oil capacity NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 593 of 3066

PREPARATION

ATC-15

C

D

E

F

G

H

I

K

L

MA

B

AT C

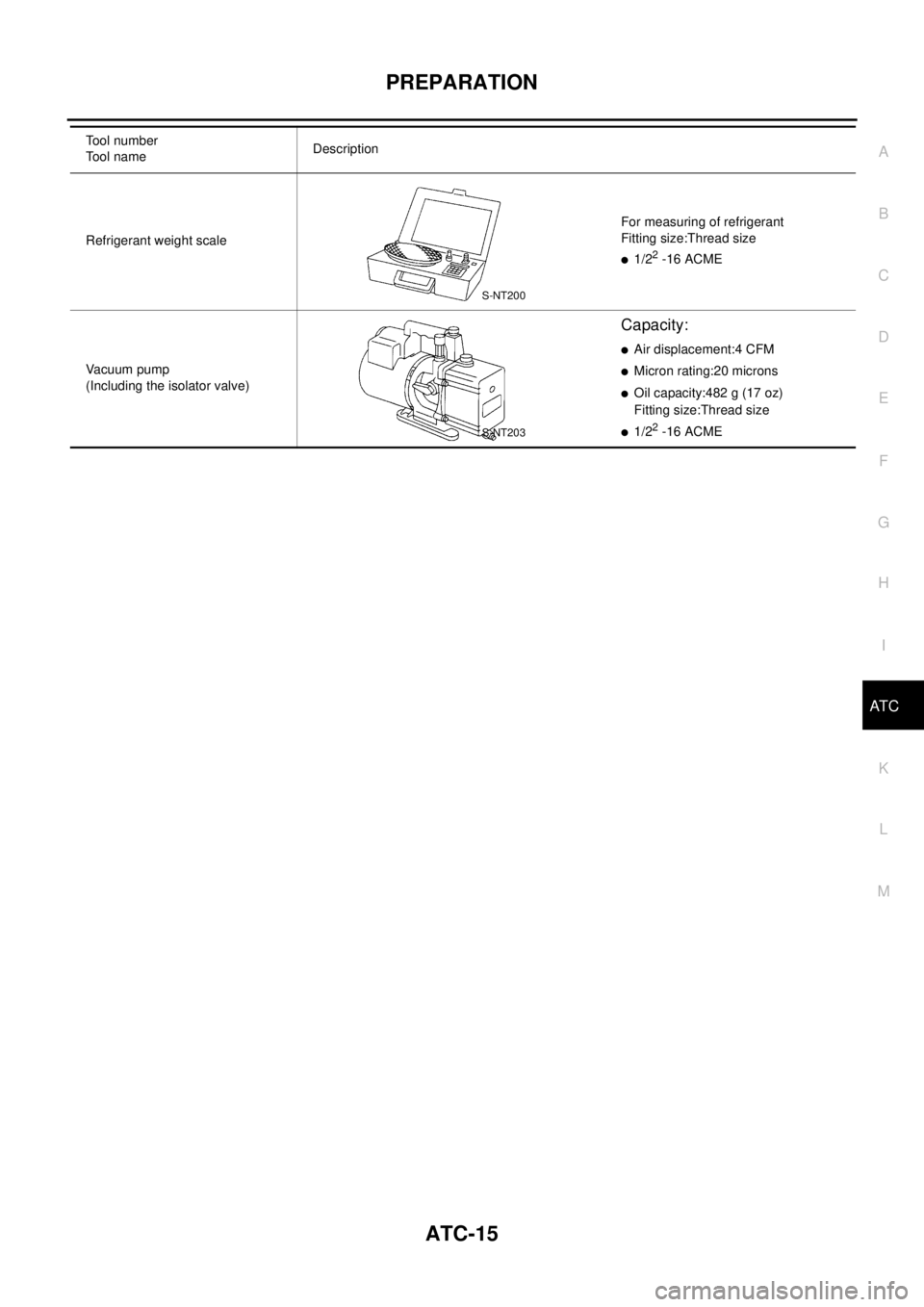

Refrigerant weight scaleFor measuring of refrigerant

Fitting size:Thread size

l1/22-16 ACME

Vacuum pump

(Including the isolator valve)

Capacity:

lAir displacement:4 CFM

lMicron rating:20 microns

lOilcapacity:482g(17oz)

Fitting size:Thread size

l1/22-16 ACME Tool number

To o l n a m eDescription

S-NT200

S-NT203

Page 722 of 3066

ATC-144

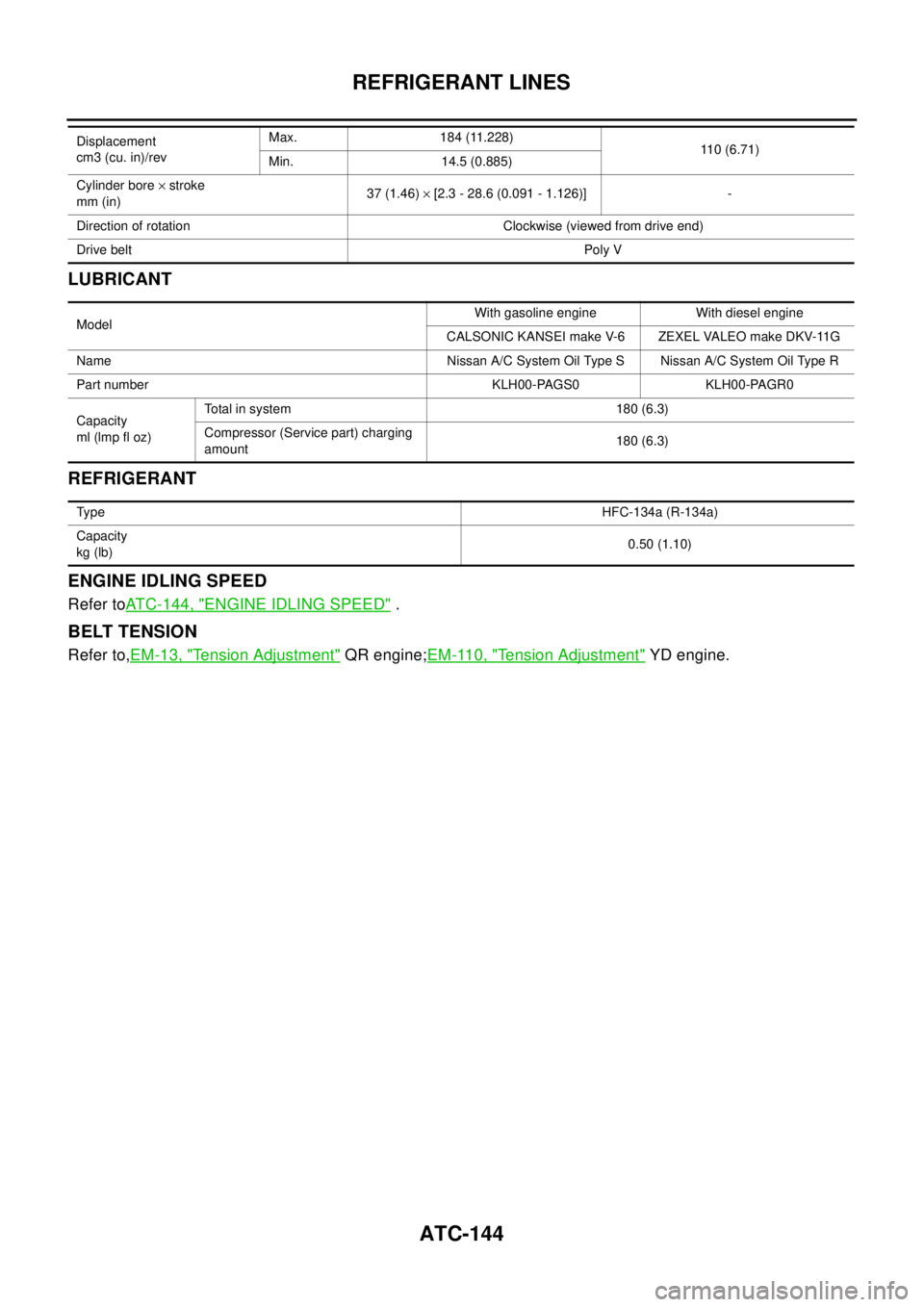

REFRIGERANT LINES

LUBRICANT

REFRIGERANT

ENGINE IDLING SPEED

Refer toATC-144, "ENGINE IDLING SPEED".

BELT TENSION

Refer to,EM-13, "Tension Adjustment"QR engine;EM-110, "Tension Adjustment"YD engine.

Displacement

cm3 (cu. in)/revMax. 184 (11.228)

110 (6.71)

Min. 14.5 (0.885)

Cylinder bore´stroke

mm (in)37 (1.46)´[2.3 - 28.6 (0.091 - 1.126)] -

Direction of rotation Clockwise (viewed from drive end)

Drive beltPoly V

ModelWith gasoline engine With diesel engine

CALSONIC KANSEI make V-6 ZEXEL VALEO make DKV-11G

Name Nissan A/C System Oil Type S Nissan A/C System Oil Type R

Part number KLH00-PAGS0 KLH00-PAGR0

Capacity

ml (lmp fl oz)Total in system 180 (6.3)

Compressor (Service part) charging

amount180 (6.3)

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.50 (1.10)

Page 2467 of 3066

LU-1

ENGINE LUBRICATION SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

LU

ENGINE LUBRICATION SYSTEM

QR20DE

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET SEALING .......... 3

LIQUID GASKET APPLICATION PROCEDURE..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

LUBRICATION SYSTEM ............................................ 5

Lubrication Circuit .................................................... 5

System Drawing ....................................................... 6

ENGINE OIL ............................................................... 7

Inspection ................................................................. 7

OIL LEVEL AND MUDDINESS ............................. 7

OIL LEAKAGE ....................................................... 7

OIL PRESSURE CHECK ...................................... 7

Changing Engine Oil ................................................ 8

OIL FILTER ................................................................. 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

OIL PUMP ................................................................. 10

Removal and Installation ........................................ 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ............... 10

ASSEMBLY ......................................................... 12

OIL COOLER ............................................................ 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSPECTION ...................................................... 13

INSTALLATION ................................................... 13

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 14

Standard and Limit ................................................. 14

OIL PRESSURE .................................................. 14

OIL PUMP ........................................................... 14

REGULATOR VALVE .......................................... 14

OIL CAPACITY .................................................... 14

TIGHTENING TORQUE ...................................... 14

YD22DDTi

PRECAUTIONS ........................................................ 15

Precautions For Liquid Gasket ............................... 15

REMOVAL OF LIQUID GASKET SEALING ........ 15

LIQUID GASKET APPLICATION PROCEDURE... 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

LUBRICATION SYSTEM .......................................... 17

Lubrication Circuit ................................................... 17

ENGINE OIL .............................................................. 18

Inspection ............................................................... 18

OIL LEVEL AND MUDDINESS ........................... 18

OIL LEAKAGE ..................................................... 18

OIL PRESSURE CHECK .................................... 18

Changing Engine Oil ............................................... 19

OIL FILTER ............................................................... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSTALLATION ................................................... 21

OIL FILTER BRACKET ............................................. 22

Removal and Installation ........................................ 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

OIL PUMP ................................................................. 23

Removal and Installation ........................................ 23

Disassembly and Assembly .................................... 23

DISASSEMBLY ................................................... 23

INSPECTION AFTER DISASSEMBLY ................ 23

ASSEMBLY ......................................................... 24

OIL COOLER ............................................................ 25

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSPECTION ...................................................... 25

INSTALLATION ................................................... 25

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 26

Standard and Limit .................................................. 26

OIL PRESSURE .................................................. 26

OIL PUMP ........................................................... 26

REGULATOR VALVE .......................................... 26

Page 2468 of 3066

LU-2

OIL CAPACITY .................................................... 26

Tightening Torque ................................................... 26

Page 2474 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LU-8

[QR20DE]

ENGINE OIL

Changing Engine Oil

EBS009SV

WAR NIN G:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine oil may

cause skin cancer: NISSAN X-TRAIL 2003 Electronic Repair Manual LU-8

[QR20DE]

ENGINE OIL

Changing Engine Oil

EBS009SV

WAR NIN G:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine oil may

cause skin cancer:](/img/5/57402/w960_57402-2473.png)

LU-8

[QR20DE]

ENGINE OIL

Changing Engine Oil

EBS009SV

WAR NIN G:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine oil may

cause skin cancer: try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine compo-

nents.

2. Stop engine and wait for 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity:

lAPI grade SG, SH or SJ.

lILSAC grade GF-I or GF-II

lRefer toMA-17, "RECOMMENDED FLUIDS AND LUBRICANTS".

Oil capacity (Approximate):

CAUTION:

lBe sure to clean drain plug and install with new washer.

lThe refill capacity depends on the oil temperature and drain time. Use these specifications for ref-

erence only.

Always use the dipstick to the determine when the proper amount of oil is in the engine.

5. Warm up engine and check area around drain plug and oil filter for oil leakage.

6. Stop engine and wait for 10 minutes.

7. Check oil level.

Drain and refillWith oil filter change

3.9 (3-3/8 Imp qt)

Without oil filter change

3.5 (3-1/8 Imp qt)

Dry engine (engine overhaul)

4.5 (4 Imp qt)

Oil pan drain plug:

: 29.4 - 39.2 N·m (3.0 - 4.0 kg-m, 22 - 28 ft-lb)

PBIC0250E

Page 2480 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LU-14

[QR20DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00BLZ

OIL PRESSURE

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

OIL CA NISSAN X-TRAIL 2003 Electronic Repair Manual LU-14

[QR20DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00BLZ

OIL PRESSURE

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

OIL CA](/img/5/57402/w960_57402-2479.png)

LU-14

[QR20DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00BLZ

OIL PRESSURE

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

OIL CAPACITY

Unit: · (Imp qt)

TIGHTENING TORQUE

Unit: N·m (kg-m, ft-lb) N·m(kg-m, in-lb)* Engine speed rpm

Approximate discharge pressure kPa (bar, kg/cm

2,psi)

Idle speed

2,000

6,000More than 98 (0.98, 1.0, 14)

294 (2.9, 3.0, 43)

392 (3.9, 4.0, 57)

Body to outer rotor radial clearance 0.114 - 0.179 (0.0045 - 0.0070)

Inner rotor to outer rotor tip clearance Below 0.220 (0.0087)

Body to inner rotor axial clearance 0.030 - 0.070 (0.0012 - 0.0028)

Body to outer rotor axial clearance 0.060 - 0.110 (0.0024 - 0.0043)

Inner rotor to brazed portion of housing clearance 0.035 - 0.070 (0.0014 - 0.0028)

Regulator valve to oil pump cover clearance 0.040 - 0.097 (0.0016 - 0.0038)

With oil filter change Approximately 3.9 (3-3/8)

Without oil filter change Approximately 3.5 (3-1/8)

Dry engine (engine overhaul) Approximately 4.5 (4)

Oil pressure switch 12.3 - 17.2 (1.25 - 1.75, 9 - 12)

Oil pan drain plug 29.4 - 39.2 (3.0 - 4.0, 22 - 28)

Oil pump assembly 6.4 - 7.5 (0.66 - 0.76, 57 - 66)*

Oil pump cover 5.9 - 7.9 (0.60 - 0.81, 52 - 70)*

Regulator plug 39.2 - 68.6 (4.0 - 7.0, 29 - 50)

Page 2485 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE OIL

LU-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LUChanging Engine OilEBS00B04

WA RN ING:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE OIL

LU-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LUChanging Engine OilEBS00B04

WA RN ING:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine](/img/5/57402/w960_57402-2484.png)

ENGINE OIL

LU-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LUChanging Engine OilEBS00B04

WA RN ING:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine oil may

cause skin cancer: try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine compo-

nents.

2. Stop engine and wait for 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity:

lAPI grade CF-4.

lRefer toMA-17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

Oil capcity (Approximate):

lThe refill capacity depends on the oil temperature and drain time. Use these specifications for reference

only.

Always use the dipstick to the determine when the proper amount of oil is in the engine.

CAUTION:

lBe sure to clean drain plug and install with new washer.

lThe refill capacity depends on the oil temperature and drain time. Use these specifications for ref-

erence only.

Always use the dipstick to the determine when the proper amount of oil is in the engine.

5. Warm up engine and check area around drain plug and oil filter for oil leakage.

6. Stop engine and wait for 10 minutes.

7. Check oil level.Oil pressure switch:

: 12.3 - 17.2 N·m (1.3 - 1.7 kg-m, 9 - 12 ft-lb)

PBIC0527E

Drain and refillWith oil filter change

5.2 (4-5/8 Imp qt)

Without oil filter change

4.9 (4-3/8 Imp qt)

Dry engine (engine overhaul)6.3 (5-1/2 Imp qt)

Oil pan drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

SBIA0122E

Page 2490 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LU-24

[YD22DDTi]

OIL PUMP

lCalculate the clearance between inner rotor and oil pump hous-

ing as follows.

1. Measure the outer diameter of protruded portion of inner rotor

(Position 5)

2. Measure the NISSAN X-TRAIL 2003 Electronic Repair Manual LU-24

[YD22DDTi]

OIL PUMP

lCalculate the clearance between inner rotor and oil pump hous-

ing as follows.

1. Measure the outer diameter of protruded portion of inner rotor

(Position 5)

2. Measure the](/img/5/57402/w960_57402-2489.png)

LU-24

[YD22DDTi]

OIL PUMP

lCalculate the clearance between inner rotor and oil pump hous-

ing as follows.

1. Measure the outer diameter of protruded portion of inner rotor

(Position 5)

2. Measure the inner diameter of oil pump housing with inside

micrometer (Position 6)

(Clearance) = (Inner diameter of oil pump housing) – (Outer

diameter of inner rotor)

Regulator Valve

1. Visually inspect components for wear and damage.

2. Check oil pressure regulator valve sliding surface and valve spring.

3. Coat regulator valve with engine oil. Check that it falls smoothly into the valve hole by its own weight.

If damaged, replace regulator valve set or oil pump housing.

4. Check regulator valve to oil pump housing clearance.

CAUTION:

Coat regulator valve with engine oil.

Check that it falls smoothly into the valve hole by its own

weight.

ASSEMBLY

lAssemble in the reverse order of disassembly.

lInstall the inner rotor and outer rotor with the punched marks on

the oil pump cover side.

lThe refill capacity depends on the oil temperature and drain

time. Use these specifications for reference only.

Always use the dipstick to the determine when the proper

amount of oil is in the engine.

PBIC0253E

Standard : 0.045 - 0.091mm (0.0018 - 0.0036 in)

SBIA0124E

Clearance 6 :

6 : 0.040 - 0.097 mm (0.0016 - 0.0038 in)

JLC358B

JLC286B

Page 2492 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LU-26

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00CTZ

OIL PRESSURE

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

OIL NISSAN X-TRAIL 2003 Electronic Repair Manual LU-26

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00CTZ

OIL PRESSURE

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

OIL](/img/5/57402/w960_57402-2491.png)

LU-26

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00CTZ

OIL PRESSURE

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

OIL CAPACITY

Unit: · (Imp qt)

Tightening TorqueEBS00B0F

Unit: N·m (kg-m, ft-lb), N·m (kg-m, in-lb)* Engine speed rpm

Approximate discharge pressure kPa (bar, kg/cm

2,psi)

Idle speed

2,000

4,000More than 140 (1.40, 1.43, 20.3)

More than 270 (2.69, 2.75, 39.1)

More than 430 (4.29, 4.38, 62.3)

Body to outer rotor radial clearance 0.114 - 0.260 (0.0045 - 0.0102)

Inner rotor to outer rotor tip clearance Below 0.18 (0.0071)

Body to inner rotor axial clearance 0.050 - 0.090 (0.0020 - 0.0035)

Body to outer rotor axial clearance 0.030 - 0.190 (0.0012 - 0.0075)

Inner rotor to brazed portion of housing clearance 0.045 - 0.091 (0.0018 - 0.0036)

Regulator valve to oil pump cover clearance 0.040 - 0.097 (0.0016 - 0.0038)

With oil filter change Approximately 5.2 (4-5/8 Imp qt)

Without oil filter change Approximately 4.9 (4-3/8 Imp qt)

Dry engine (engine overhaul) Approximately 6.3 (5-1/2 Imp qt)

Oil pressure switch 12.3 - 17.2 (1.3 - 1.7, 9 - 12)

Oil pan drain plug 29 - 39 (3.0 - 4.0, 22 - 29)

Oil filter bracket20 -23 (2.0 - 2.4, 15 - 17)

Oil filter body20 - 24 (2.0 - 2.5, 15 - 18)

Oil pump assembly 6.4 - 7.4 (0.65 - 0.76, 57 - 65)*

Oil pump cover 5.9 - 7.8 (0.6 - 0.8, 52 - 69)*

Regulator plug40 - 68 (4.0 - 7.0, 29 - 50)

Water hose connector for oil cooler 25 - 31 (2.5 - 3.2, 18 - 23)

Connecting bolt 34.3 - 44.1 (3.5 - 4.4, 26 - 32)

Page 2509 of 3066

RECOMMENDED FLUIDS AND LUBRICANTS

MA-17

C

D

E

F

G

H

I

J

K

MA

B

MA

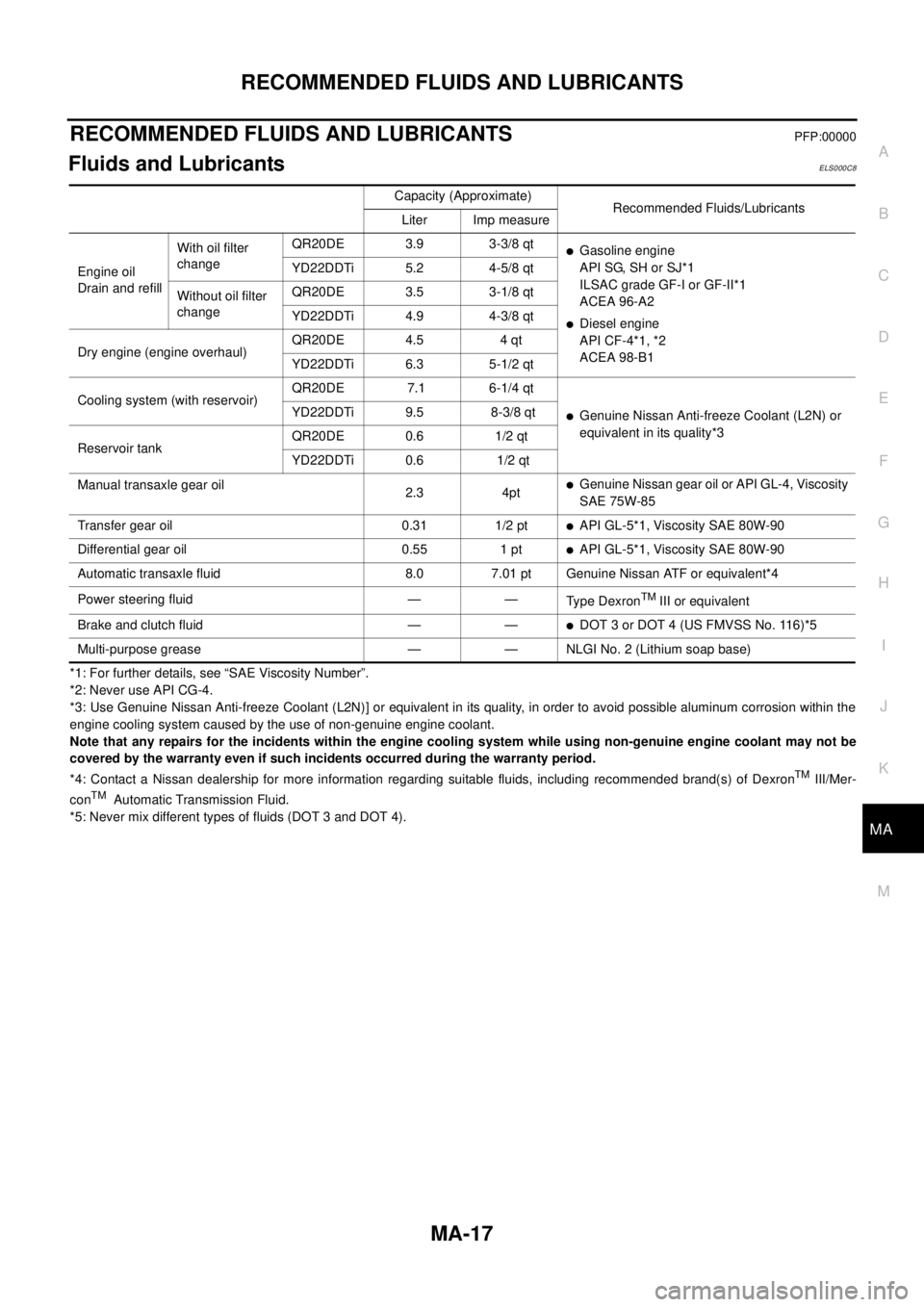

RECOMMENDED FLUIDS AND LUBRICANTSPFP:00000

Fluids and LubricantsELS000C8

*1: For further details, see “SAE Viscosity Number”.

*2: Never use API CG-4.

*3: Use Genuine Nissan Anti-freeze Coolant (L2N)] or equivalent in its quality, in order to avoid possible aluminum corrosion within the

engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of Dexron

TMIII/Mer-

conTMAutomatic Transmission Fluid.

*5: Never mix different types of fluids (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp measure

Engine oil

Drain and refillWith oil filter

changeQR20DE 3.9 3-3/8 qt

lGasoline engine

API SG, SH or SJ*1

ILSAC grade GF-I or GF-II*1

ACEA 96-A2

lDiesel engine

API CF-4*1, *2

ACEA 98-B1 YD22DDTi 5.2 4-5/8 qt

Without oil filter

changeQR20DE 3.5 3-1/8 qt

YD22DDTi 4.9 4-3/8 qt

Dry engine (engine overhaul)QR20DE 4.5 4 qt

YD22DDTi 6.3 5-1/2 qt

Cooling system (with reservoir)QR20DE 7.1 6-1/4 qt

lGenuine Nissan Anti-freeze Coolant (L2N) or

equivalent in its quality*3 YD22DDTi 9.5 8-3/8 qt

Reservoir tankQR20DE 0.6 1/2 qt

YD22DDTi 0.6 1/2 qt

Manual transaxle gear oil

2.3 4pt

lGenuine Nissan gear oil or API GL-4, Viscosity

SAE 75W-85

Transfer gear oil 0.31 1/2 pt

lAPI GL-5*1, Viscosity SAE 80W-90

Differential gear oil 0.55 1 pt

lAPI GL-5*1, Viscosity SAE 80W-90

Automatic transaxle fluid 8.0 7.01 pt Genuine Nissan ATF or equivalent*4

Power steering fluid — —

Ty p e D e x r o n

TMIII or equivalent

Brake and clutch fluid — —

lDOT 3 or DOT 4 (US FMVSS No. 116)*5

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)