brake rotor OLDSMOBILE SILHOUETTE 1996 Owners Manual

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 1996, Model line: SILHOUETTE, Model: OLDSMOBILE SILHOUETTE 1996Pages: 372, PDF Size: 19.39 MB

Page 243 of 372

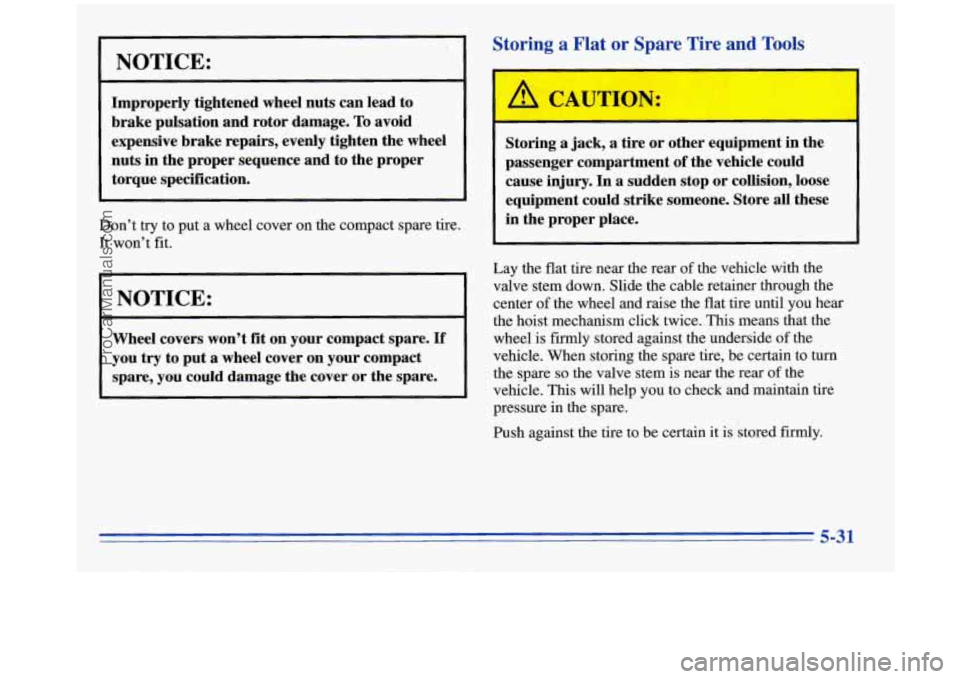

NOTICE:

Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage.

To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification.

Don’t try to put

a wheel cover on the compact spare tire.

It won’t fit.

NOTICE:

Wheel covers won’t fit on your compact spare. If

you try to put a wheel cover on your compact

spare, you could damage the cover or the spare.

Storing a Flat or Spare Tire and Tools

Storing a jack, a tire or other equipment in the

passenger compartment of the vehicle could

cause injury. In

a sudden stop or collision, loose

equipment could strike someone. Store all these

in the proper place.

Lay the flat tire near the rear of the vehicle with the

valve stem down. Slide the cable retainer through the

center of the wheel and raise the flat tire until you hear

the hoist mechanism click twice. This means that the

wheel is firmly stored against the underside of the

vehicle. When storing the spare tire, be certain to turn the spare

so the valve stem is near the rear of the

vehicle. This will help you to check and maintain tire

pressure

in the spare.

Push against the tire to be certain it is stored firmly.

5-31

ProCarManuals.com

Page 344 of 372

Part C: Periodic Maintenance

Inspections

Listed below are inspections and services which should

be performed at least twice a year (for instance, each

spring and fall).

You should let your GM retailer’s

service department or other qualified service center do

these jobs. Make sure any necessary repairs are

completed at once.

Proper procedures to perform these services may be

found

in an Oldsmobile Service Manual. See “Service

and Owner Publications’’ in the Index.

Steering, Suspension and Front-Wheel-Drive

Axle Boot and Seal Inspection

Inspect the front and rear suspension and steering system

for damaged, loose or missing parts, signs of wear or lack

of lubrication. Inspect the power steering lines and hoses

for proper hook-up, binding, leaks, cracks, chafing, etc.

Clean and then inspect the drive axle boot seals for

damage, tears or leakage. Replace seals if necessary.

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body

near the exhaust system. Look for broken, damaged,

missing or out-of-position parts as well as open seams, holes, loose connections

or other conditions which could

cause a heat build-up in the floor pan or could

let

exhaust fumes into the vehicle. See “Engine Exhaust’’ in

the Index.

Radiator anc d Heater Hose Inspection

Inspect the hoses and have them replaced if they are

cracked, swollen or deteriorated. Inspect all pipes,

fittings and clamps; replace as needed.

Throttle Linkage Inspect!. :

Inspect the throttle linkage for interrerence or binding,

and for damage or missing parts. Replace parts as

needed. Replace any cables that have high effort or

excessive wear.

Do not lubricate accelerator and cruise

control cables.

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses for proper hook-up, binding, leaks, cracks, chafing, etc. Inspect disc brake pads for wear and rotors

for surface condition.

Also inspect drum brake linings

for wear and cracks. Inspect other brake parts, including

drums, wheel cylinders, calipers, parking brake, etc.

Check parking brake adjustment. You may need to have

your brakes inspected more often

if your driving habits

or conditions result

in frequent braking.

ProCarManuals.com