steering Oldsmobile Aurora 1998 s Owner's Guide

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 1998, Model line: Aurora, Model: Oldsmobile Aurora 1998Pages: 380, PDF Size: 19.75 MB

Page 250 of 380

If Youâre Stuck: In Sand, Mud,

Ice or Snow

What you donât want to do when your vehicle is stuck is

to spin your wheels too fast. The method known as

ârockingâ

can help you get out when youâre stuck, but

you must use caution.

If you let your tires spin at high speed, they can

explode, and you or others could be injured. And,

the transaxle or other parts of the vehicle can

overheat. That could cause an engine

compartment fire

or other damage. When youâre

stuck, spin the wheels as little as possible.

Donât

spin the wheels above 35 mph (55 km/h) as shown

on the speedometer.

NOTICE:

Spinning your wheels can destroy parts of your

vehicle as well as the tires. If you spin the wheels

too

fast while shifting your transaxle back and

forth, you can destroy your transaxle.

For information about using tire chains on your vehicle,

see âTire Chainsâ in the Index.

Rocking Your Vehicle To Get It Out

First, turn your steering wheel left and right. That will

clear the area around your fiont wheels.

You should turn

your traction control system off. (See âTraction Control

Systemâ

in the Index.) Then shift back and forth

between REVERSE (R) and a forward gear, spinning the

wheels as little as possible. Release the accelerator pedal

while you shift, and press lightly on the accelerator

pedal when the transaxle

is in gear. If that doesnât get

you out after a few tries, you may need to be towed out.

If you do need to be towed out, see âTowing Your

Vehicleâ in the Index.

5-34

I

I

Page 258 of 380

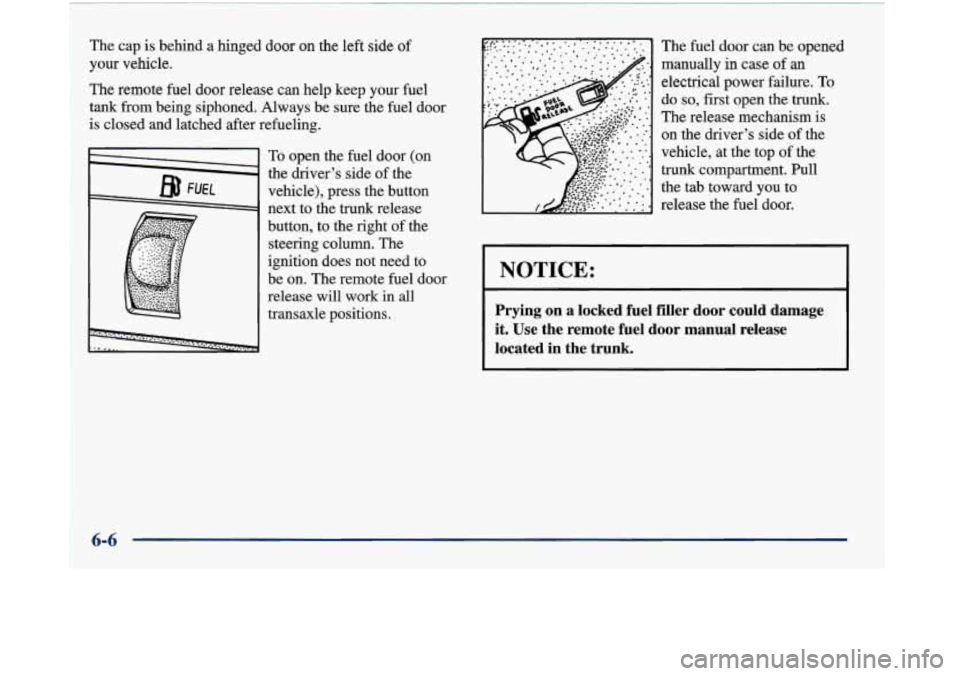

The cap is behind a hinged door on the left side of

your vehicle.

The remote fuel door release can help keep your fuel

tank from being siphoned. Always be sure the fuel door

is closed and latched after refueling.

To open the fuel door (on

the driver's side of the

vehicle), press the button

next to the trunk release

button, to the right of the

steering column. The

ignition does not need to

be

on. The remote fuel door

release will work in all

transaxle positions. The fuel

door can

be opened

manually in case

of an

electrical power failure. To

do so, first open the trunk.

The release mechanism is

on the driver's side

of the

vehicle, at the top

of the

trunk compartment. Pull

the tab toward you to

release the

fuel door.

NOTICE:

Prying on a locked fuel filler door could damage

it. Use the remote fuel door manual release

located

in the trunk.

6-6

Page 261 of 380

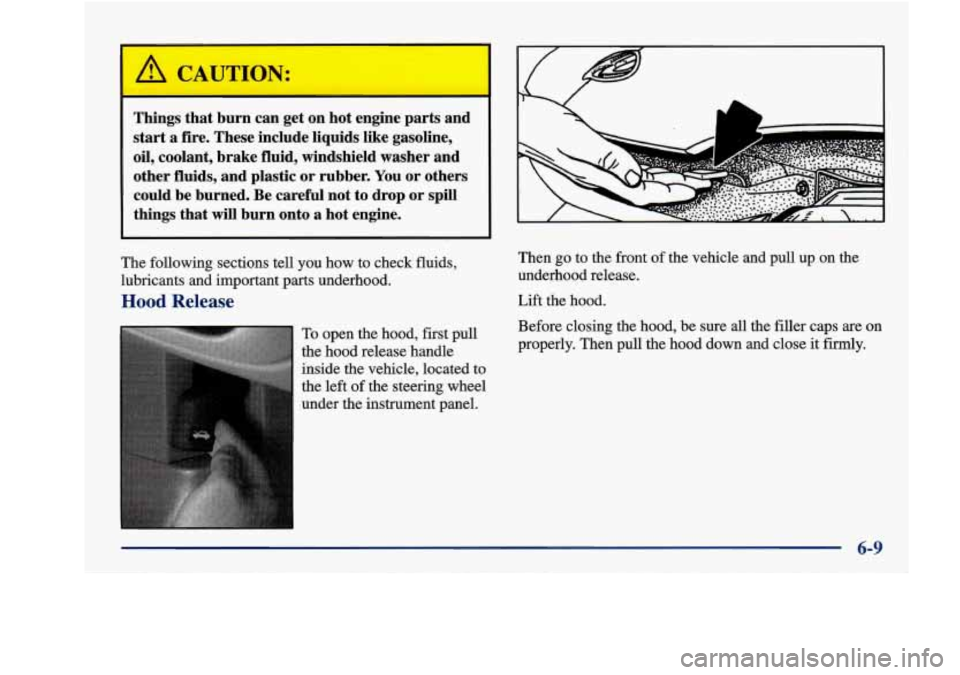

I A CAUTION:

Things that burn can get on hot engine parts and

start a fire. These include liquids like gasoline,

oil, coolant, brake fluid, windshield washer and

other fluids, and plastic or rubber. You or others

could be burned. Be careful not to drop or spill

things that will burn onto a hot engine.

The following sections tell you how to check fluids,

lubricants and important parts underhood.

Hood Release

To open the hood, first pull

the hood release handle

inside the vehicle, located to

the left of the steering wheel

under the instrument panel. Then

go to the front

of the vehicle and pull up on the

underhood release.

Lift the hood.

Before closing the hood, be sure

all the filler caps are on

properly. Then pull the hood down and close it fiiy.

6-9

Page 262 of 380

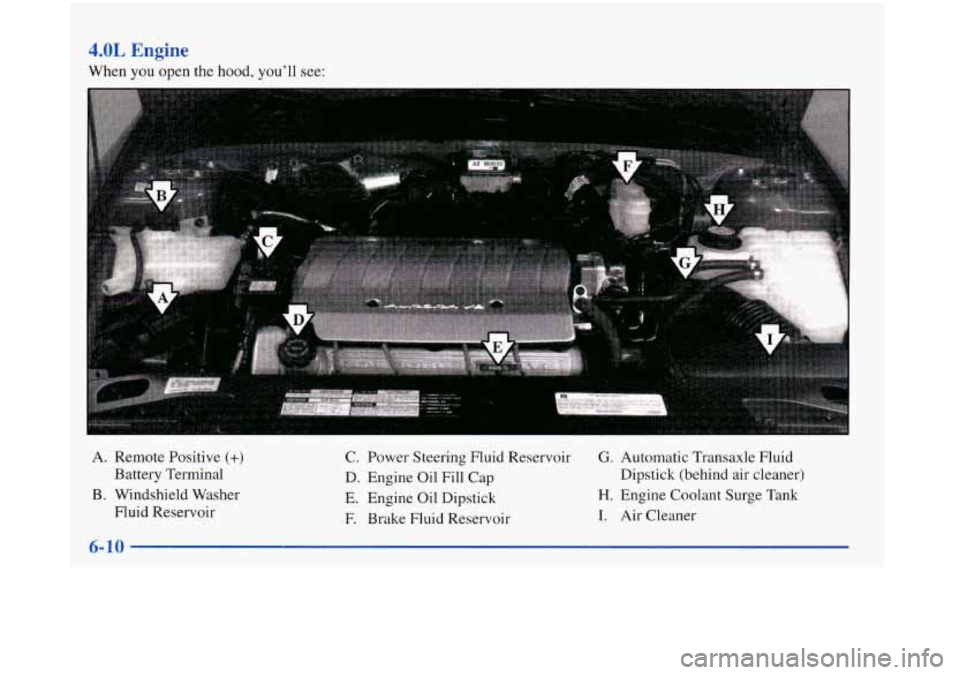

4.0L Engine

When you open the hood, you'll see:

A. Remote Positive (+)

Battery Terminal

B. Windshield Washer

fluid Reservoir

C. Power Steering Fluid Reservoir G. Automatic Transaxle Fluid

D. Engine Oil Fill Cap Dipstick

(behind air cleaner)

E. Engine Oil Dipstick H. Engine Coolant Surge Tank

E Brake Fluid Reservoir I. Air Cleaner

Page 277 of 380

A CAUTION:

You can be burned if you spill coolant on hot

engine parts. Coolant contains ethylene glycol,

and it

will burn if the engine parts are hot

enough. Donât spill coolant on a hot engine.

11

Power Steering Fluid

I I I

When replacing the pressure cap, make sure it is tight.

Thermostat

Engine coolant temperature is controlled by a thermostat

in the engine coolant system. The thermostat stops the

flow

of coolant through the radiator until the coolant

reaches a preset temperature.

When you replace your thermostat, a GM thermostat

is recommended.

When to Check Power Steering Fluid

It is not necessary to regularly check power steering

fluid unless you suspect there is a leak

in the system or

you hear an unusual noise.

A fluid loss in this system

could indicate a problem. Have the system inspected

and repaired.

6-25

Page 278 of 380

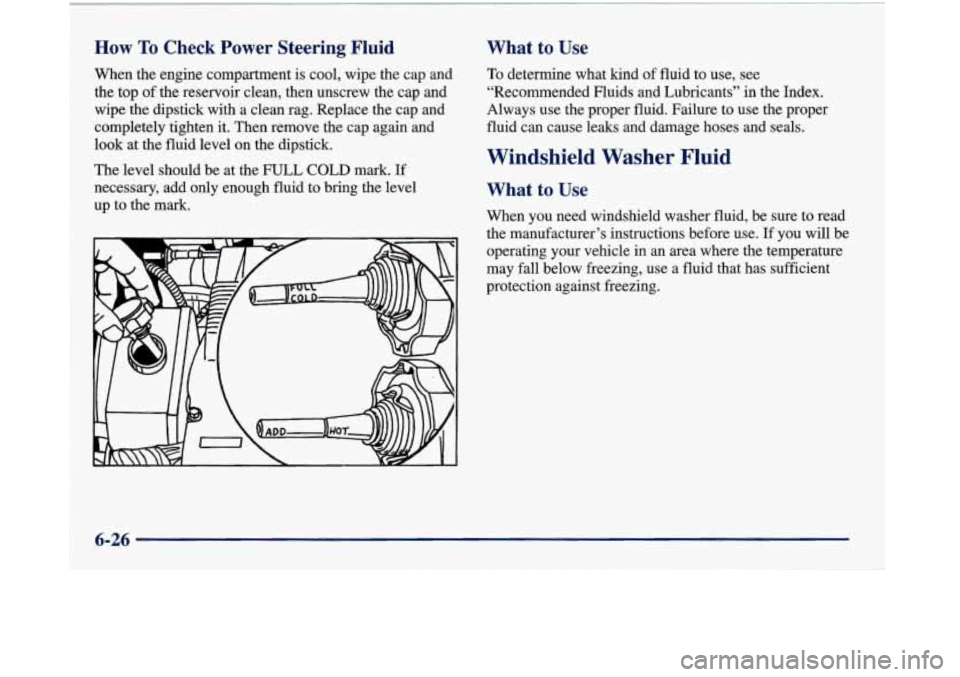

How To Check F wer Steering Fluid

When the engine compartment is cool, wipe the cap and

the top of the reservoir clean, then unscrew the cap and

wipe the dipstick with a clean rag. Replace the cap and

completely tighten it. Then remove the cap again and

look at the fluid level on the dipstick.

The level should be at the FULL COLD mark.

If

necessary, add only enough fluid to bring the level

up to the mark.

What to Use

To determine what kind of fluid to use, see

âRecommended Fluids and Lubricantsâ in the Index.

Always use the proper fluid. Failure to use the proper

fluid can cause leaks and damage hoses and seals.

Windshield Washer Fluid

What to Use

When you need windshield washer fluid, be sure to read

the manufacturerâs instructions before use. If you will be

operating your vehicle in an area where the temperature

may fall below freezing, use a fluid that has sufficient

protection against freezing.

6-26

Page 323 of 380

Power Steering

Pump Only ....................... 1 pint (0.5 L)

Complete System ............... 1.5 pints (0.7 L)

Tire Pressures ...... See Tire-Loading Information

label on the rear edge

of the driverâs doox

Wheel Nut Torque .......... 100 lb-ft (140 Nam)

Refrigerant (R=134a),

Air Conditioning

.... See refrigeran.t charge label

under the hood.

NOTE: All capacities are approximate. When adding,

be sure to fill

to the appropriate level as recommended

in this manual.

Air Conditioning Refrigerants

Not all air conditioning refrigerants are the same.

If the air conditioning system

in your vehicle needs

refrigerant, be sure the proper refrigerant is used.

If

youâre not sure, ask your retailer.

Engine Specifications

VIN Engine Code ........................... C

Type

.................................... V8

Displacement ............................. 4 L

Horsepower ............................. 250

Compression Ratio

...................... 10.3: 1

Firing Order ................... 1-2-7-3-4-5-6-8

Thermostat Temperature

Specification

................... 180°F (82°C)

Normal Maintenance

Replacement Parts

Air Cleaner Element .......... AC Type A-1096C

Engine Oil Filter

................ AC Type PF-58

Gap:

0.050 inch (1.52 mm)

Spark Plugs

................... AC Type 4

1-929

Windshield Wiper Blades

Type

............................... 6.32Pin

Length

..................... 22 inches (56 cm)

Page 324 of 380

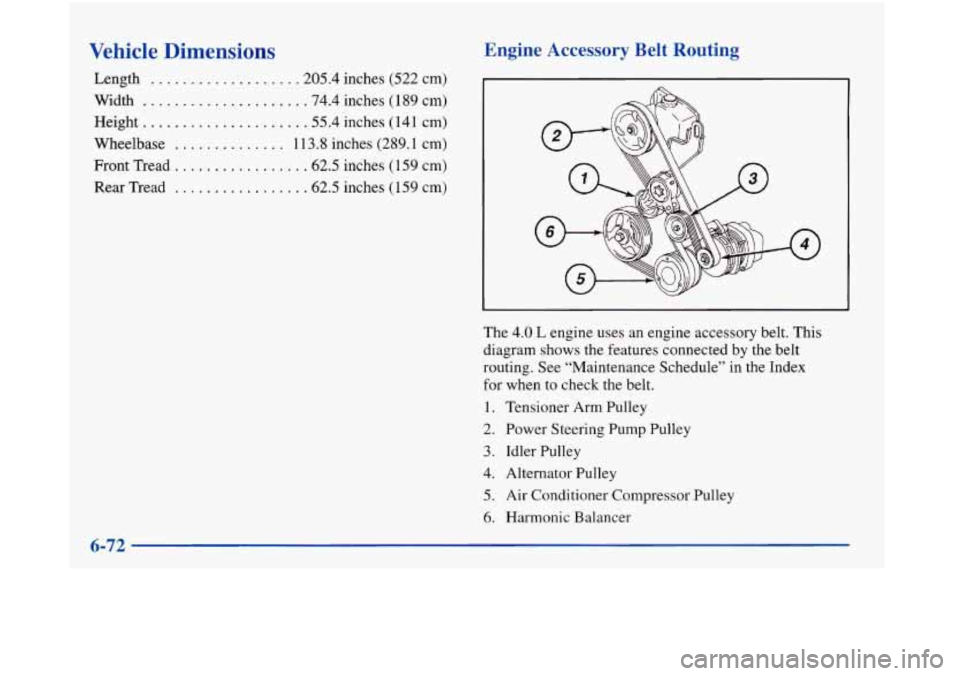

Vehicle Dimensions

Length .................. .205.4 inches (522 cm)

Width

.................... .74.4 inches (1 89 cm)

Height

.................... .55.4 inches (141 cm)

Wheelbase

.............. 1 13.8 inches (289.1 cm)

Front Tread

................ .62.5 inches (1 59 cm)

Rear Tread ................ .62.5 inches (159 cm)

Engine Accessory Belt Routing

The 4.0 L engine uses an engine accessory belt. This

diagram shows the features connected by the belt

routing. See âMaintenance Scheduleâ in the Index

for when to check the belt.

1. Tensioner Arm Pulley

2. Power Steering Pump Pulley

3. Idler Pulley

4. Alternator Pulley

5. Air Conditioner Compressor Pulley

6. Harmonic Balancer

Page 331 of 380

Maintenance Schedule

The services shown in this schedule up to 100,000 miles

(166 000 km) should be performed after 100,000 miles

(166

000 km) at the same intervals. The services shown

at 150,000 miles (240

000 km) should be performed at

the same interval after 150,000

miles (240 000 km).

See âOwner Checks and Servicesââ and âPeriodic

Maintenance Inspectionsâ following.

Footnotes

fâ The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicleâs useful life. We, however,

urge that all recommended maintenance services be

performed at

the indicated intervals and the maintenance

be recorded.

+ A good time to check your brakes is during tire

rotation.

See âBrake System Inspectionâ under âPeriodic

Maintenance Inspectionsâ in Part

C of this schedule.

# Lubricate the suspension and steering linkage,

transaxle shift linkage, parking brake cable guides

and underbody contact points and linkage.

* Your vehicle has an Engine Oil Life Monitor. This

monitor will show you when to change the engine oil

and filter

-- usually between 3,000 miles (5 000 km)

and 7,500 miles (12 500 km) since your last oil change.

Under severe conditions, the indicator may come on

before

3,000 miles (5 000 km). Never drive your vehicle

more than 7,500 miles (12 500 km) or 12 months

without an oil and filter change.

The system wonât detect dust in the oil.

So if you drive

in

a dusty area, be sure to change your oil and filter

every

3,000 miles (5 000 km) or sooner if the CHANGE

OIL SOON message appears. Remember to reset the

Oil Life Monitor when the oil has been changed. For

more information, see âEngine Oil Life Monitorâ in

the Index.

7-5

Page 344 of 380

Part C: Periodic

Maintenance Inspections

Listed below are inspections and services which should

be performed at least twice a year (for instance, each

spring and fall). You should let your retailerâs service

department or other qualified service center do these

jobs. Make sure any necessary repairs are completed

at once.

Proper procedures to perform these services may be

found

in a service manual. See âService and Owner

Publicationsâ in the Index.

Steering, Suspension and Front Drive

Axle Boot and Seal Inspection

Inspect the front and rear suspension and steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

lines and hoses for proper hook-up, binding, leaks,

cracks, chafing, etc. Clean and then inspect the drive

axle boot seals for damage, tears or leakage. Replace

seals if necessary.

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body

near the exhaust system. Look for broken, damaged,

missing or out-of-position parts as well as open seams,

holes, loose connections or other conditions which

could cause a heat build-up in the floor pan or could let

exhaust fumes into the vehicle. See âEngine Exhaustâ

in the Index.

Engine Cooling System Inspection

Inspect the hoses and have them replaced if they are

cracked, swollen or deteriorated. Inspect all pipes,

fittings and clamps; replace as needed. Clean the

outside of the radiator and air conditioning condenser.

To help ensure proper operation, a pressure test of the

cooling system and pressure cap is recommended at

least once a year.

7-18