brake Oldsmobile Bravada 2003 s Workshop Manual

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 2003, Model line: Bravada, Model: Oldsmobile Bravada 2003Pages: 410, PDF Size: 20.1 MB

Page 296 of 410

Brake Pedal Travel

The brake wear warning sound means that

soon your brakes won’t work well. That could

lead to an accident. When you hear the brake

wear warning sound, have your vehicle

serviced.

Notice: Continuing to drive with worn-out brake

pads could result

in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary

to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence

to GM torque specifications.

Brake linings should always be replaced as complete

axle sets.

See

Brake System Inspection on page 6-16.

See your dealer if the brake pedal does not return to

normal height, or

if there is a rapid increase in

pedal travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you make a brake stop, your disc brakes

adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have

to be of top quality and work well together if

the vehicle is to have really good braking. Your

vehicle was designed and tested with top-quality GM

brake parts. When you replace parts

of your braking

system

- for example, when your brake linings

wear down and you need new ones put in

- be sure

you get new approved GM replacement parts.

If

you don’t, your brakes may no longer work properly. For

example,

if someone puts in brake linings that are

wrong for your vehicle, the balance between your front

and rear brakes can change

- for the worse. The

braking performance you’ve come

to expect can change

in many other ways

if someone puts in the wrong

replacement brake parts.

5-37

Page 298 of 410

Jump Starting

If your battery has run down, you may want to use

another vehicle and some jumper cables to start your

vehicle. But please use the following steps

to do it

safely.

can be dangerous

* They contain acid that can burn you.

0 They contain gas that can explode or

* They contain enough electricity to

If you don’t follow these steps exactly, some

Notice: Ignoring these steps could result in costly

damage to your vehicle that wouldn’t be covered

by your warranty.

Trying to start your vehicle by pushing or pulling

it

won’t work, and it could damage your vehicle.

1. Check the other vehicle. It must have a 12-volt

battery with

a negative ground system.

Notice: If the other system isn’t a 12-volt system

with a negative ground, both vehicles can be damaged.

2. Get the vehicles close enough so the jumper cables

can reach, but be sure the vehicles aren’t touching

each other. If they are, it could cause a ground

connection you don’t want.

You wouldn’t be able to

start your vehicle, and the bad grounding could

damage the electrical systems.

To avoid the possibility of the vehicles rolling, set

the parking brake firmly on both vehicles involved in

the jump start procedure. Put an automatic

transmission in

PARK (P) or a manual transmission

in NEUTRAL before setting the parking brake. If

you have a four- wheel-drive vehicle, be sure

the transfer case is not in NEUTRAL.

Notice: If you leave your radio on, it could be badly

damaged. The repairs wouldn’t be covered by

your warranty.

3. Turn off the ignition on both vehicles. Unplug

unnecessary accessories plugged into the cigarette

lighter or accessory power outlets (if equipped).

Turn

off the radio and all lamps that aren’t needed.

This will avoid sparks and help

to save both

batteries. And it could save your radio!

5-39

Page 318 of 410

If you need to replace any of your wheels, wheel bolts

or wheel nuts, replace them only with new

GM

original equipment parts. This way, you will be sure to

have the right wheel, wheel bolts and wheel nuts

for your vehicle.

Lb CAUTION:

Using the wrong replacement wheels, wheel

bolts or wheel nuts on your vehicle can be

dangerous.

It could affect the braking and

handling

of your vehicle, make your tires lose

air and make you lose control. You could have

a collision in which you or others could be injured. Always use the correct wheel, wheel

bolts and wheel nuts for replacement.

Notice: The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or odometer calibration, headlamp aim, bumper height,

vehicle ground clearance and tire clearance to the body and chassis.

See

Changing a Flat Tire on page 5-62 for more

information.

Used Replacement Wheels

Putting a used wheel on 1 lr vehicle is

dangerous. You can’t know how it’s been used

or how far

it’s been driven. It could fail

suddenly and cause a crash. If you have to replace a wheel, use a new

GM original

equipment wheel.

5-59

Page 319 of 410

lire Chains

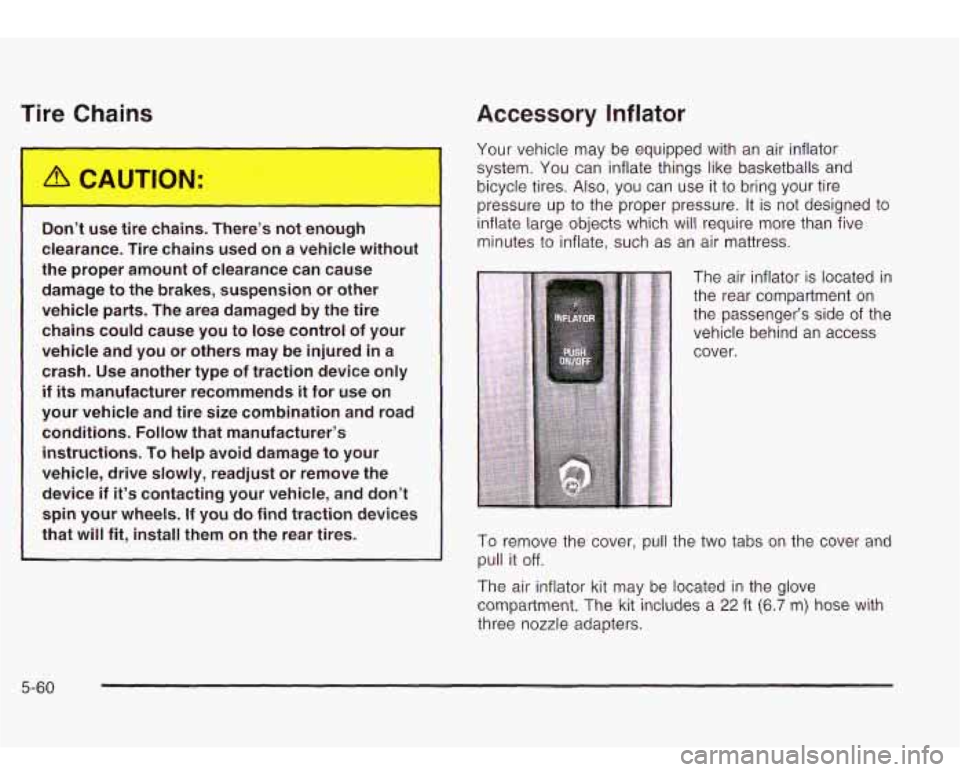

Accessory Inflator

I^

Do.. - use tire ch-..ls. There’s no- _.__ugh

clearance. Tire chains used on a vehicle without

the proper amount of clearance can cause

damage to the brakes, suspension or other

vehicle parts. The area damaged by the tire

chains could cause you to lose control of your

vehicle and you or others may be injured

in a

crash. Use another type of traction device only if

its manufacturer recommends it for use on

your vehicle and tire size combination and road

conditions. Follow that manufacturer’s instructions.

To help avoid damage to your

vehicle, drive slowly, readjust or remove the device

if it’s contacting your vehicle, and don’t

spin your wheels.

If you do find traction devices

that will fit, install them on the rear tires. Your

vehicle may be equipped with an air inflator

system. You can inflate things like basketballs and

bicycle tires.

Also, you can use it to bring your tire

pressure up to the proper pressure. It is not designed to

inflate large objects which will require more than five

minutes to inflate, such as an air mattress.

To remove the cover, pull the two tabs on the cover and

pull

it off.

The air inflator kit may be located in the glove

compartment. The kit includes a

22 ft (6.7 m) hose with

three nozzle adapters.

5-60

Page 320 of 410

To use the air inflator attach the appropriate nozzle

adapter to the end of the hose

if required. Then attach

that end of the hose to the object you wish to inflate.

Attach the other end of the hose to the outlet.

Press and release the switch to turn the air inflator on.

The indicator light will remain on when the inflator is

running.

The system has an internal clock to prevent overheating.

The system will allow about five minutes of running

time, then the compressor will stop. The indicator light

will then begin to flash. When the indicator is off,

the inflator can be started again by pressing the switch.

If the compressor is still hot,

it may only run for a

short time before shutting off again.

Press and release the switch to turn the inflator off.

Place the inflator kit

tools in the pouch and store

it properly. Remove the inflator hose from the outlet

during loading and unloading. Load leveling will

not function with the inflator hose attached

to the inflator

outlet. See ”Electronically Controlled Air Suspension

System” in the Index.

To reinstall the cover, line up the tabs at the back of the

cover, put it in place and latch the tabs.

A continuous flashing indicator light may also indicate a

malfunction in the air suspension system. See

“Electronically Controlled Air Suspension System” in the

Index.

Inllarlllg something too m,.-h can make it

explode, and you or others could be injured.

Be sure to read the inflator instructions, and

inflate any object only to its recommended

If a Tire Goes Flat

It’s unusual for a tire to “blowout” while you’re driving,

especially

if you maintain your tires properly. If air goes

out of a tire, it’s much more likely to leak out slowly.

But

if you should ever have a “blowout”, here are a few

tips about what to expect and what to do:

If a front tire fails, the flat tire will create a drag that

pulls the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

5-61

Page 321 of 410

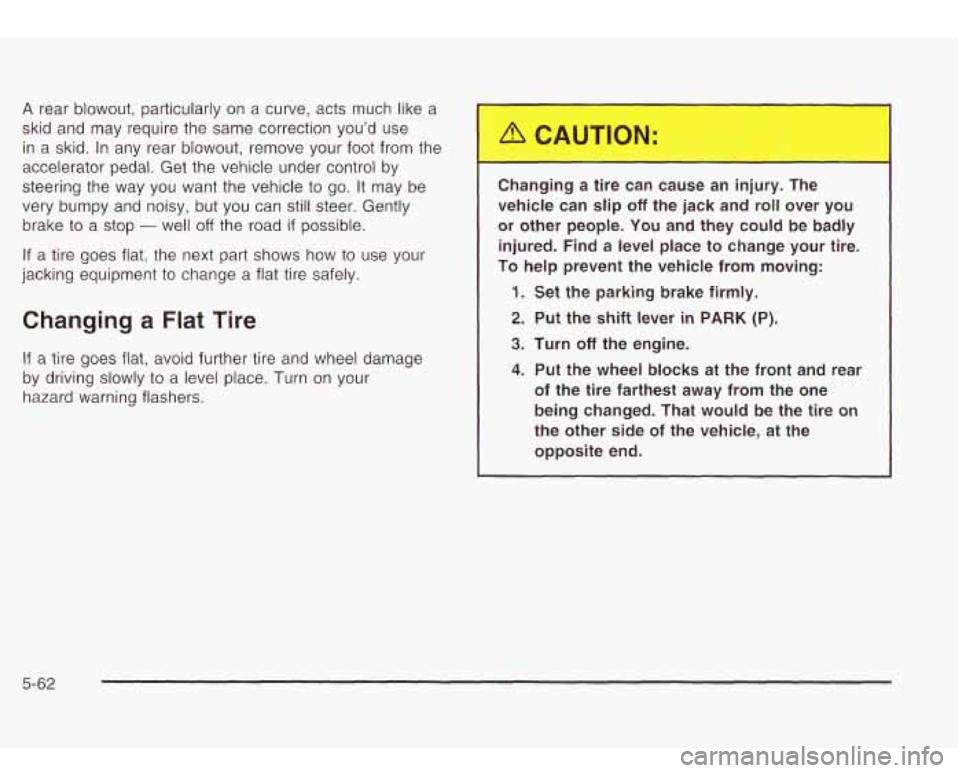

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you’d use

in a skid. In any rear blowout, remove your foot from the

accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle

to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake

to a stop - well off the road if possible.

If

a tire goes flat, the next part shows how to use your

jacking equipment

to change a flat tire safely.

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly

to a level place. Turn on your

hazard warning flashers. Cha..,ing

a tire can ca-.-e an injc.

,. The

vehicle can slip

off the jack and roll over you

or other people. You and they could be badly

injured. Find a level place to change your tire.

To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put the shift lever in PARK (P).

3. Turn off the engine.

4. Put the wheel blocks at the front and rear

of the tire farthest away from the one

being changed. That would be the tire on

the other side of the vehicle,

at the

opposite end.

5-62

Page 332 of 410

1

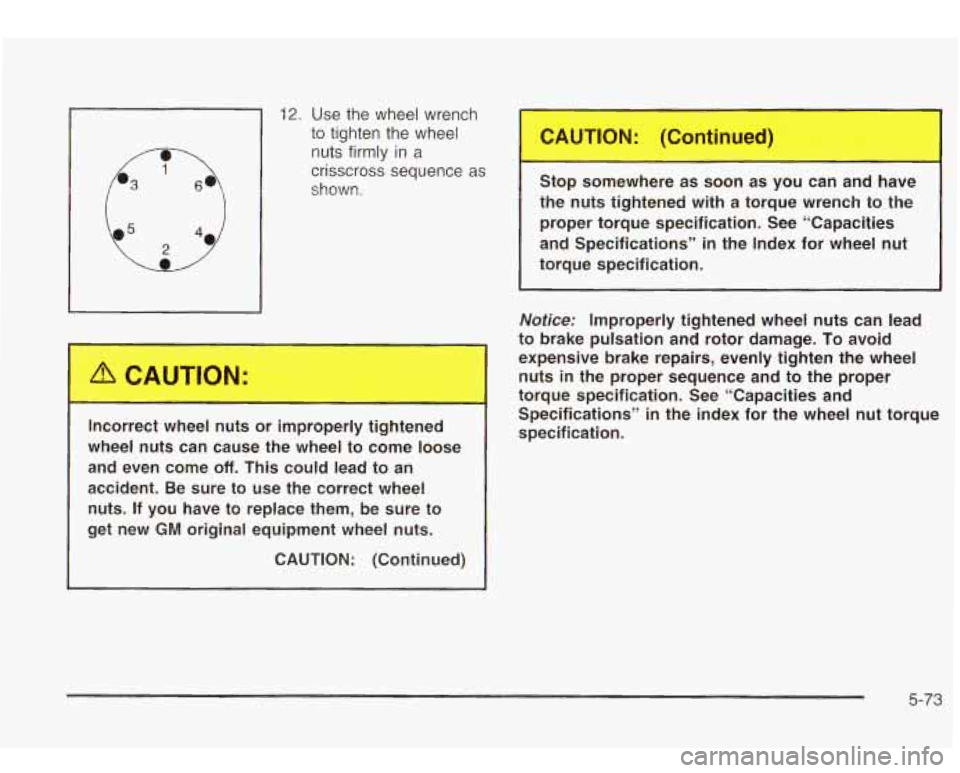

12. Use the wheel wrench

to tighten the wheel

nuts firmly in

a

crisscross sequence as

shown.

c

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come

off. This could lead to an

accident. Be sure to use the correct wheel nuts.

If you have to replace them, be sure to

get new GM original equipment wheel nuts.

I

CAUTION: (Continued) Stop somewhere as soon

as you can and have

the nuts tightened with a torque wrench to the

proper torque specification. See “Capacities

and Specifications”

in the Index for wheel nut

torque specification.

Notice: Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage.

To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification. See “Capacities and

Specifications”

in the index for the wheel nut torque

specification.

5-73

Page 348 of 410

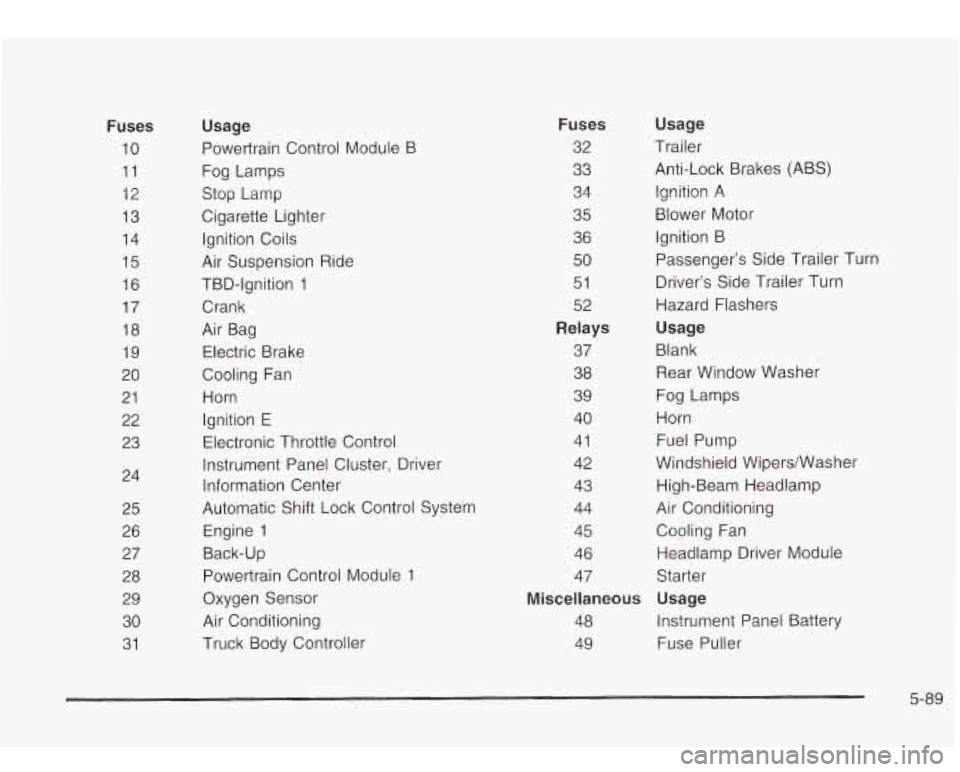

Fuses

10

11 12

13 14

15 16

17

18

19

20

21 22

23

24

25

26

27

28

29

30

31

Usage

Powertrain Control Module B

Fog Lamps

Stop Lamp

Cigarette Lighter

Ignition Coils

Air Suspension Ride

TBD-Ignition

1

Crank

Air Bag

Electric Brake

Cooling Fan

Horn Ignition

E

Electronic Throttle Control

Instrument Panel Cluster, Driver

Information Center

Automatic Shift Lock Control System

Engine 1

Back-up Powertrain Control Module 1

Oxygen Sensor

Air Conditioning

Truck Body Controller

Fuses

32

33

34

35

36

50

51

52

Relays

37

38

39

40

41

42

43

44

45

46 47

Usage

Trailer

Anti-Lock Brakes (ABS) Ignition A

Blower Motor Ignition B Passenger’s Side Trailer Turn

Driver’s Side Trailer Turn

Hazard Flashers

Usage

Blank Rear Window Washer

Fog Lamps

Horn Fuel Pump

Windshield WipersNasher

High-Beam Headlamp

Air Conditioning

Cooling Fan

Headlamp Driver Module

Starter

Miscellaneous Usage

48 Instrument Panel Battery

49 Fuse Puller

5-89

Page 351 of 410

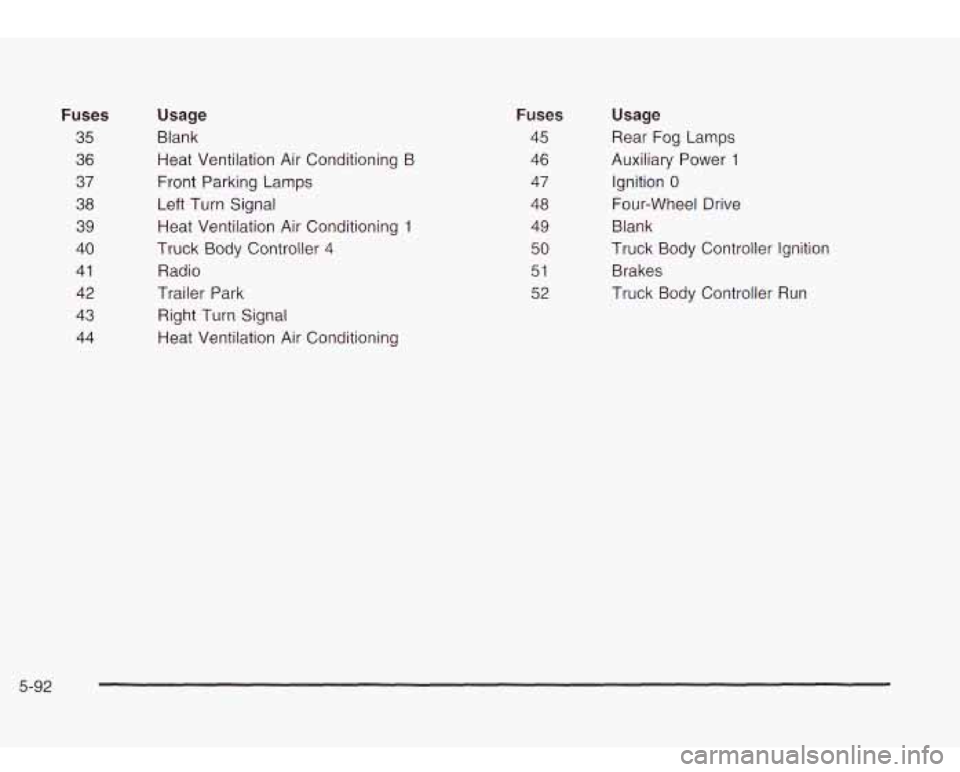

Fuses

35

36

37

38

39

40

41

42

43

44

Usage

Blank Heat Ventilation Air Conditioning B

Front Parking Lamps

Left Turn Signal Heat Ventilation Air Conditioning

1

Truck Body Controller 4

Radio

Trailer Park

Right Turn Signal

Heat Ventilation Air Conditioning

Fuses

45

46

47

48

49

50

51

52

Usage

Rear Fog Lamps

Auxiliary Power

1

Ignition 0

Four-wheel Drive

Blank

Truck Body Controller Ignition Brakes

Truck Body Controller Run

5-92

Page 354 of 410

6 Maintenance Schedule

Maintenance Schedule ...................................... 6-2

Introduction

................................................... 6-2

Maintenance Requirements

.............................. 6-2

How This Section is Organized ......................... 6-3

Part A: Scheduled Maintenance Services

........... 6-4

Using Your Maintenance Schedule

.................... 6-4

Scheduled Maintenance

................................... 6-5

Part

B: Owner Checks and Services ................ 6-10

At Each Fuel Fill

.......................................... 6-10

At Least Once a Month

................................. 6-10

At Least Twice a Year

................................... 6-11

Your

Vehicle and the Environment

.................... 6-2 At

Least Once a Year

................................... 6-12

Part

C: Periodic Maintenance Inspections ......... 6.15

Boot and Seal Inspection

............................ 6.15

Exhaust System Inspection

............................ 6.15

Fuel System Inspection

.................................. 6.15

Engine Cooling System Inspection

................... 6.15

Brake System Inspection

................................ 6-16

Part E: Maintenance Record

........................... 6.19

Steering, Suspension and Front Drive

Axle

Transfer Case and Front Axle

(All-Wheel Drive) Inspection

........................ 6.16

Part D: Recommended Fluids and Lubricants

.... 6-17

6- 1