towing NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3 of 3833

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for NATS (NISSAN ANTI-THEFT SYS-

TEM) ........................................................................ 3

General Precautions ................................................ 4

Precautions for All Mode 4 × 4 System .................... 5

Precautions for Three Way Catalyst ......................... 5

Precautions for Fuel ................................................. 5

GASOLINE ENGINE ............................................. 5

DIESEL ENGINE ................................................... 5

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 6

Precautions for Turbocharger (If Equipped) ............. 6

Precautions for Hoses .............................................. 6

HOSE REMOVAL AND INSTALLATION ............... 6

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 7

HEALTH PROTECTION PRECAUTIONS ............. 7

ENVIRONMENTAL PROTECTION PRECAU-

TIONS ................................................................... 7

Precautions for Air Conditioning ............................... 7

HOW TO USE THIS MANUAL ................................... 8

Description ............................................................... 8

Terms ....................................................................... 8

Units ......................................................................... 8

Contents ................................................................... 8

Components ............................................................. 8

SYMBOLS ............................................................. 9

How to Follow Trouble Diagnoses ............................ 9

DESCRIPTION ...................................................... 9

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ............................................... 10

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ........................................ 11

KEY TO SYMBOLS SIGNIFYING MEASURE-

MENTS OR PROCEDURES ............................... 12

How to Read Wiring Diagrams ............................... 14CONNECTOR SYMBOLS ................................... 14

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 15

DESCRIPTION .................................................... 16

Abbreviations .......................................................... 22

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 23

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 23

WORK FLOW ...................................................... 23

INCIDENT SIMULATION TESTS ........................ 23

CIRCUIT INSPECTION ....................................... 26

Control Units and Electrical Parts ........................

... 31

PRECAUTIONS .................................................. 31

CONSULT-II CHECKING SYSTEM .......................... 33

Description .............................................................. 33

Function and System Application ........................... 33

Nickel Metal Hydride Battery Replacement ............ 33

Checking Equipment .............................................. 34

CONSULT-II Data Link Connector (DLC) Circuit .... 34

INSPECTION PROCEDURE .............................. 34

LIFTING POINT ......................................................... 35

Special Service Tools ............................................. 35

Garage Jack and Safety Stand ............................... 35

2-pole Lift ................................................................ 36

Board-on Lift ........................................................... 37

TOW TRUCK TOWING ............................................. 38

Tow Truck Towing ................................................... 38

TOWING AN AUTOMATIC TRANSAXLE

MODEL WITH FOUR WHEELS ON GROUND ... 38

T O W I N G T H E V E H I C L E W I T H R E A R W H E E L S

R A I S E D ( W I T H F R O N T W H E E L S O N G R O U N D )

OR FRONT WHEELS RAISED ........................... 39

Vehicle Recovery (Freeing a stuck vehicle) ............ 39

TIGHTENING TORQUE OF STANDARD BOLTS .... 40

Tightening Torque Table ......................................... 40

IDENTIFICATION INFORMATION ............................ 41

Model Variation ....................................................... 41

IDENTIFICATION NUMBER ................................ 42

IDENTIFICATION PLATE .................................... 43

ENGINE SERIAL NUMBER ................................ 43

Page 40 of 3833

GI-38

TOW TRUCK TOWING

TOW TRUCK TOWING

PFP:00000

Tow Truck TowingEAS000FL

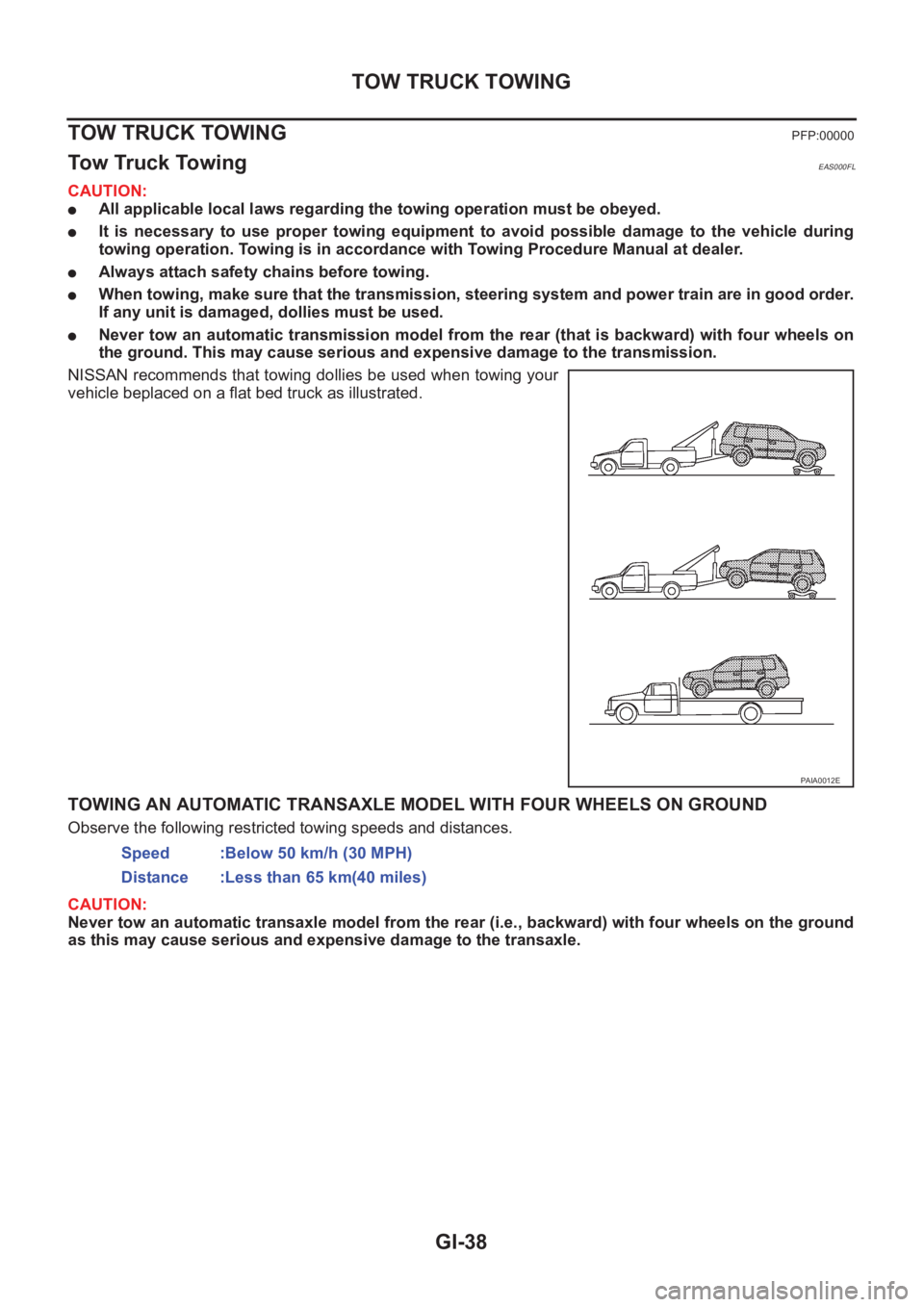

CAUTION:

●All applicable local laws regarding the towing operation must be obeyed.

●It is necessary to use proper towing equipment to avoid possible damage to the vehicle during

towing operation. Towing is in accordance with Towing Procedure Manual at dealer.

●Always attach safety chains before towing.

●When towing, make sure that the transmission, steering system and power train are in good order.

If any unit is damaged, dollies must be used.

●Never tow an automatic transmission model from the rear (that is backward) with four wheels on

the ground. This may cause serious and expensive damage to the transmission.

NISSAN recommends that towing dollies be used when towing your

vehicle beplaced on a flat bed truck as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH FOUR WHEELS ON GROUND

Observe the following restricted towing speeds and distances.

CAUTION:

Never tow an automatic transaxle model from the rear (i.e., backward) with four wheels on the ground

as this may cause serious and expensive damage to the transaxle.

PAIA0012E

Speed :Below 50 km/h (30 MPH)

Distance :Less than 65 km(40 miles)

Page 41 of 3833

TOW TRUCK TOWING

GI-39

C

D

E

F

G

H

I

J

K

L

MB

GI

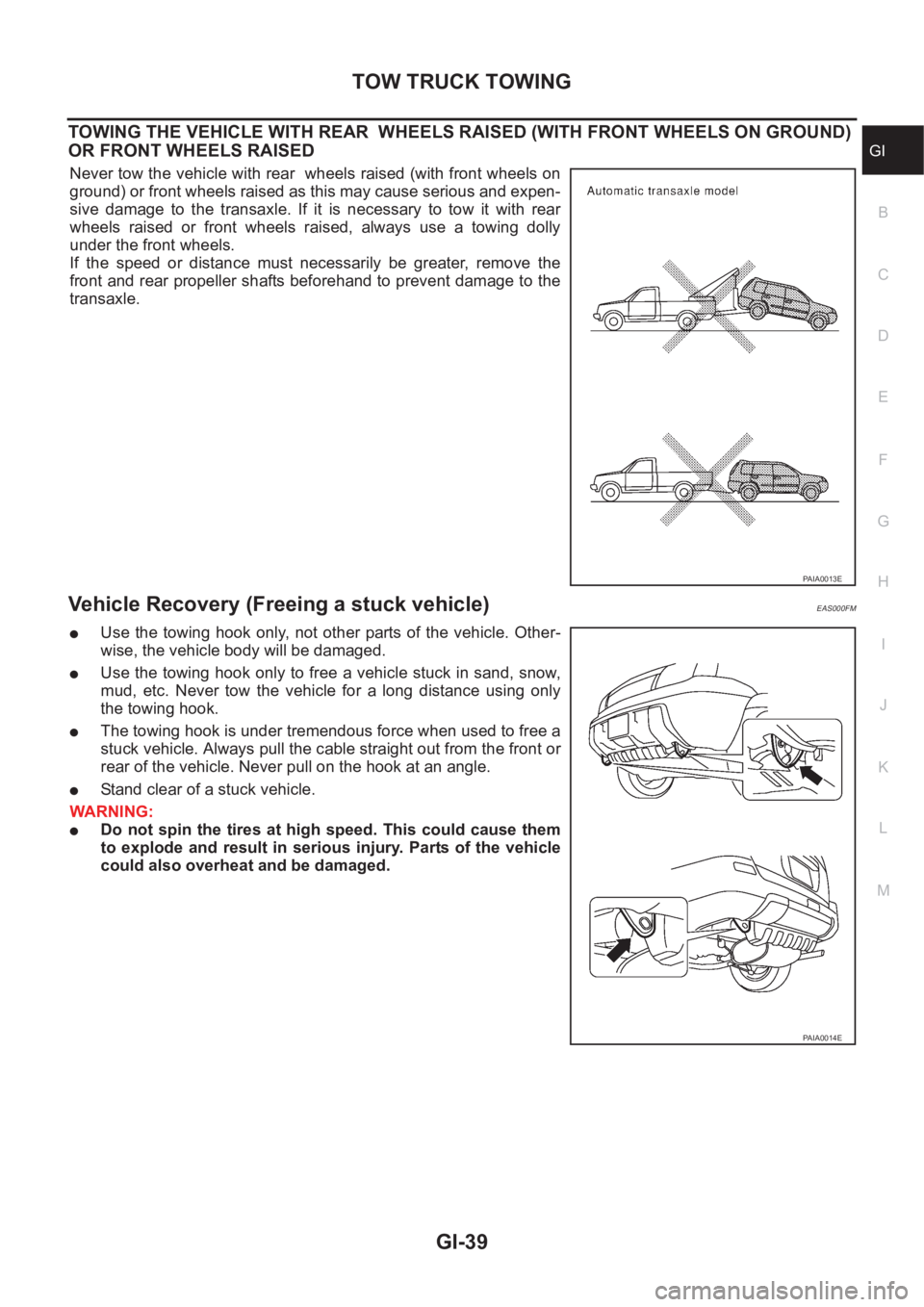

TOWING THE VEHICLE WITH REAR WHEELS RAISED (WITH FRONT WHEELS ON GROUND)

OR FRONT WHEELS RAISED

Never tow the vehicle with rear wheels raised (with front wheels on

ground) or front wheels raised as this may cause serious and expen-

sive damage to the transaxle. If it is necessary to tow it with rear

wheels raised or front wheels raised, always use a towing dolly

under the front wheels.

If the speed or distance must necessarily be greater, remove the

front and rear propeller shafts beforehand to prevent damage to the

transaxle.

Vehicle Recovery (Freeing a stuck vehicle) EAS000FM

●Use the towing hook only, not other parts of the vehicle. Other-

wise, the vehicle body will be damaged.

●Use the towing hook only to free a vehicle stuck in sand, snow,

mud, etc. Never tow the vehicle for a long distance using only

the towing hook.

●The towing hook is under tremendous force when used to free a

stuck vehicle. Always pull the cable straight out from the front or

rear of the vehicle. Never pull on the hook at an angle.

●Stand clear of a stuck vehicle.

WARNING:

●Do not spin the tires at high speed. This could cause them

to explode and result in serious injury. Parts of the vehicle

could also overheat and be damaged.

PAIA0013E

PAIA0014E

Page 3790 of 3833

MA-10

PERIODIC MAINTENANCE

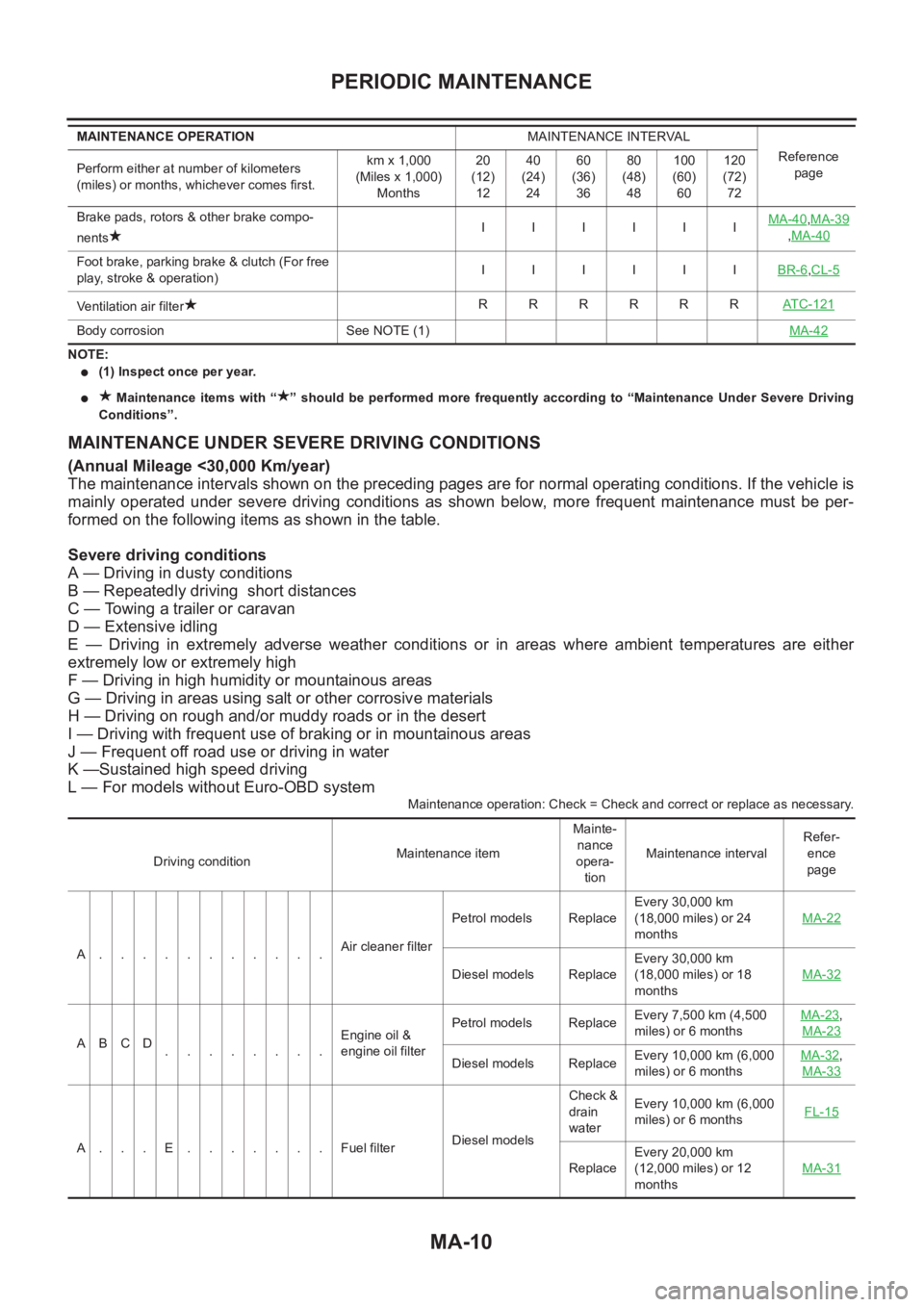

NOTE:

●(1) Inspect once per year.

● Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage <30,000 Km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Repeatedly driving short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity or mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K —Sustained high speed driving

L — For models without Euro-OBD system

Maintenance operation: Check = Check and correct or replace as necessary. Brake pads, rotors & other brake compo-

nentsIIIIIIMA-40

,MA-39

,MA-40

Foot brake, parking brake & clutch (For free

play, stroke & operation)IIIIIIBR-6,CL-5

Ventilation air filterRRRRRRAT C - 1 2 1

Body corrosion See NOTE (1)MA-42

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers

(miles) or months, whichever comes first.km x 1,000

(Miles x 1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Driving conditionMaintenance itemMainte-

nance

opera-

tionMaintenance intervalRefer-

ence

page

A...........Air cleaner filterPetrol models ReplaceEvery 30,000 km

(18,000 miles) or 24

monthsMA-22

Diesel models ReplaceEvery 30,000 km

(18,000 miles) or 18

monthsMA-32

ABCD

........Engine oil &

engine oil filter Petrol models ReplaceEvery 7,500 km (4,500

miles) or 6 monthsMA-23

,

MA-23

Diesel models ReplaceEvery 10,000 km (6,000

miles) or 6 monthsMA-32,

MA-33

A...E.......Fuel filter Diesel models Check &

drain

waterEvery 10,000 km (6,000

miles) or 6 monthsFL-15

ReplaceEvery 20,000 km

(12,000 miles) or 12

monthsMA-31

Page 3794 of 3833

MA-14

PERIODIC MAINTENANCE

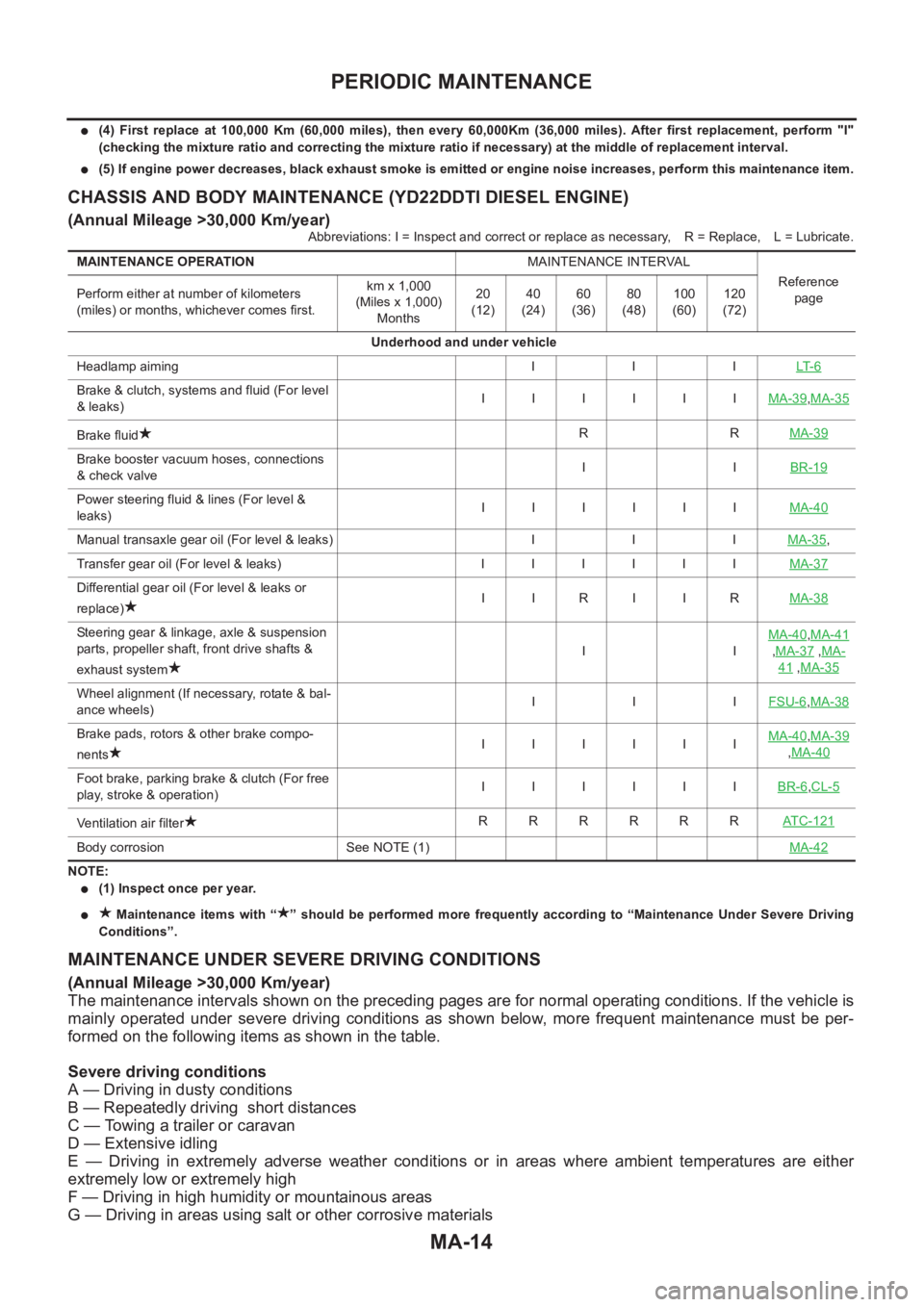

●(4) First replace at 100,000 Km (60,000 miles), then every 60,000Km (36,000 miles). After first replacement, perform "I"

(checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

●(5) If engine power decreases, black exhaust smoke is emitted or engine noise increases, perform this maintenance item.

CHASSIS AND BODY MAINTENANCE (YD22DDTI DIESEL ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary,R = Replace, L = Lubricate.

NOTE:

●(1) Inspect once per year.

● Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage >30,000 Km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Repeatedly driving short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity or mountainous areas

G — Driving in areas using salt or other corrosive materials

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers

(miles) or months, whichever comes first.km x 1,000

(Miles x 1,000)

Months20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

Underhood and under vehicle

Headlamp aiming I I ILT- 6

Brake & clutch, systems and fluid (For level

& leaks)IIIIIIMA-39,MA-35

Brake fluidRRMA-39

Brake booster vacuum hoses, connections

& check valveIIBR-19

Power steering fluid & lines (For level &

leaks)IIIIIIMA-40

Manual transaxle gear oil (For level & leaks) I I IMA-35,

Transfer gear oil (For level & leaks) IIIIIIMA-37

Differential gear oil (For level & leaks or

replace)IIRIIRMA-38

Steering gear & linkage, axle & suspension

parts, propeller shaft, front drive shafts &

exhaust systemIIMA-40,MA-41

,MA-37 ,MA-

41 ,MA-35

Wheel alignment (If necessary, rotate & bal-

ance wheels)IIIFSU-6,MA-38

Brake pads, rotors & other brake compo-

nentsIIIIIIMA-40,MA-39

,MA-40

Foot brake, parking brake & clutch (For free

play, stroke & operation)IIIIIIBR-6,CL-5

Ventilation air filterRRRRRRAT C - 1 2 1

Body corrosion See NOTE (1)MA-42