NISSAN X-TRAIL 2005 Service Repair Manual

X-TRAIL 2005

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57403/w960_57403-0.png

NISSAN X-TRAIL 2005 Service Repair Manual

Trending: tow bar, Safety stands points, wiper fluid, Solenoid evap, fender, rear view mirror, wipers

Page 3301 of 4555

SUNLOAD SENSOR

ATC-123

C

D

E

F

G

H

I

K

L

MA

B

AT C

SUNLOAD SENSORPFP:27721

Removal and InstallationEJS004GC

REMOVAL

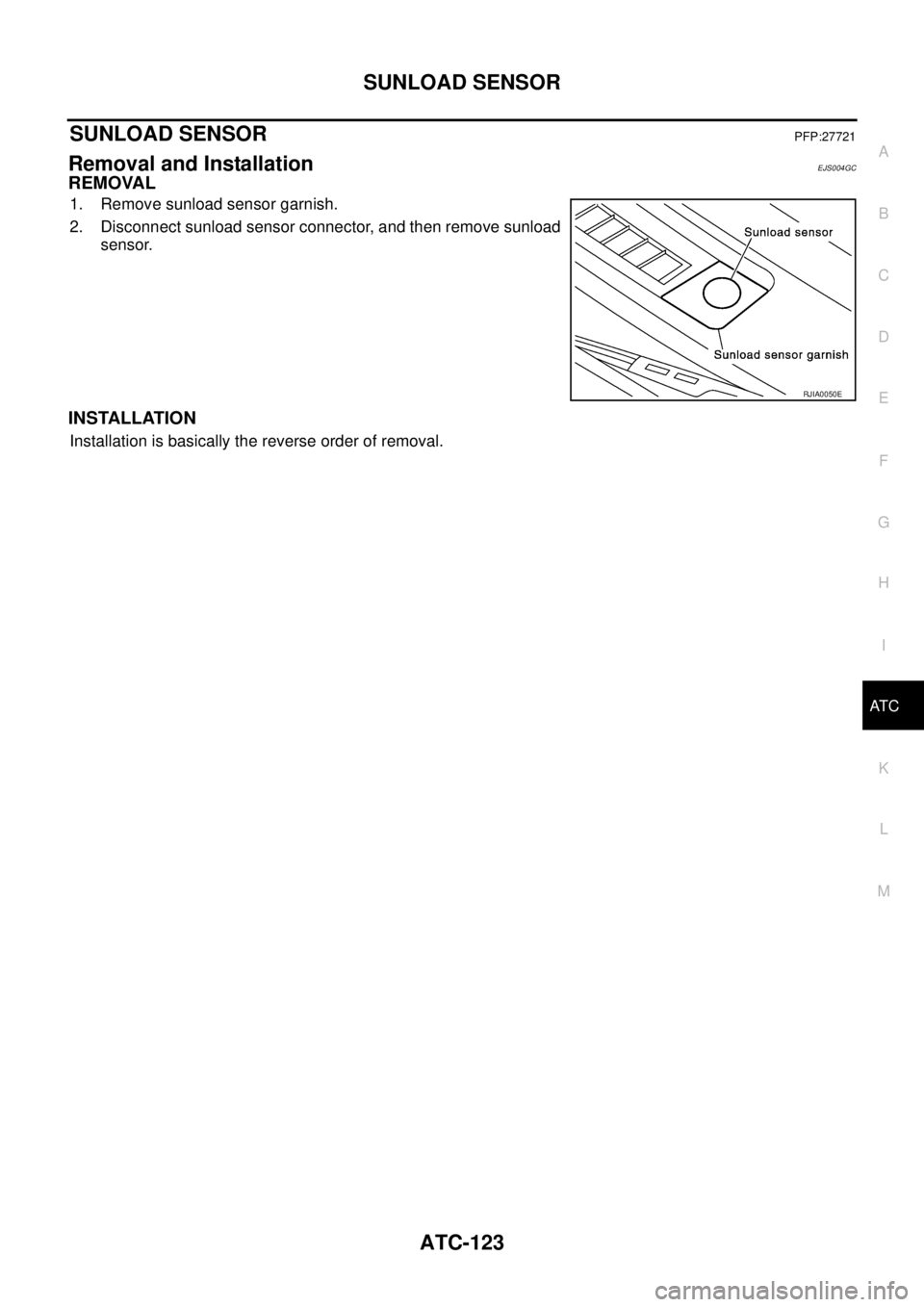

1. Remove sunload sensor garnish.

2. Disconnect sunload sensor connector, and then remove sunload

sensor.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA0050E

Page 3302 of 4555

ATC-124

INTAKE SENSOR

INTAKE SENSORPFP:27723

Removal and InstallationEJS004GI

REMOVAL

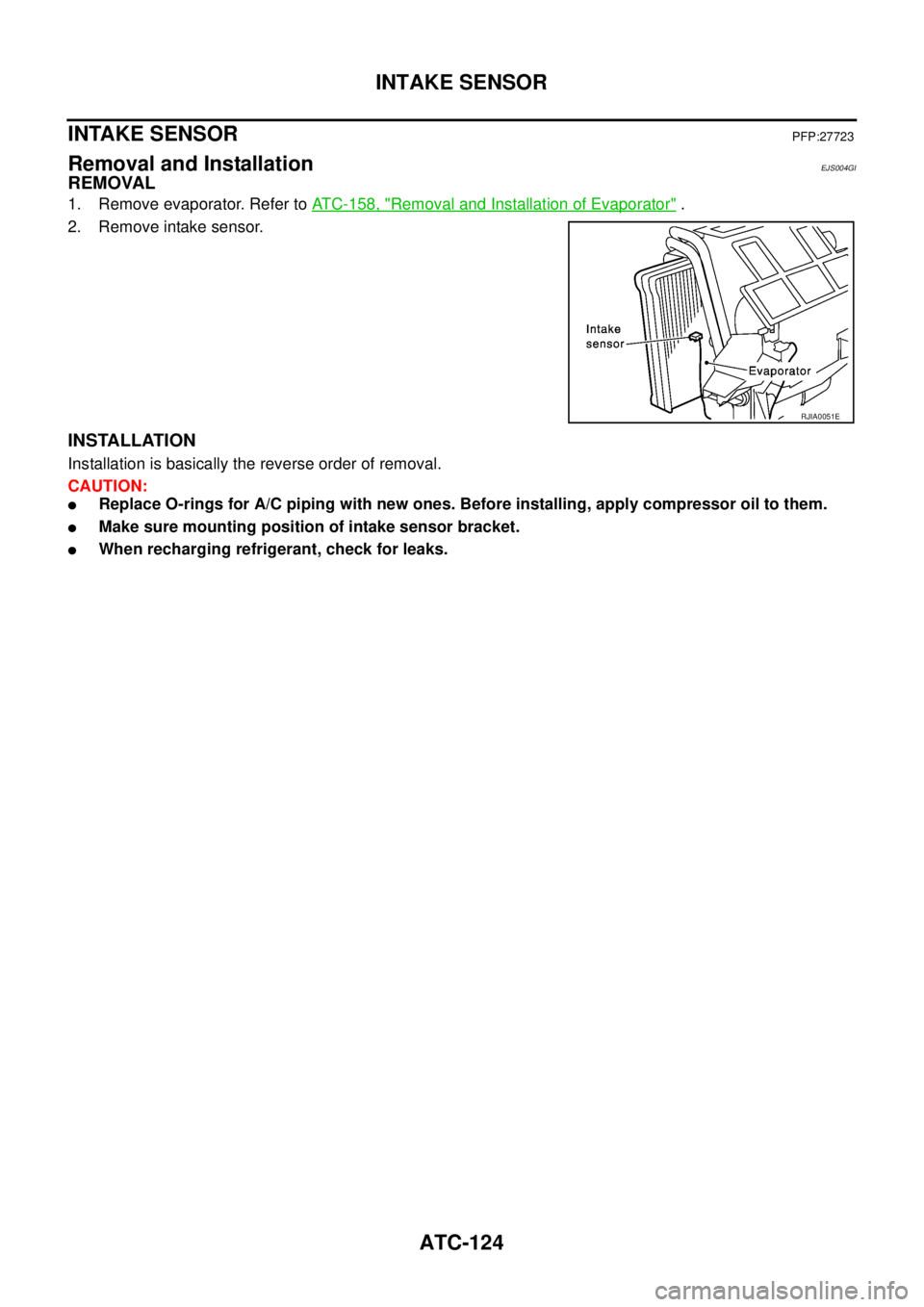

1. Remove evaporator. Refer to ATC-158, "Removal and Installation of Evaporator" .

2. Remove intake sensor.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

�Replace O-rings for A/C piping with new ones. Before installing, apply compressor oil to them.

�Make sure mounting position of intake sensor bracket.

�When recharging refrigerant, check for leaks.

RJIA0051E

Page 3303 of 4555

BLOWER UNIT

ATC-125

C

D

E

F

G

H

I

K

L

MA

B

AT C

BLOWER UNITPFP:27200

Removal and InstallationEJS000UL

REMOVAL

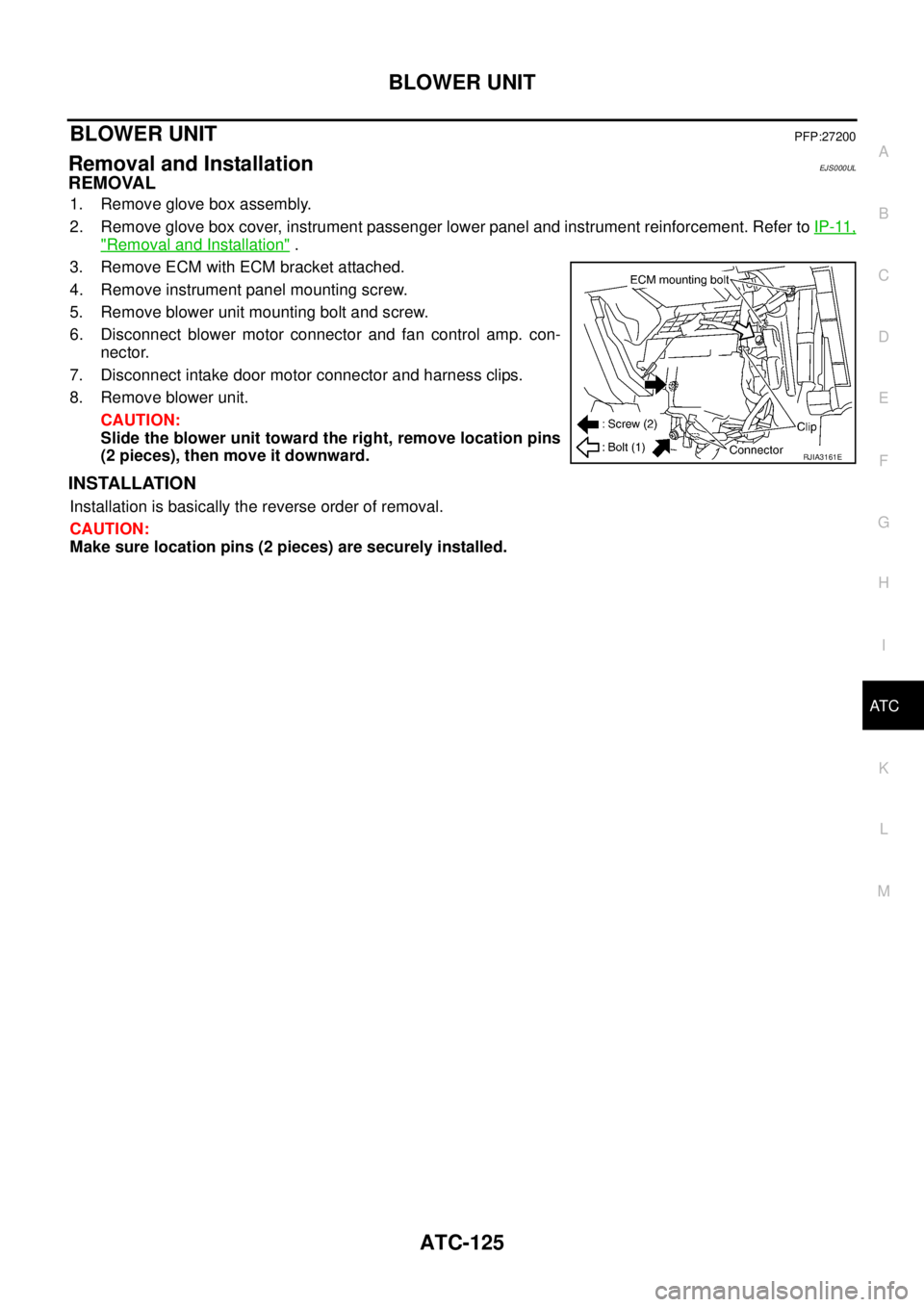

1. Remove glove box assembly.

2. Remove glove box cover, instrument passenger lower panel and instrument reinforcement. Refer to IP-11,

"Removal and Installation" .

3. Remove ECM with ECM bracket attached.

4. Remove instrument panel mounting screw.

5. Remove blower unit mounting bolt and screw.

6. Disconnect blower motor connector and fan control amp. con-

nector.

7. Disconnect intake door motor connector and harness clips.

8. Remove blower unit.

CAUTION:

Slide the blower unit toward the right, remove location pins

(2 pieces), then move it downward.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Make sure location pins (2 pieces) are securely installed.

RJIA3161E

Page 3304 of 4555

ATC-126

BLOWER UNIT

Disassembly and AssemblyEJS000UM

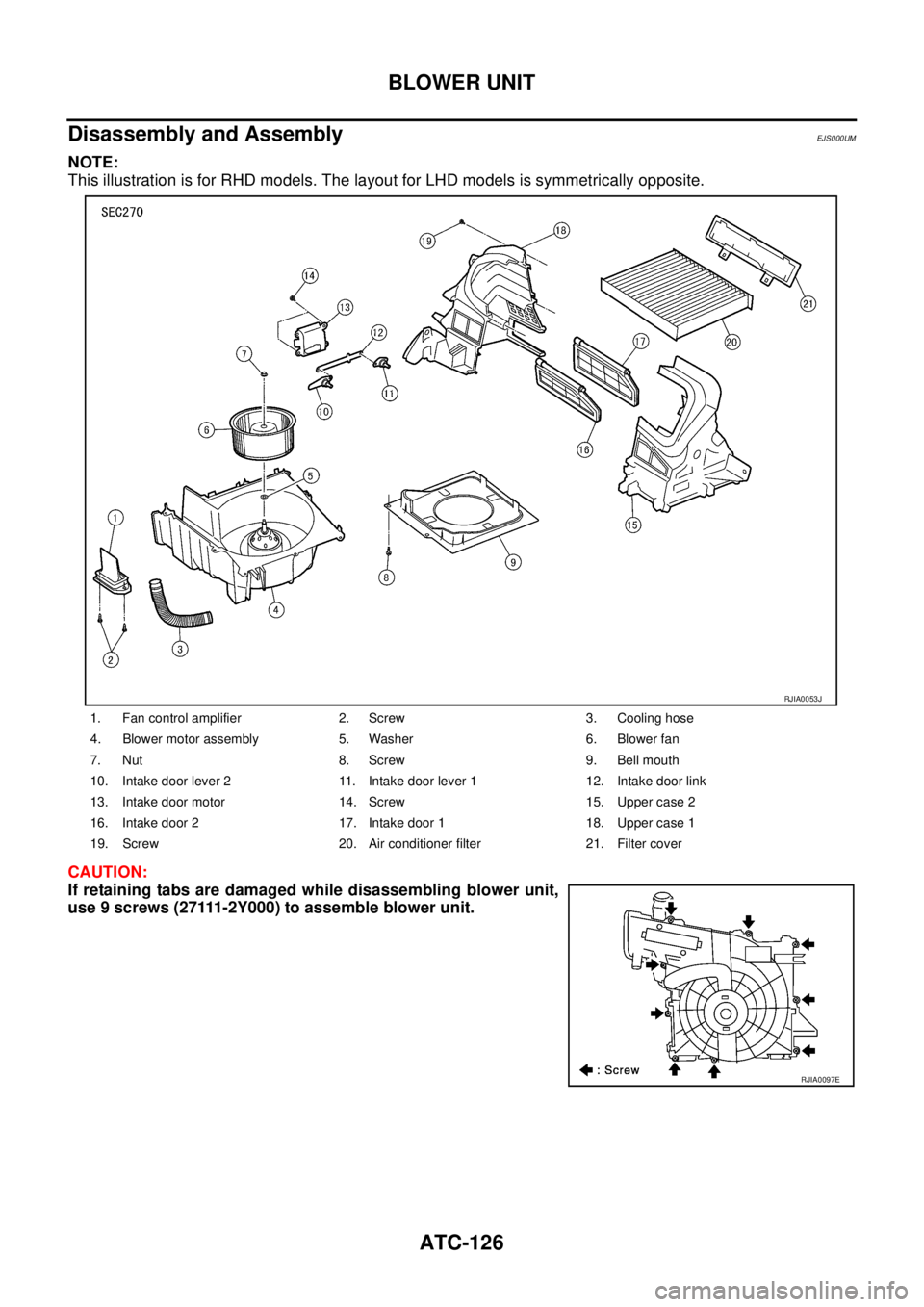

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

CAUTION:

If retaining tabs are damaged while disassembling blower unit,

use 9 screws (27111-2Y000) to assemble blower unit.

1. Fan control amplifier 2. Screw 3. Cooling hose

4. Blower motor assembly 5. Washer 6. Blower fan

7. Nut 8. Screw 9. Bell mouth

10. Intake door lever 2 11. Intake door lever 1 12. Intake door link

13. Intake door motor 14. Screw 15. Upper case 2

16. Intake door 2 17. Intake door 1 18. Upper case 1

19. Screw 20. Air conditioner filter 21. Filter cover

RJIA0053J

RJIA0097E

Page 3305 of 4555

BLOWER MOTOR

ATC-127

C

D

E

F

G

H

I

K

L

MA

B

AT C

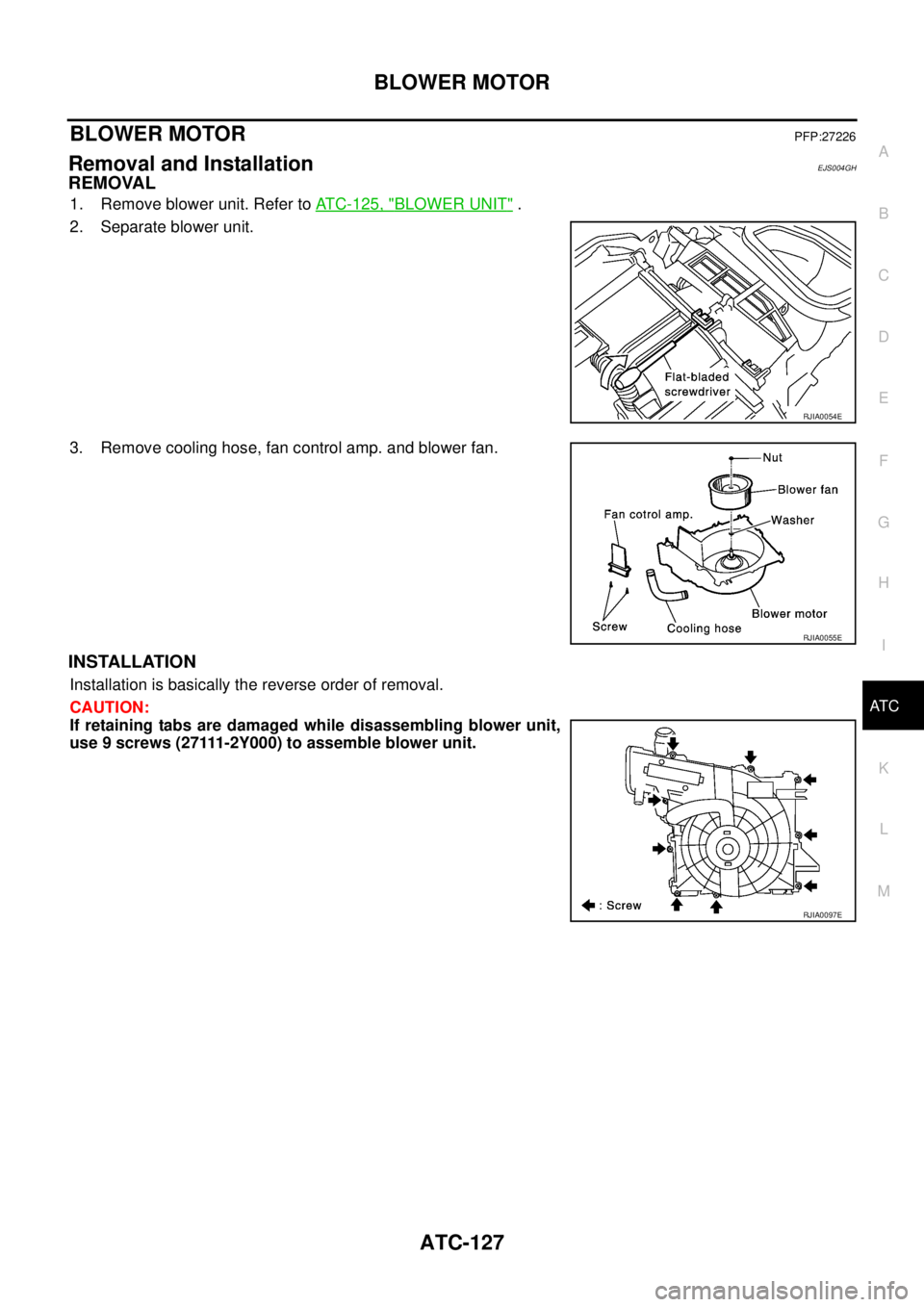

BLOWER MOTORPFP:27226

Removal and InstallationEJS004GH

REMOVAL

1. Remove blower unit. Refer to ATC-125, "BLOWER UNIT" .

2. Separate blower unit.

3. Remove cooling hose, fan control amp. and blower fan.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

If retaining tabs are damaged while disassembling blower unit,

use 9 screws (27111-2Y000) to assemble blower unit.

RJIA0054E

RJIA0055E

RJIA0097E

Page 3306 of 4555

ATC-128

INTAKE DOOR MOTOR

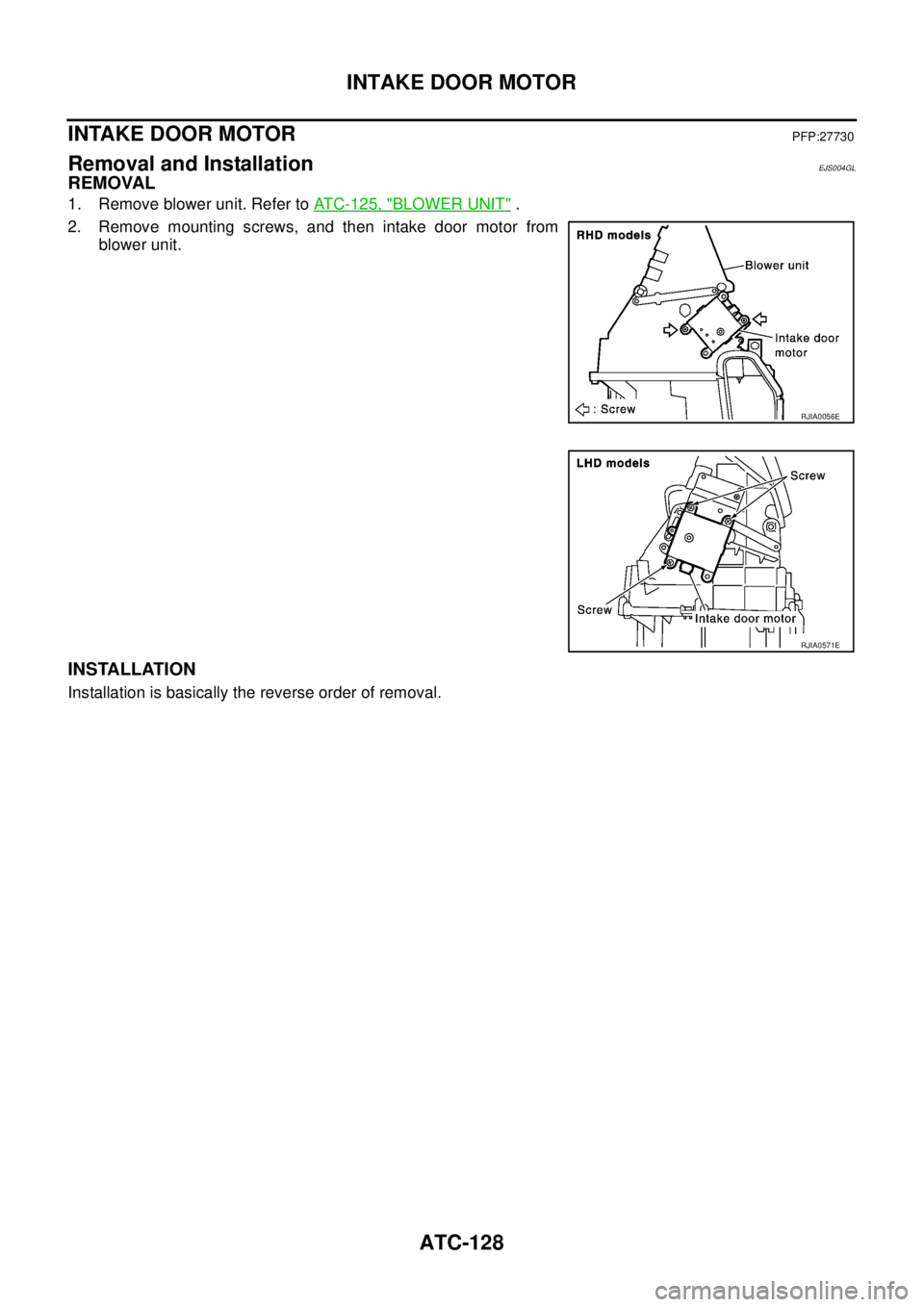

INTAKE DOOR MOTORPFP:27730

Removal and InstallationEJS004GL

REMOVAL

1. Remove blower unit. Refer to ATC-125, "BLOWER UNIT" .

2. Remove mounting screws, and then intake door motor from

blower unit.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA0056E

RJIA0571E

Page 3307 of 4555

FAN CONTROL AMPLIFIER

ATC-129

C

D

E

F

G

H

I

K

L

MA

B

AT C

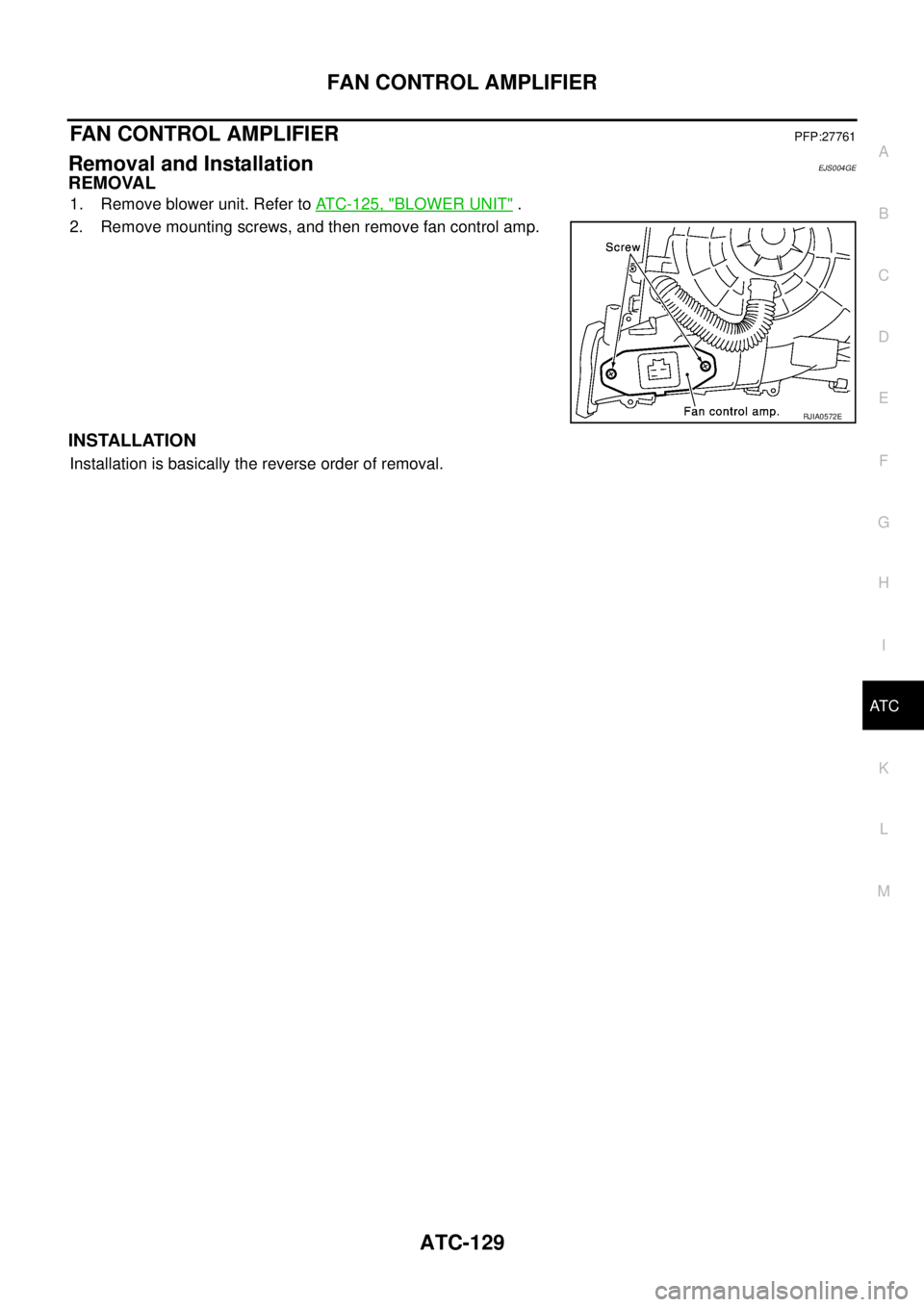

FAN CONTROL AMPLIFIERPFP:27761

Removal and InstallationEJS004GE

REMOVAL

1. Remove blower unit. Refer to ATC-125, "BLOWER UNIT" .

2. Remove mounting screws, and then remove fan control amp.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA0572E

Page 3308 of 4555

ATC-130

AIR CONDITIONER FILTER

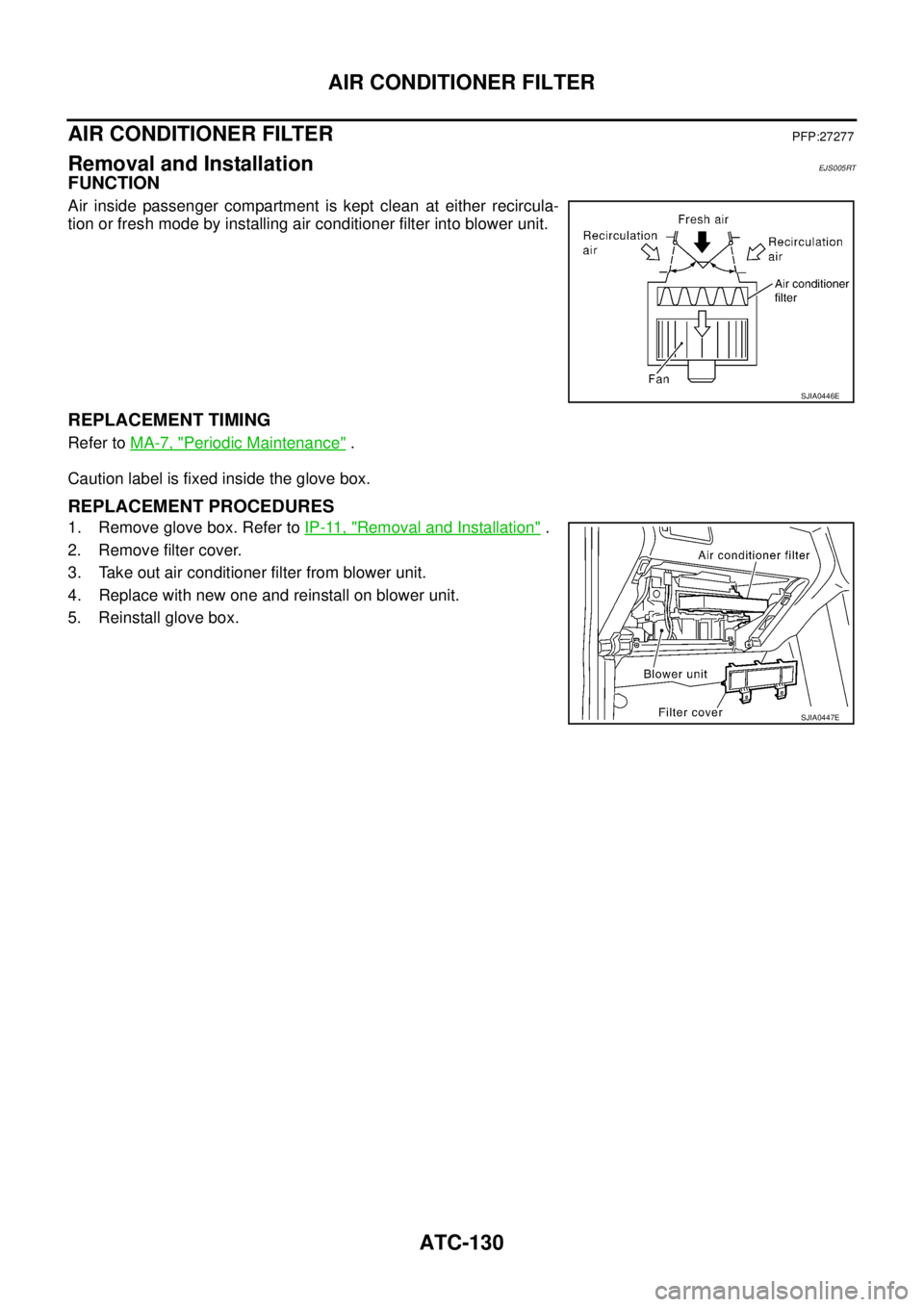

AIR CONDITIONER FILTERPFP:27277

Removal and InstallationEJS005RT

FUNCTION

Air inside passenger compartment is kept clean at either recircula-

tion or fresh mode by installing air conditioner filter into blower unit.

REPLACEMENT TIMING

Refer to MA-7, "Periodic Maintenance" .

Caution label is fixed inside the glove box.

REPLACEMENT PROCEDURES

1. Remove glove box. Refer to IP-11, "Removal and Installation" .

2. Remove filter cover.

3. Take out air conditioner filter from blower unit.

4. Replace with new one and reinstall on blower unit.

5. Reinstall glove box.

SJIA0446E

SJIA0447E

Page 3309 of 4555

HEATER & COOLING UNIT ASSEMBLY

ATC-131

C

D

E

F

G

H

I

K

L

MA

B

AT C

HEATER & COOLING UNIT ASSEMBLYPFP:27110

Removal and InstallationEJS000UT

REMOVAL

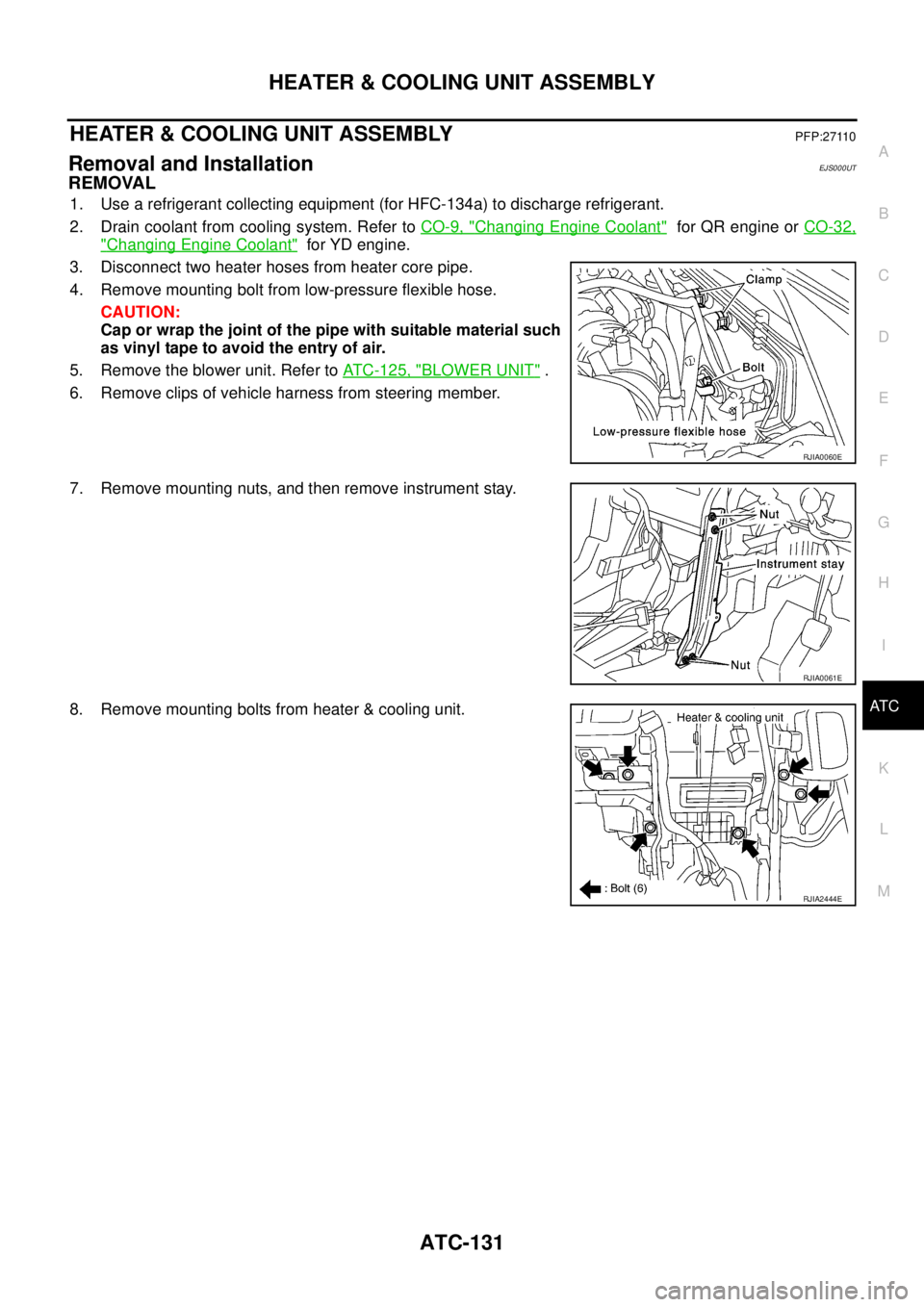

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge refrigerant.

2. Drain coolant from cooling system. Refer to CO-9, "

Changing Engine Coolant" for QR engine or CO-32,

"Changing Engine Coolant" for YD engine.

3. Disconnect two heater hoses from heater core pipe.

4. Remove mounting bolt from low-pressure flexible hose.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

5. Remove the blower unit. Refer to ATC-125, "

BLOWER UNIT" .

6. Remove clips of vehicle harness from steering member.

7. Remove mounting nuts, and then remove instrument stay.

8. Remove mounting bolts from heater & cooling unit.

RJIA0060E

RJIA0061E

RJIA2444E

Page 3310 of 4555

ATC-132

HEATER & COOLING UNIT ASSEMBLY

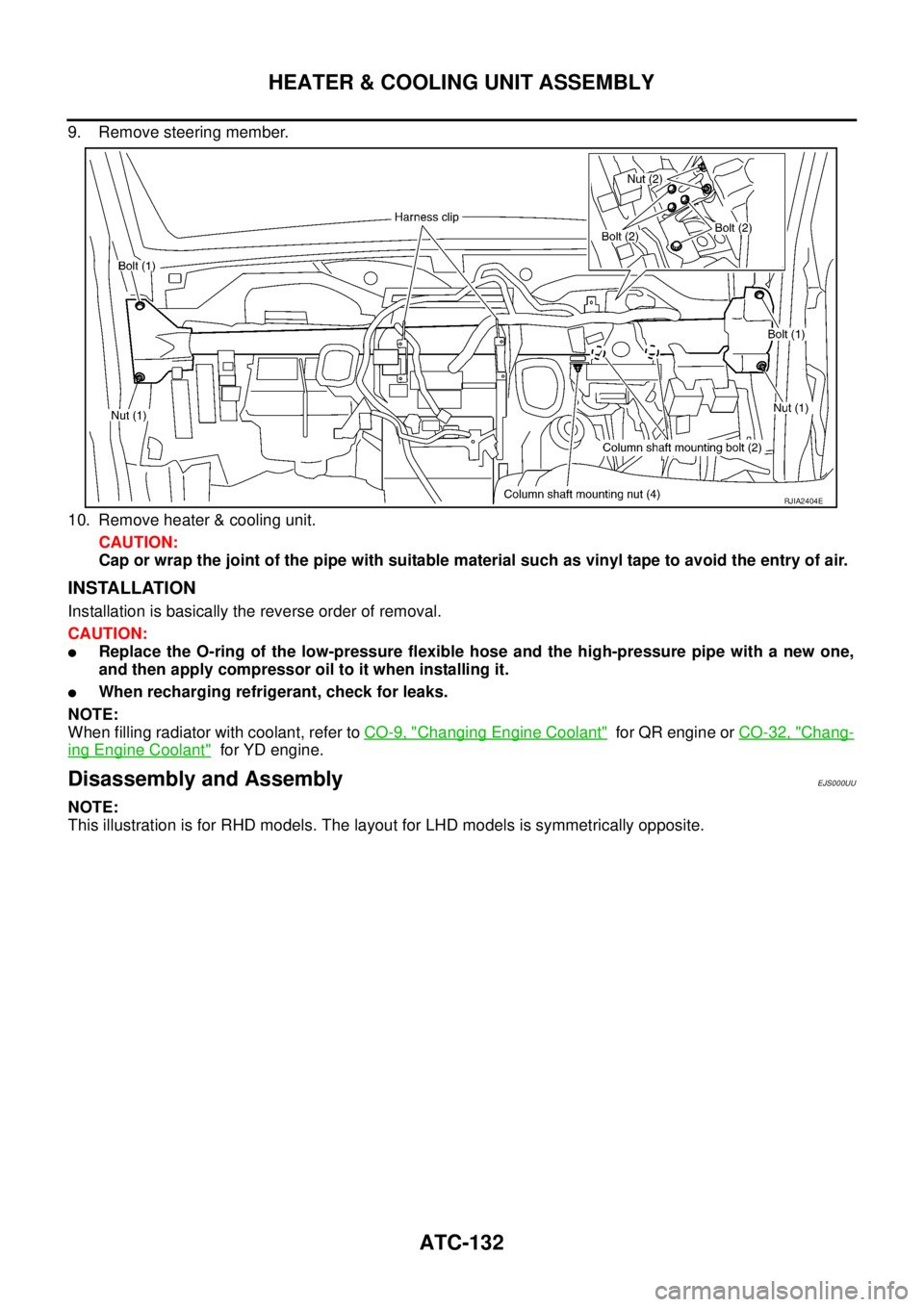

9. Remove steering member.

10. Remove heater & cooling unit.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

�Replace the O-ring of the low-pressure flexible hose and the high-pressure pipe with a new one,

and then apply compressor oil to it when installing it.

�When recharging refrigerant, check for leaks.

NOTE:

When filling radiator with coolant, refer to CO-9, "

Changing Engine Coolant" for QR engine or CO-32, "Chang-

ing Engine Coolant" for YD engine.

Disassembly and AssemblyEJS000UU

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

RJIA2404E

Trending: BRC-26, maintenance schedule, Evap, DTC P0444 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE, muffler, Cp pulley, troubleshooting