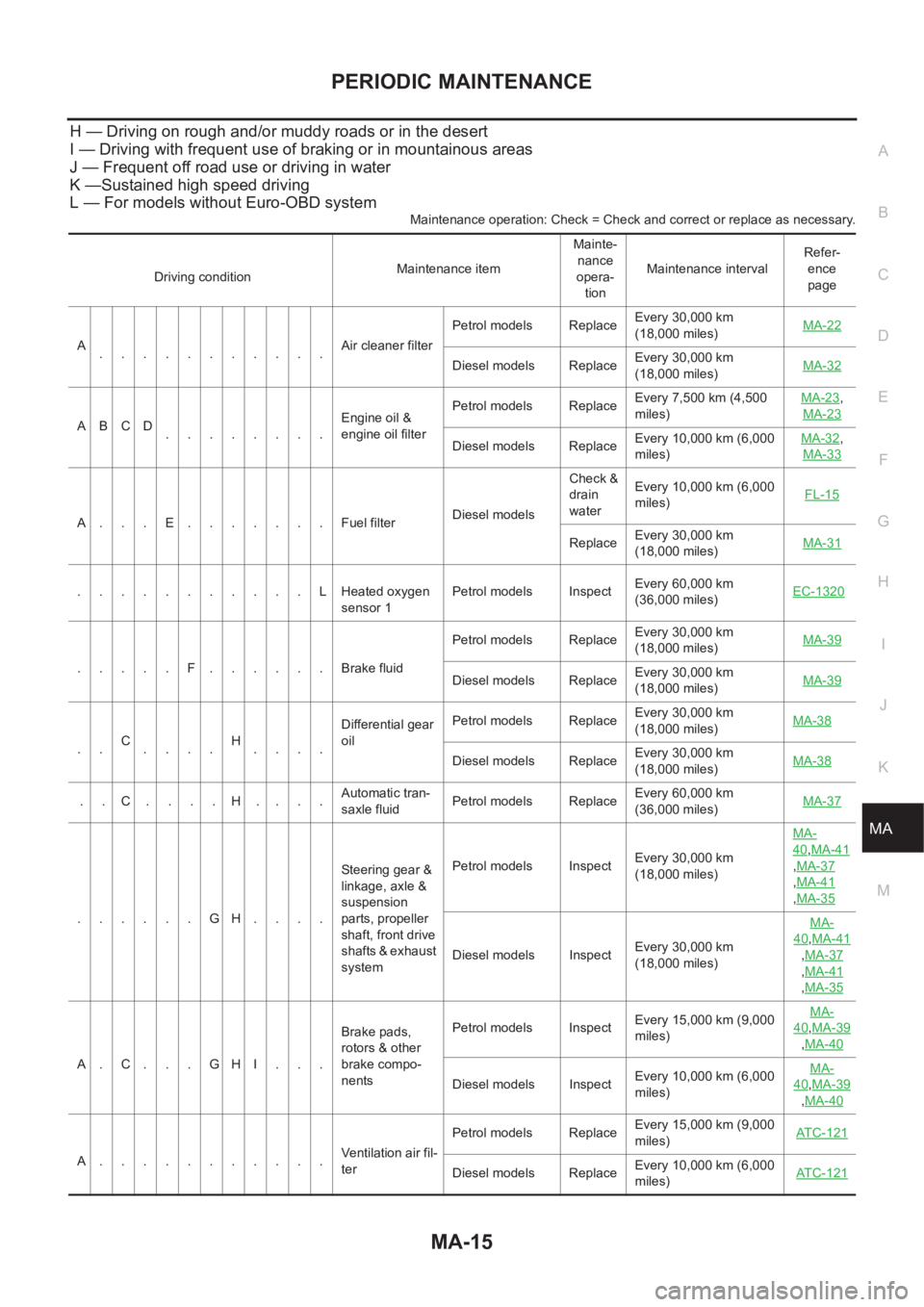

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage >30,000 Km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Repeatedly driving short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity or mountainous areas

G — Driving in areas using salt or other corrosive materials

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers

(miles) or months, whichever comes first.km x 1,000

(Miles x 1,000)

Months20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

Underhood and under vehicle

Headlamp aiming I I ILT- 6

Brake & clutch, systems and fluid (For level

& leaks)IIIIIIMA-39,MA-35

Brake fluidRRMA-39

Brake booster vacuum hoses, connections

& check valveIIBR-19

Power steering fluid & lines (For level &

leaks)IIIIIIMA-40

Manual transaxle gear oil (For level & leaks) I I IMA-35,

Transfer gear oil (For level & leaks) IIIIIIMA-37

Differential gear oil (For level & leaks or

replace)IIRIIRMA-38

Steering gear & linkage, axle & suspension

parts, propeller shaft, front drive shafts &

exhaust systemIIMA-40,MA-41

,MA-37 ,MA-

41 ,MA-35

Wheel alignment (If necessary, rotate & bal-

ance wheels)IIIFSU-6,MA-38

Brake pads, rotors & other brake compo-

nentsIIIIIIMA-40,MA-39

,MA-40

Foot brake, parking brake & clutch (For free

play, stroke & operation)IIIIIIBR-6,CL-5

Ventilation air filterRRRRRRAT C - 1 2 1

Body corrosion See NOTE (1)MA-42

Page 3795 of 3833

PERIODIC MAINTENANCE

MA-15

C

D

E

F

G

H

I

J

K

MA

B

MA

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K —Sustained high speed driving

L — For models without Euro-OBD system

Maintenance operation: Check = Check and correct or replace as necessary.

Driving conditionMaintenance itemMainte-

nance

opera-

tionMaintenance intervalRefer-

ence

page

A

...........Air cleaner filterPetrol models ReplaceEvery 30,000 km

(18,000 miles) MA-22

Diesel models ReplaceEvery 30,000 km

(18,000 miles) MA-32

ABCD

........Engine oil &

engine oil filter Petrol models ReplaceEvery 7,500 km (4,500

miles) MA-23

,

MA-23

Diesel models ReplaceEvery 10,000 km (6,000

miles) MA-32,

MA-33

A...E.......Fuel filter Diesel models Check &

drain

waterEvery 10,000 km (6,000

miles) FL-15

ReplaceEvery 30,000 km

(18,000 miles) MA-31

...........LHeated oxygen

sensor 1Petrol models InspectEvery 60,000 km

(36,000 miles) EC-1320

.....F......Brake fluidPetrol models ReplaceEvery 30,000 km

(18,000 miles) MA-39Diesel models ReplaceEvery 30,000 km

(18,000 miles) MA-39

..C

....H

....Differential gear

oilPetrol models ReplaceEvery 30,000 km

(18,000 miles) MA-38Diesel models ReplaceEvery 30,000 km

(18,000 miles) MA-38

..C....H....Automatic tran-

saxle fluidPetrol models ReplaceEvery 60,000 km

(36,000 miles) MA-37

......GH....Steering gear &

linkage, axle &

suspension

parts, propeller

shaft, front drive

shafts & exhaust

systemPetrol models InspectEvery 30,000 km

(18,000 miles) MA-

40,MA-41

,MA-37

,MA-41

,MA-35

Diesel models InspectEvery 30,000 km

(18,000 miles) MA-

40,MA-41

,MA-37

,MA-41

,MA-35

A.C...GHI...Brake pads,

rotors & other

brake compo-

nentsPetrol models InspectEvery 15,000 km (9,000

miles) MA-

40,MA-39

,MA-40

Diesel models InspectEvery 10,000 km (6,000

miles) MA-40,MA-39

,MA-40

A...........Ventilation air fil-

terPetrol models ReplaceEvery 15,000 km (9,000

miles) AT C - 1 2 1Diesel models ReplaceEvery 10,000 km (6,000

miles) AT C - 1 2 1

Page 3796 of 3833

MA-16

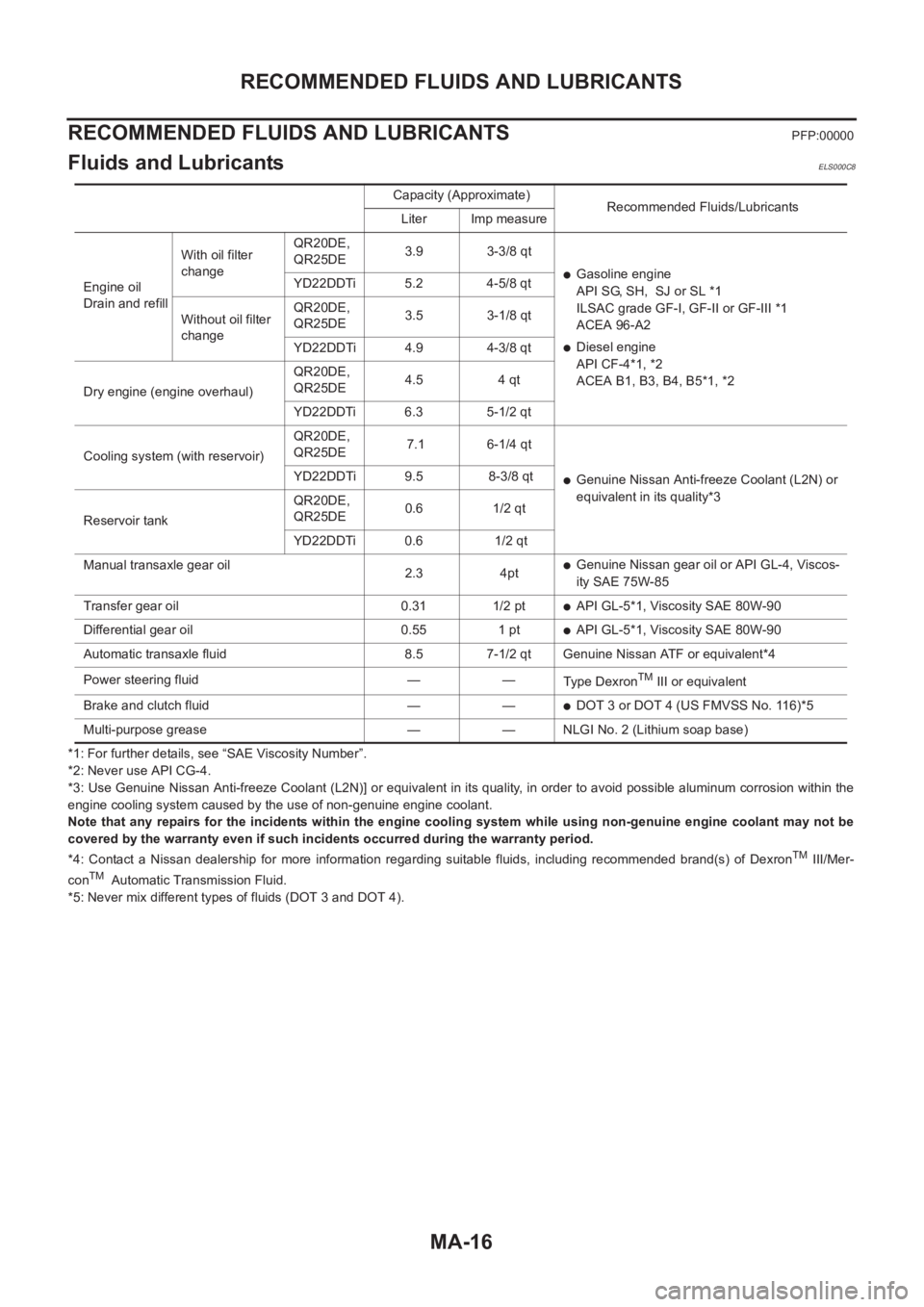

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

PFP:00000

Fluids and LubricantsELS000C8

*1: For further details, see “SAE Viscosity Number”.

*2: Never use API CG-4.

*3: Use Genuine Nissan Anti-freeze Coolant (L2N)] or equivalent in its quality, in order to avoid possible aluminum corrosion within the

engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of Dexron

TM III/Mer-

conTM Automatic Transmission Fluid.

*5: Never mix different types of fluids (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp measure

Engine oil

Drain and refillWith oil filter

changeQR20DE,

QR25DE3.9 3-3/8 qt

●Gasoline engine

API SG, SH, SJ or SL *1

ILSAC grade GF-I, GF-II or GF-III *1

ACEA 96-A2

●Diesel engine

API CF-4*1, *2

ACEA B1, B3, B4, B5*1, *2 YD22DDTi 5.2 4-5/8 qt

Without oil filter

changeQR20DE,

QR25DE3.5 3-1/8 qt

YD22DDTi 4.9 4-3/8 qt

Dry engine (engine overhaul)QR20DE,

QR25DE4.5 4 qt

YD22DDTi 6.3 5-1/2 qt

Cooling system (with reservoir)QR20DE,

QR25DE 7.1 6-1/4 qt

●Genuine Nissan Anti-freeze Coolant (L2N) or

equivalent in its quality*3 YD22DDTi 9.5 8-3/8 qt

Reservoir tankQR20DE,

QR25DE0.6 1/2 qt

YD22DDTi 0.6 1/2 qt

Manual transaxle gear oil

2.3 4pt

●Genuine Nissan gear oil or API GL-4, Viscos-

ity SAE 75W-85

Transfer gear oil 0.31 1/2 pt

●API GL-5*1, Viscosity SAE 80W-90

Differential gear oil 0.55 1 pt

●API GL-5*1, Viscosity SAE 80W-90

Automatic transaxle fluid 8.5 7-1/2 qt Genuine Nissan ATF or equivalent*4

Power steering fluid — —

Type Dexron

TM III or equivalent

Brake and clutch fluid — —

●DOT 3 or DOT 4 (US FMVSS No. 116)*5

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

Page 3797 of 3833

RECOMMENDED FLUIDS AND LUBRICANTS

MA-17

C

D

E

F

G

H

I

J

K

MA

B

MA

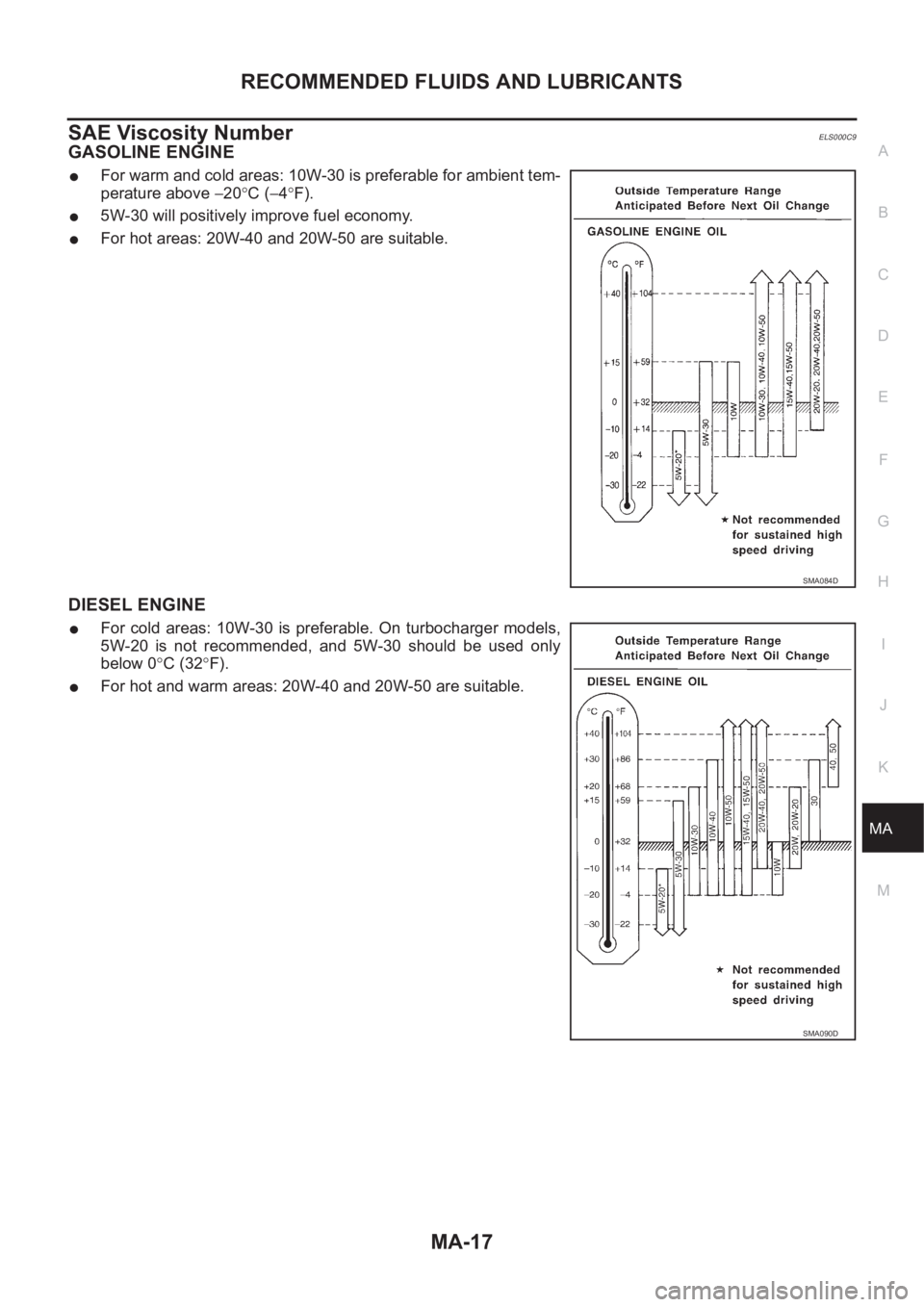

SAE Viscosity NumberELS000C9

GASOLINE ENGINE

●For warm and cold areas: 10W-30 is preferable for ambient tem-

perature above −20°C (−4°F).

●5W-30 will positively improve fuel economy.

●For hot areas: 20W-40 and 20W-50 are suitable.

DIESEL ENGINE

●For cold areas: 10W-30 is preferable. On turbocharger models,

5W-20 is not recommended, and 5W-30 should be used only

below 0°C (32°F).

●For hot and warm areas: 20W-40 and 20W-50 are suitable.

SMA084D

SMA090D

Page 3798 of 3833

MA-18

RECOMMENDED FLUIDS AND LUBRICANTS

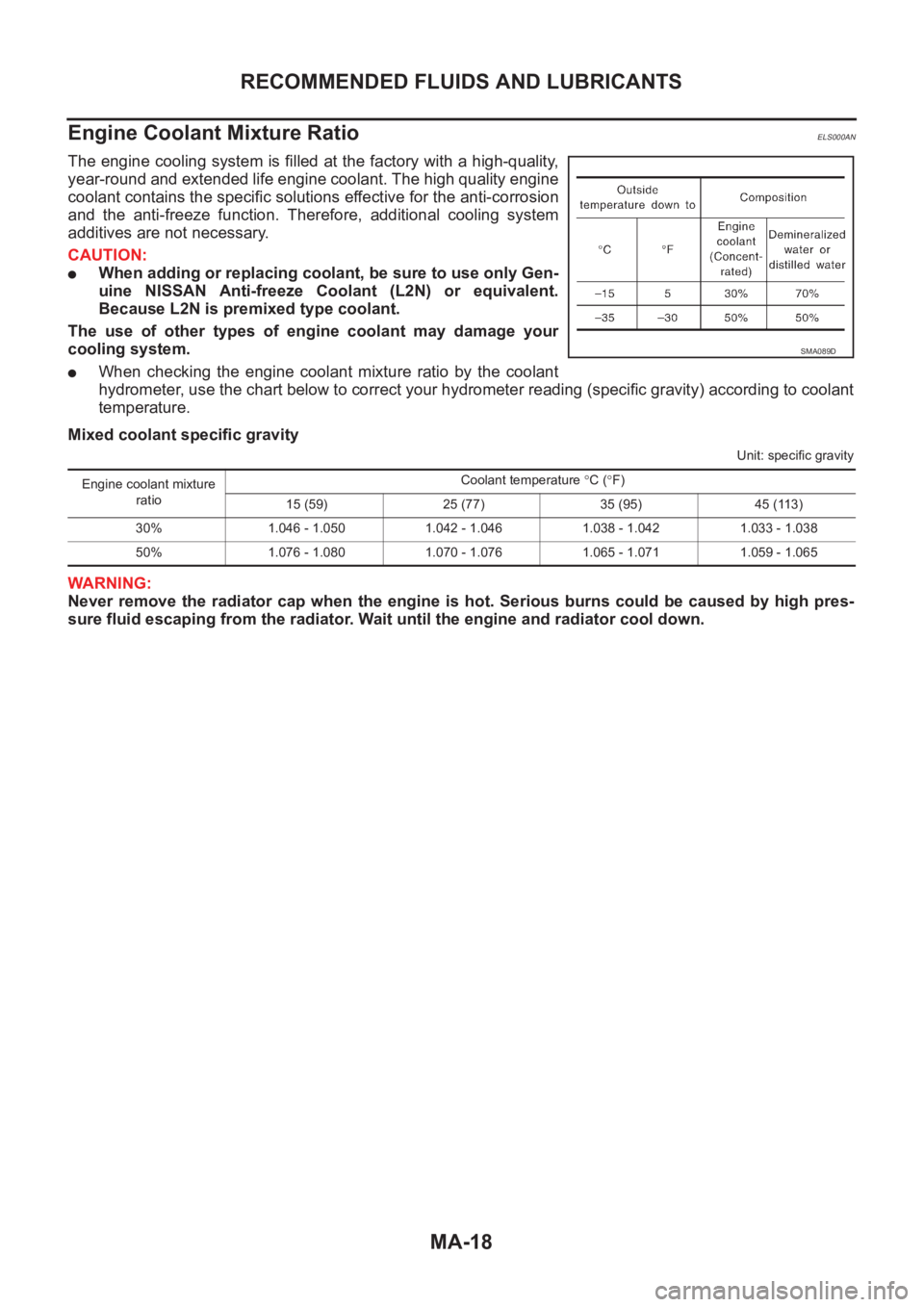

Engine Coolant Mixture Ratio

ELS000AN

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality engine

coolant contains the specific solutions effective for the anti-corrosion

and the anti-freeze function. Therefore, additional cooling system

additives are not necessary.

CAUTION:

●When adding or replacing coolant, be sure to use only Gen-

uine NISSAN Anti-freeze Coolant (L2N) or equivalent.

Because L2N is premixed type coolant.

The use of other types of engine coolant may damage your

cooling system.

●When checking the engine coolant mixture ratio by the coolant

hydrometer, use the chart below to correct your hydrometer reading (specific gravity) according to coolant

temperature.

Mixed coolant specific gravity

Unit: specific gravity

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator. Wait until the engine and radiator cool down.

SMA089D

Engine coolant mixture

ratioCoolant temperature °C (°F)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

Page 3799 of 3833

ENGINE MAINTENANCE (QR20DE·QR25DE)

MA-19

C

D

E

F

G

H

I

J

K

MA

B

MA

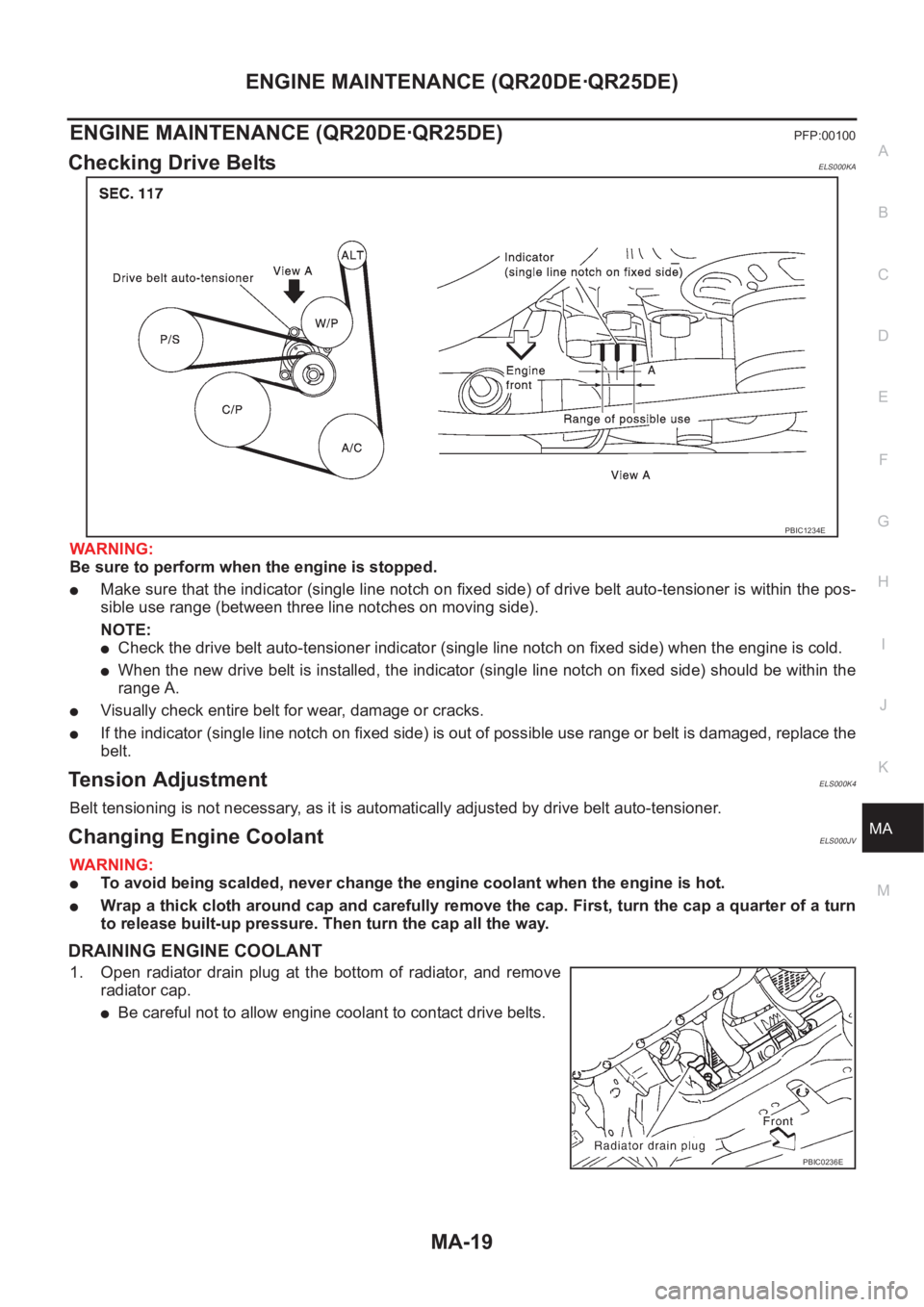

ENGINE MAINTENANCE (QR20DE·QR25DE) PFP:00100

Checking Drive BeltsELS000KA

WARNING:

Be sure to perform when the engine is stopped.

●Make sure that the indicator (single line notch on fixed side) of drive belt auto-tensioner is within the pos-

sible use range (between three line notches on moving side).

NOTE:

●Check the drive belt auto-tensioner indicator (single line notch on fixed side) when the engine is cold.

●When the new drive belt is installed, the indicator (single line notch on fixed side) should be within the

range A.

●Visually check entire belt for wear, damage or cracks.

●If the indicator (single line notch on fixed side) is out of possible use range or belt is damaged, replace the

belt.

Tension AdjustmentELS000K4

Belt tensioning is not necessary, as it is automatically adjusted by drive belt auto-tensioner.

Changing Engine CoolantELS000JV

WARNING:

●To avoid being scalded, never change the engine coolant when the engine is hot.

●Wrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

●Be careful not to allow engine coolant to contact drive belts.

PBIC1234E

PBIC0236E

Page 3800 of 3833

MA-20

ENGINE MAINTENANCE (QR20DE·QR25DE)

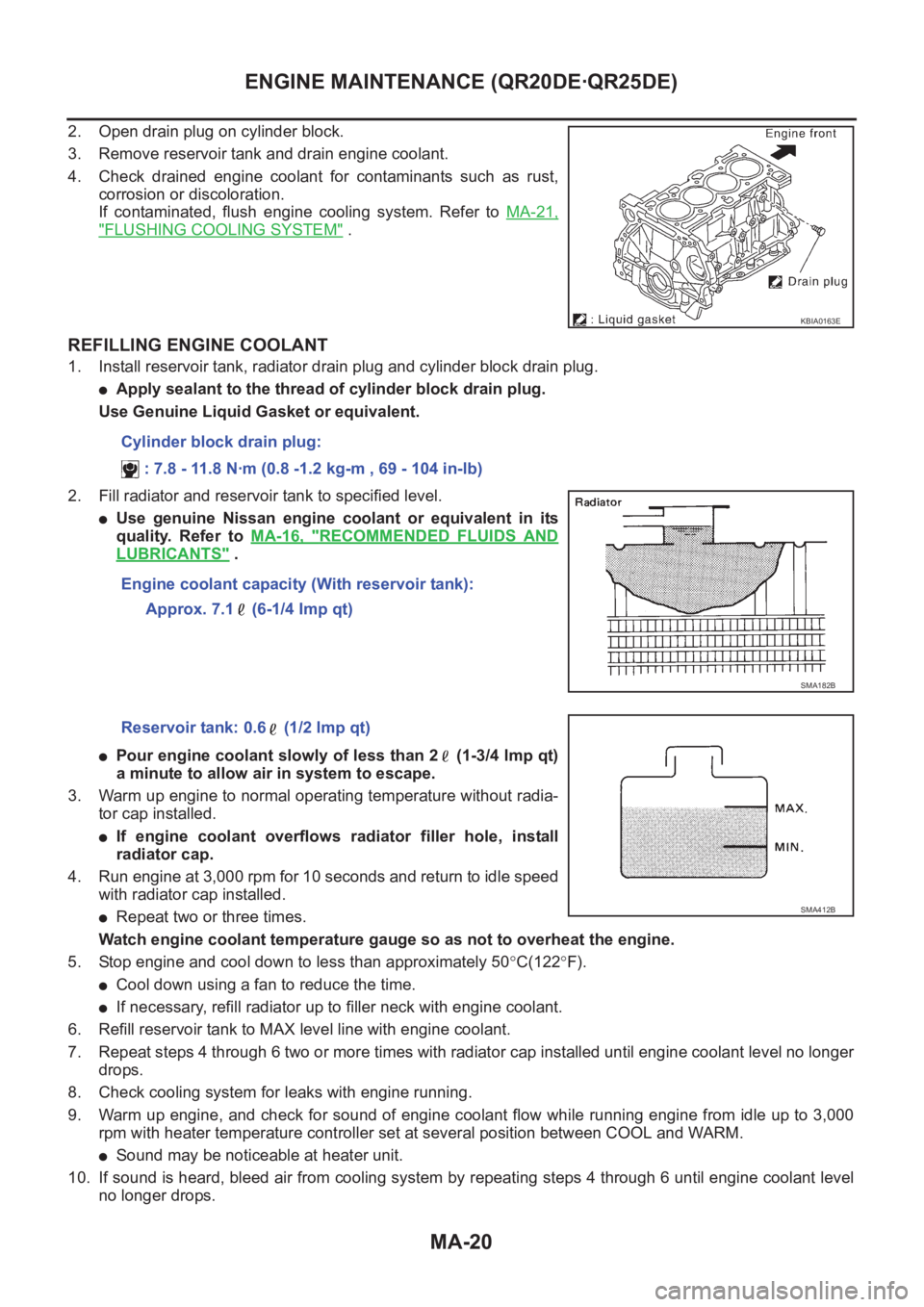

2. Open drain plug on cylinder block.

3. Remove reservoir tank and drain engine coolant.

4. Check drained engine coolant for contaminants such as rust,

corrosion or discoloration.

If contaminated, flush engine cooling system. Refer to MA-21,

"FLUSHING COOLING SYSTEM" .

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

●Use genuine Nissan engine coolant or equivalent in its

quality. Refer to MA-16, "

RECOMMENDED FLUIDS AND

LUBRICANTS" .

●Pour engine coolant slowly of less than 2 (1-3/4 lmp qt)

a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

●If engine coolant overflows radiator filler hole, install

radiator cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

●Repeat two or three times.

Watch engine coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

●Cool down using a fan to reduce the time.

●If necessary, refill radiator up to filler neck with engine coolant.

6. Refill reservoir tank to MAX level line with engine coolant.

7. Repeat steps 4 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

●Sound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 4 through 6 until engine coolant level

no longer drops.

KBIA0163E

Cylinder block drain plug:

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank: 0.6 (1/2 lmp qt)

SMA412B

Page 3801 of 3833

ENGINE MAINTENANCE (QR20DE·QR25DE)

MA-21

C

D

E

F

G

H

I

J

K

MA

B

MA

●Clean excess engine coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

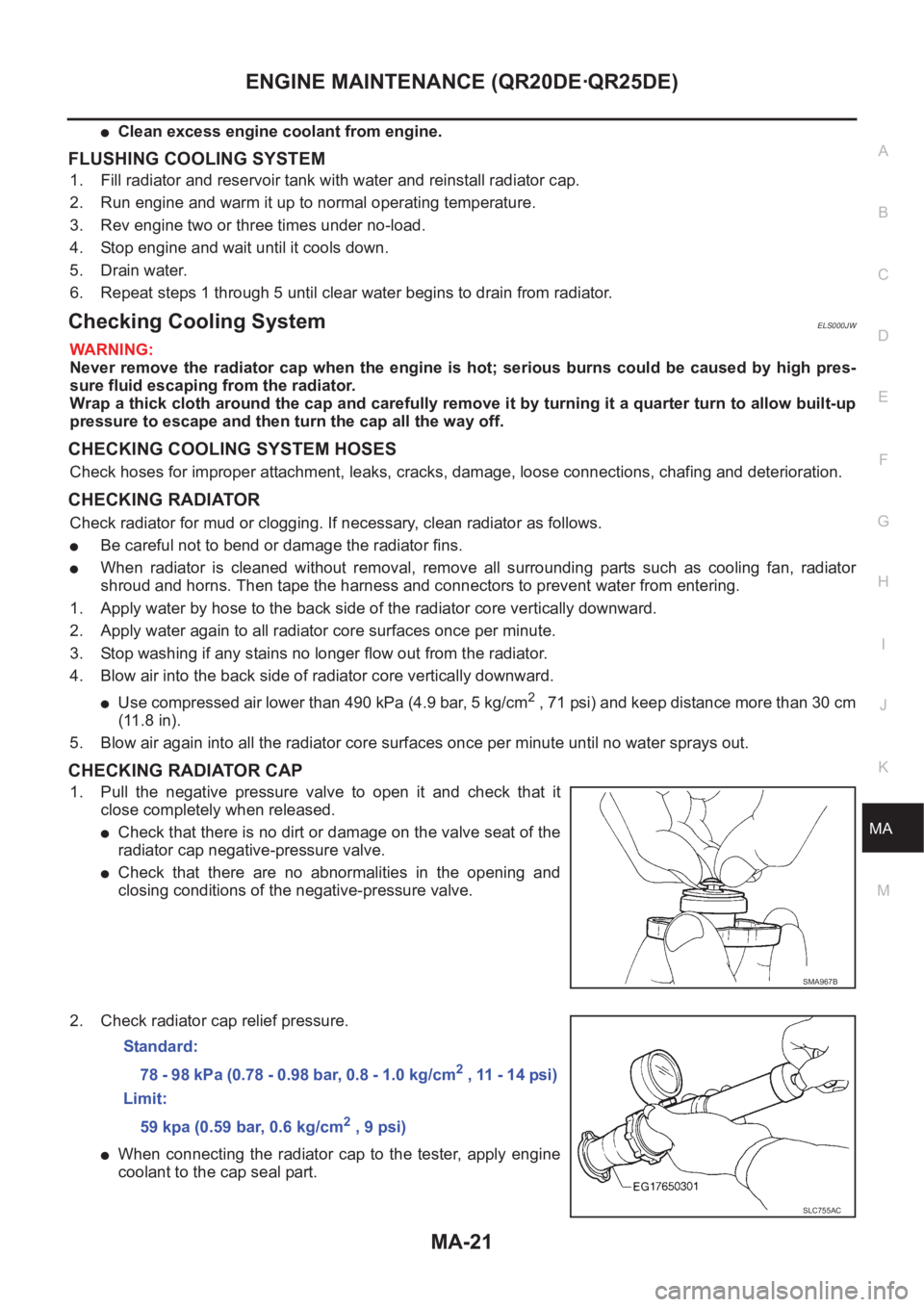

Checking Cooling SystemELS000JW

WARNING:

Never remove the radiator cap when the engine is hot; serious burns could be caused by high pres-

sure fluid escaping from the radiator.

Wrap a thick cloth around the cap and carefully remove it by turning it a quarter turn to allow built-up

pressure to escape and then turn the cap all the way off.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

●Be careful not to bend or damage the radiator fins.

●When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surfaces once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downward.

●Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm2 , 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

CHECKING RADIATOR CAP

1. Pull the negative pressure valve to open it and check that it

close completely when released.

●Check that there is no dirt or damage on the valve seat of the

radiator cap negative-pressure valve.

●Check that there are no abnormalities in the opening and

closing conditions of the negative-pressure valve.

2. Check radiator cap relief pressure.

●When connecting the radiator cap to the tester, apply engine

coolant to the cap seal part.

SMA967B

Standard:

78 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2 , 11 - 14 psi)

Limit:

59 kpa (0.59 bar, 0.6 kg/cm

2 , 9 psi)

SLC755AC

Page 3802 of 3833

MA-22

ENGINE MAINTENANCE (QR20DE·QR25DE)

●Replace the radiator cap if there is an abnormality in the negative-pressure valve, or if the open-valve

pressure is outside of the standard values.

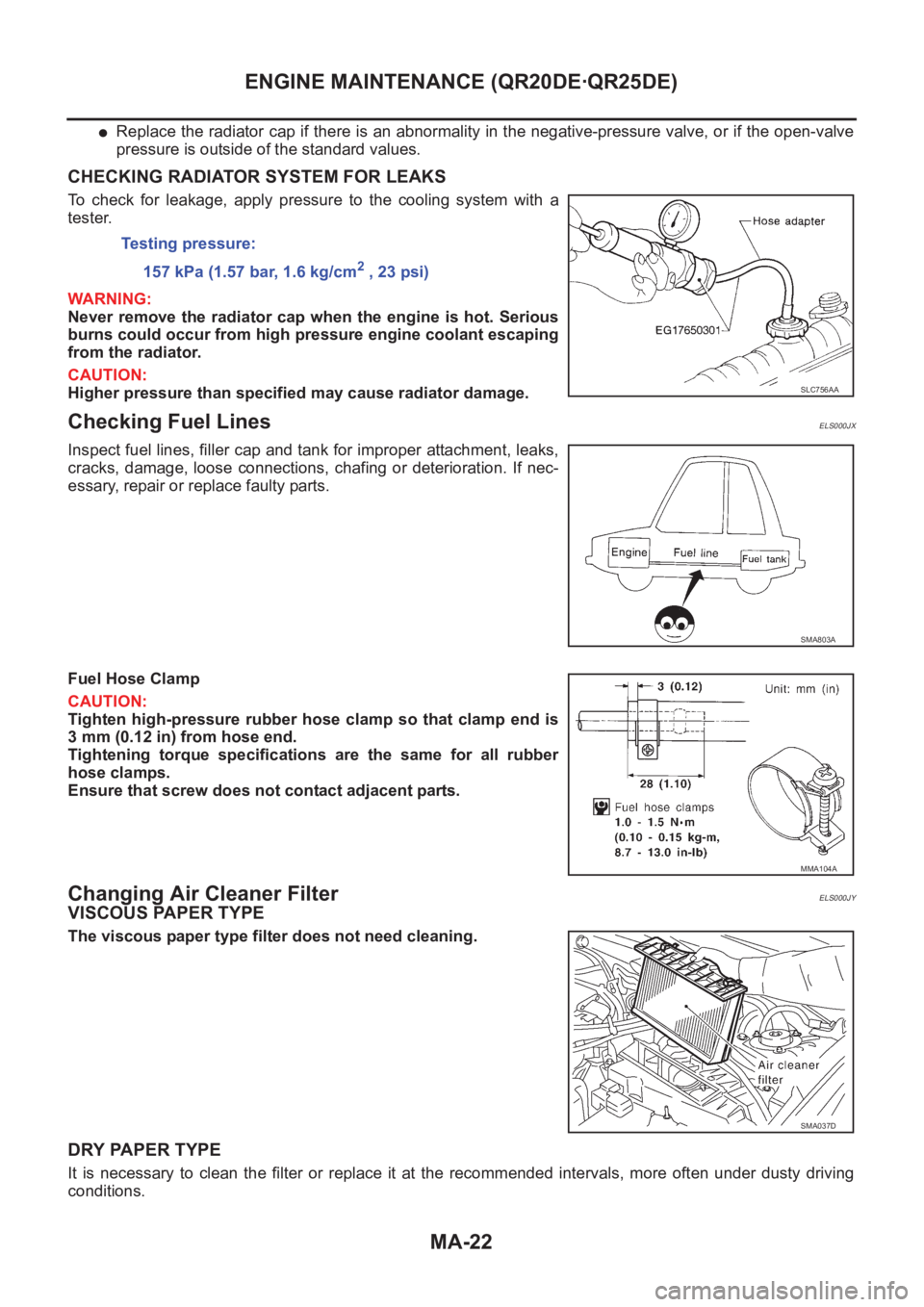

CHECKING RADIATOR SYSTEM FOR LEAKS

To check for leakage, apply pressure to the cooling system with a

tester.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure engine coolant escaping

from the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Checking Fuel LinesELS000JX

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration. If nec-

essary, repair or replace faulty parts.

Fuel Hose Clamp

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

Changing Air Cleaner FilterELS000JY

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning.

DRY PAPER TYPE

It is necessary to clean the filter or replace it at the recommended intervals, more often under dusty driving

conditions.Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2 , 23 psi)

SLC756AA

SMA803A

MMA104A

SMA037D

Page 3803 of 3833

ENGINE MAINTENANCE (QR20DE·QR25DE)

MA-23

C

D

E

F

G

H

I

J

K

MA

B

MA

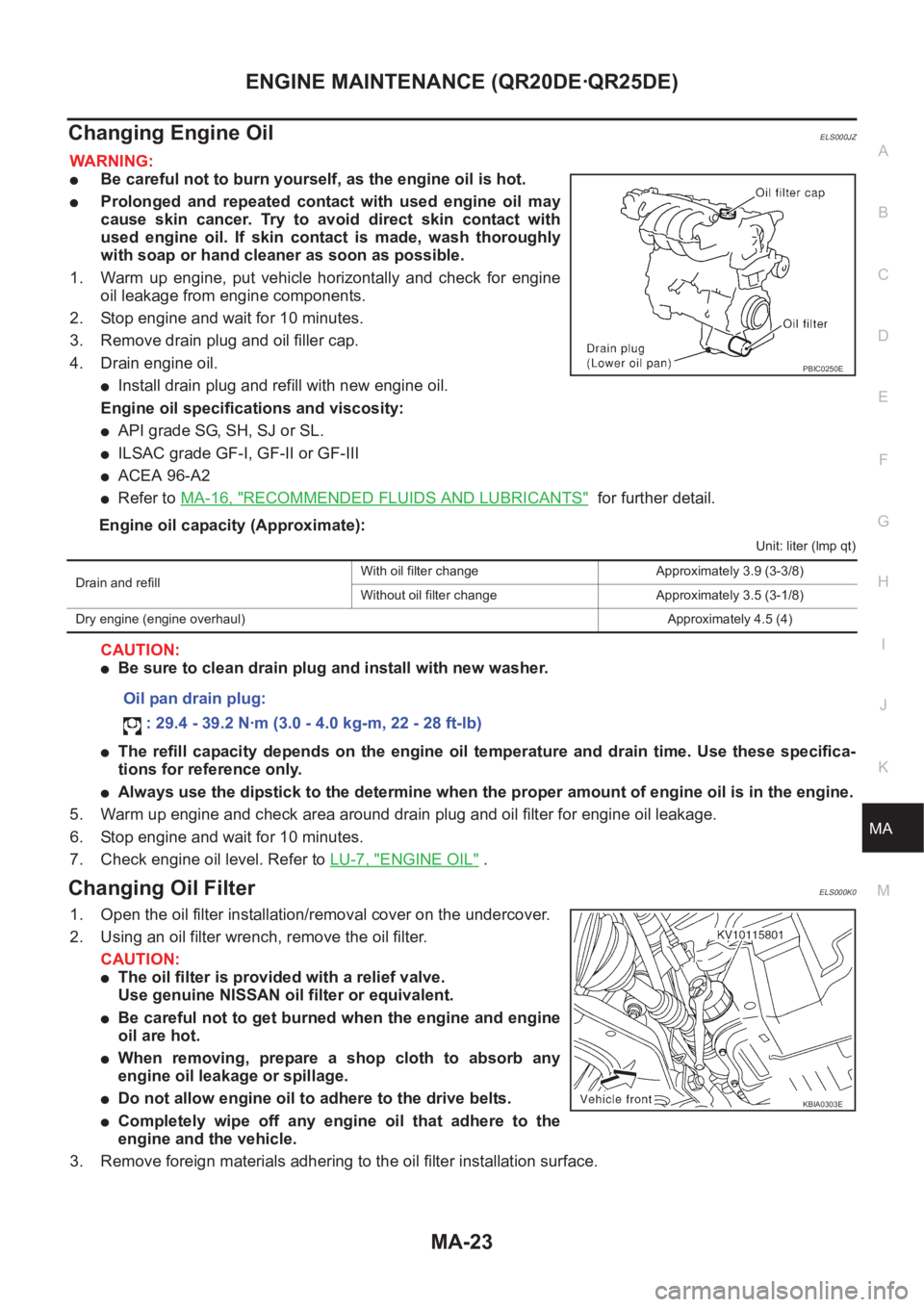

Changing Engine OilELS000JZ

WARNING:

●Be careful not to burn yourself, as the engine oil is hot.

●Prolonged and repeated contact with used engine oil may

cause skin cancer. Try to avoid direct skin contact with

used engine oil. If skin contact is made, wash thoroughly

with soap or hand cleaner as soon as possible.

1. Warm up engine, put vehicle horizontally and check for engine

oil leakage from engine components.

2. Stop engine and wait for 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain engine oil.

●Install drain plug and refill with new engine oil.

Engine oil specifications and viscosity:

●API grade SG, SH, SJ or SL.

●ILSAC grade GF-I, GF-II or GF-III

●ACEA 96-A2

●Refer to MA-16, "RECOMMENDED FLUIDS AND LUBRICANTS" for further detail.

Engine oil capacity (Approximate):

Unit: liter (lmp qt)

CAUTION:

●Be sure to clean drain plug and install with new washer.

●The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

●Always use the dipstick to the determine when the proper amount of engine oil is in the engine.

5. Warm up engine and check area around drain plug and oil filter for engine oil leakage.

6. Stop engine and wait for 10 minutes.

7. Check engine oil level. Refer to LU-7, "

ENGINE OIL" .

Changing Oil FilterELS000K0

1. Open the oil filter installation/removal cover on the undercover.

2. Using an oil filter wrench, remove the oil filter.

CAUTION:

●The oil filter is provided with a relief valve.

Use genuine NISSAN oil filter or equivalent.

●Be careful not to get burned when the engine and engine

oil are hot.

●When removing, prepare a shop cloth to absorb any

engine oil leakage or spillage.

●Do not allow engine oil to adhere to the drive belts.

●Completely wipe off any engine oil that adhere to the

engine and the vehicle.

3. Remove foreign materials adhering to the oil filter installation surface.

PBIC0250E

Drain and refillWith oil filter change Approximately 3.9 (3-3/8)

Without oil filter change Approximately 3.5 (3-1/8)

Dry engine (engine overhaul)Approximately 4.5 (4)

Oil pan drain plug:

: 29.4 - 39.2 N·m (3.0 - 4.0 kg-m, 22 - 28 ft-lb)

KBIA0303E