AUX NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 34 of 3066

AT-28

OVERALL SYSTEM

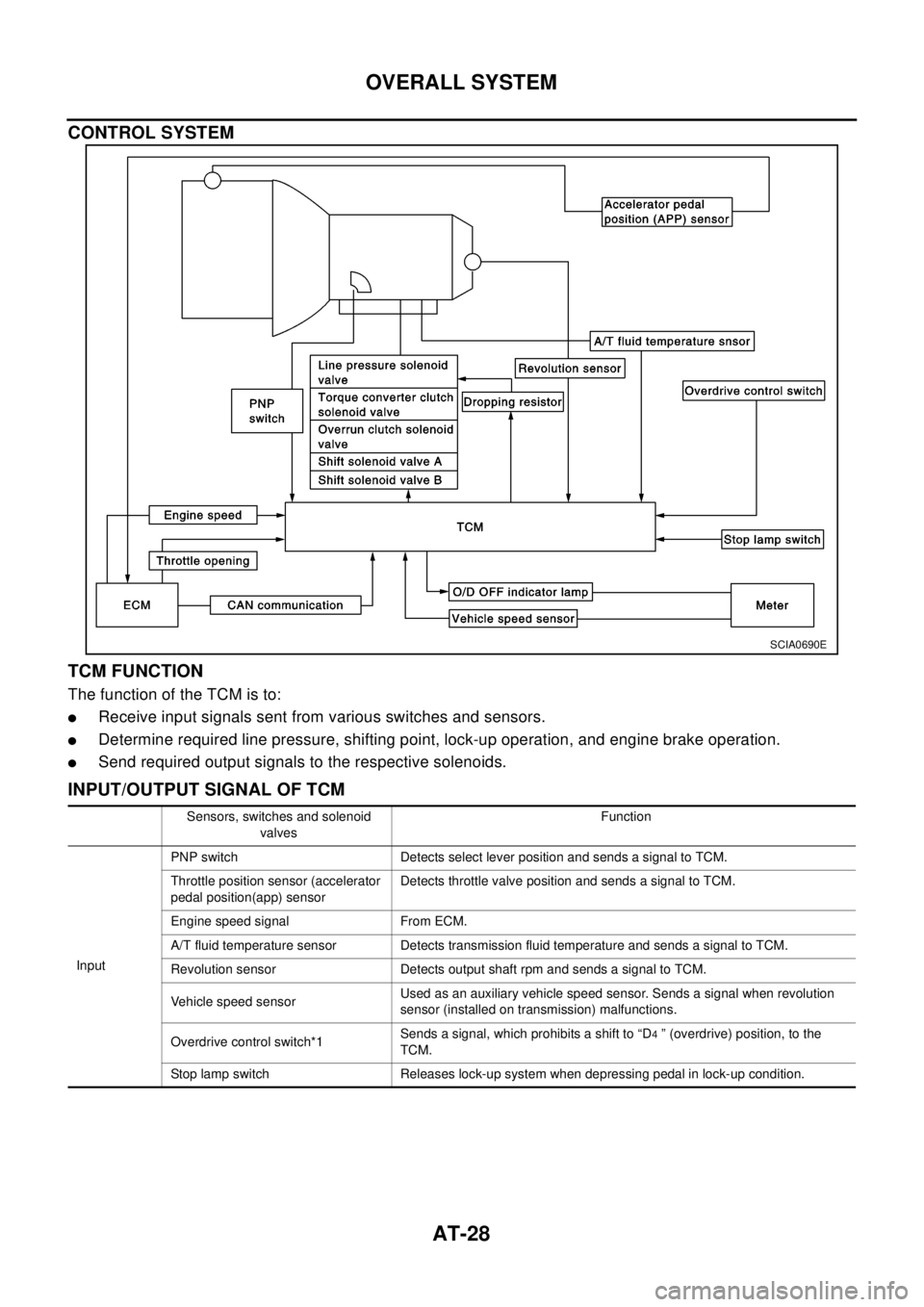

CONTROL SYSTEM

TCM FUNCTION

ThefunctionoftheTCMisto:

lReceive input signals sent from various switches and sensors.

lDetermine required line pressure, shifting point, lock-up operation, and engine brake operation.

lSend required output signals to the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

SCIA0690E

Sensors, switches and solenoid

valvesFunction

InputPNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor (accelerator

pedal position(app) sensorDetects throttle valve position and sends a signal to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensorUsed as an auxiliary vehicle speed sensor. Sends a signal when revolution

sensor (installed on transmission) malfunctions.

Overdrive control switch*1Sends a signal, which prohibits a shift to “D

4” (overdrive) position, to the

TCM.

Stop lamp switch Releases lock-up system when depressing pedal in lock-up condition.

Page 228 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-222

[EURO-OBD]

DTC VEHICLE SPEED SENSOR MTR

DTC VEHICLE SPEED SENSOR MTR

PFP:24814

DescriptionECS004SM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. The sensor functions a NISSAN X-TRAIL 2003 Electronic Repair Manual AT-222

[EURO-OBD]

DTC VEHICLE SPEED SENSOR MTR

DTC VEHICLE SPEED SENSOR MTR

PFP:24814

DescriptionECS004SM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. The sensor functions a](/img/5/57402/w960_57402-227.png)

AT-222

[EURO-OBD]

DTC VEHICLE SPEED SENSOR MTR

DTC VEHICLE SPEED SENSOR MTR

PFP:24814

DescriptionECS004SM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. The sensor functions as an auxiliary device to the revolution sen-

sor when it is malfunctioning. The TCM will then use a signal sent

from the vehicle speed sensor·MTR.

TCM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values.

ON BOARD DIAGNOSIS LOGIC

SCIA0716E

Te r m i -

nal No.Wire color Item ConditionJudgement stan-

dard

(Approx.)

40 L/BVehicle speed

sensorWhen moving vehicle at 2 to 3 km/h

(1 to 2 MPH) for 1 m (3 ft) or more.Vo ltag e v a rie s

between less

than 1V and

more than 4.5V

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: VHCL SPEED SEN·MTR

TCM does not receive the proper voltage

signal from the sensor.

lHarness or connectors

(The sensor circuit is open or shorted.)

lVehicle speed sensor

: 2nd judgement flicker

Page 403 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual DTC VEHICLE SPEED SENSOR MTR

AT-397

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC VEHICLE SPEED SENSOR MTRPFP:24814

DescriptionECS004TM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. Th NISSAN X-TRAIL 2003 Electronic Repair Manual DTC VEHICLE SPEED SENSOR MTR

AT-397

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC VEHICLE SPEED SENSOR MTRPFP:24814

DescriptionECS004TM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. Th](/img/5/57402/w960_57402-402.png)

DTC VEHICLE SPEED SENSOR MTR

AT-397

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC VEHICLE SPEED SENSOR MTRPFP:24814

DescriptionECS004TM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. The sensor functions as an auxiliary device to the revolution sen-

sor when it is malfunctioning. The TCM will then use a signal sent

from the vehicle speed sensor·MTR.

TCM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values.

ON BOARD DIAGNOSIS LOGIC

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURE

After the repair, perform the following procedure to confirm the malfunction is eliminated.

With CONSULT-II

1. Start engine.

2. Select “SELF-DIAG RESULTS” mode for A/T with CONSULT-II.

3. Drive vehicle under the following conditions:

Selector lever in “D” position and vehicle speed higher than 20

km/h (12 MPH).

SCIA0716E

Te r m i -

nal No.Wire color Item ConditionJudgement stan-

dard

(Approx.)

40 L/BVehicle speed

sensorWhen moving vehicle at 2 to 3 km/h

(1to2MPH)for1m(3ft)ormore.Voltage varies

between less

than 0V and

more than 4.5V

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: VHCL SPEED SEN·MTR

TCM does not receive the proper voltage

signal from the sensor.

lHarness or connectors

(The sensor circuit is open or shorted.)

lVehicle speed sensor

: 2nd judgement flicker

SAT014K

Page 580 of 3066

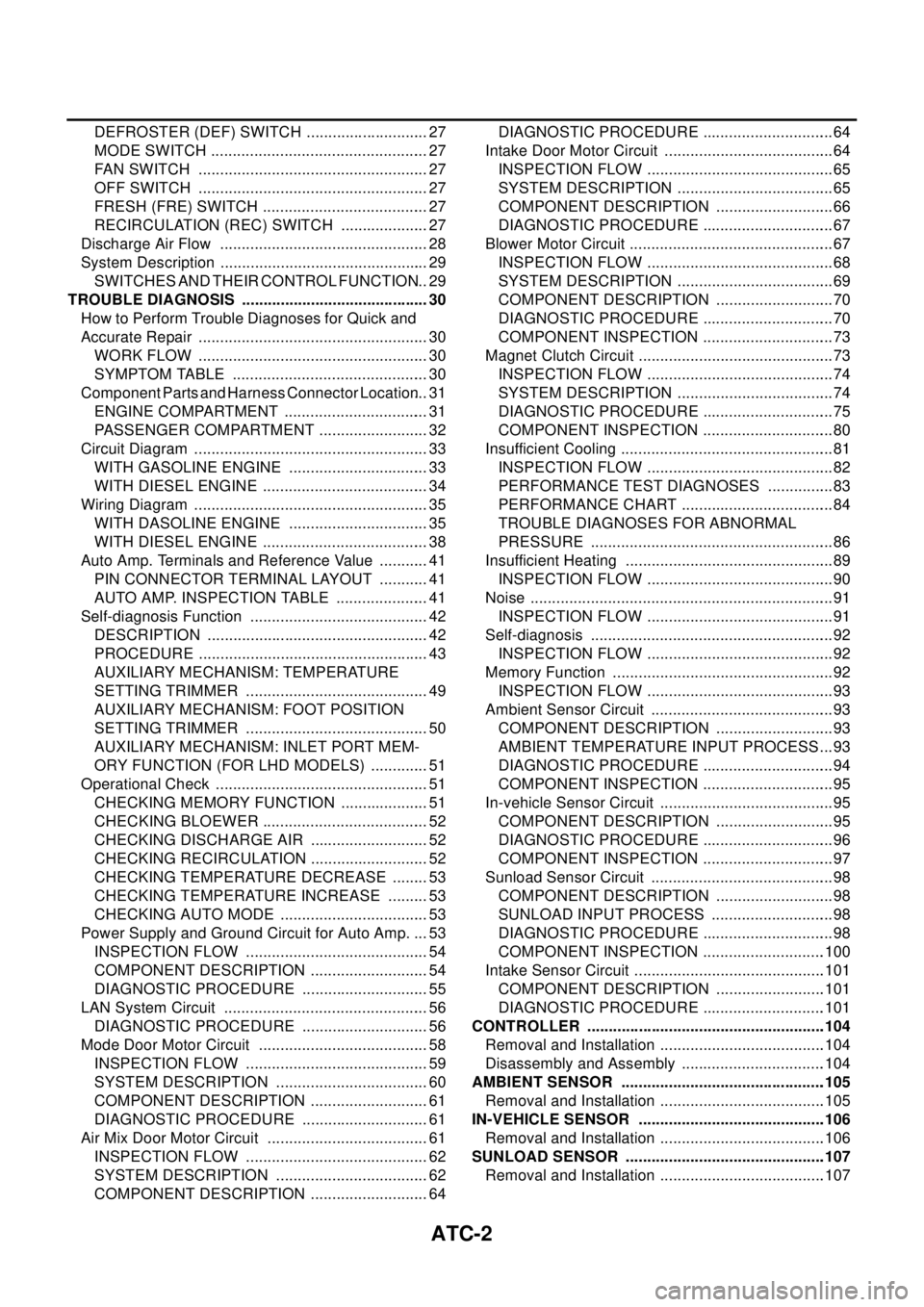

ATC-2

DEFROSTER (DEF) SWITCH ............................. 27

MODE SWITCH ................................................... 27

FAN SWITCH ...................................................... 27

OFF SWITCH ...................................................... 27

FRESH (FRE) SWITCH ....................................... 27

RECIRCULATION (REC) SWITCH ..................... 27

Discharge Air Flow ................................................. 28

System Description ................................................. 29

SWITCHES AND THEIR CONTROL FUNCTION... 29

TROUBLE DIAGNOSIS ............................................ 30

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ...................................................... 30

WORK FLOW ...................................................... 30

SYMPTOM TABLE .............................................. 30

Component Parts and Harness Connector Location... 31

ENGINE COMPARTMENT .................................. 31

PASSENGER COMPARTMENT .......................... 32

Circuit Diagram ....................................................... 33

WITH GASOLINE ENGINE ................................. 33

WITH DIESEL ENGINE ....................................... 34

Wiring Diagram ....................................................... 35

WITH DASOLINE ENGINE ................................. 35

WITH DIESEL ENGINE ....................................... 38

Auto Amp. Terminals and Reference Value ............ 41

PIN CONNECTOR TERMINAL LAYOUT ............ 41

AUTO AMP. INSPECTION TABLE ...................... 41

Self-diagnosis Function .......................................... 42

DESCRIPTION .................................................... 42

PROCEDURE ...................................................... 43

AUXILIARY MECHANISM: TEMPERATURE

SETTING TRIMMER ........................................... 49

AUXILIARY MECHANISM: FOOT POSITION

SETTING TRIMMER ........................................... 50

AUXILIARY MECHANISM: INLET PORT MEM-

ORY FUNCTION (FOR LHD MODELS) .............. 51

Operational Check .................................................. 51

CHECKING MEMORY FUNCTION ..................... 51

CHECKING BLOEWER ....................................... 52

CHECKING DISCHARGE AIR ............................ 52

CHECKING RECIRCULATION ............................ 52

CHECKING TEMPERATURE DECREASE ......... 53

CHECKING TEMPERATURE INCREASE .......... 53

CHECKING AUTO MODE ................................... 53

Power Supply and Ground Circuit for Auto Amp. ... 53

INSPECTION FLOW ........................................... 54

COMPONENT DESCRIPTION ............................ 54

DIAGNOSTIC PROCEDURE .............................. 55

LAN System Circuit ................................................ 56

DIAGNOSTIC PROCEDURE .............................. 56

Mode Door Motor Circuit ........................................ 58

INSPECTION FLOW ........................................... 59

SYSTEM DESCRIPTION .................................... 60

COMPONENT DESCRIPTION ............................ 61

DIAGNOSTIC PROCEDURE .............................. 61

Air Mix Door Motor Circuit ...................................... 61

INSPECTION FLOW ........................................... 62

SYSTEM DESCRIPTION .................................... 62

COMPONENT DESCRIPTION ............................ 64DIAGNOSTIC PROCEDURE ...............................64

Intake Door Motor Circuit ........................................64

INSPECTION FLOW ............................................65

SYSTEM DESCRIPTION .....................................65

COMPONENT DESCRIPTION ............................66

DIAGNOSTIC PROCEDURE ...............................67

Blower Motor Circuit ................................................67

INSPECTION FLOW ............................................68

SYSTEM DESCRIPTION .....................................69

COMPONENT DESCRIPTION ............................70

DIAGNOSTIC PROCEDURE ...............................70

COMPONENT INSPECTION ...............................73

Magnet Clutch Circuit ..............................................73

INSPECTION FLOW ............................................74

SYSTEM DESCRIPTION .....................................74

DIAGNOSTIC PROCEDURE ...............................75

COMPONENT INSPECTION ...............................80

Insufficient Cooling ..................................................81

INSPECTION FLOW ............................................82

PERFORMANCE TEST DIAGNOSES ................83

PERFORMANCE CHART ....................................84

TROUBLE DIAGNOSES FOR ABNORMAL

PRESSURE .........................................................86

Insufficient Heating .................................................89

INSPECTION FLOW ............................................90

Noise .......................................................................91

INSPECTION FLOW ............................................91

Self-diagnosis .........................................................92

INSPECTION FLOW ............................................92

Memory Function ....................................................92

INSPECTION FLOW ............................................93

Ambient Sensor Circuit ...........................................93

COMPONENT DESCRIPTION ............................93

AMBIENT TEMPERATURE INPUT PROCESS...93

DIAGNOSTIC PROCEDURE ...............................94

COMPONENT INSPECTION ...............................95

In-vehicle Sensor Circuit .........................................95

COMPONENT DESCRIPTION ............................95

DIAGNOSTIC PROCEDURE ...............................96

COMPONENT INSPECTION ...............................97

Sunload Sensor Circuit ...........................................98

COMPONENT DESCRIPTION ............................98

SUNLOAD INPUT PROCESS .............................98

DIAGNOSTIC PROCEDURE ...............................98

COMPONENT INSPECTION ............................. 100

Intake Sensor Circuit ............................................. 101

COMPONENT DESCRIPTION .......................... 101

DIAGNOSTIC PROCEDURE ............................. 101

CONTROLLER ........................................................ 104

Removal and Installation ....................................... 104

Disassembly and Assembly .................................. 104

AMBIENT SENSOR ................................................ 105

Removal and Installation ....................................... 105

IN-VEHICLE SENSOR ............................................ 106

Removal and Installation ....................................... 106

SUNLOAD SENSOR ............................................... 107

Removal and Installation ....................................... 107

Page 621 of 3066

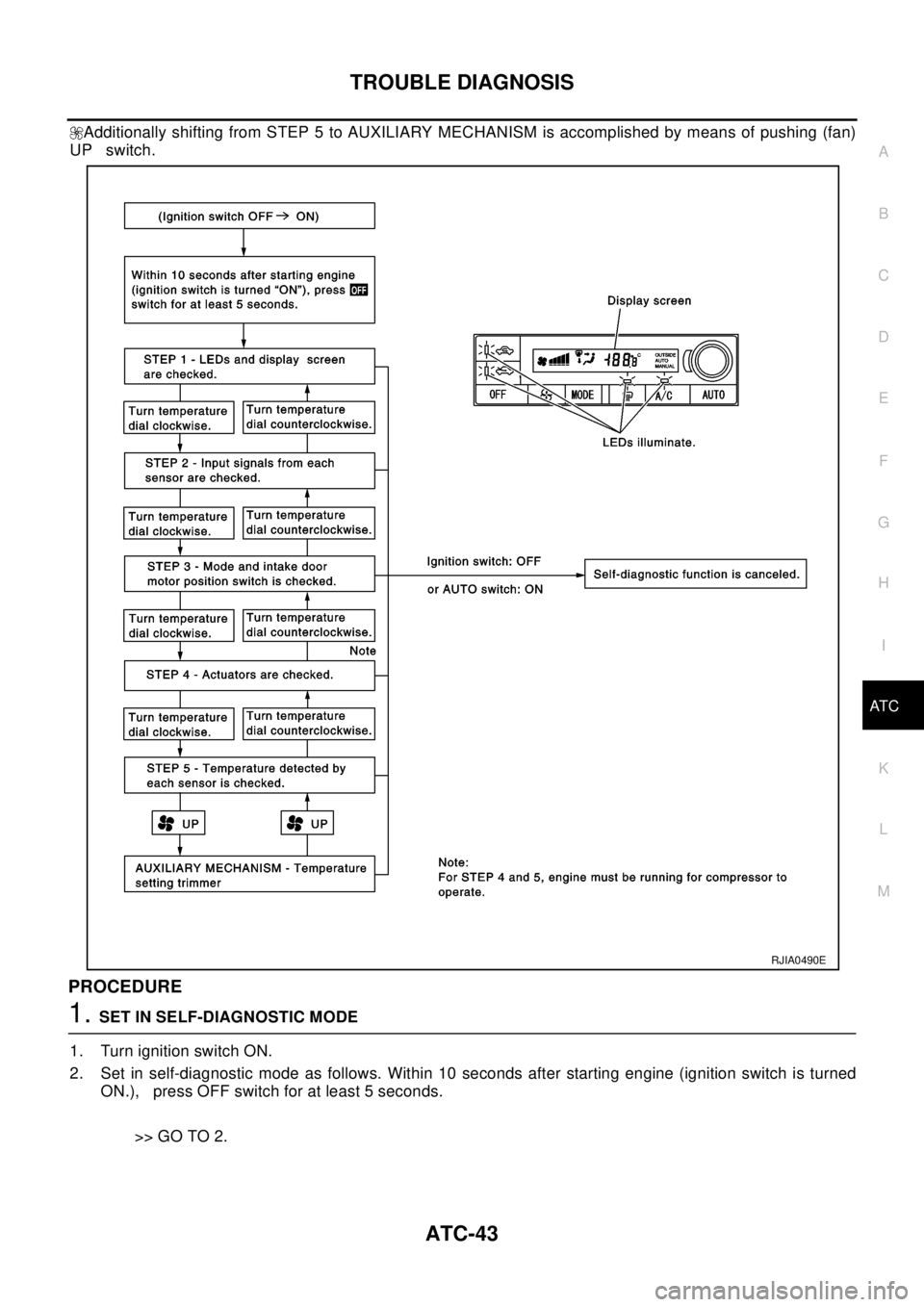

TROUBLE DIAGNOSIS

ATC-43

C

D

E

F

G

H

I

K

L

MA

B

AT C

Additionally shifting from STEP 5 to AUXILIARY MECHANISM is accomplished by means of pushing (fan)

UP switch.

PROCEDURE

1.SET IN SELF-DIAGNOSTIC MODE

1. Turn ignition switch ON.

2. Set in self-diagnostic mode as follows. Within 10 seconds after starting engine (ignition switch is turned

ON.), press OFF switch for at least 5 seconds.

>> GO TO 2.

RJIA0490E

Page 627 of 3066

TROUBLE DIAGNOSIS

ATC-49

C

D

E

F

G

H

I

K

L

MA

B

AT C

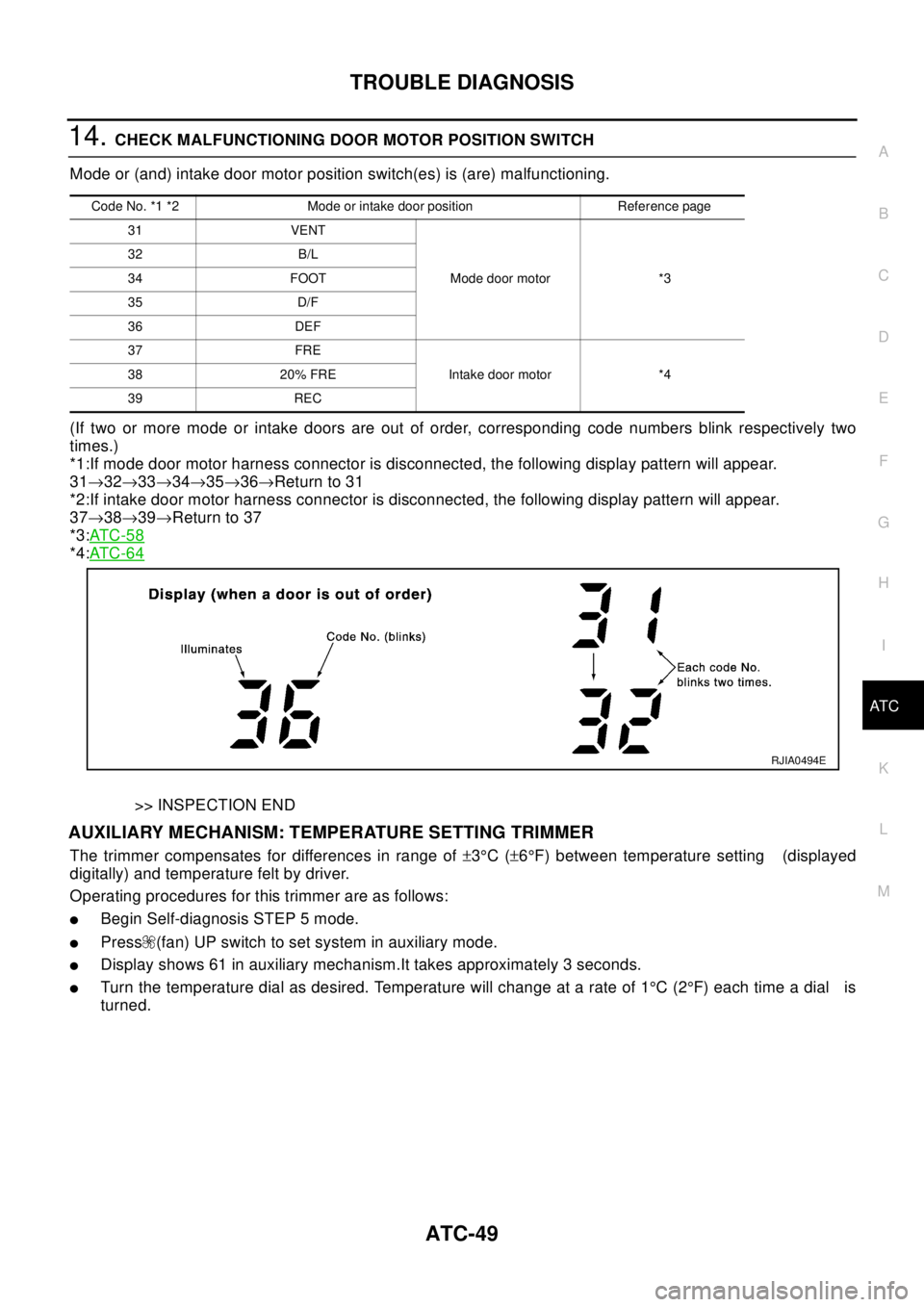

14.CHECK MALFUNCTIONING DOOR MOTOR POSITION SWITCH

Mode or (and) intake door motor position switch(es) is (are) malfunctioning.

(If two or more mode or intake doors are out of order, corresponding code numbers blink respectively two

times.)

*1:If mode door motor harness connector is disconnected, the following display pattern will appear.

31®32®33®34®35®36®Return to 31

*2:If intake door motor harness connector is disconnected, the following display pattern will appear.

37®38®39®Return to 37

*3:AT C - 5 8

*4:AT C - 6 4

>> INSPECTION END

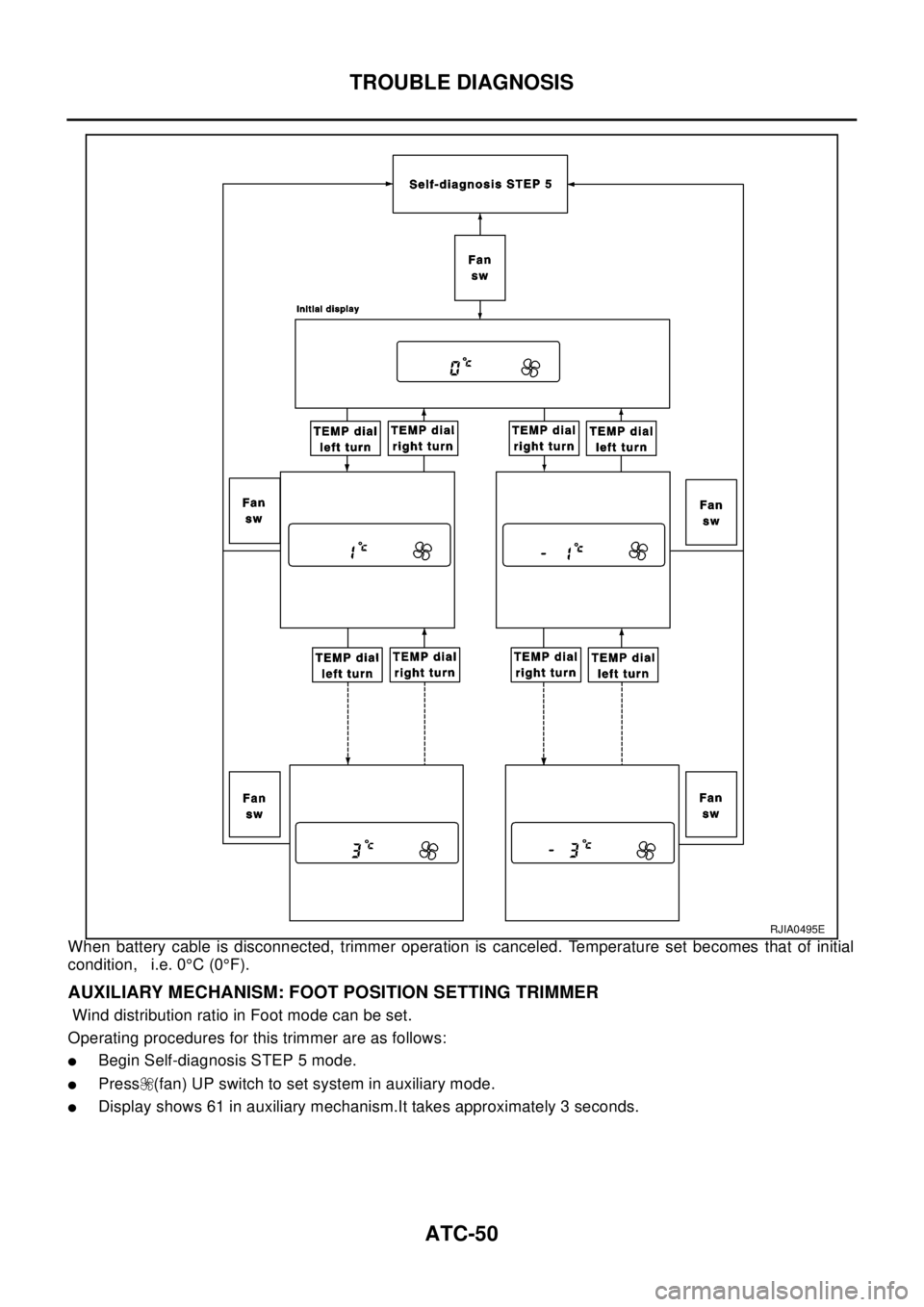

AUXILIARY MECHANISM: TEMPERATURE SETTING TRIMMER

The trimmer compensates for differences in range of±3°C(±6°F) between temperature setting (displayed

digitally) and temperature felt by driver.

Operating procedures for this trimmer are as follows:

lBegin Self-diagnosis STEP 5 mode.

lPress (fan) UP switch to set system in auxiliary mode.

lDisplay shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

lTurn the temperature dial as desired. Temperature will change at a rate of 1°C(2°F)eachtimeadial is

turned.

Code No. *1 *2 Mode or intake door position Reference page

31 VENT

Mode door motor *3 32 B/L

34 FOOT

35 D/F

36 DEF

37 FRE

Intake door motor *4 38 20% FRE

39 REC

RJIA0494E

Page 628 of 3066

ATC-50

TROUBLE DIAGNOSIS

When battery cable is disconnected, trimmer operation is canceled. Temperature set becomes that of initial

condition, i.e. 0°C(0°F).

AUXILIARY MECHANISM: FOOT POSITION SETTING TRIMMER

Wind distribution ratio in Foot mode can be set.

Operating procedures for this trimmer are as follows:

lBegin Self-diagnosis STEP 5 mode.

lPress (fan) UP switch to set system in auxiliary mode.

lDisplay shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

RJIA0495E

Page 629 of 3066

TROUBLE DIAGNOSIS

ATC-51

C

D

E

F

G

H

I

K

L

MA

B

AT C

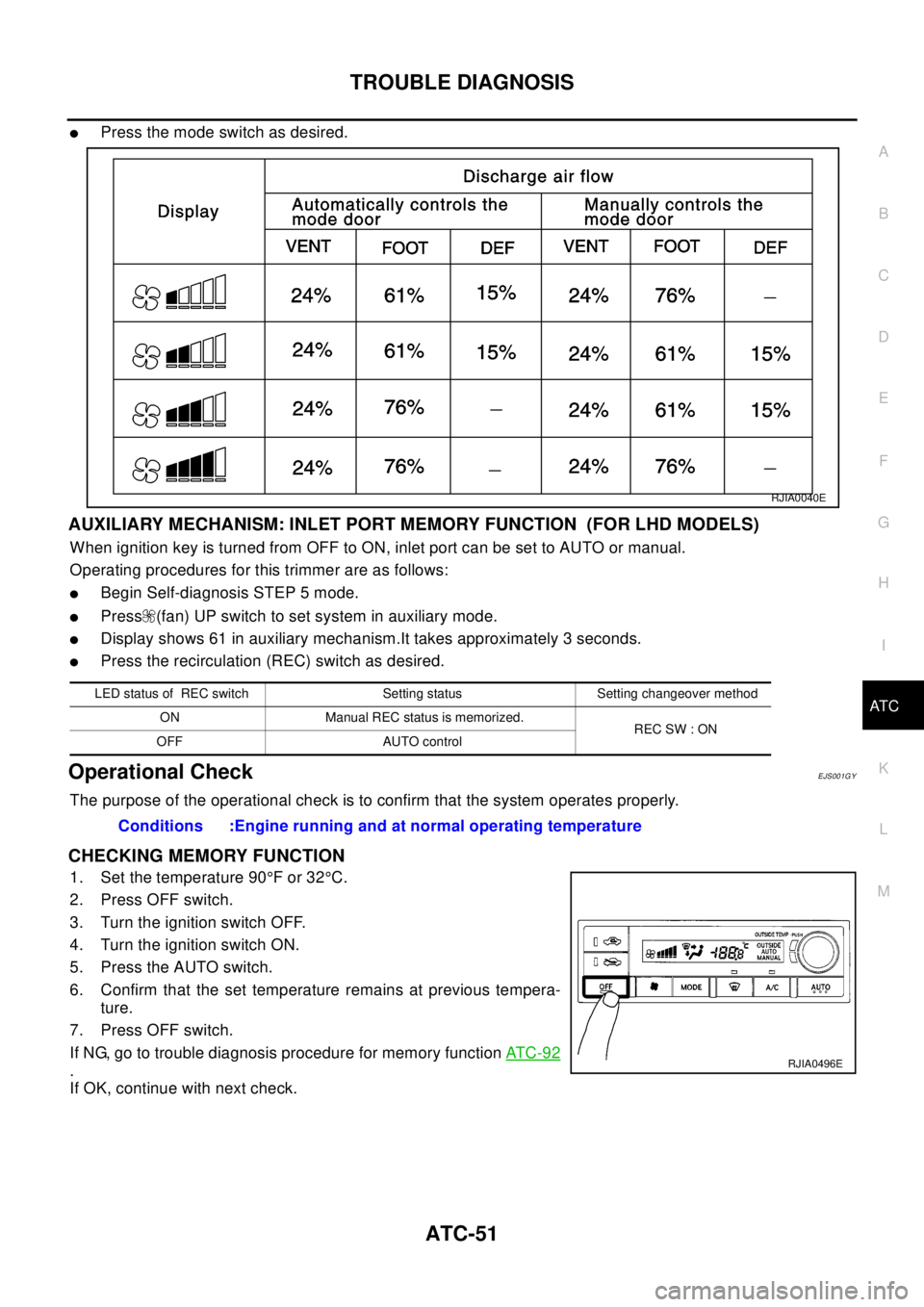

lPress the mode switch as desired.

AUXILIARY MECHANISM: INLET PORT MEMORY FUNCTION (FOR LHD MODELS)

When ignition key is turned from OFF to ON, inlet port can be set to AUTO or manual.

Operating procedures for this trimmer are as follows:

lBegin Self-diagnosis STEP 5 mode.

lPress (fan) UP switch to set system in auxiliary mode.

lDisplay shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

lPress the recirculation (REC) switch as desired.

Operational CheckEJS001GY

The purpose of the operational check is to confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Set the temperature 90°For32°C.

2. Press OFF switch.

3. Turn the ignition switch OFF.

4. Turn the ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous tempera-

ture.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for memory functionAT C - 9 2

.

If OK, continue with next check.

RJIA0040E

LED status of REC switch Setting status Setting changeover method

ON Manual REC status is memorized.

REC SW : ON

OFF AUTO control

Conditions :Engine running and at normal operating temperature

RJIA0496E

Page 660 of 3066

ATC-82

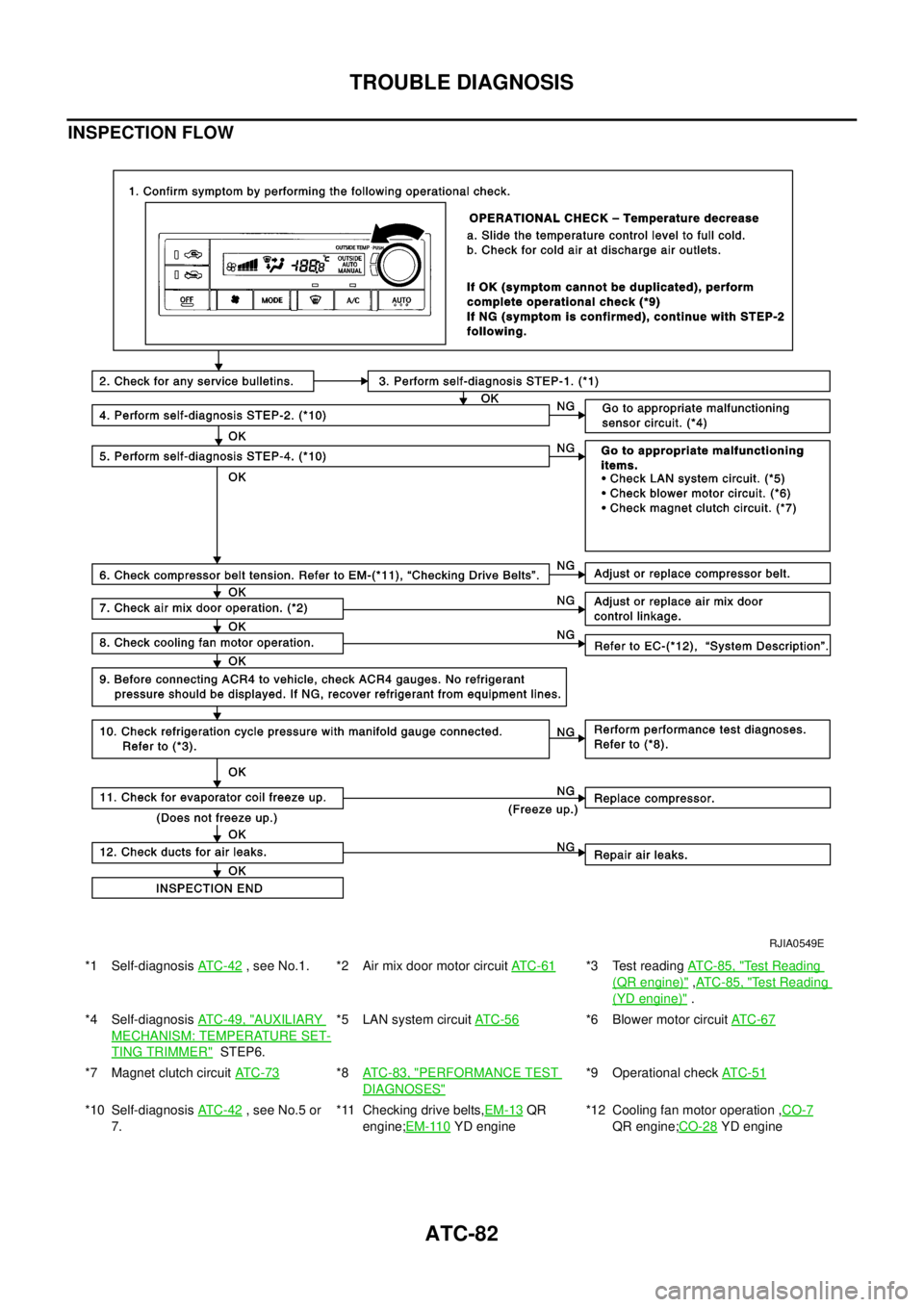

TROUBLE DIAGNOSIS

INSPECTION FLOW

*1 Self-diagnosisAT C - 4 2, see No.1. *2 Air mix door motor circuitAT C - 6 1*3 Test readingAT C - 8 5 , "Te s t R e a d i n g

(QR engine)",AT C - 8 5 , "Test Reading

(YD engine)".

*4 Self-diagnosisAT C - 4 9 , "

AUXILIARY

MECHANISM: TEMPERATURE SET-

TING TRIMMER"STEP6.*5 LAN system circuitAT C -5 6

*6 Blower motor circuitAT C -6 7

*7 Magnet clutch circuitAT C - 7 3*8AT C - 8 3 , "PERFORMANCE TEST

DIAGNOSES"

*9 Operational checkAT C - 5 1

*10 Self-diagnosisAT C - 4 2, see No.5 or

7.*11 Checking drive belts,EM-13QR

engine;EM-110

YD engine*12 Cooling fan motor operation ,CO-7QR engine;CO-28YD engine

RJIA0549E

Page 734 of 3066

AV-12

AUDIO

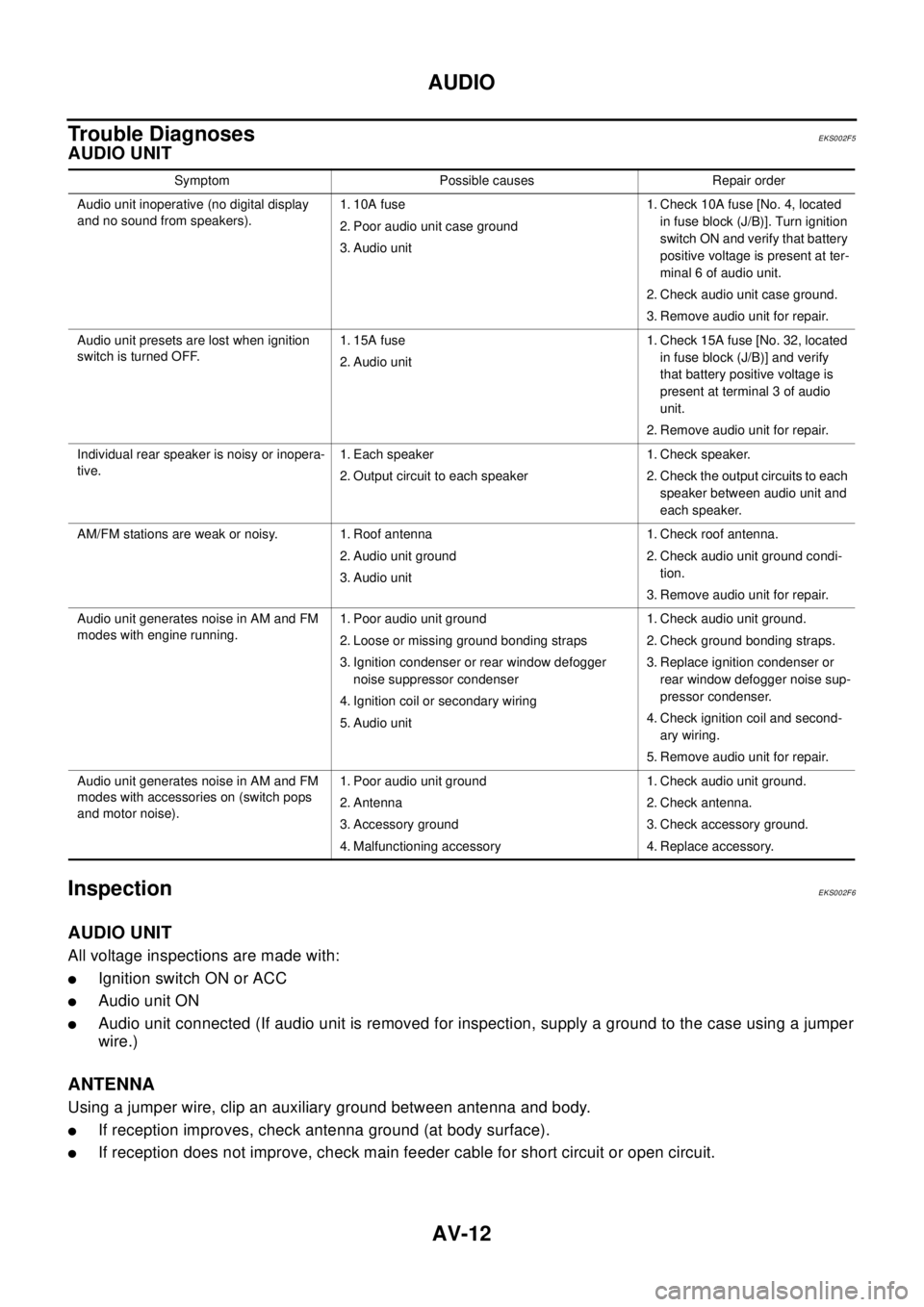

Trouble Diagnoses

EKS002F5

AUDIO UNIT

InspectionEKS002F6

AUDIO UNIT

All voltage inspections are made with:

lIgnition switch ON or ACC

lAudio unit ON

lAudio unit connected (If audio unit is removed for inspection, supply a ground to the case using a jumper

wire.)

ANTENNA

Using a jumper wire, clip an auxiliary ground between antenna and body.

lIf reception improves, check antenna ground (at body surface).

lIf reception does not improve, check main feeder cable for short circuit or open circuit.

Symptom Possible causes Repair order

Audio unit inoperative (no digital display

and no sound from speakers).1. 10A fuse

2. Poor audio unit case ground

3. Audio unit1. Check 10A fuse [No. 4, located

in fuse block (J/B)]. Turn ignition

switch ON and verify that battery

positive voltage is present at ter-

minal 6 of audio unit.

2. Check audio unit case ground.

3. Remove audio unit for repair.

Audio unit presets are lost when ignition

switch is turned OFF.1. 15A fuse

2. Audio unit1. Check 15A fuse [No. 32, located

in fuse block (J/B)] and verify

that battery positive voltage is

present at terminal 3 of audio

unit.

2. Remove audio unit for repair.

Individual rear speaker is noisy or inopera-

tive.1. Each speaker

2. Output circuit to each speaker1. Check speaker.

2. Check the output circuits to each

speaker between audio unit and

each speaker.

AM/FM stations are weak or noisy. 1. Roof antenna

2. Audio unit ground

3. Audio unit1. Check roof antenna.

2. Check audio unit ground condi-

tion.

3. Remove audio unit for repair.

Audio unit generates noise in AM and FM

modes with engine running.1. Poor audio unit ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Ignition coil or secondary wiring

5. Audio unit1. Check audio unit ground.

2. Check ground bonding straps.

3. Replace ignition condenser or

rear window defogger noise sup-

pressor condenser.

4. Check ignition coil and second-

ary wiring.

5. Remove audio unit for repair.

Audio unit generates noise in AM and FM

modes with accessories on (switch pops

and motor noise).1. Poor audio unit ground

2. Antenna

3. Accessory ground

4. Malfunctioning accessory1. Check audio unit ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.