Oldsmobile Achieva 1997 Owner's Manuals

Manufacturer: OLDSMOBILE, Model Year: 1997, Model line: Achieva, Model: Oldsmobile Achieva 1997Pages: 372, PDF Size: 18.52 MB

Page 331 of 372

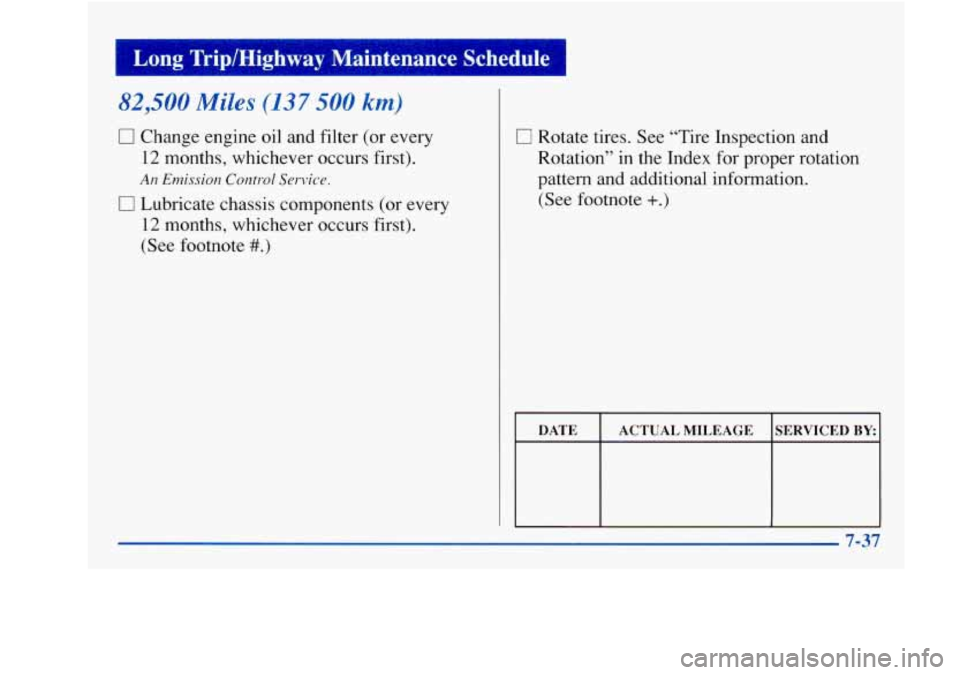

Long Trip/Highway Maintenance Schedule

82,500 Miles (137 500 km)

0 Change engine oil and filter (or every

12 months, whichever occurs first).

An Emission Control Service.

0 Lubricate chassis components (or every

12 months, whichever occurs first).

(See footnote

#.)

0 Rotate tires. See “Tire Inspection and

Rotation”

in the Index for proper rotation

pattern and additional information.

(See footnote

+.)

I DATE I ACTUAL MILEAGE SERVICED BY

7-37

Page 332 of 372

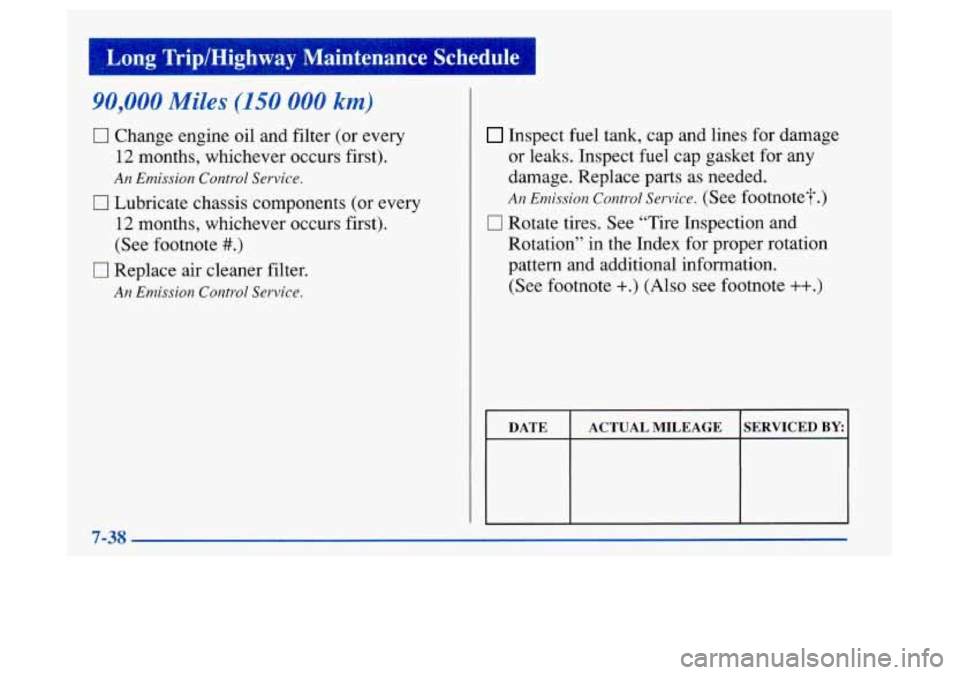

1 Long Trip/Highway Maintenance Schedule

90,000 Miles (150 000 km)

0 Change engine oil and filter (or every

12 months, whichever occurs first).

17 Lubricate chassis components (or every

12 months, whichever occurs first).

(See footnote

#.)

An Emission Control Service.

0 Replace air cleaner filter.

An Emission Control Service.

Inspect fuel tank, cap and lines for damage

or leaks. Inspect fuel cap gasket for any

damage. Replace parts as needed.

An Emission Control Service. (See footnote?.)

0 Rotate tires. See “Tire Inspection and

Rotation” in the Index for proper rotation

pattern and additional information.

(See footnote

+.) (Also see footnote ++.)

DATE ACTUAL MILEAGE SERVICED BY:

7-38

Page 333 of 372

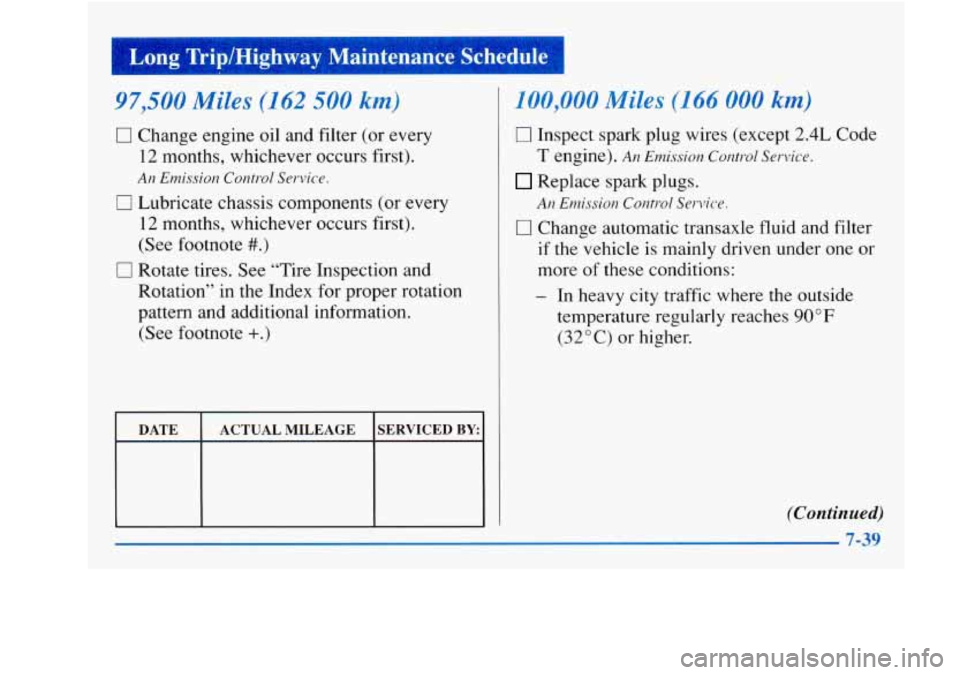

97,500 Miles (162 500 km)

0 Change engine oil and filter (or every

12 months, whichever occurs first).

An Emission Control Service.

0 Lubricate chassis components (or every

12 months, whichever occurs first).

(See footnote

#.)

0 Rotate tires. See “Tire Inspection and

Rotation’’ in the Index for proper rotation

pattern and additional information.

(See footnote

+.)

I DATE I ACTUAL MILEAGE lSERYICED BY I

100,000 Miles (166 000 km)

0 Inspect spark plug wires (except 2.4L Code

Replace spark plugs.

0 Change automatic transaxle fluid and filter

if the vehicle

is mainly driven under one or

more of these conditions:

T engine).

An Emission

Control Service.

An Enzission Control Service.

- In heavy city traffic where the outside

temperature regularly reaches

90 OF

(32 O C) or higher.

(Continued)

7-39

Page 334 of 372

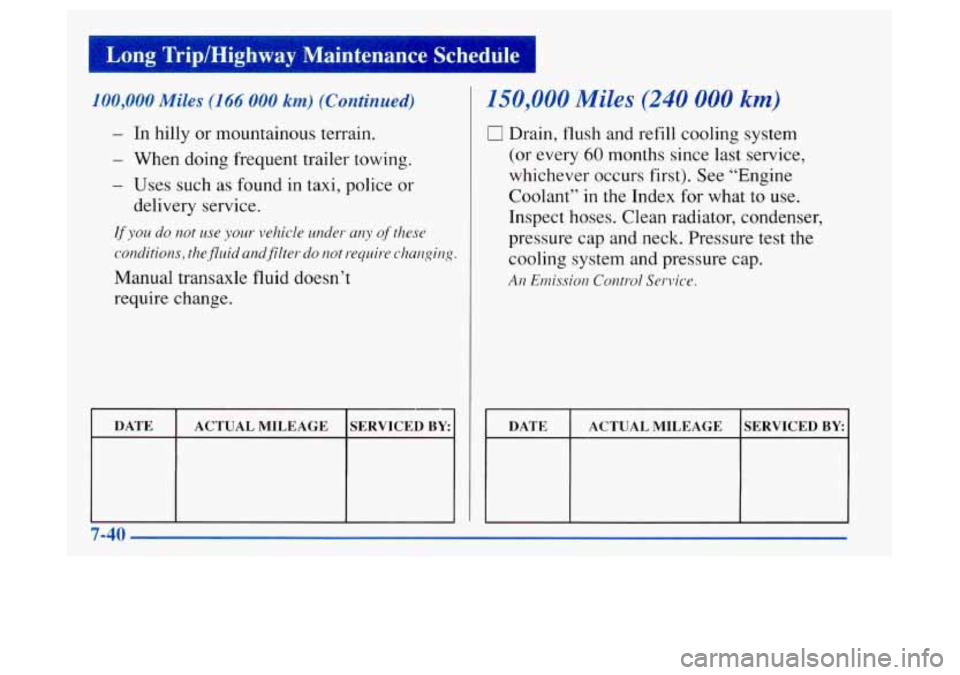

LUII~ Trip/High LY Maintenance Schedule

100,000 --Xes (1 66 000 km) (Continued)

- In hilly or mountainous terrain. wing.

- When doing frequent trailer to

- Uses such as found in taxi, pol

delivery service. ice or

If you do

not use your vehicle under any of these

conditions, the.fluid and.filtep. do not require changing.

Manual transaxle fluid doesn’t

require change.

I 1 I I

DATE

SERVICED BY ACTUAL MILEAGE

150,000 Miles (240 000 km)

0 Drain, flush and refill cooling system

(or every

60 months since last service,

whichever occurs first). See “Engine

Coolant” in the Index for what to use.

Inspect hoses. Clean radiator, condenser,

pressure cap and neck. Pressure test the

cooling system and pressure cap.

An En.zissiol.2 Control Service.

DATE

SERVICED BY ACTUAL MILEAGE

7-40

Page 335 of 372

Part B: Owner Checks and Services

Listed below are owner checks and services which

should be performed at the intervals specified to help

ensure the safety, dependability and emission control

performance of your vehicle.

Be sure any necessary repairs are completed at once.

Whenever any fluids or lubricants

are added to your

vehicle, make sure

they are the proper ones, as shown in

Part

D.

At Each Fuel Fill

It is important for you or a service station attendant to

perform these underhood checks at each fuel fill.

Engine Oil Level Check

Check the engine oil level and add the proper oil if

necessary. See “Engine Oil” in the Index for

further details.

Engine Coolant Level Check

Check the engine coolant level and add DEX-COOL@

coolant mix if necessary. See “Engine Coolant’’ in the

Index for further details.

Windshield Washer Fluid Level Check

Check the windshield washer fluid level in the

windshield washer tank and add

the proper fluid if

necessary. See “Windshield Washer Fluid”

in the Index

for further details.

At Least Once a Month

Tire Inflation Check

Make sure tires are inflated to the correct pressures. See

“Tires” in the Index for further details.

Cassette Deck Service

Clean cassette deck. Cleaning should be done every

50 hours of tape play. See “Audio Systems” in the Index

for further details.

7-41

Page 336 of 372

At Least Twice a Year

Restraint System Check

Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages are

working properly. Look for any other loose or damaged

safety belt system parts. If you see anything that might

keep a safety belt system from doing its job, have it

repaired. Have any torn or frayed safety belts replaced.

Also look for any opened or broken air bag covers, and

have them repaired or replaced. (The air bag system

does not need regular maintenance.)

Wiper Blade Check

Inspect wiper blades for wear or cracking. Replace blade

inserts that appear worn or damaged or that streak or

miss areas of the windshield. Also see “Wiper Blades,

Cleaning” in

the Index.

Manual Transaxle Check

Check the transaxle fluid level; add if needed. See

“Manual Transaxle”

in the Index. Check for leaks. A fluid

loss may indicate a problem. Have the system inspected

and repaired if needed.

Automatic Transaxle Check

Check the transaxle fluid level; add if needed. See

“Automatic Transaxle” in the Index.

A fluid loss may

indicate a problem. Check the system and repair

if needed.

Hydraulic Clutch System Check

Check the fluid level in the clutch reservoir. See

“Hydraulic Clutch Fluid” in the Index. A fluid

loss in

this system could indicate a problem. Have the system

inspected and repaired at once.

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

specified in Part

D.

Body Lubrication Service

Lubricate all body door hinges. Also lubricate all hinges

and latches, including those for the hood, trunk lid,

glove box door and console door. Part

D tells you what

to use. More frequent lubrication may be required when

exposed to a corrosive environment.

7-42

Page 337 of 372

Starter Switch Check

When you are doing this check, the vehicle could

move suddenly. If it does, you or others could be

injured. Follow the steps below.

1. Before you start, be sure you have enough room

2. Firmly apply both the parking brake (see “Parking around the

vehicle.

Brake”

in the Index if necessary) and the regular brake.

NOTE:

Do not use the accelerator pedal, and be

ready to turn off the engine immediately if it starts.

3. On automatic transaxle vehicles, try to start the

engine in each gear. The starter should work only in

PARK

(P) or NEUTRAL (N). If the starter works in

any other position, your vehicle needs service.

On manual transaxle vehicles, put the shift lever in

NEUTRAL

(N), push the clutch down halfway and

try to start the engine. The starter should work only

when the clutch

is pushed down all the way to the

floor.

If the starter works when the clutch isn’t

pushed all the way down, your vehicle needs service.

Brake-Transaxle Shift Interlock (BTSI) Check

(Automatic Transaxle)

I

When you are doing this check, the vehicle could

move suddenly.

If it does, you or others could be

injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked

on a

level surface.

2. Firmly apply the parking brake (see “Parking Brake”

in the Index if necessary).

NOTE: Be ready to apply the regular brake

immediately

if the vehicle begins to move.

3. With the engine off, turn the key to the RUN

position, but don’t start

the engine. Without applying

the regular brake, try to move the shift lever out of

PARK (P) with normal effort. If the shift lever

moves out of PARK (P), your vehicle’s

BTSI

needs service.

7-43

Page 338 of 372

Ignition Transaxle Lock Check

While parked, and with the parking brake set, try to turn

the ignition key to LOCK in each shift lever position.

With an automatic transaxle, the key should turn to

LOCK only when the shift lever is in PARK (P).

With a manual transaxle, the key should turn to LOCK

only when the shift lever is in REVERSE (R).

On vehicles with

a key release button, try to turn the key

to

LOCK without pressing the button. The key should

turn to

LOCK only when you press the key button.

On all vehicles, the key should come out only

in LOCK.

Parking Brake and Automatic Transaxle PARK (P)

Mechanism Check

When you are doing this check, your vehicle

could begin

to move. You or others could be

injured and property could be damaged. Make

sure there

is room in front of your vehicle in case

it begins to roll. Be ready to apply the regular

brake at once should the vehicle begin to move. Park

on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot

on the regular brake, set the

parking brake.

0

0

To check the parking brake’s holding ability: With

the engine running and transaxle in NEUTRAL

(N),

slowly remove foot pressure from the regular brake

pedal.

Do this until the vehicle is held by the parking

brake only.

To check the PARK (P) mechanism’s holding ability:

With the engine running, shift to PARK

(P). Then

release all brakes.

Underbody Flushing Service

At least every spring, use plain water to flush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

7-44

Page 339 of 372

Part C: Periodic Maintenance

Inspections

Listed below are inspections and services which should

be performed at least twice a year (for instance, each

spring and fall). You should let your GM retailer’s

service department or other qualified service center do

these jobs. Make sure any necessary repairs are

completed at once.

Proper procedures to perform these services may be

found in a

GM service manual. See “Service and Owner

Publications” in the Index.

Steering, Suspension and Front Drive Axle

Boot and Seal Inspection

Inspect the front and rear suspension and steering

system for damaged, loose or missing parts, signs of

wear

or lack of lubrication. Inspect the power steering

lines and hoses for proper hook-up, binding, leaks,

cracks, chafing, etc. Clean and then inspect the drive

axle boot seals for damage, tears or leakage. Replace

seals if necessary.

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body

near the exhaust system. Look for broken, damaged,

missing or out-of-position parts as well as open seams,

holes, loose connections or other conditions which could

cause a heat build-up in the

floor pan or could let

exhaust fumes into the vehicle. See “Engine Exhaust’’ in

the Index.

Radiator and Heater Hose Inspection

Inspect the hoses and have them replaced if they are

cracked, swollen or deteriorated. Inspect all pipes,

fittings and clamps; replace as needed.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

and for damage or missing parts. Replace parts as

needed. Replace any cables that have high effort

or

excessive wear. Do not lubricate accelerator and cruise

control cables.

7-45

Page 340 of 372

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses for proper hook-up, binding, leaks, cracks,

chafing, etc. Inspect disc brake pads for wear and rotors

for surface condition. Also inspect drum brake linings

for wear and cracks. Inspect other brake parts, including

drums, wheel cylinders, calipers, parking brake, etc. The

parking brake is self-adjusting

and no manual

adjustment is required. You

may need to have your

brakes inspected more often if your driving habits or

conditions result in frequent braking.

CalipedKnuckle Maintenance Inspection

If you operate your vehicle in a highly corrosive

environment, as indicated

by the shaded areas on the

map following this text, your vehicle may require

additional brake service. Refer to the appropriate

GM

Service Bulletin for the proper caliper inspection

procedure.

As necessary, caliper pins and knuckle brake pad

abutments should be lubricated at every other tire

rotation. Also, see your

GM retailer’s service

department or qualified service center for

additional information.

7-46