maintenance NISSAN X-TRAIL 2001 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3815 of 3833

CHASSIS AND BODY MAINTENANCE

MA-35

C

D

E

F

G

H

I

J

K

MA

B

MA

CHASSIS AND BODY MAINTENANCEPFP:00100

Checking Exhaust SystemELS000B9

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage, chafing or deterioration.

Checking Clutch Fluid Level and LeaksELS000BA

If fluid level is extremely low, check clutch system for leaks.

Checking Clutch SystemELS000BB

Check fluid lines and operating cylinder for improper attachment,

cracks, damage, loose connections, chafing and deterioration.

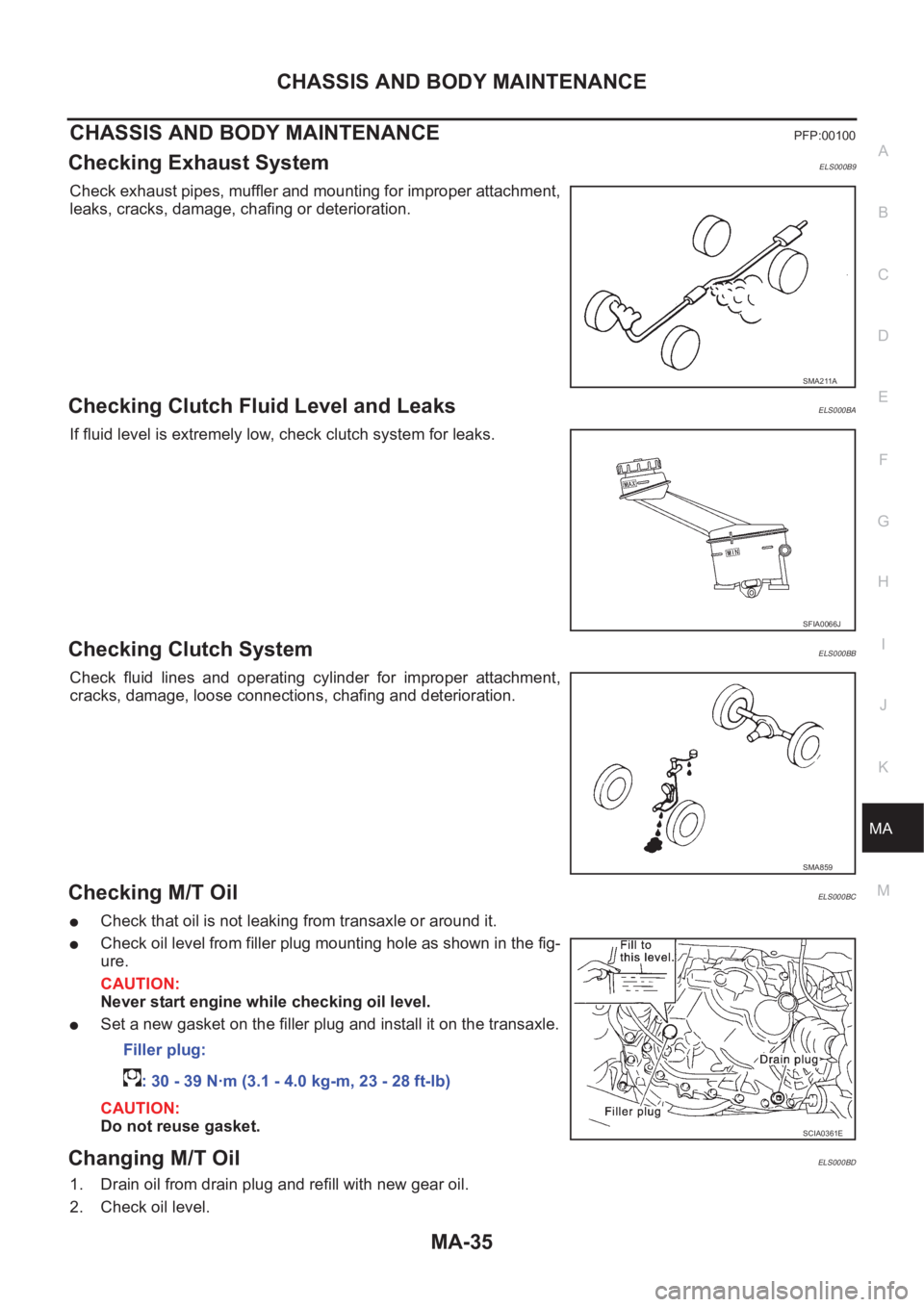

Checking M/T OilELS000BC

●Check that oil is not leaking from transaxle or around it.

●Check oil level from filler plug mounting hole as shown in the fig-

ure.

CAUTION:

Never start engine while checking oil level.

●Set a new gasket on the filler plug and install it on the transaxle.

CAUTION:

Do not reuse gasket.

Changing M/T OilELS000BD

1. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

SMA211A

SFIA0066J

SMA859

Filler plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SCIA0361E

Page 3816 of 3833

MA-36

CHASSIS AND BODY MAINTENANCE

CAUTION:

Do not reuse gasket.

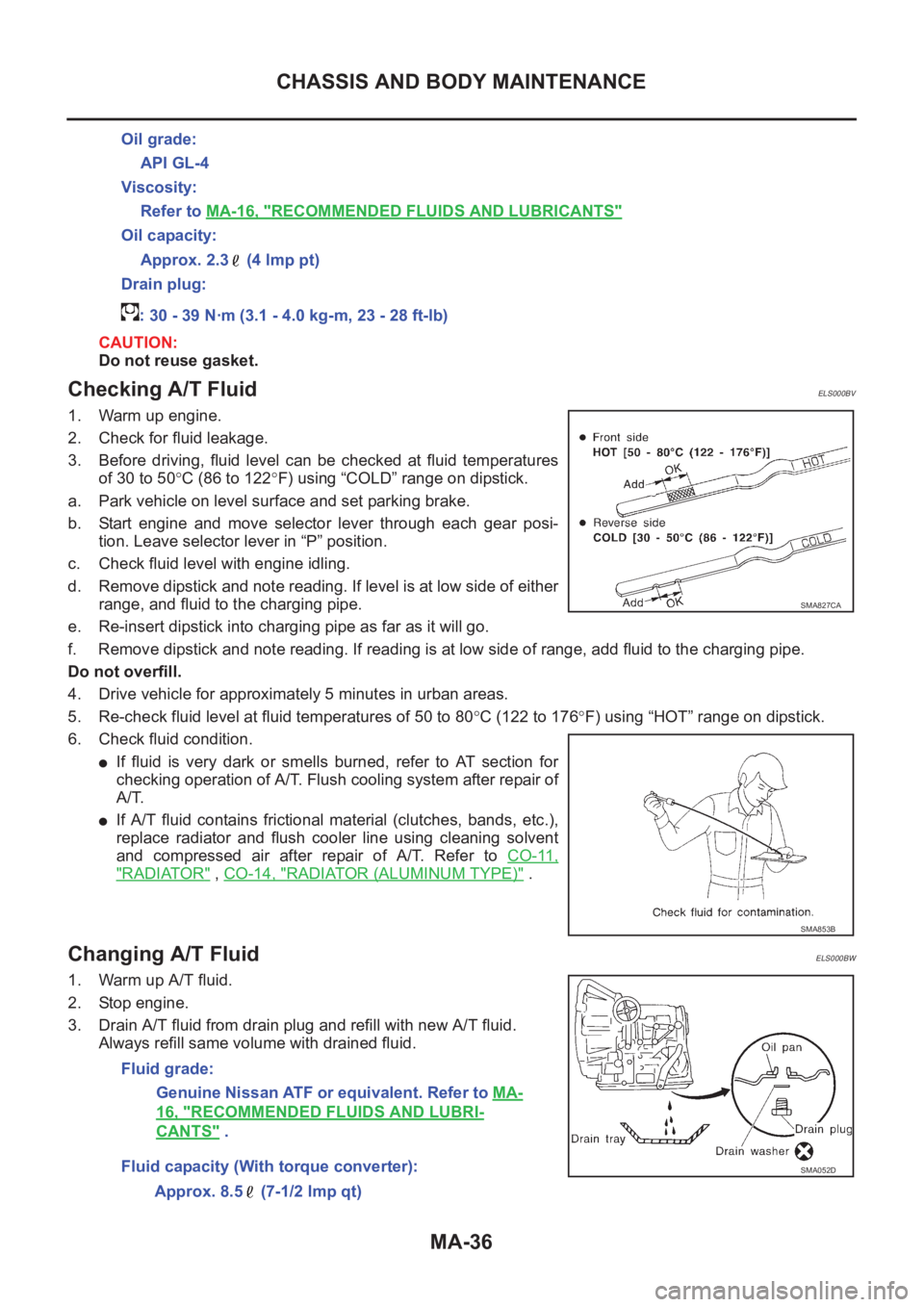

Checking A/T FluidELS000BV

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

●If fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

●If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to CO-11,

"RADIATOR" , CO-14, "RADIATOR (ALUMINUM TYPE)" .

Changing A/T FluidELS000BW

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.Oil grade:

API GL-4

Viscosity:

Refer to MA-16, "

RECOMMENDED FLUIDS AND LUBRICANTS"

Oil capacity:

Approx. 2.3 (4 lmp pt)

Drain plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer to MA-

16, "RECOMMENDED FLUIDS AND LUBRI-

CANTS" .

Fluid capacity (With torque converter):

Approx. 8.5 (7-1/2 lmp qt)

SMA052D

Page 3817 of 3833

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to MA-36, "

Checking A/T Fluid" . If fluid is still dirty, repeat steps 2

through 5.

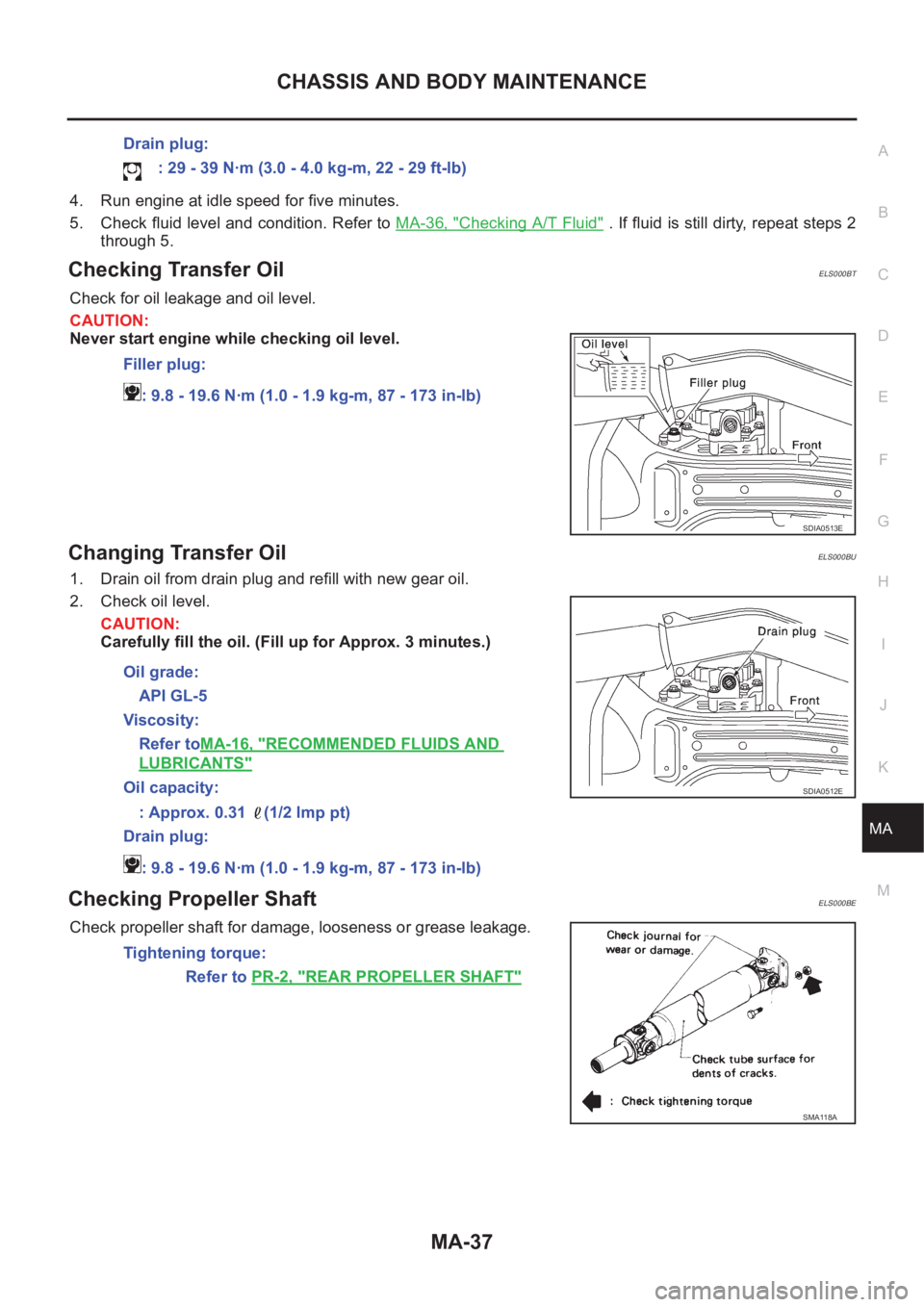

Checking Transfer OilELS000BT

Check for oil leakage and oil level.

CAUTION:

Never start engine while checking oil level.

Changing Transfer OilELS000BU

1. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

CAUTION:

Carefully fill the oil. (Fill up for Approx. 3 minutes.)

Checking Propeller ShaftELS000BE

Check propeller shaft for damage, looseness or grease leakage.Drain plug:

: 29 - 39 N·m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

Filler plug:

: 9.8 - 19.6 N·m (1.0 - 1.9 kg-m, 87 - 173 in-lb)

SDIA0513E

Oil grade:

API GL-5

Viscosity:

Refer toMA-16, "

RECOMMENDED FLUIDS AND

LUBRICANTS"

Oil capacity:

: Approx. 0.31 (1/2 lmp pt)

Drain plug:

: 9.8 - 19.6 N·m (1.0 - 1.9 kg-m, 87 - 173 in-lb)SDIA0512E

Tightening torque:

Refer to PR-2, "

REAR PROPELLER SHAFT"

SMA118A

Page 3818 of 3833

MA-38

CHASSIS AND BODY MAINTENANCE

Checking Differential Gear Oil

ELS000BF

1. Check for oil leakage and oil level.

CAUTION:

Gaskets are not reusable. Never reuse them.

Changing Differential Gear OilELS000BG

1. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

CAUTION:

Gaskets are not reusable. Never reuse them.

Balancing WheelsELS000BH

Adjust wheel balance using the road wheel center.

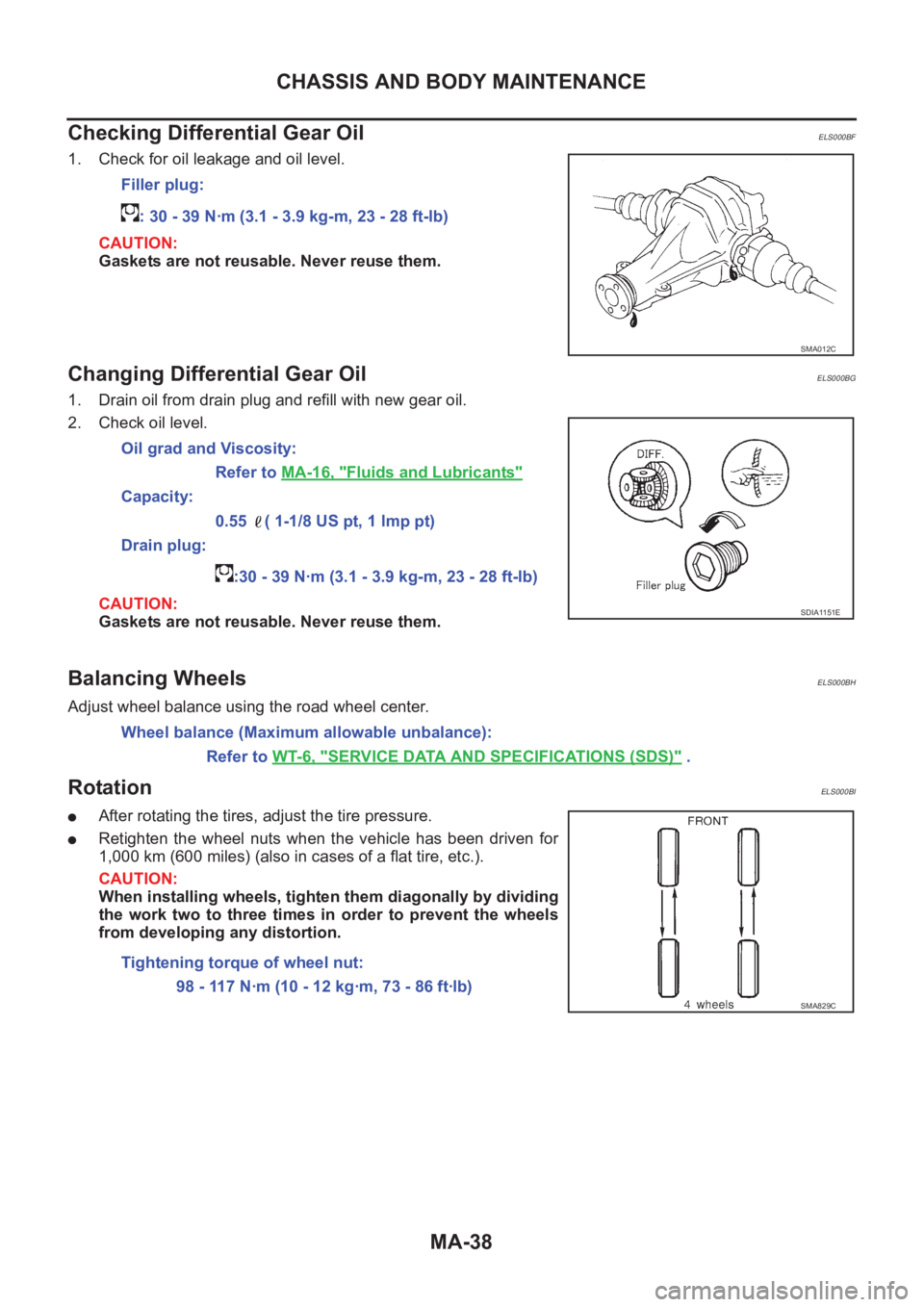

RotationELS000BI

●After rotating the tires, adjust the tire pressure.

●Retighten the wheel nuts when the vehicle has been driven for

1,000 km (600 miles) (also in cases of a flat tire, etc.).

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.Filler plug:

: 30 - 39 N·m (3.1 - 3.9 kg-m, 23 - 28 ft-lb)

SMA012C

Oil grad and Viscosity:

Refer to MA-16, "

Fluids and Lubricants"

Capacity:

0.55 ( 1-1/8 US pt, 1 lmp pt)

Drain plug:

:30 - 39 N·m (3.1 - 3.9 kg-m, 23 - 28 ft-lb)

SDIA1151E

Wheel balance (Maximum allowable unbalance):

Refer to WT-6, "

SERVICE DATA AND SPECIFICATIONS (SDS)" .

Tightening torque of wheel nut:

98 - 117 N·m (10 - 12 kg·m, 73 - 86 ft·lb)

SMA829C

Page 3819 of 3833

CHASSIS AND BODY MAINTENANCE

MA-39

C

D

E

F

G

H

I

J

K

MA

B

MA

Checking Brake Fluid Level and LeaksELS000BJ

●If fluid level is extremely low, check brake system for leaks.

Checking Brake Lines and CablesELS000BK

●Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasions, deterioration, etc.

Changing Brake FluidELS000BL

1. Drain brake fluid from each air bleeder valve.

2. Refill until new brake fluid comes out from each air bleeder

valve.

Use same procedure as in bleeding hydraulic system to refill

brake fluid.

Refer to BR-9, "

Changing Brake Fluid" .

●Refill with recommended Genuine Brake Fluid or equivalent

“DOT 3” or “DO4”.

Refer to MA-16, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS" .

●Never reuse drained brake fluid.

●Be careful not to splash brake fluid on painted areas.

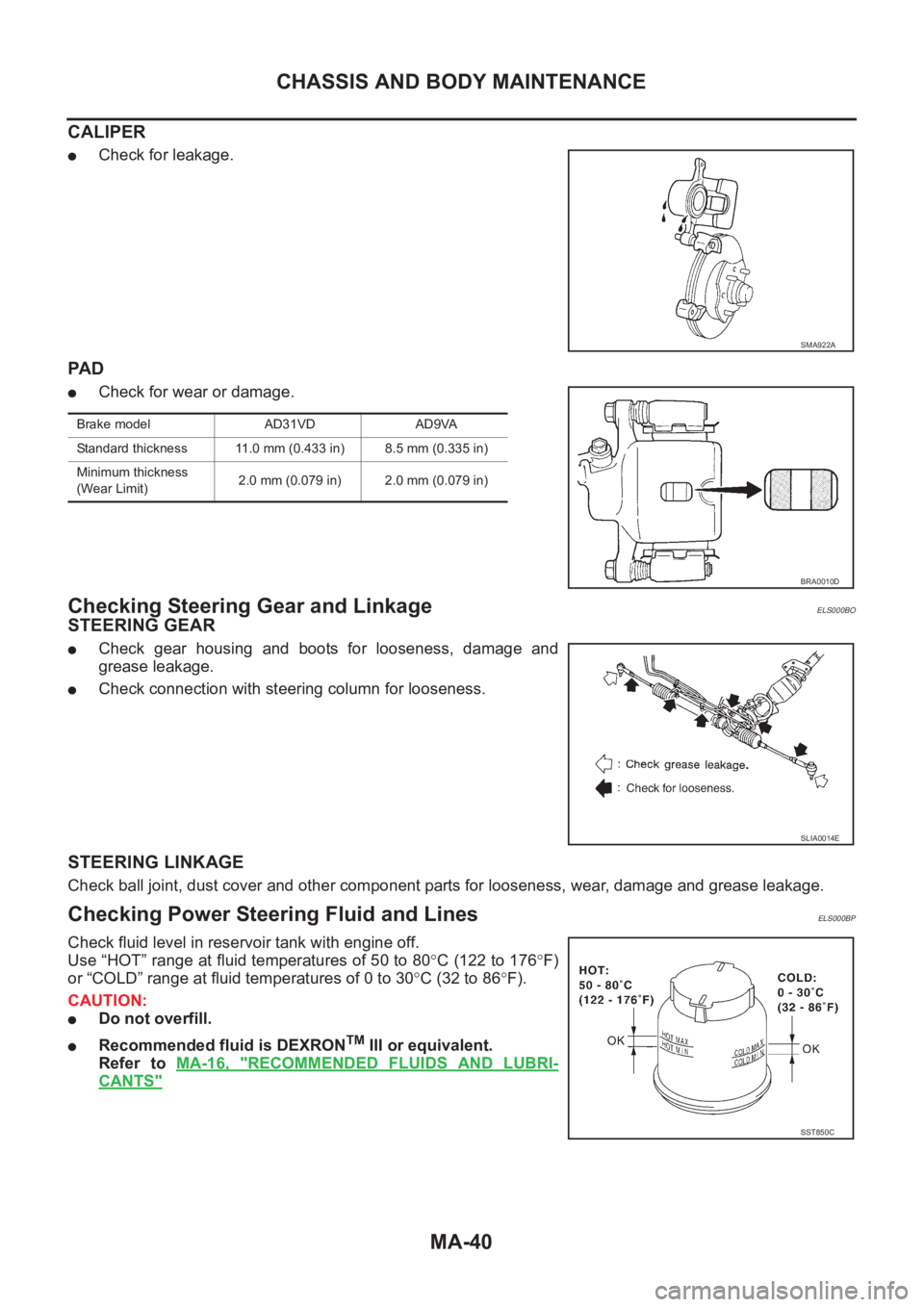

Checking Disc BrakeELS000BM

ROTOR

Check condition, wear, and damage.

SFIA0066J

SBR389C

SBR419C

Applied Front Rear

Brake model AD31VD AD9VA

Standard thickness 28.0 mm (1.102 in) 16 mm (0.63 in)

Maximum runout 0.04 mm (0.0016 in) 0.07 mm (0.0028 in)

Minimum thickness (Wear limit) 26.0 mm (1.024 in) 14 mm (0.55 in)

Page 3820 of 3833

MA-40

CHASSIS AND BODY MAINTENANCE

CALIPER

●Check for leakage.

PA D

●Check for wear or damage.

Checking Steering Gear and LinkageELS000BO

STEERING GEAR

●Check gear housing and boots for looseness, damage and

grease leakage.

●Check connection with steering column for looseness.

STEERING LINKAGE

Check ball joint, dust cover and other component parts for looseness, wear, damage and grease leakage.

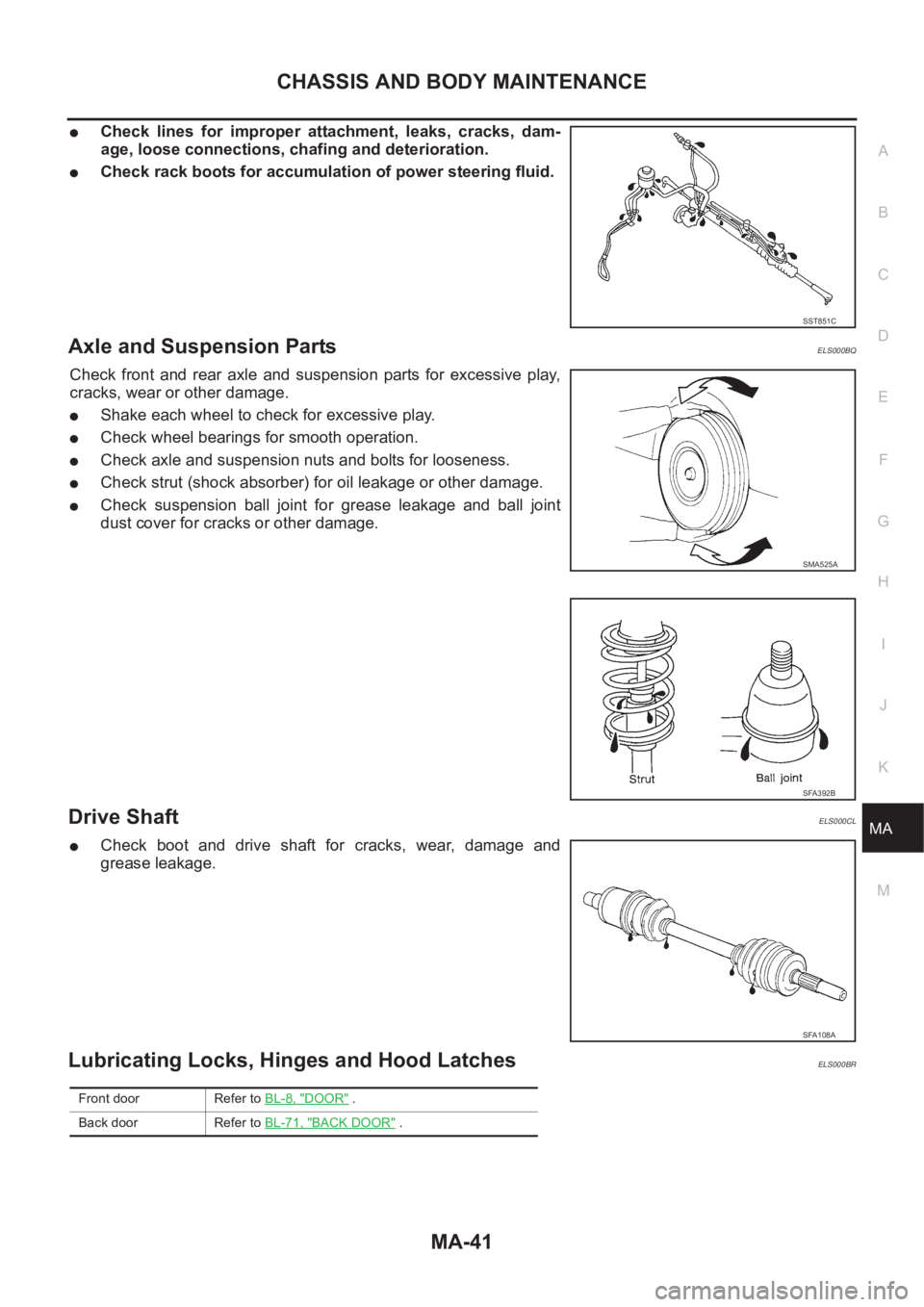

Checking Power Steering Fluid and LinesELS000BP

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80°C (122 to 176°F)

or “COLD” range at fluid temperatures of 0 to 30°C (32 to 86°F).

CAUTION:

●Do not overfill.

●Recommended fluid is DEXRONTM III or equivalent.

Refer to MA-16, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS"

SMA922A

Brake model AD31VD AD9VA

Standard thickness 11.0 mm (0.433 in) 8.5 mm (0.335 in)

Minimum thickness

(Wear Limit)2.0 mm (0.079 in) 2.0 mm (0.079 in)

BRA0010D

SLIA0014E

SST850C

Page 3821 of 3833

CHASSIS AND BODY MAINTENANCE

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

●Check lines for improper attachment, leaks, cracks, dam-

age, loose connections, chafing and deterioration.

●Check rack boots for accumulation of power steering fluid.

Axle and Suspension PartsELS000BQ

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

●Shake each wheel to check for excessive play.

●Check wheel bearings for smooth operation.

●Check axle and suspension nuts and bolts for looseness.

●Check strut (shock absorber) for oil leakage or other damage.

●Check suspension ball joint for grease leakage and ball joint

dust cover for cracks or other damage.

Drive ShaftELS000CL

●Check boot and drive shaft for cracks, wear, damage and

grease leakage.

Lubricating Locks, Hinges and Hood LatchesELS000BR

SST851C

SMA525A

SFA392B

SFA108A

Front door Refer to BL-8, "DOOR" .

Back door Refer to BL-71, "

BACK DOOR" .

Page 3822 of 3833

MA-42

CHASSIS AND BODY MAINTENANCE

Checking Seat Belts, Buckles, Retractors, Anchors and Adjusters

ELS000BS

Checking Body CorrosionELS000C0

Visually check body panels for collision damage (scratches, chipping, rubbing, etc.) or damage to the anti-cor-

rosion materials. In particular, check the following locations.

HEMMED PANELS

Hood front end, door lower end, trunk lid rear end, etc.

PANEL JOINT

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine com-

partment, etc.

PANEL EDGE

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

PARTS CONTACT

Waist moulding, windshield moulding, bumper, etc.

PROTECTORS

Damage or condition of mudguard, fender protector, chipping protector, etc.

ANTI-CORROSION MATERIALS

Damage or separation of anti-corrosion materials under the body.

DRAIN HOLES

Condition of drain holes at door and side sill. When repairing corroded areas, refer to the Corrosion Repair

Manual.

Page 3827 of 3833

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

MTC-17,MTC-21

Blower resistor ................................................ MTC-22

Blower unit ...................................... ATC-116,MTC-21

Boring/horning cylinder block(QR20DE•QR25DE) .......

EM-93

Brake booster .................................................... BR-17

Brake fluid change ............................................... BR-9

Brake fluid level ................................................. MA-39

Brake fluid level and line check ........................... BR-9

Brake hydraulic line ........................................... BR-11

Brake inspection ................................................ MA-39

Brake lines and cables inspection ..................... MA-39

Brake master cylinder ........................................ BR-13

Brake pedal ......................................................... BR-6

Brake switch .... EC-349,EC-625,EC-1068,EC-1301,

EC-1558

BRK/SW - Wiring diagram EC-351,EC-627,EC-1070,

EC-1303

,EC-1559

Bulb specifications .............................................. LT-67

Bumper, front ......................................................... EI-6

Bumper, rear .......................................................... EI-9

C

Camshaft inspection(QR20DE•QR25DE) .......... EM-51

Camshaft inspection(YD22DDTi) .................... EM-159

Camshaft position sensor (CMPS) ................ EC-1484

Camshaft position sensor (PHASE) . EC-233,EC-557,

EC-962

,EC-1246

Camshaft(QR20DE•QR25DE) ........................... EM-46

Camshaft(YD22DDTi) ...................................... EM-158

CAN - Wiring diagram ......... EC-123,EC-514,EC-855,

EC-1200

,EC-1449,LAN-6,LAN-13

CAN (Controller Area Network) LAN-3,LAN-5,LAN-12

CAN Communication .......................................... TF-53

CAN communication ........... EC-122,EC-513,EC-854,

EC-1199

,EC-1448,AT-109,AT-190,AT-309,AT-403,

BRC-54

,BRC-62,BRC-92,BRC-110,LAN-3,LAN-5,

LAN-12

Canister-See EVAP canister ............ EC-427,EC-748,

EC-1114

,EC-1388

CHARGE - Wiring diagram ................................ SC-13

Charging system ................................................ SC-12

Chassis and body maintenance ........................ MA-35

CHIME - Wiring diagram ..................................... DI-59

CIGAR - Wiring diagram .................................. WW-25

Cigarette lighter ............................................... WW-25

Circuit breaker ................................................... PG-12

CKPS - Wiring diagram ................................. EC-1481

Clearance lamp ........................................ LT-4,LT-40

Clock ................................................................... DI-70

CLOCK - Wiring diagram .................................... DI-70

Closed loop control EC-34,EC-444,EC-766,EC-1130

Clutch cover ....................................................... CL-15

Clutch disc ......................................................... CL-15

Clutch master cylinder ......................................... CL-9

Clutch operating cylinder ................................... CL-11

Clutch pedal ......................................................... CL-5

Clutch release bearing ....................................... CL-13

Clutch release mechanism ................................ CL-13

Clutch withdrawal lever ...................................... CL-13

CMPS - Wiring diagram ................................. EC-1486

Coil spring (rear) ............................................... RSU-8

Collision diagnosis .......................................... SRS-47

Combination meter .................................... DI-4,DI-24

Combination switch ................................. LT-24,LT-44

Common rail fuel pressure sensor ................. EC-1468

Component Location (auto A/C) ......... ATC-34,MTC-4

Compression pressure(QR20DE•QR25DE) ..... EM-59

Compression pressure(YD22DDTi) ................ EM-182

Compressor clutch removal and installation .. ATC-135

Compressor special service tool ...................... ATC-14

Condenser ..................................................... ATC-143

Connecting rod bearing clearance(QR20DE•QR25DE)

EM-91

Connecting rod bearing clearance(YD22DDTi) EM-216

Connecting rod bushing clearance(QR20DE•QR25DE)

EM-91

Connecting rod bushing clearance(YD22DDTi) EM-210

Connecting rod(QR20DE•QR25DE) ................. EM-91

Connecting rod(YD22DDTi) .............. EM-207,EM-212

Console box - See Instrument panel .......... IP-3,IP-10

CONSULT for engine ........... EC-94,EC-486,EC-826,

EC-1173

,EC-1431

CONSULT for VDC ......................................... BRC-80

Control lever (M/T) ............................................. MT-13

Control unit ..................................... ATC-111,MTC-20

Control units (terminal arrangement) ................. PG-71

Controller Area Network (CAN) LAN-3,LAN-5,LAN-12

Converter housing installation ........... AT-419,AT-514

COOL/F - Wiring diagram EC-327,EC-607,EC-1054,

EC-1291

,EC-1510

Coolant replacement(QR20DE•QR25DE) ........ MA-19

Coolant replacement(YD22DDTi) ..................... MA-27

Cooling circuit (engine)(QR20DE•QR25DE) ....... CO-7

Cooling circuit (engine)(YD22DDTi) ................. CO-27

Cooling fan control system(QR20DE•QR25DE) CO-12

Cooling fan motor EC-336,EC-616,EC-1063,EC-1300

Cooling fan relay EC-336,EC-616,EC-1063,EC-1300

Cooling fan(QR20DE•QR25DE) ....................... CO-12

Cooling fan(YD22DDTi) .................................... CO-33

Coupling sleeve (M/T) ........................... MT-18,MT-23

Cowl top .............................................................. EI-12

Cowl top cover .................................................... EI-12

Crankcase ventilation system ........................ EC-1402

Crankcase ventilation system - See Positive crankcase

ventilation .......... EC-428

,EC-749,EC-1115,EC-1389

Crankshaft position sensor (POS) .... EC-227,EC-551,

EC-956

,EC-1240

Crankshaft position sensor (TDC) ................. EC-1479

Crankshaft(QR20DE•QR25DE) ........................ EM-74

CRFPS - Wiring diagram ............................... EC-1469

Cylinder block boring(QR20DE•QR25DE) ........ EM-94

Cylinder block boring(YD22DDTi) ................... EM-214

Cylinder block(QR20DE•QR25DE) ................... EM-73

Cylinder block(YD22DDTi) .............................. EM-197

Cylinder head bolt tightening(QR20DE•QR25DE) ........

EM-61

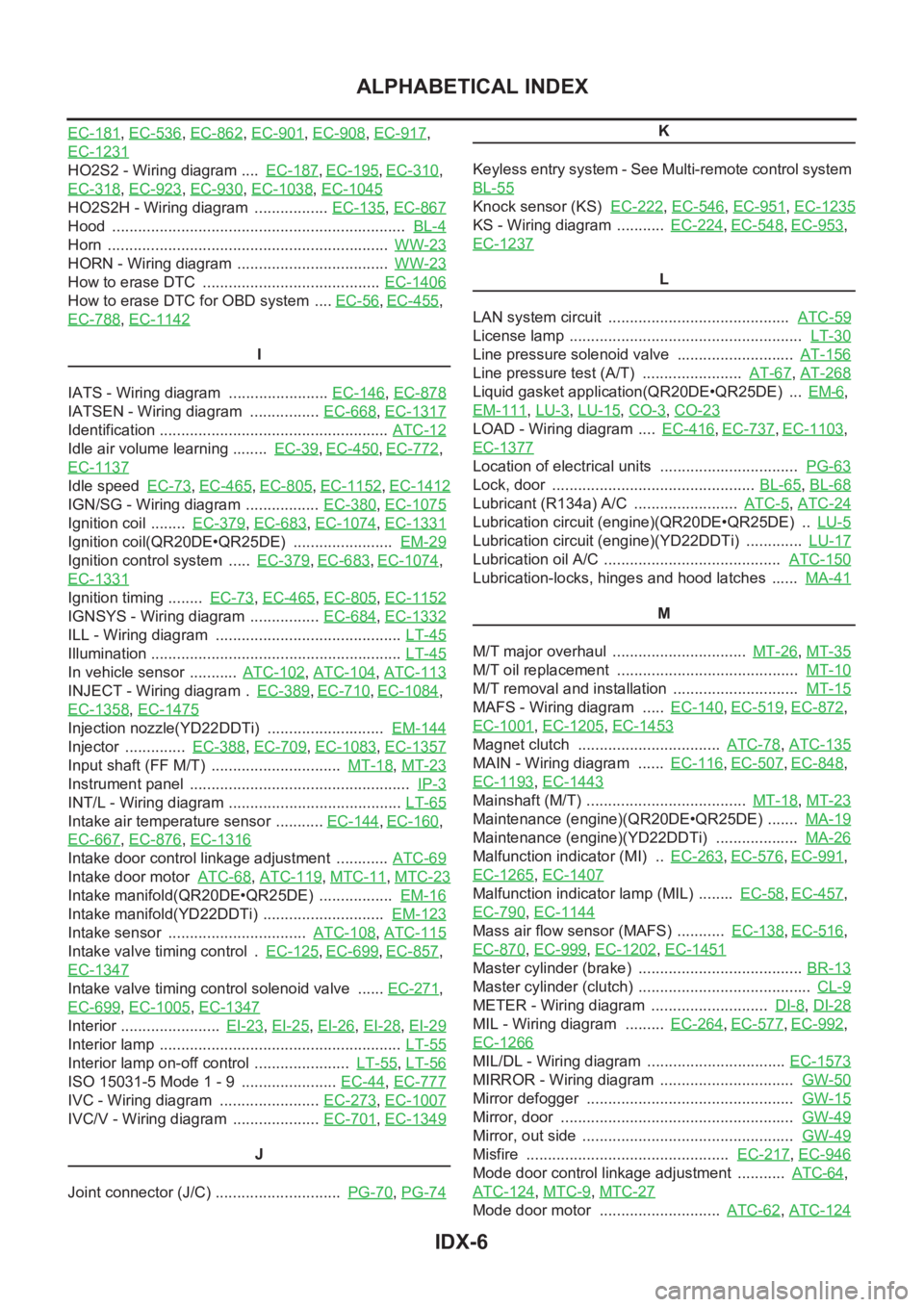

Page 3830 of 3833

IDX-6

ALPHABETICAL INDEX

EC-181,EC-536,EC-862,EC-901,EC-908,EC-917,

EC-1231

HO2S2 - Wiring diagram .... EC-187,EC-195,EC-310,

EC-318

,EC-923,EC-930,EC-1038,EC-1045

HO2S2H - Wiring diagram ................. EC-135,EC-867

Hood .................................................................... BL-4

Horn ................................................................. WW-23

HORN - Wiring diagram ................................... WW-23

How to erase DTC ......................................... EC-1406

How to erase DTC for OBD system .... EC-56,EC-455,

EC-788

,EC-1142

I

IATS - Wiring diagram ....................... EC-146

,EC-878

IATSEN - Wiring diagram ................ EC-668,EC-1317

Identification ..................................................... ATC-12

Idle air volume learning ........ EC-39,EC-450,EC-772,

EC-1137

Idle speed EC-73,EC-465,EC-805,EC-1152,EC-1412

IGN/SG - Wiring diagram ................. EC-380,EC-1075

Ignition coil ........ EC-379,EC-683,EC-1074,EC-1331

Ignition coil(QR20DE•QR25DE) ....................... EM-29

Ignition control system ..... EC-379,EC-683,EC-1074,

EC-1331

Ignition timing ........ EC-73,EC-465,EC-805,EC-1152

IGNSYS - Wiring diagram ................ EC-684,EC-1332

ILL - Wiring diagram ........................................... LT-45

Illumination .......................................................... LT-45

In vehicle sensor ........... ATC-102,ATC-104,ATC-113

INJECT - Wiring diagram . EC-389,EC-710,EC-1084,

EC-1358

,EC-1475

Injection nozzle(YD22DDTi) ........................... EM-144

Injector .............. EC-388,EC-709,EC-1083,EC-1357

Input shaft (FF M/T) .............................. MT-18,MT-23

Instrument panel ................................................... IP-3

INT/L - Wiring diagram ........................................ LT-65

Intake air temperature sensor ........... EC-144,EC-160,

EC-667

,EC-876,EC-1316

Intake door control linkage adjustment ............ ATC-69

Intake door motor ATC-68,ATC-119,MTC-11,MTC-23

Intake manifold(QR20DE•QR25DE) ................. EM-16

Intake manifold(YD22DDTi) ............................ EM-123

Intake sensor ................................ ATC-108,ATC-115

Intake valve timing control . EC-125,EC-699,EC-857,

EC-1347

Intake valve timing control solenoid valve ...... EC-271,

EC-699

,EC-1005,EC-1347

Interior ....................... EI-23,EI-25,EI-26,EI-28,EI-29

Interior lamp ........................................................ LT-55

Interior lamp on-off control ...................... LT-55,LT-56

ISO 15031-5 Mode 1 - 9 ...................... EC-44,EC-777

IVC - Wiring diagram ....................... EC-273,EC-1007

IVC/V - Wiring diagram .................... EC-701,EC-1349

J

Joint connector (J/C) ............................. PG-70

,PG-74

K

Keyless entry system - See Multi-remote control system

BL-55

Knock sensor (KS) EC-222,EC-546,EC-951,EC-1235

KS - Wiring diagram ........... EC-224,EC-548,EC-953,

EC-1237

L

LAN system circuit .......................................... ATC-59

License lamp ...................................................... LT-30

Line pressure solenoid valve ........................... AT-156

Line pressure test (A/T) ....................... AT-67,AT-268

Liquid gasket application(QR20DE•QR25DE) ... EM-6,

EM-111

,LU-3,LU-15,CO-3,CO-23

LOAD - Wiring diagram .... EC-416,EC-737,EC-1103,

EC-1377

Location of electrical units ................................ PG-63

Lock, door ............................................... BL-65,BL-68

Lubricant (R134a) A/C ........................ ATC-5,ATC-24

Lubrication circuit (engine)(QR20DE•QR25DE) .. LU-5

Lubrication circuit (engine)(YD22DDTi) ............. LU-17

Lubrication oil A/C ......................................... ATC-150

Lubrication-locks, hinges and hood latches ...... MA-41

M

M/T major overhaul ............................... MT-26

,MT-35

M/T oil replacement .......................................... MT-10

M/T removal and installation ............................. MT-15

MAFS - Wiring diagram ..... EC-140,EC-519,EC-872,

EC-1001

,EC-1205,EC-1453

Magnet clutch ................................. ATC-78,ATC-135

MAIN - Wiring diagram ...... EC-116,EC-507,EC-848,

EC-1193

,EC-1443

Mainshaft (M/T) ..................................... MT-18,MT-23

Maintenance (engine)(QR20DE•QR25DE) ....... MA-19

Maintenance (engine)(YD22DDTi) ................... MA-26

Malfunction indicator (MI) .. EC-263,EC-576,EC-991,

EC-1265

,EC-1407

Malfunction indicator lamp (MIL) ........ EC-58,EC-457,

EC-790

,EC-1144

Mass air flow sensor (MAFS) ........... EC-138,EC-516,

EC-870

,EC-999,EC-1202,EC-1451

Master cylinder (brake) ...................................... BR-13

Master cylinder (clutch) ........................................ CL-9

METER - Wiring diagram ........................... DI-8,DI-28

MIL - Wiring diagram ......... EC-264,EC-577,EC-992,

EC-1266

MIL/DL - Wiring diagram ................................ EC-1573

MIRROR - Wiring diagram ............................... GW-50

Mirror defogger ................................................ GW-15

Mirror, door ...................................................... GW-49

Mirror, out side ................................................. GW-49

Misfire ............................................... EC-217,EC-946

Mode door control linkage adjustment ........... ATC-64,

ATC-124

,MTC-9,MTC-27

Mode door motor ............................ ATC-62,ATC-124