stop start NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 8 of 3833

GI-6

PRECAUTIONS

CAUTION:

●Do not use home heating oil, gasoline or other alternate fuels in your diesel engine. The use of

those can cause engine damage.

●Do not use summer fuel at temperatures below –7°C (20°F). The cold temperatures will cause wax

to form in the fuel. As a result, it may prevent the engine from running smoothly.

●Do not add gasoline or other alternate fuels to diesel fuel.

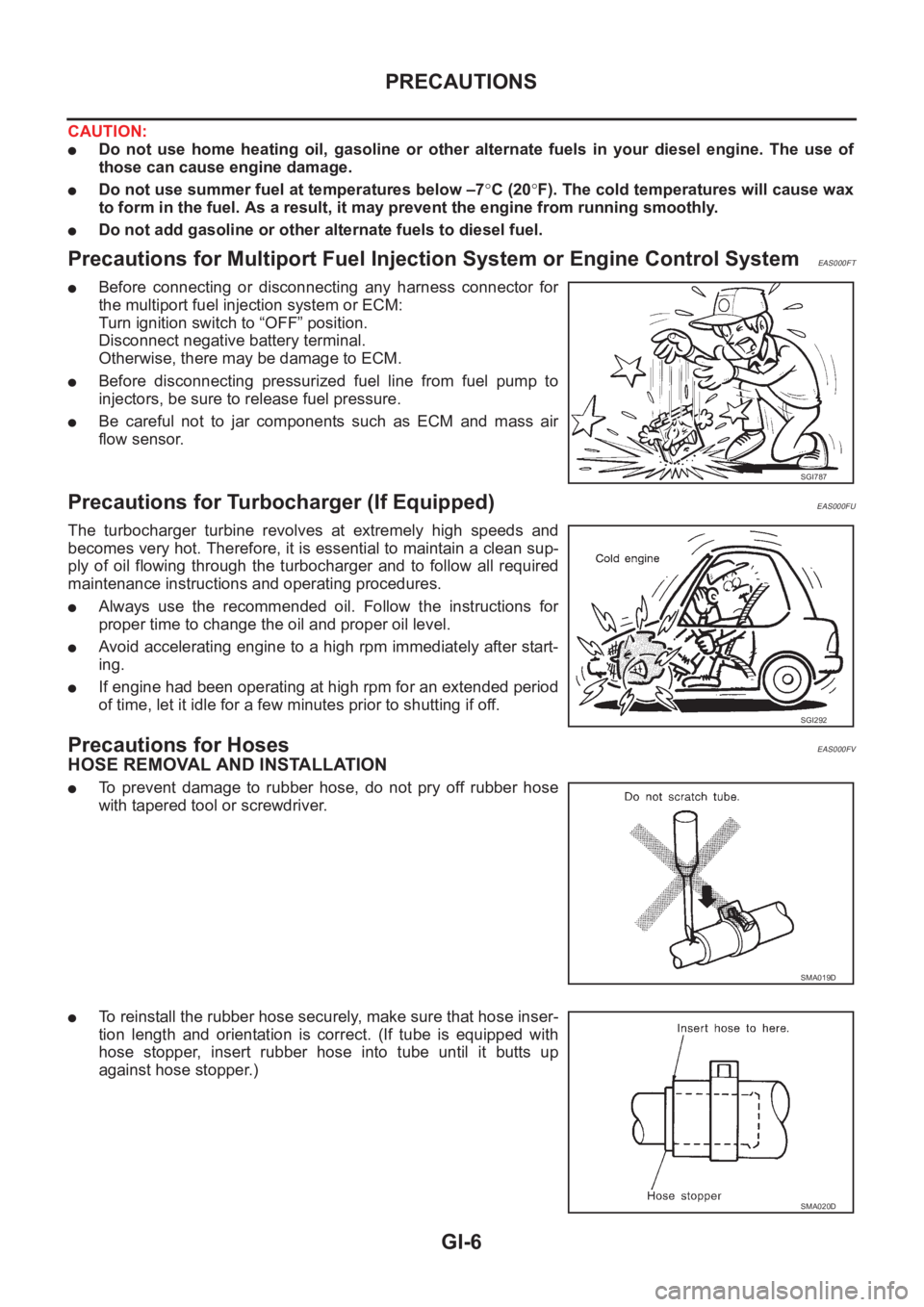

Precautions for Multiport Fuel Injection System or Engine Control SystemEAS000FT

●Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

●Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

●Be careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Turbocharger (If Equipped)EAS000FU

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean sup-

ply of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

●Always use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

●Avoid accelerating engine to a high rpm immediately after start-

ing.

●If engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting if off.

Precautions for HosesEAS000FV

HOSE REMOVAL AND INSTALLATION

●To prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

●To reinstall the rubber hose securely, make sure that hose inser-

tion length and orientation is correct. (If tube is equipped with

hose stopper, insert rubber hose into tube until it butts up

against hose stopper.)

SGI787

SGI292

SMA019D

SMA020D

Page 15 of 3833

HOW TO USE THIS MANUAL

GI-13

C

D

E

F

G

H

I

J

K

L

MB

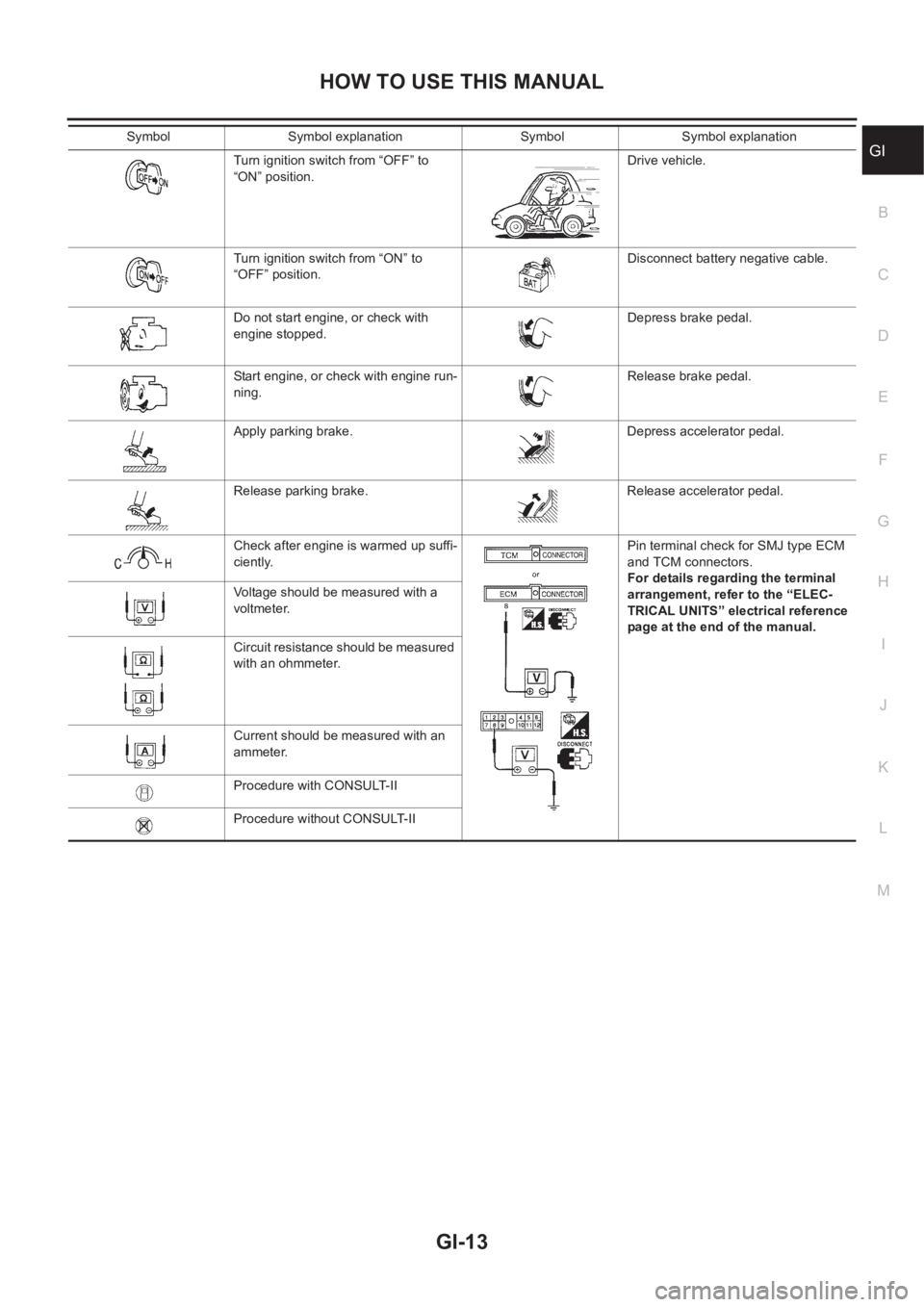

GITurn ignition switch from “OFF” to

“ON” position.Drive vehicle.

Turn ignition switch from “ON” to

“OFF” position.Disconnect battery negative cable.

Do not start engine, or check with

engine stopped.Depress brake pedal.

Start engine, or check with engine run-

ning.Release brake pedal.

Apply parking brake. Depress accelerator pedal.

Release parking brake. Release accelerator pedal.

Check after engine is warmed up suffi-

ciently.Pin terminal check for SMJ type ECM

and TCM connectors.

For details regarding the terminal

arrangement, refer to the “ELEC-

TRICAL UNITS” electrical reference

page at the end of the manual. Voltage should be measured with a

voltmeter.

Circuit resistance should be measured

with an ohmmeter.

Current should be measured with an

ammeter.

Procedure with CONSULT-II

Procedure without CONSULT-II Symbol Symbol explanation Symbol Symbol explanation

Page 55 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual PRECAUTIONS

EM-5

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00KN0

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel Pip NISSAN X-TRAIL 2001 Service Repair Manual PRECAUTIONS

EM-5

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00KN0

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel Pip](/img/5/57405/w960_57405-54.png)

PRECAUTIONS

EM-5

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00KN0

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEBS00KN1

●Before starting work, make sure no fire or spark producing items are in the work area.

●Release fuel pressure before disassembly.

●After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyEBS00KN2

●When instructed to use special service tools, use the specified tools. Always be careful to work safely,

avoid forceful or uninstructed operations.

●Exercise maximum care to avoid damage to mating or sliding surfaces.

●Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

●Mark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

●When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified.

Precautions for Inspection, Repair and ReplacementEBS00KN3

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precautions for Assembly and InstallationEBS00MRZ

●Use torque wrench to tighten bolts or nuts to specification.

●When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is speci-

fied, do exactly as specified.

●Replace with new gasket, packing, oil seal or O-ring.

●Thoroughly wash, clean, and air-blow each part. Carefully check oil or coolant passages for any restriction

and blockage.

●Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

●Release air within route when refilling after draining coolant.

●Before starting engine, apply fuel pressure to fuel lines with turning ignition switch ON (with engine

stopped). Then mark sure that there are no leaks at fuel line connections.

●After repairing, start engine and increase engine speed to check coolant, fuel, oil, and exhaust systems

for leakage.

Parts Requiring Angular TighteningEBS00KN5

●Use an angle wrench for the final tightening of the following engine parts.

–Cylinder head bolts

–Lower cylinder block bolts

–Connecting rod cap bolts

–Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angular

tightening)

●Do not use a torque value for final tightening.

●The torque value for these parts are for a preliminary step.

●Ensure thread and seat surfaces are clean and coated with engine oil.

Page 72 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-22

[QR]

INTAKE MANIFOLD

3. Align center to insert quick connector straightly into fuel tube.

●Insert fuel tube into quick connector until the first spool on fuel

tubes is inserted completely and NISSAN X-TRAIL 2001 Service Repair Manual EM-22

[QR]

INTAKE MANIFOLD

3. Align center to insert quick connector straightly into fuel tube.

●Insert fuel tube into quick connector until the first spool on fuel

tubes is inserted completely and](/img/5/57405/w960_57405-71.png)

EM-22

[QR]

INTAKE MANIFOLD

3. Align center to insert quick connector straightly into fuel tube.

●Insert fuel tube into quick connector until the first spool on fuel

tubes is inserted completely and the second one is positioned

slightly below the quick connectors bottom end.

CAUTION:

●Hold A position in illustration when inserting fuel tube

into quick connector.

●Carefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

●Insert until you hear a “click” sound and actually feel

the engagement.

●To avoid misidentification of engagement with a similar sound, be sure to perform the next

step.

4. Before clamping fuel hose with hose clamps, pull quick connector hard by hand holding A position. Make

sure it is completely engaged (connected) so that it does not come out from fuel tube.

NOTE:

Recommended pulling force is 50 N (5.1 kg, 11.2 lb).

5. Install quick connector cap on quick connector joint.

●Direct arrow mark on quick connector cap to upper side.

6. Install fuel hose to hose clamp.

Connecting Quick Connector of Fuel Hose (Vehicle side)

Install quick connector as follows.

1. Make sure no foreign substances are deposited in and around tube and quick connector and no damage

on them.

2. Align center to insert quick connector straightly into fuel tube.

●Insert fuel tube until a click is heard.

●Install quick connector cap on quick connector joint. Direct

arrow mark on quick connector cap to upper side.

3. Install fuel hose to hose clamp.

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections in the following steps.

1. Apply fuel pressure to fuel lines with turning ignition switch ON (with engine stopped). Then check for fuel

leaks at connections.

2. Start the engine and rev it up and check for fuel leaks at connections.

NOTE:

Use mirrors for checking on invisible points.

CAUTION:

Do not touch the engine immediately after stopped as engine becomes extremely hot.

KBIA0272E

KBIA0298E

PBIC0662E

Page 84 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-34

[QR]

FUEL INJECTOR AND FUEL TUBE

b. Tighten mounting bolts in two steps in the numerical order

shown in the figure.

5. Install intake manifold collector. Refer to EM-16, "

INTAKE MA NISSAN X-TRAIL 2001 Service Repair Manual EM-34

[QR]

FUEL INJECTOR AND FUEL TUBE

b. Tighten mounting bolts in two steps in the numerical order

shown in the figure.

5. Install intake manifold collector. Refer to EM-16, "

INTAKE MA](/img/5/57405/w960_57405-83.png)

EM-34

[QR]

FUEL INJECTOR AND FUEL TUBE

b. Tighten mounting bolts in two steps in the numerical order

shown in the figure.

5. Install intake manifold collector. Refer to EM-16, "

INTAKE MANI-

FOLD" .

6. Connect fuel hose. Refer to EM-16, "

INTAKE MANIFOLD" .

7. Install all removed parts in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Check connections for fuel leakage.

1. Start the engine, and run it for a few minutes with engine at idle.

2. Stop the engine, and check for fuel leakage both visually and by odor of gasoline.

NOTE:

Use mirrors for checking on invisible points.

CAUTION:

Do not touch the engine immediately after stopped as engine becomes extremely hot. 1st step:

: 9.3 - 10.8 N·m (0.95 - 1.1 kg-m, 0.7 - 0.8 ft-lb)

2nd step:

: 20.6 - 26.5 N·m (2.1 - 2.7 kg-m, 16 - 19 ft-lb)

KBIA0239E

Page 103 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CAMSHAFT

EM-53

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

Valve Lifter Hole Diameter

Using inside micrometer, measure diameter of valve lifter hole of cyl-

inder head.

Calculation of Valve Lifter Clearance

(Valve NISSAN X-TRAIL 2001 Service Repair Manual CAMSHAFT

EM-53

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

Valve Lifter Hole Diameter

Using inside micrometer, measure diameter of valve lifter hole of cyl-

inder head.

Calculation of Valve Lifter Clearance

(Valve](/img/5/57405/w960_57405-102.png)

CAMSHAFT

EM-53

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

Valve Lifter Hole Diameter

Using inside micrometer, measure diameter of valve lifter hole of cyl-

inder head.

Calculation of Valve Lifter Clearance

(Valve lifter clearance) = (hole diameter of valve lifter) – (outer diam-

eter of valve lifter).

●When out of specified range, referring to each specification of

outer and inner diameter, replace either or both valve lifter and

cylinder head.

Va l v e C l e a r a n c eEBS00LS3

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if

there is unusual engine conditions due to changes in valve clearance over time (starting, idling, and/or noise).

1. Warm up engine. Then stop it.

2. Remove splash cover on RH undercover.

3. Remove rocker cover. Refer to EM-35, "

ROCKER COVER" .

4. Turn crankshaft pulley in normal direction (clockwise when

viewed from front) to align TDC identification notch (without

paint mark) with timing indicator.

5. At this time, check that the both intake and exhaust cam noses

of No. 1 cylinder face outside.

●If they do not face outside, turn crankshaft pulley once more.

6. By referring to the figure, measure valve clearances at locations

marked X as shown in the table below (locations indicated with

black arrow in figure) with a feeler gauge.

●No. 1 cylinder compression TDC.Standard: 34.000 - 34.021 mm (1.3386 - 1.3394 in)

Standard: 0.020 - 0.056 mm (0.0008 - 0.0022 in)

PBIC0043E

KBIA0190E

KBIA0400J

Measuring position No.1 CYL. No.2 CYL. No.3 CYL. No.4 CYL.

No.1 cylinder at

TDCINT X X

EXH X X

SBIA0261E

Page 109 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER HEAD

EM-59

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00KNP

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER HEAD

EM-59

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00KNP

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure](/img/5/57405/w960_57405-108.png)

CYLINDER HEAD

EM-59

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00KNP

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-775, "

FUEL PRESSURE RELEASE" [QR20DE (WITH EURO-OBD)],

EC-1139, "

FUEL PRESSURE RELEASE" [QR20DE (WITHOUT EURO-OBD)], EC-42, "FUEL PRES-

SURE RELEASE" [QR25DE (WITH EURO-OBD)] or EC-452, "FUEL PRESSURE RELEASE" [QR25DE

(WITHOUT EURO-OBD)].

3. Remove ignition coil and spark plug from each cylinder. Refer to EM-29, "

IGNITION COIL" and EM-30,

"SPARK PLUG" .

4. Connect engine tachometer (not required in use of CONSULT-II).

5. Disconnect fuel injector sub-harness to avoid fuel injection dur-

ing measurement.

6. Install compression tester with adapter onto spark plug hole.

●Use compression gauge whose picking up end inserted to

spark plug hole is smaller than 20 mm (0.79 in) in diameter.

Otherwise, it may be caught by cylinder head during removal.

7. With accelerator pedal fully depressed, turn ignition switch to

“START” for cranking. When the gauge pointer stabilizes, read

the compression pressure and engine rpm. Perform these steps

to check each cylinder.

Compression pressure

Unit: kPa (bar, kg/cm2 , psi) /rpm

CAUTION:

Always use a fully changed battery to obtain specified engine speed.

KBIA0269E

KBIA0130E

SEM387C

Engine type Standard Minimum Deference limit between cylinders

QR20DE 1,190 (11.9, 12.1, 173) / 250 990 (9.9, 10.1, 144) / 250

100 (1.0, 1.0, 14) / 250

QR25DE 1,250 (12.5, 12.8, 181.3) / 250 1,060 (10.6, 10.8, 153.7) / 250

Page 119 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual ENGINE ASSEMBLY

EM-69

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

ENGINE ASSEMBLYPFP:10001

Removal and InstallationEBS00KNT

WARNING:

●Situate vehicle on a flat and solid surface.

●Place chocks at front and bac NISSAN X-TRAIL 2001 Service Repair Manual ENGINE ASSEMBLY

EM-69

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

ENGINE ASSEMBLYPFP:10001

Removal and InstallationEBS00KNT

WARNING:

●Situate vehicle on a flat and solid surface.

●Place chocks at front and bac](/img/5/57405/w960_57405-118.png)

ENGINE ASSEMBLY

EM-69

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

ENGINE ASSEMBLYPFP:10001

Removal and InstallationEBS00KNT

WARNING:

●Situate vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●For engines not equipped with engine slingers, attach proper slingers and bolts described in

PARTS CATALOG.

CAUTION:

●Always be careful to work safely, avoid forceful or uninstructed operations.

●Do not start working until exhaust system and engine coolant are cool enough.

●If items or work required are not covered by the engine main body section, refer to the applicable

sections.

●Always use the support point specified for lifting.

●Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at the rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

●For supporting points for lifting and jacking point at rear axle, refer to GI-35, "Garage Jack and

Safety Stand" .

REMOVAL

Description of work

Remove engine, transaxle and transfer assembly with front suspension member from vehicle down ward.

Separate suspension member, and then separate engine and transaxle.

Preparation

PBIC1262E

1. Rear engine mounting insulator 2. Rear engine mounting bracket 3. RH engine mounting insulator

4. RH engine mounting bracket 5. Front engine mounting bracket 6. Front engine mounting insulator

7. Center member 8. LH engine mounting insulator 9. LH engine mounting bracket

10. Stopper 11. Grommet (2pcs)

Page 160 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-110

[YD22DDTi]

PRECAUTIONS

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00LQZ

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEBS00LR0

NISSAN X-TRAIL 2001 Service Repair Manual EM-110

[YD22DDTi]

PRECAUTIONS

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00LQZ

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEBS00LR0](/img/5/57405/w960_57405-159.png)

EM-110

[YD22DDTi]

PRECAUTIONS

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00LQZ

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEBS00LR0

●Before starting work, make sure no fire or spark producing items are in the work area.

●Release fuel pressure before disassembly.

●After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyEBS00LR1

●When instructed to use special service tools, use the specified tools. Always be careful to work safely,

avoid forceful or uninstructed operations.

●Exercise maximum care to avoid damage to mating or sliding surfaces.

●Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

●Mark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

●When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified.

Precautions for Inspection, Repair and ReplacementEBS00LR2

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precautions for Assembly and InstallationEBS00LR3

●Use torque wrench to tighten bolts or nuts to specification.

●When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is speci-

fied, do exactly as specified.

●Replace with new liquid gasket, packing, oil seal or O-ring.

●Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

●Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, engine oil sliding surfaces well.

●Release air within route when refilling after draining coolant.

●After repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust systems for leakage.

Parts Requiring Angular TighteningEBS00LR4

●Use an angle wrench for the final tightening of the following engine parts:

–Cylinder head bolts

–Main bearing cap bolts

–Connecting rod cap nuts

–Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angular

tightening)

●Do not use a torque value for final tightening.

●The torque value for these parts are for a preliminary step.

●Ensure thread and seat surfaces are clean and coated with engine oil.

Page 175 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual INTAKE MANIFOLD

EM-125

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

3. Install water hose.

●Install water hose by referring to identification marks avoiding

twisting.

●When an insert stopper is not NISSAN X-TRAIL 2001 Service Repair Manual INTAKE MANIFOLD

EM-125

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

3. Install water hose.

●Install water hose by referring to identification marks avoiding

twisting.

●When an insert stopper is not](/img/5/57405/w960_57405-174.png)

INTAKE MANIFOLD

EM-125

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

3. Install water hose.

●Install water hose by referring to identification marks avoiding

twisting.

●When an insert stopper is not provided with the pipe, insert

the hose up to dimension A. When the pipe is shorter than

dimension A, insert hose fully until it reaches the end.

●When an insert stopper is provided on the pipe side, insert the

hose until it reaches the bulge.

●When marking is provided on the pipe, insert hose until it cov-

ers half of the marking.

4. Install remaining parts in reverse order of removal.

5. Before starting engine, bleed air from fuel piping. Refer to FL-16,

"Air Bleeding" .

INSPECTION AFTER INSTALLATION

Start engine and increase engine speed to check for fuel leak.Dimension A : 25 - 30 mm (0.984 - 1.181 in)

SBIA0156E