instrument panel NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

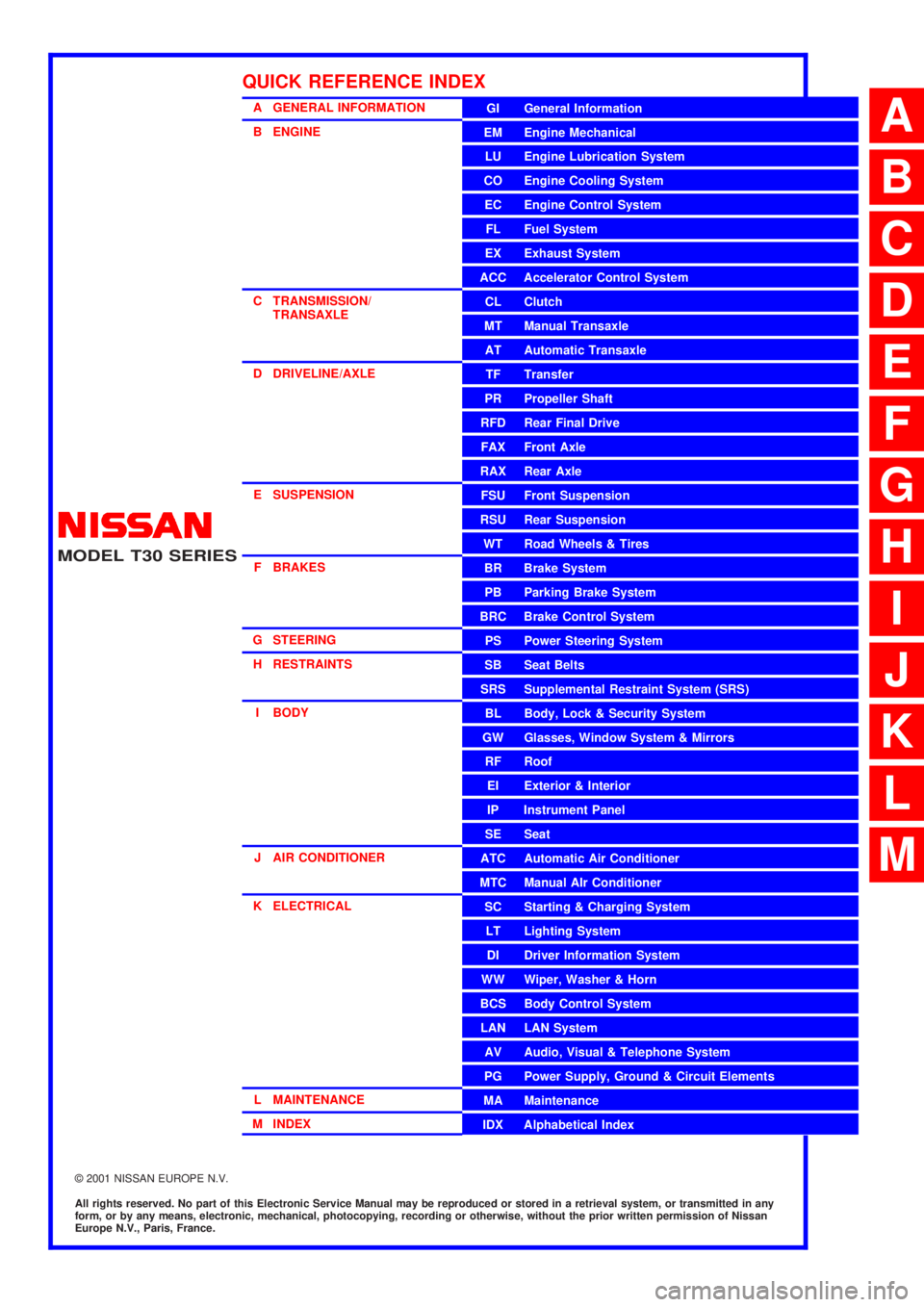

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 43 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-37

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONPFP:00000

IntroductionECS004QH

The A/T system has two self-diagnostic systems.

T NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-37

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONPFP:00000

IntroductionECS004QH

The A/T system has two self-diagnostic systems.

T](/img/5/57402/w960_57402-42.png)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-37

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONPFP:00000

IntroductionECS004QH

The A/T system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (EURO-OBD) performed by the TCM in combina-

tion with the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC

in the ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the O/D OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are overlapped with EURO-OBD self-diagnostic items. For

detail, refer toAT - 4 2 , "

SELF-DIAGNOSTIC RESULT TEST MODE".

EURO-OBD Function for A/T SystemECS004QI

The ECM provides emission-related on board diagnostic (EURO-OBD) functions for the A/T system. One

function is to receive a signal from the TCM used with EURO-OBD-related parts of the A/T system. The signal

is sent to the ECM when a malfunction occurs in the corresponding EURO-OBD-related part. The other func-

tion is to indicate a diagnostic result by means of the MIL (malfunction indicator lamp) on the instrument panel.

Sensors, switches and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of EURO-OBDECS0 04 QJ

ONETRIPDETECTIONLOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — First Trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MIL will illuminate. — Second Trip

A/T-related parts for which the MIL illuminates during the first or second test drive are listed below.

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

EURO-OBD Diagnostic Trouble Code (DTC)ECS004QK

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

(withCONSULT-IIor GST)CONSULT-II or GST (Generic Scan Tool) Examples: P0705, P0710,

P0720, P0725, etc.

These DTCs are prescribed by SAE J2012.

(CONSULT-II also displays the malfunctioning component or system.)

l1st trip DTC No. is the same as DTC No.

lOutput of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST they do not indicate whether the malfunction is still occurring

or occurred in the past and returned to normal.

CONSULT-II can identify them as shown below. Therefore, using CONSULT-II (if available) is rec-

ommended.

ItemsMIL

One trip detection Two trip detection

Shift solenoid valve A — DTC: P0750 X

Shift solenoid valve B — DTC: P0755 X

Throttle position sensor — DTC: P1705 X

Except aboveX

Page 673 of 3066

TROUBLE DIAGNOSIS

ATC-95

C

D

E

F

G

H

I

K

L

MA

B

AT C

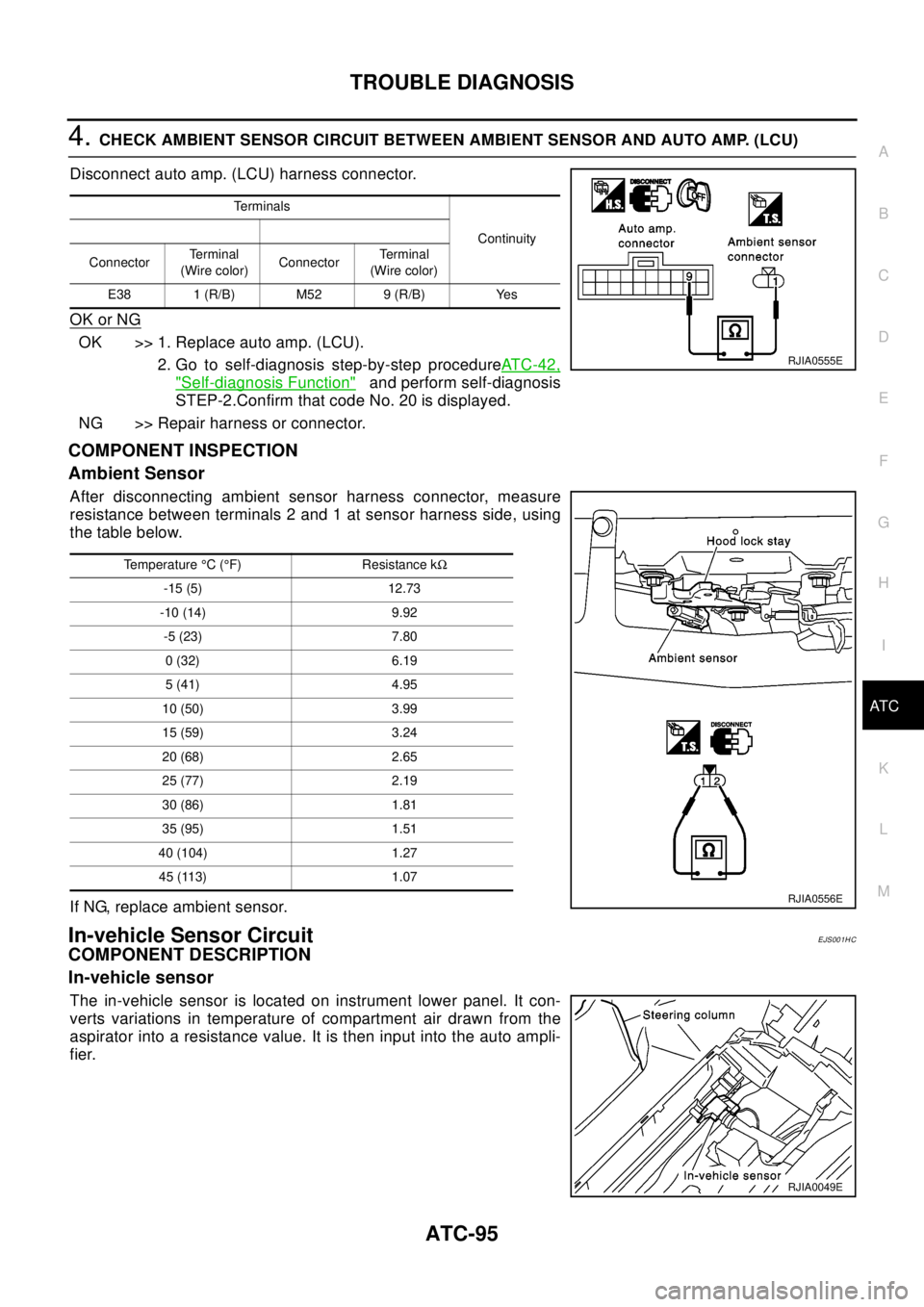

4.CHECK AMBIENT SENSOR CIRCUIT BETWEEN AMBIENT SENSOR AND AUTO AMP. (LCU)

Disconnect auto amp. (LCU) harness connector.

OK or NG

OK >> 1. Replace auto amp. (LCU).

2. Go to self-diagnosis step-by-step procedureAT C - 4 2 ,

"Self-diagnosis Function"and perform self-diagnosis

STEP-2.Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

Ambient Sensor

After disconnecting ambient sensor harness connector, measure

resistance between terminals 2 and 1 at sensor harness side, using

the table below.

If NG, replace ambient sensor.

In-vehicle Sensor CircuitEJS001HC

COMPONENT DESCRIPTION

In-vehicle sensor

The in-vehicle sensor is located on instrument lower panel. It con-

verts variations in temperature of compartment air drawn from the

aspirator into a resistance value. It is then input into the auto ampli-

fier.

Te r m i n a l s

Continuity

ConnectorTe r m i n a l

(Wire color)ConnectorTerminal

(Wire color)

E38 1 (R/B) M52 9 (R/B) Yes

RJIA0555E

Temperature°C(°F) Resistance kW

-15 (5) 12.73

-10 (14) 9.92

-5 (23) 7.80

0(32) 6.19

5(41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27

45 (113) 1.07

RJIA0556E

RJIA0049E

Page 687 of 3066

BLOWER UNIT

ATC-109

C

D

E

F

G

H

I

K

L

MA

B

AT C

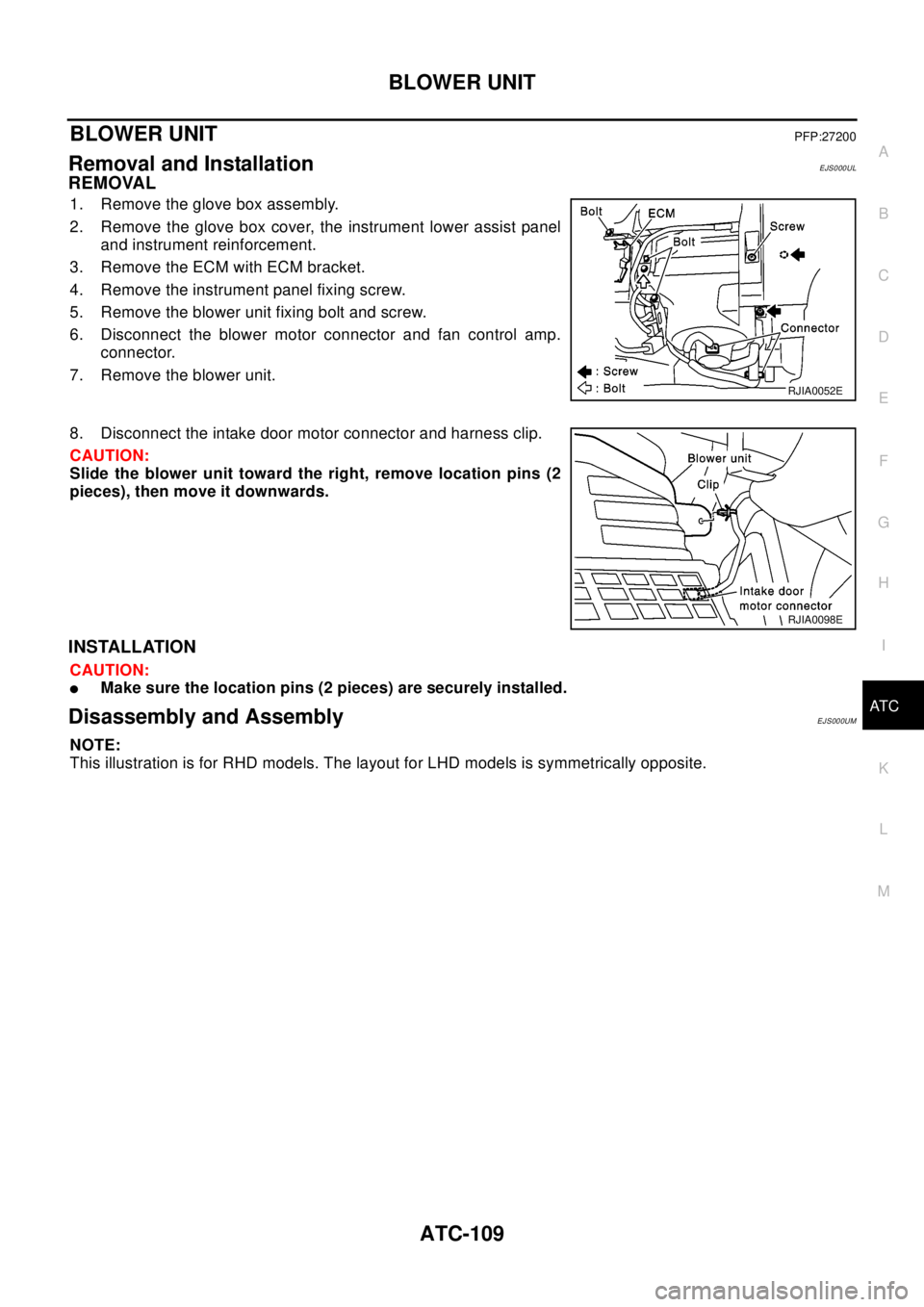

BLOWER UNITPFP:27200

Removal and InstallationEJS000UL

REMOVAL

1. Remove the glove box assembly.

2. Remove the glove box cover, the instrument lower assist panel

and instrument reinforcement.

3. Remove the ECM with ECM bracket.

4. Remove the instrument panel fixing screw.

5. Remove the blower unit fixing bolt and screw.

6. Disconnect the blower motor connector and fan control amp.

connector.

7. Remove the blower unit.

8. Disconnect the intake door motor connector and harness clip.

CAUTION:

Slide the blower unit toward the right, remove location pins (2

pieces), then move it downwards.

INSTALLATION

CAUTION:

lMake sure the location pins (2 pieces) are securely installed.

Disassembly and AssemblyEJS000UM

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

RJIA0052E

RJIA0098E

Page 693 of 3066

HEATER & COOLING UNIT ASSEMBLY

ATC-115

C

D

E

F

G

H

I

K

L

MA

B

AT C

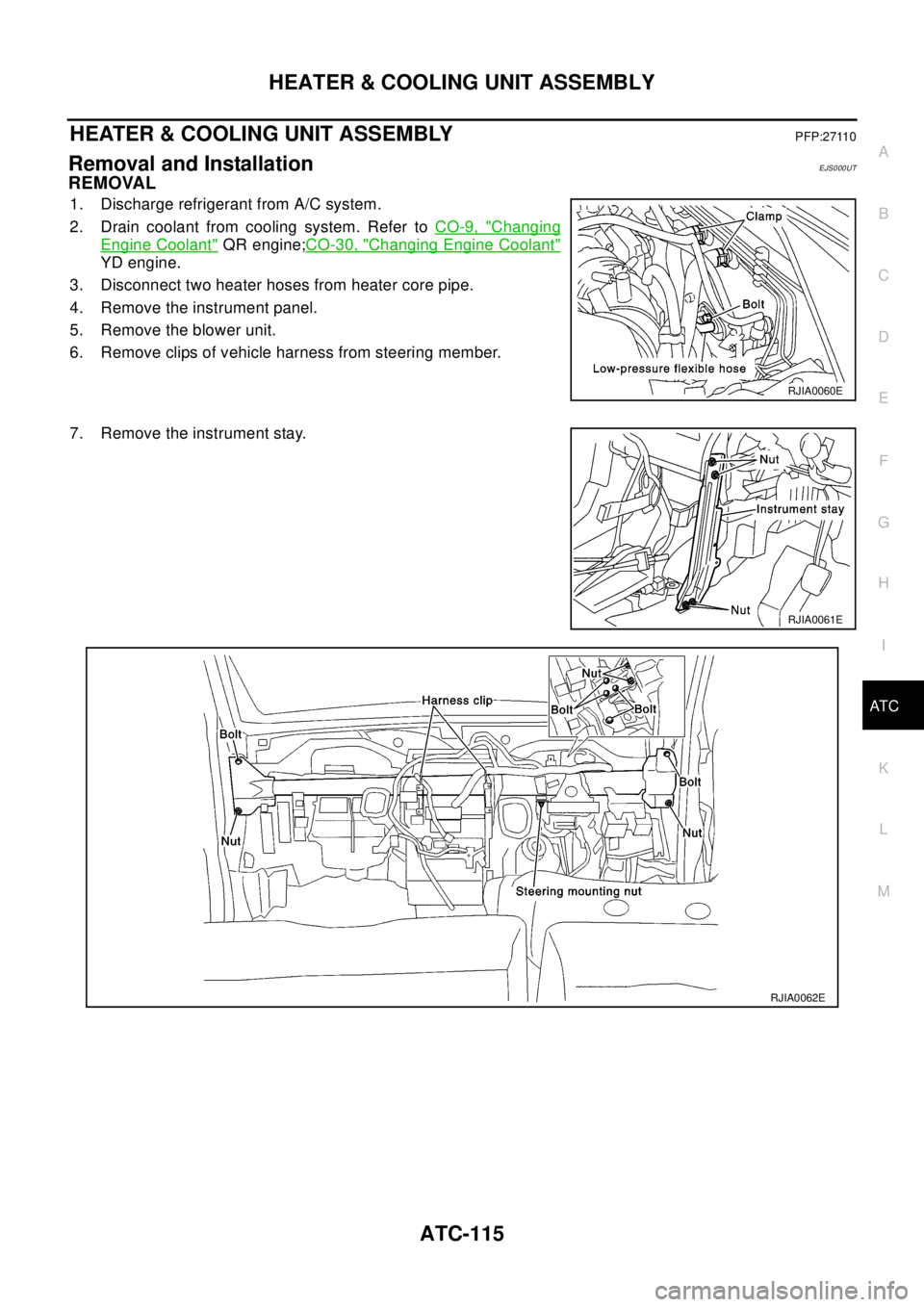

HEATER & COOLING UNIT ASSEMBLYPFP:27110

Removal and InstallationEJS000UT

REMOVAL

1. Discharge refrigerant from A/C system.

2. Drain coolant from cooling system. Refer toCO-9, "

Changing

Engine Coolant"QR engine;CO-30, "Changing Engine Coolant"

YD engine.

3. Disconnect two heater hoses from heater core pipe.

4. Remove the instrument panel.

5. Remove the blower unit.

6. Remove clips of vehicle harness from steering member.

7. Remove the instrument stay.

RJIA0060E

RJIA0061E

RJIA0062E

Page 699 of 3066

DUCTS AND GRILLES

ATC-121

C

D

E

F

G

H

I

K

L

MA

B

AT C

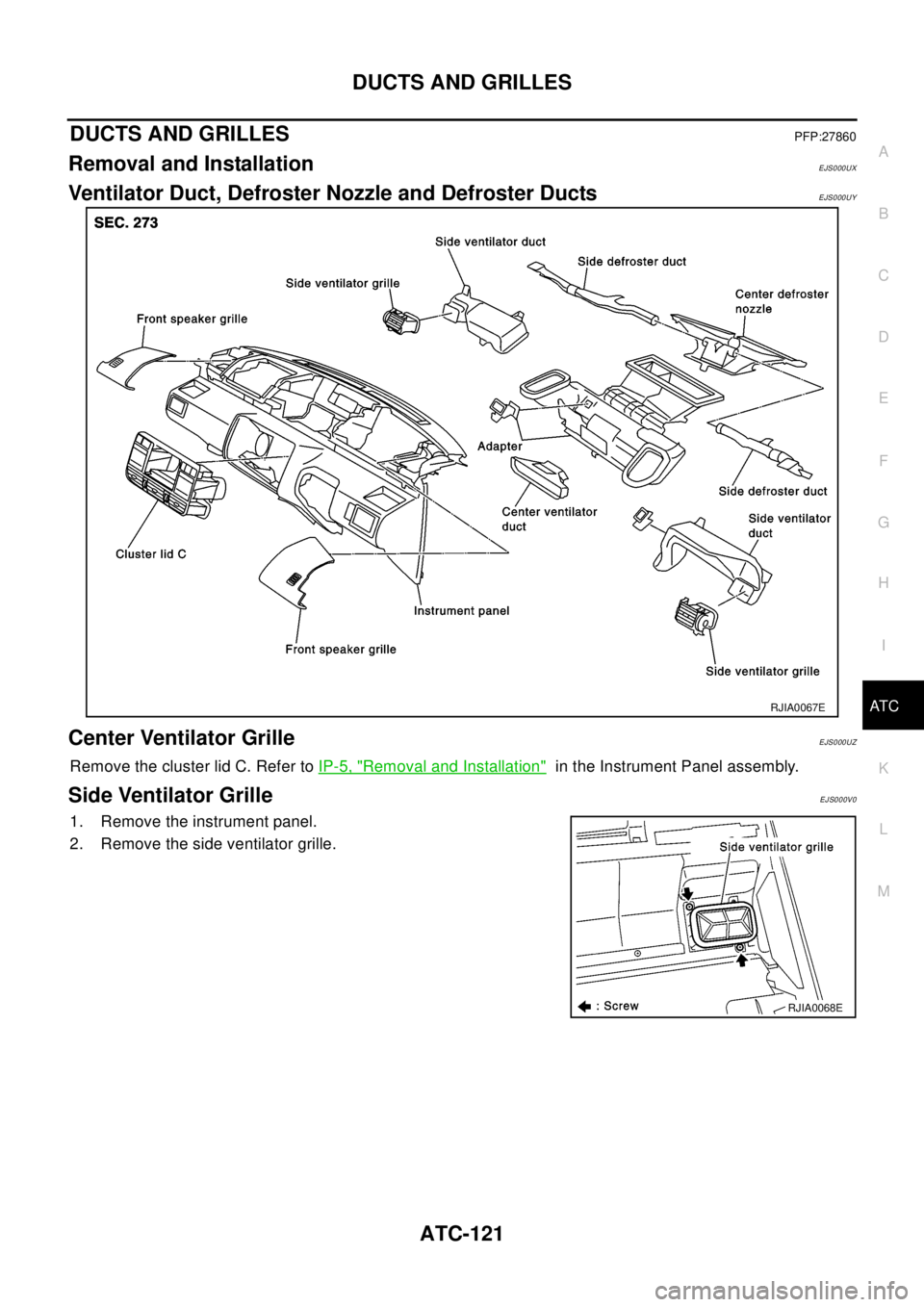

DUCTS AND GRILLESPFP:27860

Removal and InstallationEJS000UX

Ventilator Duct, Defroster Nozzle and Defroster DuctsEJS000UY

Center Ventilator GrilleEJS000UZ

Remove the cluster lid C. Refer toIP-5, "Removal and Installation"in the Instrument Panel assembly.

Side Ventilator GrilleEJS000V0

1. Remove the instrument panel.

2. Remove the side ventilator grille.

RJIA0067E

RJIA0068E

Page 700 of 3066

ATC-122

DUCTS AND GRILLES

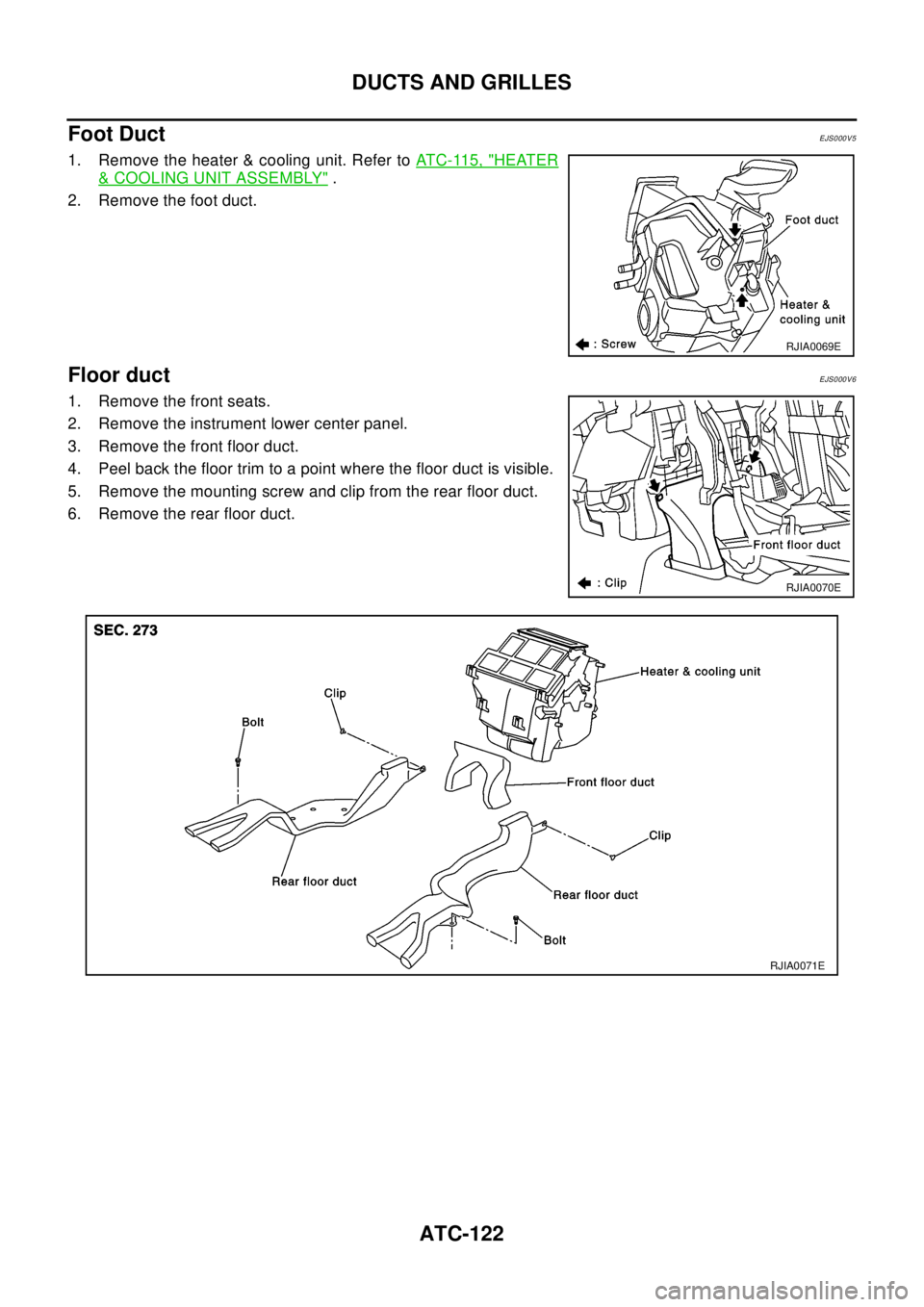

Foot Duct

EJS000V5

1. Remove the heater & cooling unit. Refer toATC-115, "HEATER

&COOLING UNIT ASSEMBLY".

2. Remove the foot duct.

Floor ductEJS000V6

1. Remove the front seats.

2. Remove the instrument lower center panel.

3. Remove the front floor duct.

4. Peel back the floor trim to a point where the floor duct is visible.

5. Remove the mounting screw and clip from the rear floor duct.

6. Remove the rear floor duct.

RJIA0069E

RJIA0070E

RJIA0071E

Page 735 of 3066

AUDIO

AV-13

C

D

E

F

G

H

I

J

L

MA

B

AV

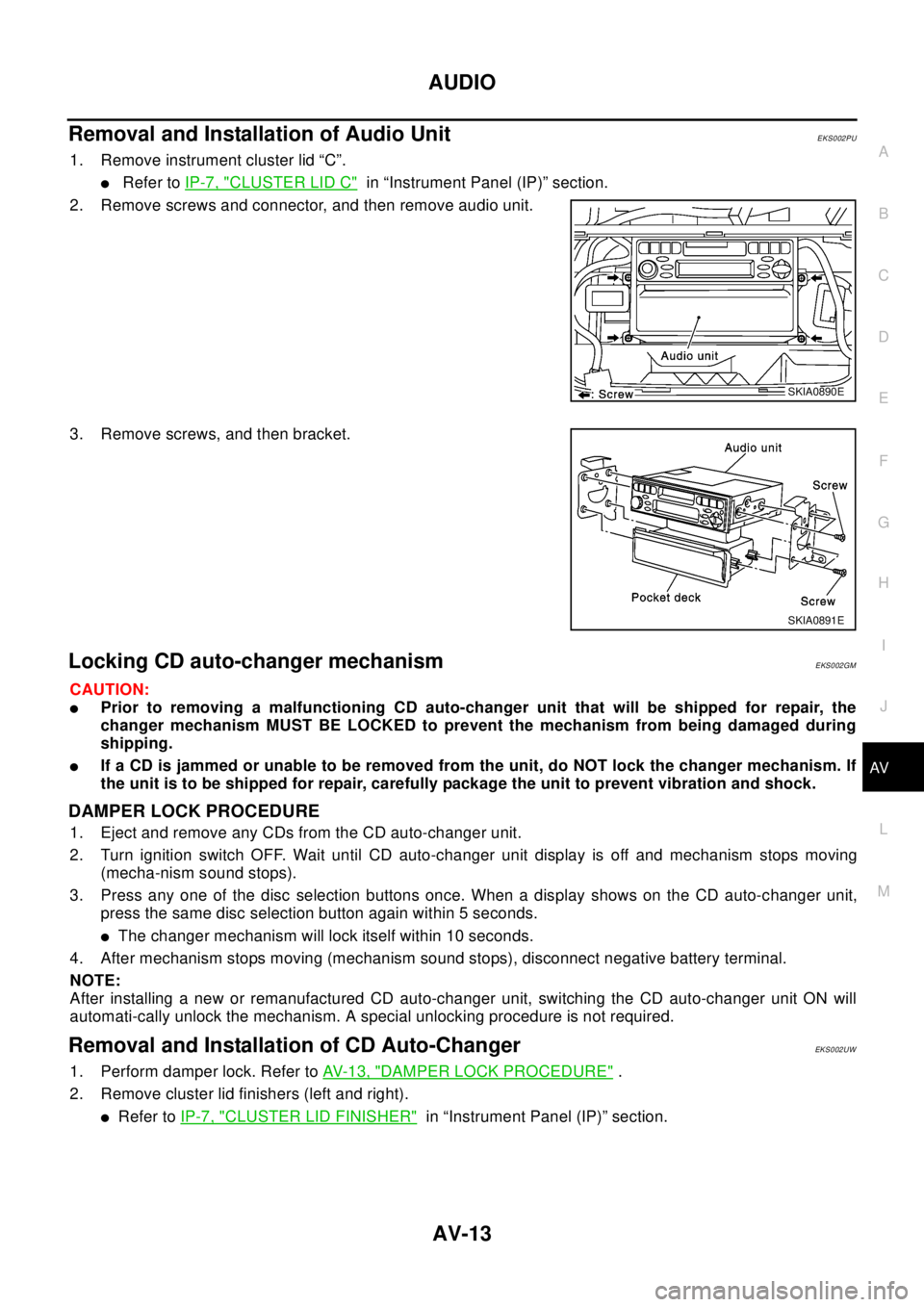

RemovalandInstallationofAudioUnitEKS002PU

1. Remove instrument cluster lid “C”.

lRefer toIP-7, "CLUSTER LID C"in “Instrument Panel (IP)” section.

2. Remove screws and connector, and then remove audio unit.

3. Remove screws, and then bracket.

Locking CD auto-changer mechanismEKS002GM

CAUTION:

lPrior to removing a malfunctioning CD auto-changer unit that will be shipped for repair, the

changer mechanism MUST BE LOCKED to prevent the mechanism from being damaged during

shipping.

lIf a CD is jammed or unable to be removed from the unit, do NOT lock the changer mechanism. If

the unit is to be shipped for repair, carefully package the unit to prevent vibration and shock.

DAMPER LOCK PROCEDURE

1. Eject and remove any CDs from the CD auto-changer unit.

2. Turn ignition switch OFF. Wait until CD auto-changer unit display is off and mechanism stops moving

(mecha-nism sound stops).

3. Press any one of the disc selection buttons once. When a display shows on the CD auto-changer unit,

press the same disc selection button again within 5 seconds.

lThe changer mechanism will lock itself within 10 seconds.

4. After mechanism stops moving (mechanism sound stops), disconnect negative battery terminal.

NOTE:

After installing a new or remanufactured CD auto-changer unit, switching the CD auto-changer unit ON will

automati-cally unlock the mechanism. A special unlocking procedure is not required.

Removal and Installation of CD Auto-ChangerEKS002UW

1. Perform damper lock. Refer toAV- 1 3 , "DAMPER LOCK PROCEDURE".

2. Remove cluster lid finishers (left and right).

lRefer toIP-7, "CLUSTER LID FINISHER"in “Instrument Panel (IP)” section.

SKIA0890E

SKIA0891E

Page 841 of 3066

BRAKE PEDAL

BR-7

C

D

E

G

H

I

J

K

L

MA

B

BR

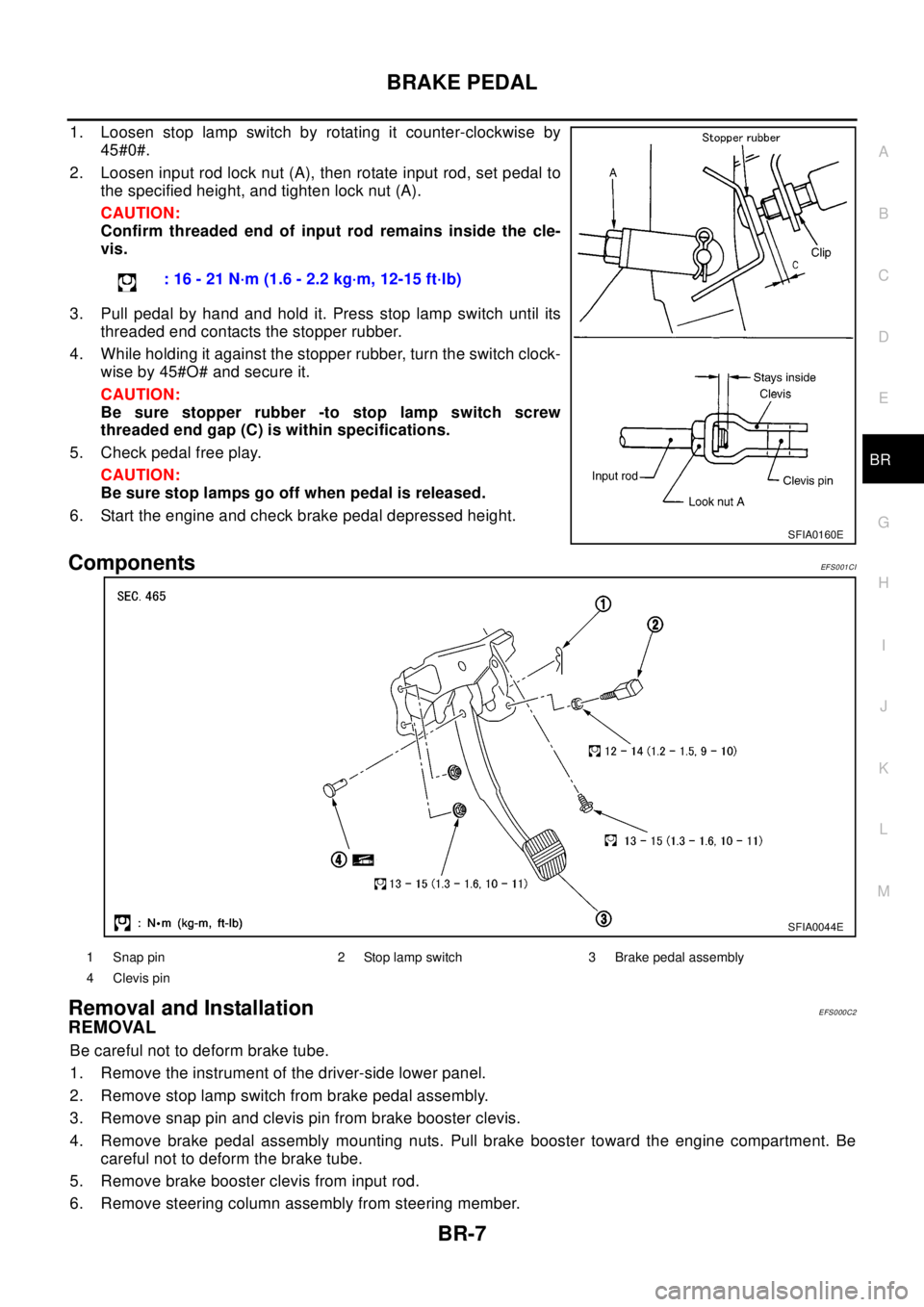

1. Loosen stop lamp switch by rotating it counter-clockwise by

45#0#.

2. Loosen input rod lock nut (A), then rotate input rod, set pedal to

the specified height, and tighten lock nut (A).

CAUTION:

Confirm threaded end of input rod remains inside the cle-

vis.

3. Pull pedal by hand and hold it. Press stop lamp switch until its

threaded end contacts the stopper rubber.

4. While holding it against the stopper rubber, turn the switch clock-

wise by 45#O# and secure it.

CAUTION:

Be sure stopper rubber -to stop lamp switch screw

threaded end gap (C) is within specifications.

5. Check pedal free play.

CAUTION:

Be sure stop lamps go off when pedal is released.

6. Start the engine and check brake pedal depressed height.

ComponentsEF S0 01 CI

Removal and InstallationEFS000C2

REMOVAL

Be careful not to deform brake tube.

1. Remove the instrument of the driver-side lower panel.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from brake booster clevis.

4. Remove brake pedal assembly mounting nuts. Pull brake booster toward the engine compartment. Be

careful not to deform the brake tube.

5. Remove brake booster clevis from input rod.

6. Remove steering column assembly from steering member.: 16 - 21 N·m (1.6 - 2.2 kg·m, 12-15 ft·lb)

SFIA0160E

SFIA0044E

1 Snap pin 2 Stop lamp switch 3 Brake pedal assembly

4 Clevis pin

Page 917 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual G-SENSOR (4WD MODEL ONLY)

BRC-49

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

G-SENSOR (4WD MODEL ONLY)PFP:47930

Removal and InstallationEFS001C2

CAUTION:

Be careful not to drop or bump G -sensor because it i NISSAN X-TRAIL 2003 Electronic Repair Manual G-SENSOR (4WD MODEL ONLY)

BRC-49

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

G-SENSOR (4WD MODEL ONLY)PFP:47930

Removal and InstallationEFS001C2

CAUTION:

Be careful not to drop or bump G -sensor because it i](/img/5/57402/w960_57402-916.png)

G-SENSOR (4WD MODEL ONLY)

BRC-49

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

G-SENSOR (4WD MODEL ONLY)PFP:47930

Removal and InstallationEFS001C2

CAUTION:

Be careful not to drop or bump G -sensor because it is sensitive to impact.

1. Remove center console and instrument. Refer to applicable sec-

tion inIP-3, "

INSTRUMENT PANEL ASSEMBLY".

2. Disconnect G -sensor connector.

3. Remove mounting nuts and remove G -sensor.

Install in the reverse order of removal observing the precautions

above.

SFIA0065E