wheel bolt torque NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 465 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

t NISSAN X-TRAIL 2003 Electronic Repair Manual REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

t](/img/5/57402/w960_57402-464.png)

REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

toEM-61, "

ENGINE ASSEMBLY".

13. Remove suspension member. Refer toFSU-12, "

FRONT SUS-

PENSION MEMBER".

14. Remove dust cover from converter housing.

Rotate crankshaft to gain access to securing bolts.

15. Remove securing bolts between drive plate and torque con-

verter. when crank shaft rotates, turn to right at the front side of

engine.

16. Support engine with a jack.

17. Remove bolts fixing transaxle to engine.

18. Lower transaxle while supporting it with a jack.

InstallationECS004ND

1. Check drive plate runout.

CAUTION:

Do not allow any magnetic materials to contact the ring

gear teeth.

lIf this runout is out of allowance, replace drive plate with ring

gear.

2. When connecting torque converter to transaxle, measure dis-

tance “A” to be certain that they are correctly assembled.

SCIA0794E

AAT259A

Maximum allowable runout :

Refer to EM-´´, “FLYWHEEL/DRIVE PLATE RUNOUT”.

SAT977H

Distance “A”: 19 mm (0.626 in) or more

SAT573D

Page 845 of 3066

BRAKE PIPING AND HOSE

BR-11

C

D

E

G

H

I

J

K

L

MA

B

BR

BRAKE PIPING AND HOSEPFP:46210

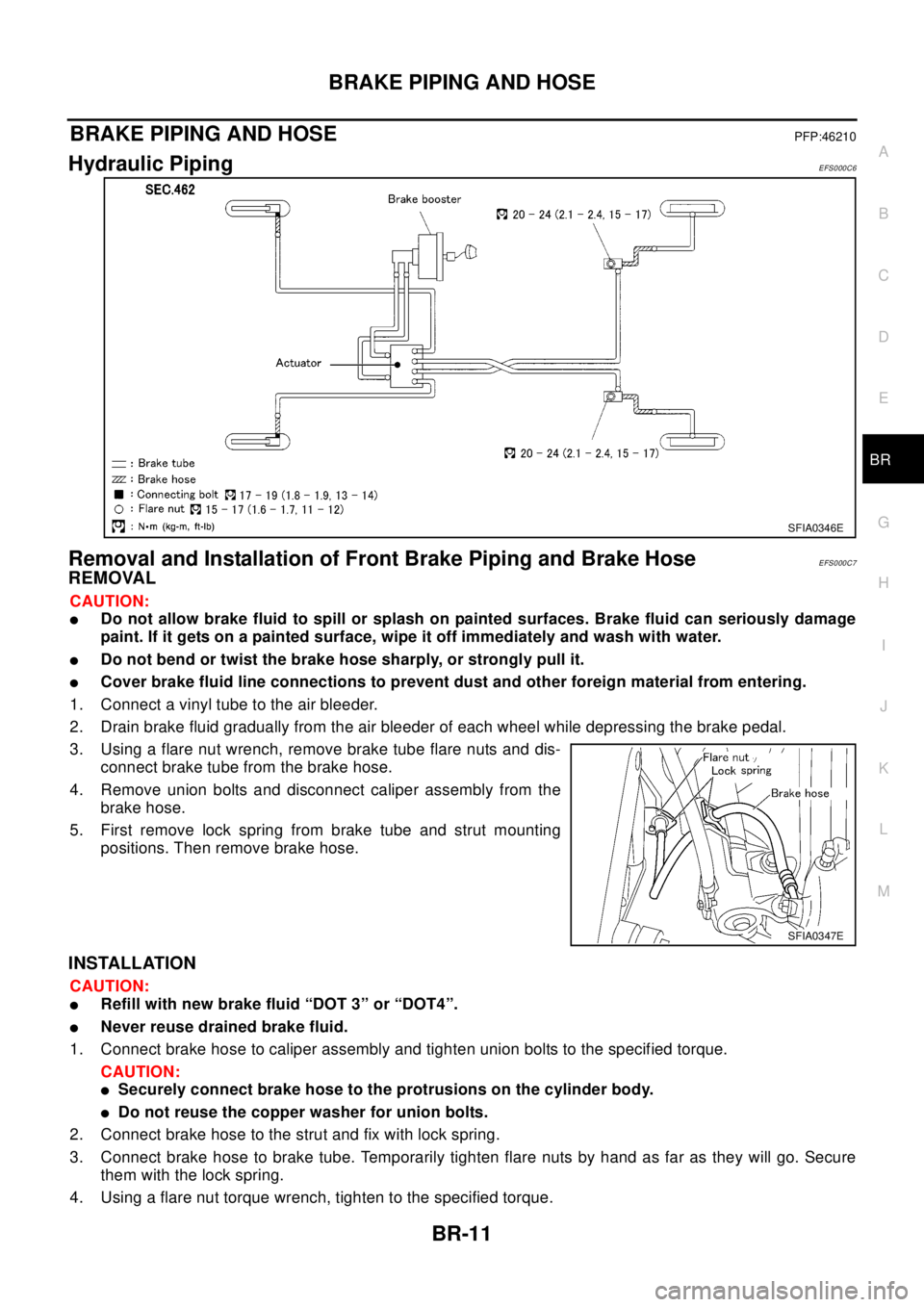

Hydraulic PipingEFS000C6

Removal and Installation of Front Brake Piping and Brake HoseEFS000C7

REMOVAL

CAUTION:

lDo not allow brake fluid to spill or splash on painted surfaces. Brake fluid can seriously damage

paint. If it gets on a painted surface, wipe it off immediately and wash with water.

lDo not bend or twist the brake hose sharply, or strongly pull it.

lCover brake fluid line connections to prevent dust and other foreign material from entering.

1. Connect a vinyl tube to the air bleeder.

2. Drain brake fluid gradually from the air bleeder of each wheel while depressing the brake pedal.

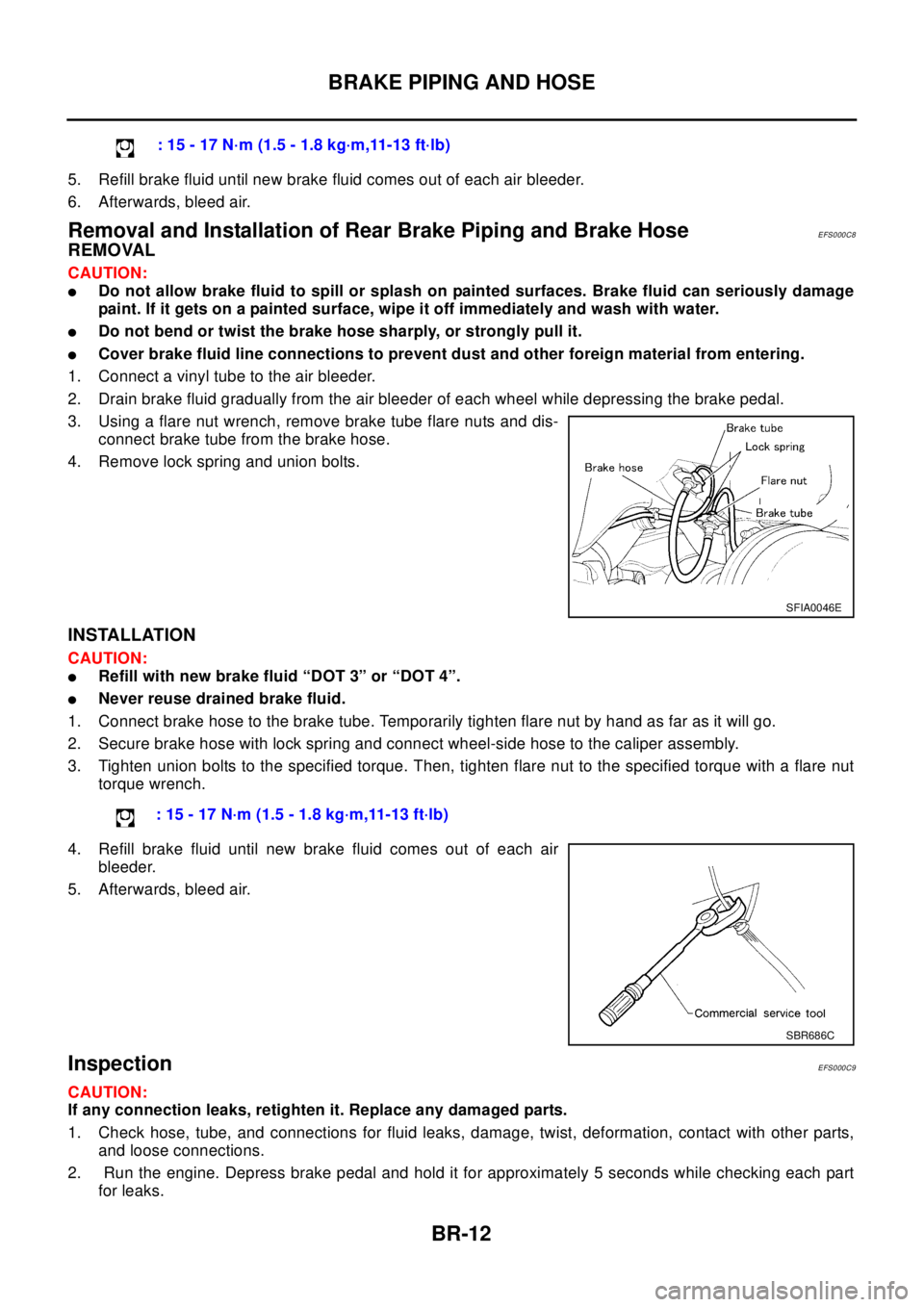

3. Using a flare nut wrench, remove brake tube flare nuts and dis-

connect brake tube from the brake hose.

4. Remove union bolts and disconnect caliper assembly from the

brake hose.

5. First remove lock spring from brake tube and strut mounting

positions. Then remove brake hose.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT4”.

lNever reuse drained brake fluid.

1. Connect brake hose to caliper assembly and tighten union bolts to the specified torque.

CAUTION:

lSecurely connect brake hose to the protrusions on the cylinder body.

lDo not reuse the copper washer for union bolts.

2. Connect brake hose to the strut and fix with lock spring.

3. Connect brake hose to brake tube. Temporarily tighten flare nuts by hand as far as they will go. Secure

them with the lock spring.

4. Using a flare nut torque wrench, tighten to the specified torque.

SFIA0346E

SFIA0347E

Page 846 of 3066

BR-12

BRAKE PIPING AND HOSE

5. Refill brake fluid until new brake fluid comes out of each air bleeder.

6. Afterwards, bleed air.

Removal and Installation of Rear Brake Piping and Brake HoseEFS000C8

REMOVAL

CAUTION:

lDo not allow brake fluid to spill or splash on painted surfaces. Brake fluid can seriously damage

paint. If it gets on a painted surface, wipe it off immediately and wash with water.

lDo not bend or twist the brake hose sharply, or strongly pull it.

lCover brake fluid line connections to prevent dust and other foreign material from entering.

1. Connect a vinyl tube to the air bleeder.

2. Drain brake fluid gradually from the air bleeder of each wheel while depressing the brake pedal.

3. Using a flare nut wrench, remove brake tube flare nuts and dis-

connect brake tube from the brake hose.

4. Remove lock spring and union bolts.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

1. Connect brake hose to the brake tube. Temporarily tighten flare nut by hand as far as it will go.

2. Secure brake hose with lock spring and connect wheel-side hose to the caliper assembly.

3. Tighten union bolts to the specified torque. Then, tighten flare nut to the specified torque with a flare nut

torque wrench.

4. Refill brake fluid until new brake fluid comes out of each air

bleeder.

5. Afterwards, bleed air.

InspectionEFS000C9

CAUTION:

If any connection leaks, retighten it. Replace any damaged parts.

1. Check hose, tube, and connections for fluid leaks, damage, twist, deformation, contact with other parts,

and loose connections.

2. Run the engine. Depress brake pedal and hold it for approximately 5 seconds while checking each part

for leaks.:15-17N·m(1.5-1.8kg·m,11-13ft·lb)

SFIA0046E

: 15 - 17 N·m (1.5 - 1.8 kg·m,11-13 ft·lb)

SBR686C

Page 855 of 3066

FRONT DISC BRAKE

BR-21

C

D

E

G

H

I

J

K

L

MA

B

BR

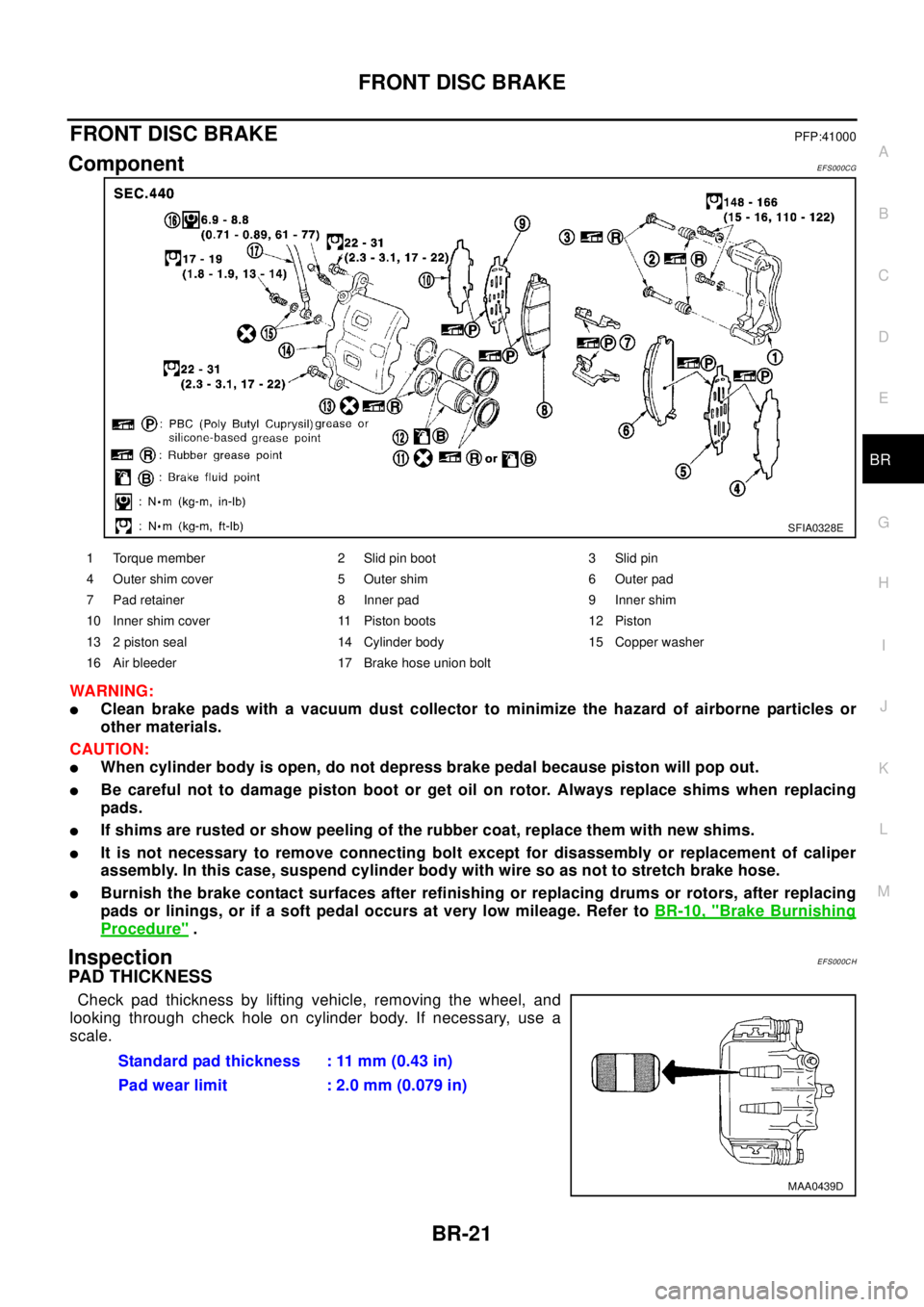

FRONT DISC BRAKEPFP:41000

ComponentEFS000CG

WA RN ING:

lClean brake pads with a vacuum dust collector to minimize the hazard of airborne particles or

other materials.

CAUTION:

lWhen cylinder body is open, do not depress brake pedal because piston will pop out.

lBe careful not to damage piston boot or get oil on rotor. Always replace shims when replacing

pads.

lIf shims are rusted or show peeling of the rubber coat, replace them with new shims.

lIt is not necessary to remove connecting bolt except for disassembly or replacement of caliper

assembly. In this case, suspend cylinder body with wire so as not to stretch brake hose.

lBurnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing

pads or linings, or if a soft pedal occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

InspectionEFS000CH

PAD THICKNESS

Check pad thickness by lifting vehicle, removing the wheel, and

looking through check hole on cylinder body. If necessary, use a

scale.

SFIA0328E

1 Torque member 2 Slid pin boot 3 Slid pin

4 Outer shim cover 5 Outer shim 6 Outer pad

7 Pad retainer 8 Inner pad 9 Inner shim

10 Inner shim cover 11 Piston boots 12 Piston

13 2 piston seal 14 Cylinder body 15 Copper washer

16 Air bleeder 17 Brake hose union bolt

Standard pad thickness : 11 mm (0.43 in)

Pad wear limit : 2.0 mm (0.079 in)

MAA0439D

Page 858 of 3066

BR-24

FRONT DISC BRAKE

2. Using a slotted screwdriver, remove piston seals.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

CAUTION:

Use new brake fluid to clean. Never use mineral oils such as gasoline or kerosene.

lCheck cylinder inner wall for corrosion, wear and damage. If corrosion, wear or damage is detected,

replace the cylinder body.

lMinor flaws caused by corrosion or foreign material can be removed by polishing the surface with fine

sandpaper. Replace the cylinder body, if necessary.

Torque Member

Check for wear, cracks and damage. If wear, cracks or damage is detected, replace the applicable part.

Piston

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Check piston surface for corrosion, wear and damage. If corrosion, wear or damage is detected, replace the

applicable part.

Sliding Pin, Pin Bolt, and Pin Boot

Check sliding pin and sliding pin boot for wear, damage and cracks. If corrosion, wear or damage is detected,

replace the applicable part.

DISC ROTOR INSPECTION

Visual Inspection

Check surface of the disc rotor for uneven wear, cracks and serious damage. If uneven wear, cracks or seri-

ous damage is detected, replace it.

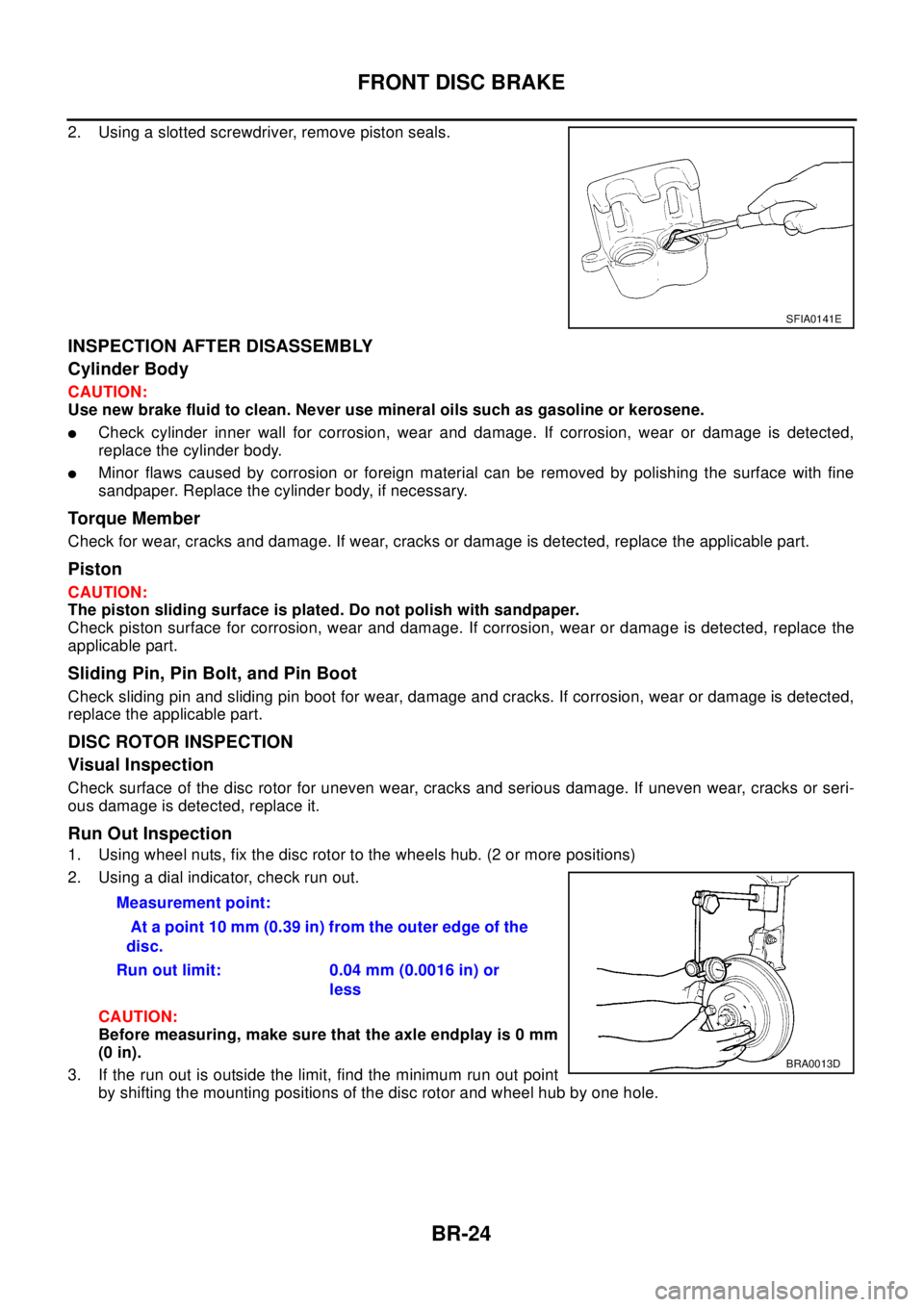

Run Out Inspection

1. Using wheel nuts, fix the disc rotor to the wheels hub. (2 or more positions)

2. Using a dial indicator, check run out.

CAUTION:

Before measuring, make sure that the axle endplay is 0 mm

(0 in).

3. If the run out is outside the limit, find the minimum run out point

by shifting the mounting positions of the disc rotor and wheel hub by one hole.

SFIA0141E

Measurement point:

At a point 10 mm (0.39 in) from the outer edge of the

disc.

Run out limit: 0.04 mm (0.0016 in) or

less

BRA0013D

Page 861 of 3066

REAR DISC BRAKE

BR-27

C

D

E

G

H

I

J

K

L

MA

B

BR

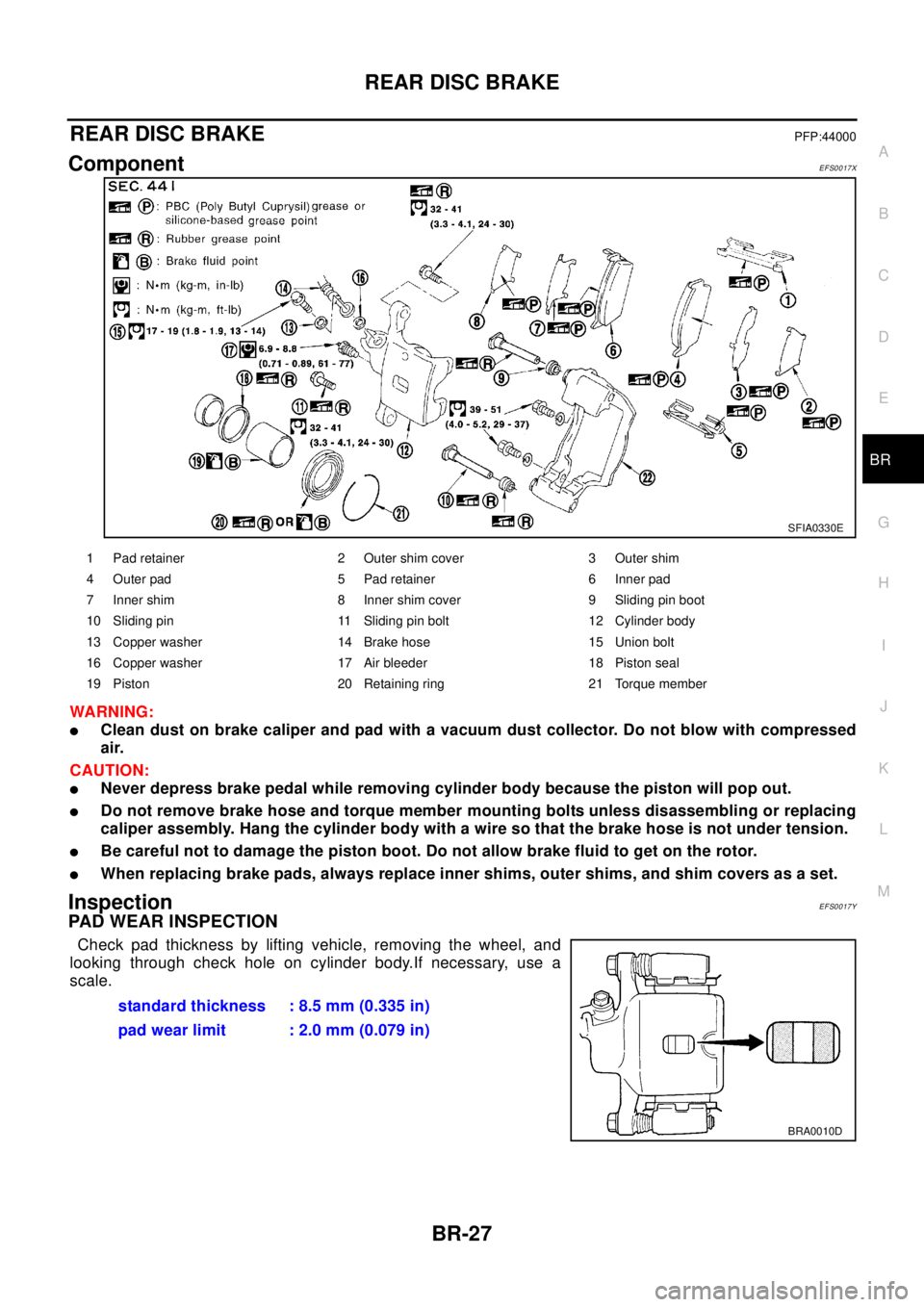

REAR DISC BRAKEPFP:44000

ComponentEFS0017X

WA RN ING:

lClean dust on brake caliper and pad with a vacuum dust collector. Do not blow with compressed

air.

CAUTION:

lNever depress brake pedal while removing cylinder body because the piston will pop out.

lDo not remove brake hose and torque member mounting bolts unless disassembling or replacing

caliper assembly. Hang the cylinder body with a wire so that the brake hose is not under tension.

lBe careful not to damage the piston boot. Do not allow brake fluid to get on the rotor.

lWhen replacing brake pads, always replace inner shims, outer shims, and shim covers as a set.

InspectionEFS0017Y

PAD WEAR INSPECTION

Check pad thickness by lifting vehicle, removing the wheel, and

looking through check hole on cylinder body.If necessary, use a

scale.

SFIA0330E

1 Pad retainer 2 Outer shim cover 3 Outer shim

4 Outer pad 5 Pad retainer 6 Inner pad

7 Inner shim 8 Inner shim cover 9 Sliding pin boot

10 Sliding pin 11 Sliding pin bolt 12 Cylinder body

13 Copper washer 14 Brake hose 15 Union bolt

16 Copper washer 17 Air bleeder 18 Piston seal

19 Piston 20 Retaining ring 21 Torque member

standard thickness : 8.5 mm (0.335 in)

pad wear limit : 2.0 mm (0.079 in)

BRA0010D

Page 864 of 3066

BR-30

REAR DISC BRAKE

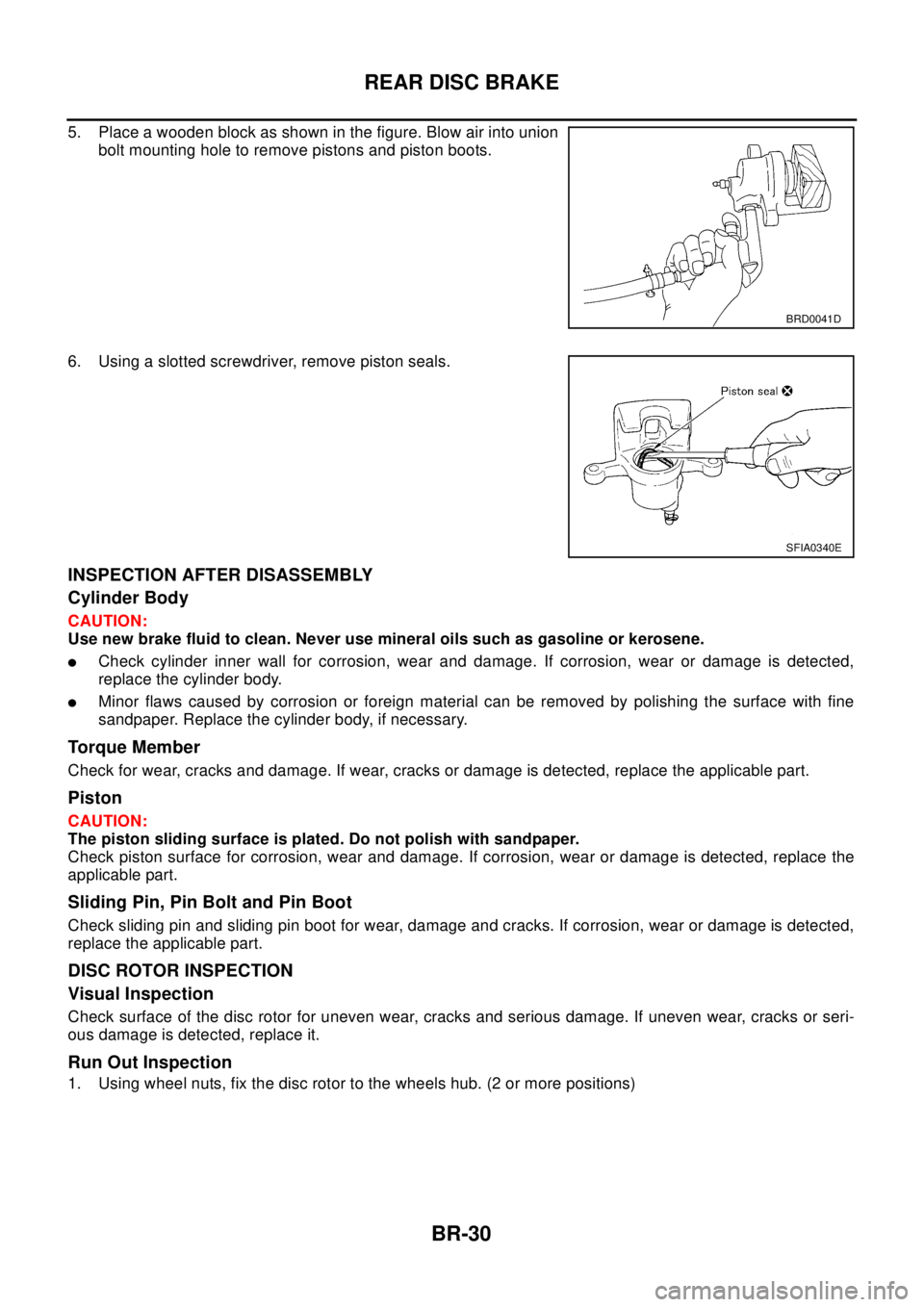

5. Place a wooden block as shown in the figure. Blow air into union

bolt mounting hole to remove pistons and piston boots.

6. Using a slotted screwdriver, remove piston seals.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

CAUTION:

Use new brake fluid to clean. Never use mineral oils such as gasoline or kerosene.

lCheck cylinder inner wall for corrosion, wear and damage. If corrosion, wear or damage is detected,

replace the cylinder body.

lMinor flaws caused by corrosion or foreign material can be removed by polishing the surface with fine

sandpaper. Replace the cylinder body, if necessary.

Torque Member

Check for wear, cracks and damage. If wear, cracks or damage is detected, replace the applicable part.

Piston

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Check piston surface for corrosion, wear and damage. If corrosion, wear or damage is detected, replace the

applicable part.

Sliding Pin, Pin Bolt and Pin Boot

Check sliding pin and sliding pin boot for wear, damage and cracks. If corrosion, wear or damage is detected,

replace the applicable part.

DISC ROTOR INSPECTION

Visual Inspection

Check surface of the disc rotor for uneven wear, cracks and serious damage. If uneven wear, cracks or seri-

ous damage is detected, replace it.

Run Out Inspection

1. Using wheel nuts, fix the disc rotor to the wheels hub. (2 or more positions)

BRD0041D

SFIA0340E

Page 916 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-48

[4WD/ABS]

WHEEL SENSORS

WHEEL SENSORS

PFP:47910

Removal and InstallationEFS001C1

CAUTION:

lBe careful not to damage sensor edge and rotor tooth. Before removing front or rear wheel hub,

remove NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-48

[4WD/ABS]

WHEEL SENSORS

WHEEL SENSORS

PFP:47910

Removal and InstallationEFS001C1

CAUTION:

lBe careful not to damage sensor edge and rotor tooth. Before removing front or rear wheel hub,

remove](/img/5/57402/w960_57402-915.png)

BRC-48

[4WD/ABS]

WHEEL SENSORS

WHEEL SENSORS

PFP:47910

Removal and InstallationEFS001C1

CAUTION:

lBe careful not to damage sensor edge and rotor tooth. Before removing front or rear wheel hub,

remove wheel speed sensor to avoid sensor wiring damage. Otherwise, sensor may be deacti-

vated.

lWhen removing sensor, avoid rotating it as much as possible. Do not forcibly pull sensor harness.

lWhen installing, check sensor pick-up and mounting hole for foreign material such as iron chips.

Check no foreign material has been caught in sensor rotor. Remove any foreign material found.

Tighten mounting bolts and nuts to the specified torque.

SFIA0042E

Page 987 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual WHEEL SPEED SENSORS

BRC-119

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

WHEEL SPEED SENSORSPFP:47910

Removal and InstallationEFS001CD

CAUTION:

lBe careful not to damage sensor edge and rotor tooth. Befor NISSAN X-TRAIL 2003 Electronic Repair Manual WHEEL SPEED SENSORS

BRC-119

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

WHEEL SPEED SENSORSPFP:47910

Removal and InstallationEFS001CD

CAUTION:

lBe careful not to damage sensor edge and rotor tooth. Befor](/img/5/57402/w960_57402-986.png)

WHEEL SPEED SENSORS

BRC-119

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

WHEEL SPEED SENSORSPFP:47910

Removal and InstallationEFS001CD

CAUTION:

lBe careful not to damage sensor edge and rotor tooth. Before removing front or rear wheel hub,

remove wheel speed sensor to avoid sensor wiring damage. Otherwise, sensor may be deacti-

vated.

lWhen removing sensor, avoid rotating it as much as possible. Do not forcibly pull sensor harness.

lWhen installing, check sensor pick-up and mounting hole for foreign material such as iron chips.

Check no foreign material has been caught in sensor rotor. Remove any foreign material found.

Tighten mounting bolts and nuts to the specified torque.

SFIA0042E

Page 1008 of 3066

CL-16

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

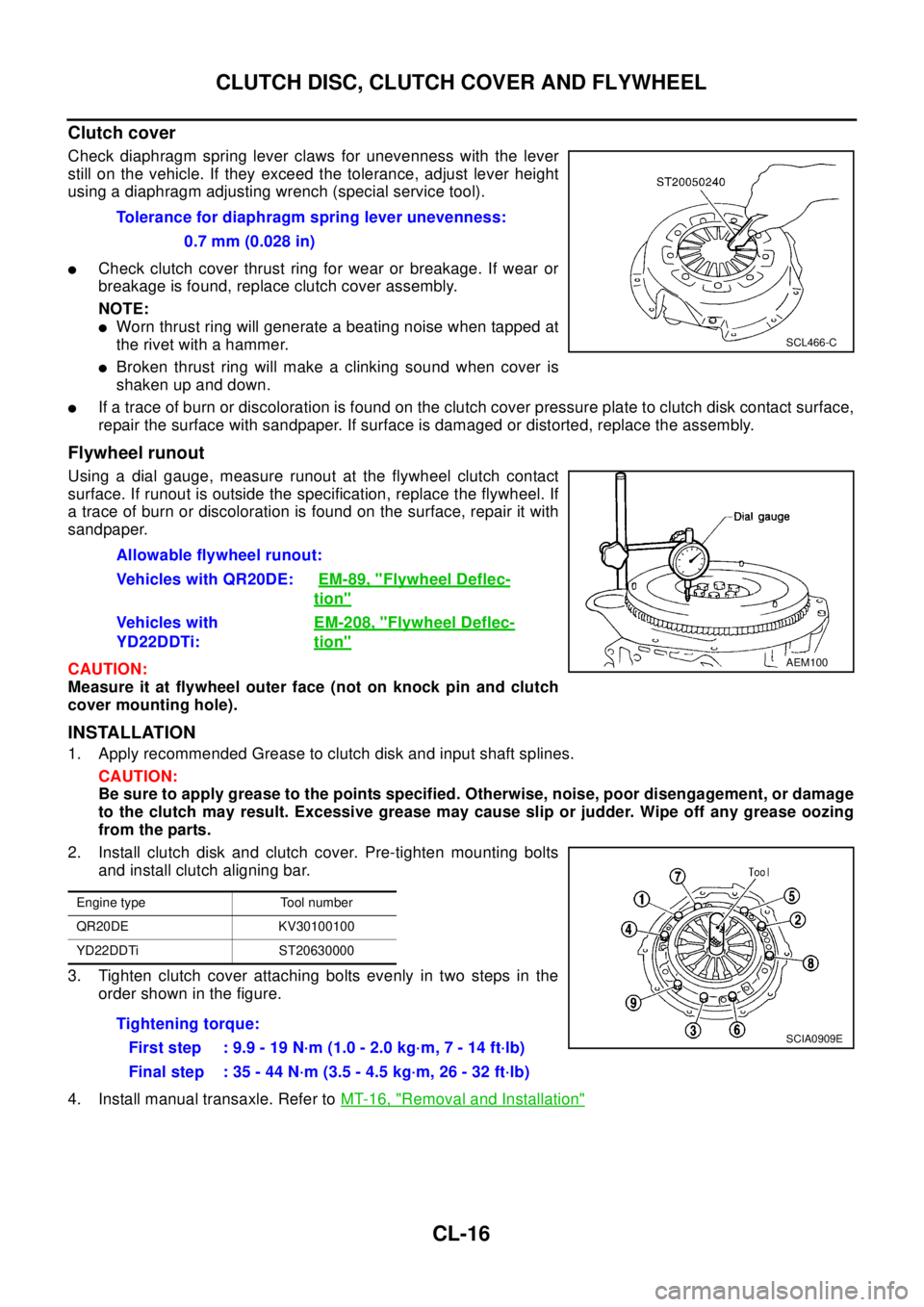

Clutch cover

Check diaphragm spring lever claws for unevenness with the lever

still on the vehicle. If they exceed the tolerance, adjust lever height

using a diaphragm adjusting wrench (special service tool).

lCheck clutch cover thrust ring for wear or breakage. If wear or

breakage is found, replace clutch cover assembly.

NOTE:

lWorn thrust ring will generate a beating noise when tapped at

therivetwithahammer.

lBroken thrust ring will make a clinking sound when cover is

shaken up and down.

lIf a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disk contact surface,

repair the surface with sandpaper. If surface is damaged or distorted, replace the assembly.

Flywheel runout

Using a dial gauge, measure runout at the flywheel clutch contact

surface. If runout is outside the specification, replace the flywheel. If

a trace of burn or discoloration is found on the surface, repair it with

sandpaper.

CAUTION:

Measure it at flywheel outer face (not on knock pin and clutch

cover mounting hole).

INSTALLATION

1. Apply recommended Grease to clutch disk and input shaft splines.

CAUTION:

Be sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage

to the clutch may result. Excessive grease may cause slip or judder. Wipe off any grease oozing

from the parts.

2. Install clutch disk and clutch cover. Pre-tighten mounting bolts

and install clutch aligning bar.

3. Tighten clutch cover attaching bolts evenly in two steps in the

order shown in the figure.

4. Install manual transaxle. Refer toMT-16, "

Removal and Installation"

Tolerance for diaphragm spring lever unevenness:

0.7 mm (0.028 in)

SCL466-C

Allowable flywheel runout:

Vehicles with QR20DE:EM-89, "

Flywheel Deflec-

tion"

Vehicles with

YD22DDTi:EM-208, "Flywheel Deflec-

tion"

AEM100

Engine type Tool number

QR20DE KV30100100

YD22DDTi ST20630000

Tightening torque:

First step : 9.9 - 19 N·m (1.0 - 2.0 kg·m, 7 - 14 ft·lb)

Final step : 35 - 44 N·m (3.5 - 4.5 kg·m, 26 - 32 ft·lb)SCIA0909E