service OPEL 1900 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 369 of 625

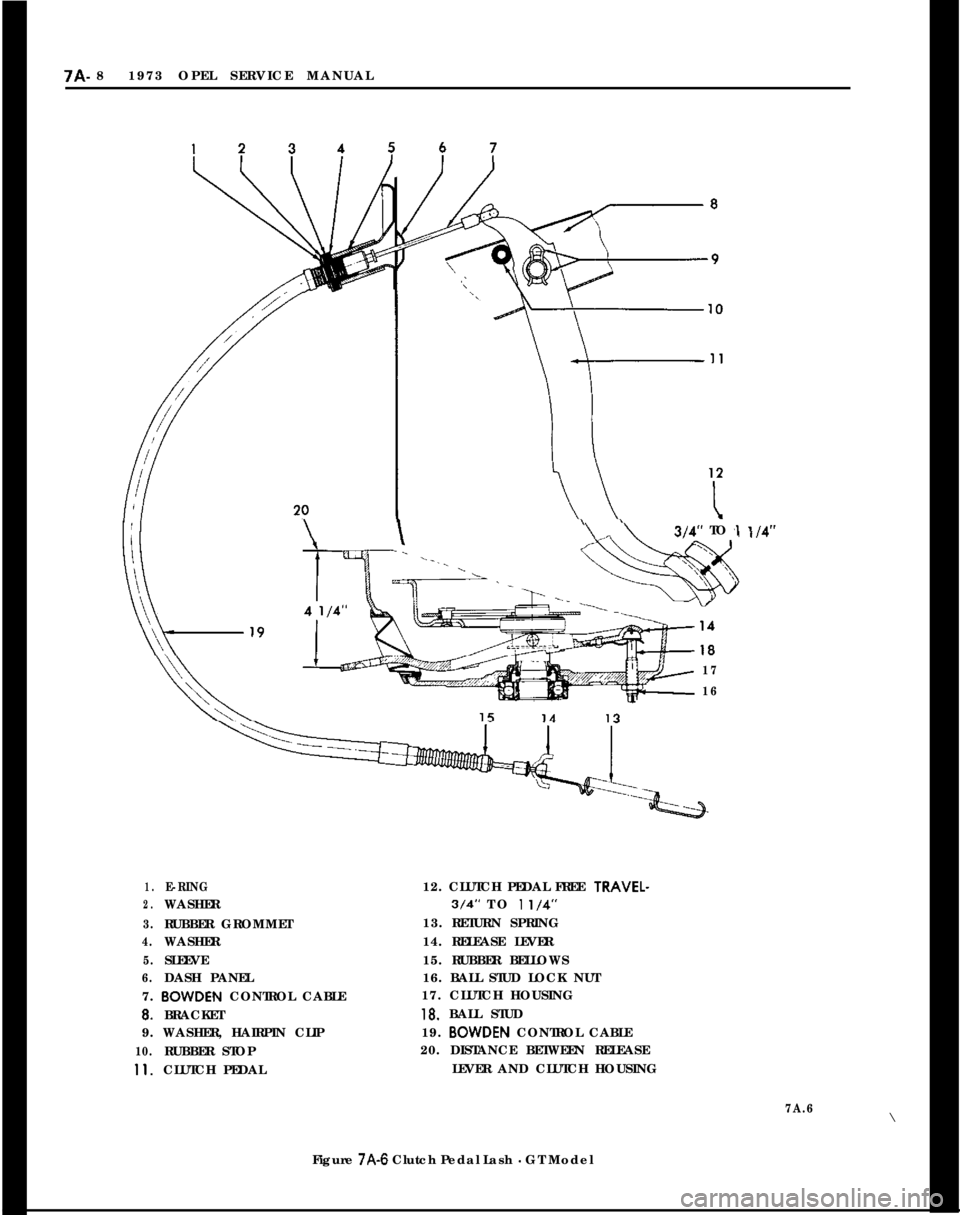

7A- 81973 OPEL SERVICE MANUAL\\“\314”TO ,l

17

16

1.E-RING12. CLUTCH PEDAL FREE TRAVEL-

2.WASHER3/4” TO 1 l/4”

3.RUBBER GROMMET13. RETURN SPRING

4.WASHER14. RELEASE LEVER

5.SLEEVE15. RUBBER BELLOWS

6.DASH PANEL16. BALL STUD LOCK NUT

7. BOWDEN CONTROL CABLE17. CLUTCH HOUSING

8.BRACKET18. BALL STUD

9. WASHER, HAIRPIN CLIP19. BOWDEN CONTROL CABLE

10.RUBBER STOP20. DISTANCE BETWEEN RELEASE

11.CLUTCH PEDALLEVER AND CLUTCH HOUSING

7A.6\

Figure

7A-6 Clutch Pedal Lash - GT Model

Page 371 of 625

7A- 101973 OPEL SERVICE MANUAL

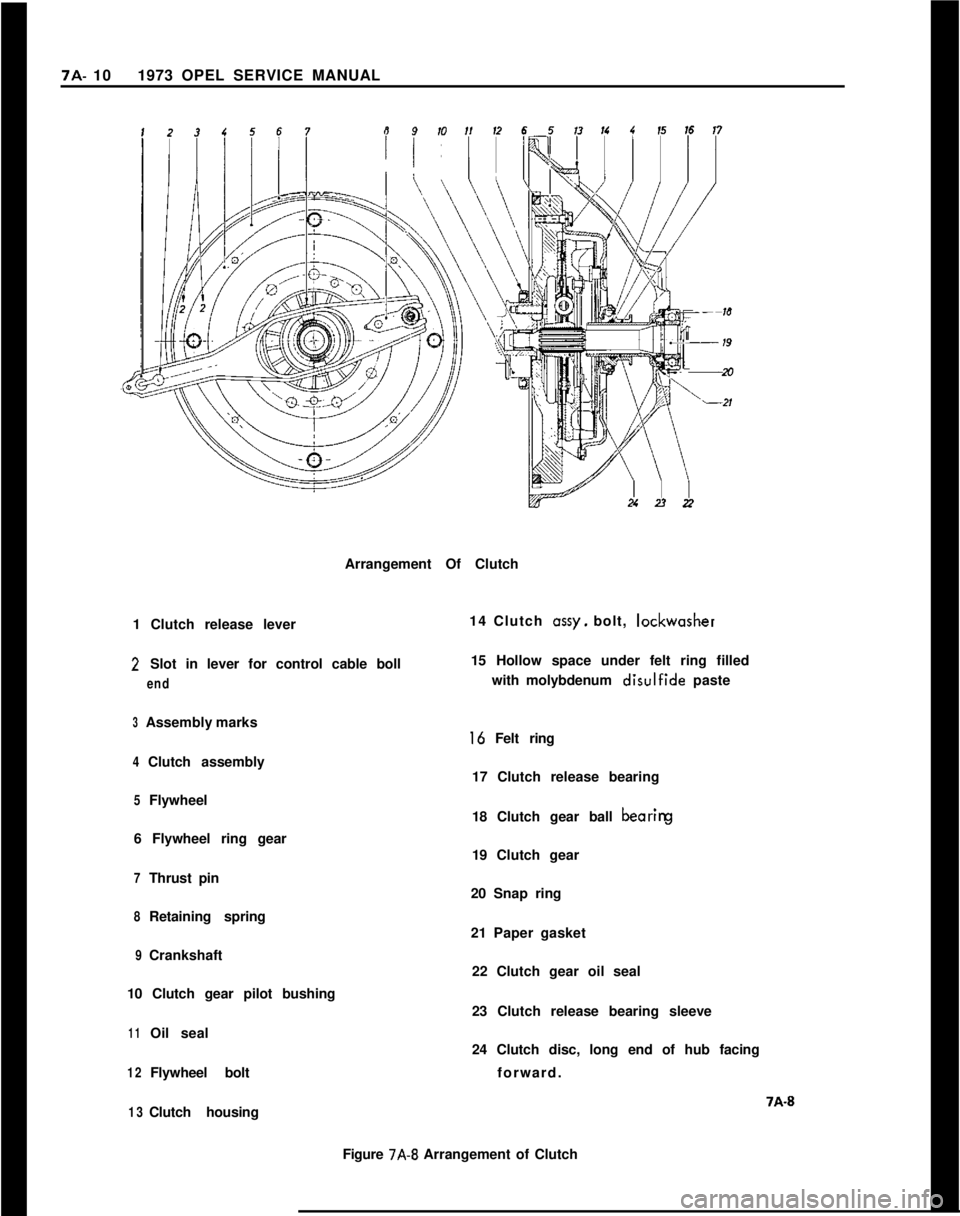

Arrangement Of Clutch

1 Clutch release lever14 Clutch ossy. bolt, lockwasher

2 Slot in lever for control cable boll15 Hollow space under felt ring filled

endwith molybdenum disulfide paste

3Assembly marks

4Clutch assembly

5Flywheel

6 Flywheel ring gear

7Thrust pin

8Retaining spring

9Crankshaft

10 Clutch gear pilot bushing

11Oil seal

12Flywheel bolt

13Clutch housing

16 Felt ring

17 Clutch release bearing

18 Clutch gear ball beorirq

19 Clutch gear

20 Snap ring

21 Paper gasket

22 Clutch gear oil seal

23 Clutch release bearing sleeve

24 Clutch disc, long end of hub facing

forward.

?A-8Figure

7A-8 Arrangement of Clutch

Page 373 of 625

7B- 121973 OPEL SERVICE MANUAL

MANUAL TRANSMISSION

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power

Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Adjusting

ReverseGearshiftBlocker. . . . . . . . . . . . . . . . . . . . . . . . . .Shift Lever Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ServicingGearshift

Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Transmission

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installation

ofTransmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removing and Installing

Speed0 Driven Gear

(Transmission

Removed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ReplacingBushinginSelectorLever. . . . . . . . . . . . . . . . . . . . . . . . . .Transmission

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Transmission

Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Specifications ..,....._....,......,.....,......,.,.....,,.,..,......,.,....,........

Page No.

78-12

7B-13

78-1978-l

9

7B-19

78-22

78-22

78-23

78-23

78-23

78-28

78-33

Page 375 of 625

7B- 141973 OPEL SERVICE MANUAL

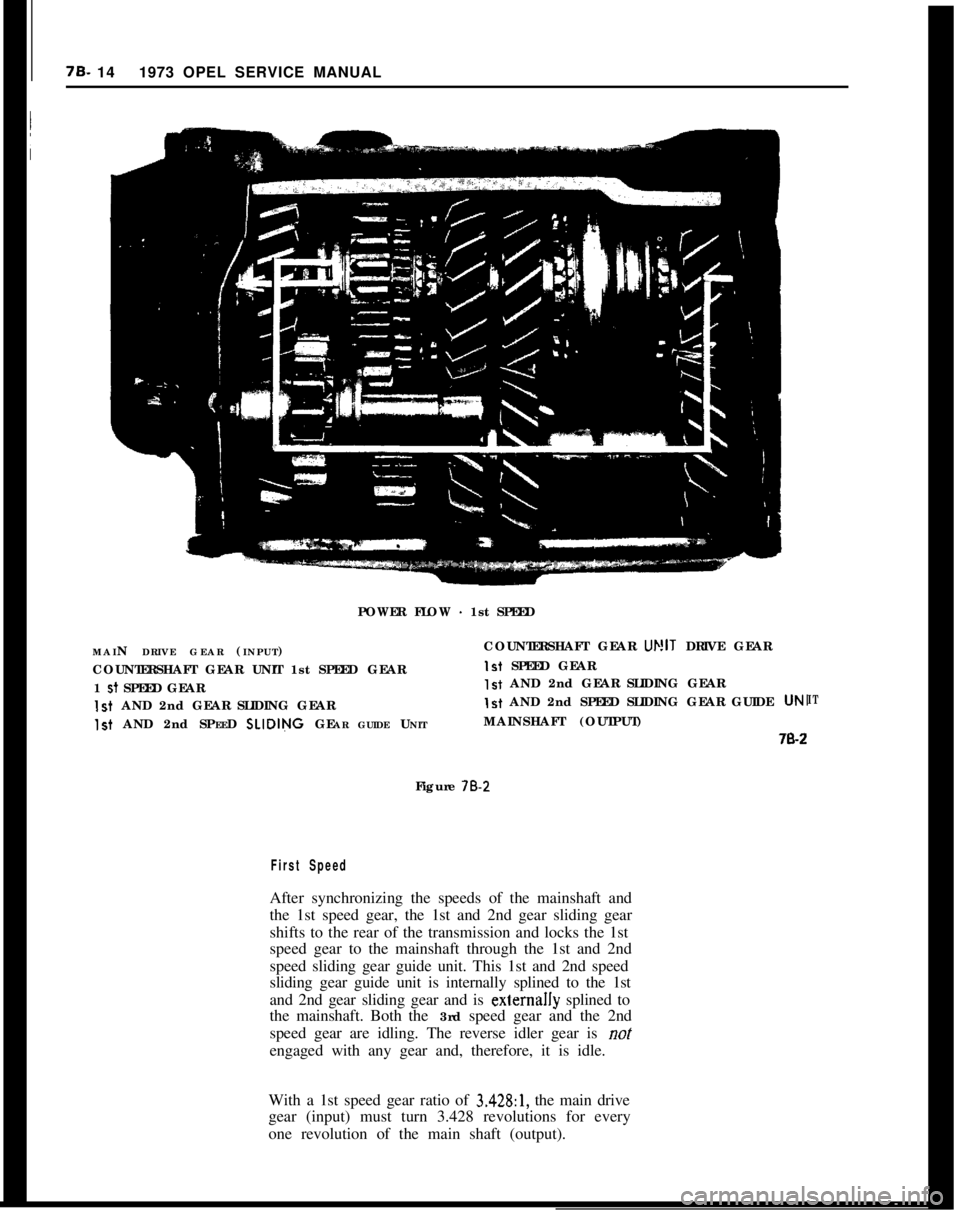

POWER FLOW - 1st SPEED

MAIN DRIVE GEAR (INPUT)

COUNTERSHAFT GEAR UNIT 1st SPEED GEAR

1 st SPEED GEAR

1st AND 2nd GEAR SLIDING GEAR1st AND 2nd SPEED SLIDING GEAR GUIDE UNITCOUNTERSHAFT GEAR

UI‘!IT DRIVE GEAR1st SPEED GEAR1st AND 2nd GEAR SLIDING GEAR

,st AND 2nd SPEED SLIDING GEAR GUIDE UN1MAINSHAFT (OUTPUT)

70-2Figure 78.2

First SpeedAfter synchronizing the speeds of the mainshaft and

the 1st speed gear, the 1st and 2nd gear sliding gear

shifts to the rear of the transmission and locks the 1st

speed gear to the mainshaft through the 1st and 2nd

speed sliding gear guide unit. This 1st and 2nd speed

sliding gear guide unit is internally splined to the 1st

and 2nd gear sliding gear and is

exl~ernally splined to

the mainshaft. Both the 3rd speed gear and the 2nd

speed gear are idling. The reverse idler gear is not

engaged with any gear and, therefore, it is idle.

With a 1st speed gear ratio of

3.428:1, the main drive

gear (input) must turn 3.428 revolutions for every

one revolution of the main shaft (output).

IT

Page 377 of 625

78. 161973 OPEL SERVICE MANUAL

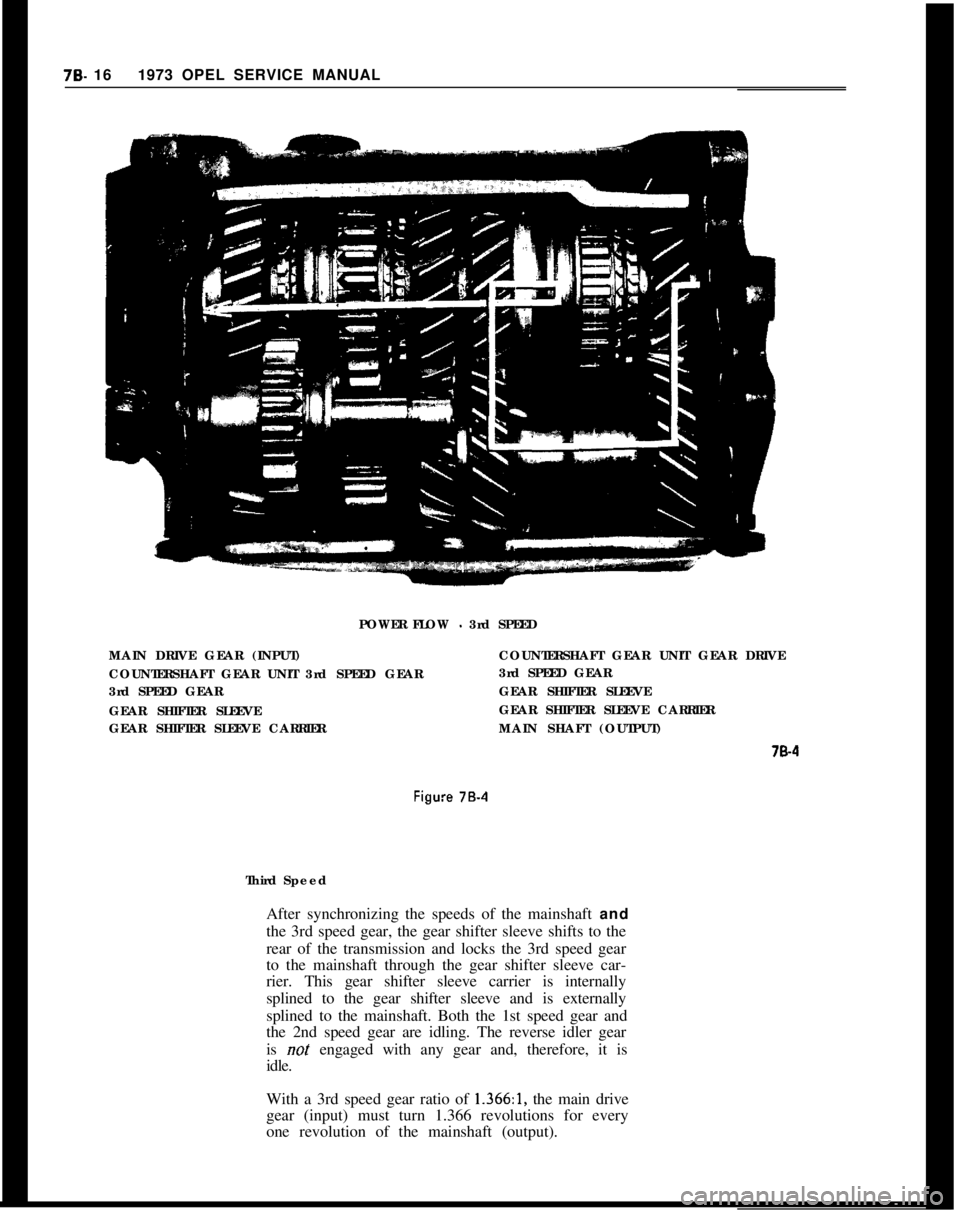

POWER FLOW

- 3rd SPEED

MAIN DRIVE GEAR (INPUT)

COUNTERSHAFT GEAR UNIT 3rd SPEED GEAR

3rd SPEED GEAR

GEAR SHIFTER SLEEVE

GEAR SHIFTER SLEEVE CARRIERCOUNTERSHAFT GEAR UNIT GEAR DRIVE

3rd SPEED GEAR

GEAR SHIFTER SLEEVE

GEAR SHIFTER SLEEVE CARRIER

MAIN SHAFT (OUTPUT)

78-4

Figure 78.4

Third Speed

After synchronizing the speeds of the mainshaft and

the 3rd speed gear, the gear shifter sleeve shifts to the

rear of the transmission and locks the 3rd speed gear

to the mainshaft through the gear shifter sleeve car-

rier. This gear shifter sleeve carrier is internally

splined to the gear shifter sleeve and is externally

splined to the mainshaft. Both the 1st speed gear and

the 2nd speed gear are idling. The reverse idler gear

is

not engaged with any gear and, therefore, it is

idle.

With a 3rd speed gear ratio of

1.366:1, the main drive

gear (input) must turn 1.366 revolutions for every

one revolution of the mainshaft (output).

Page 379 of 625

78.181973 OPEL SERVICE MANUAL

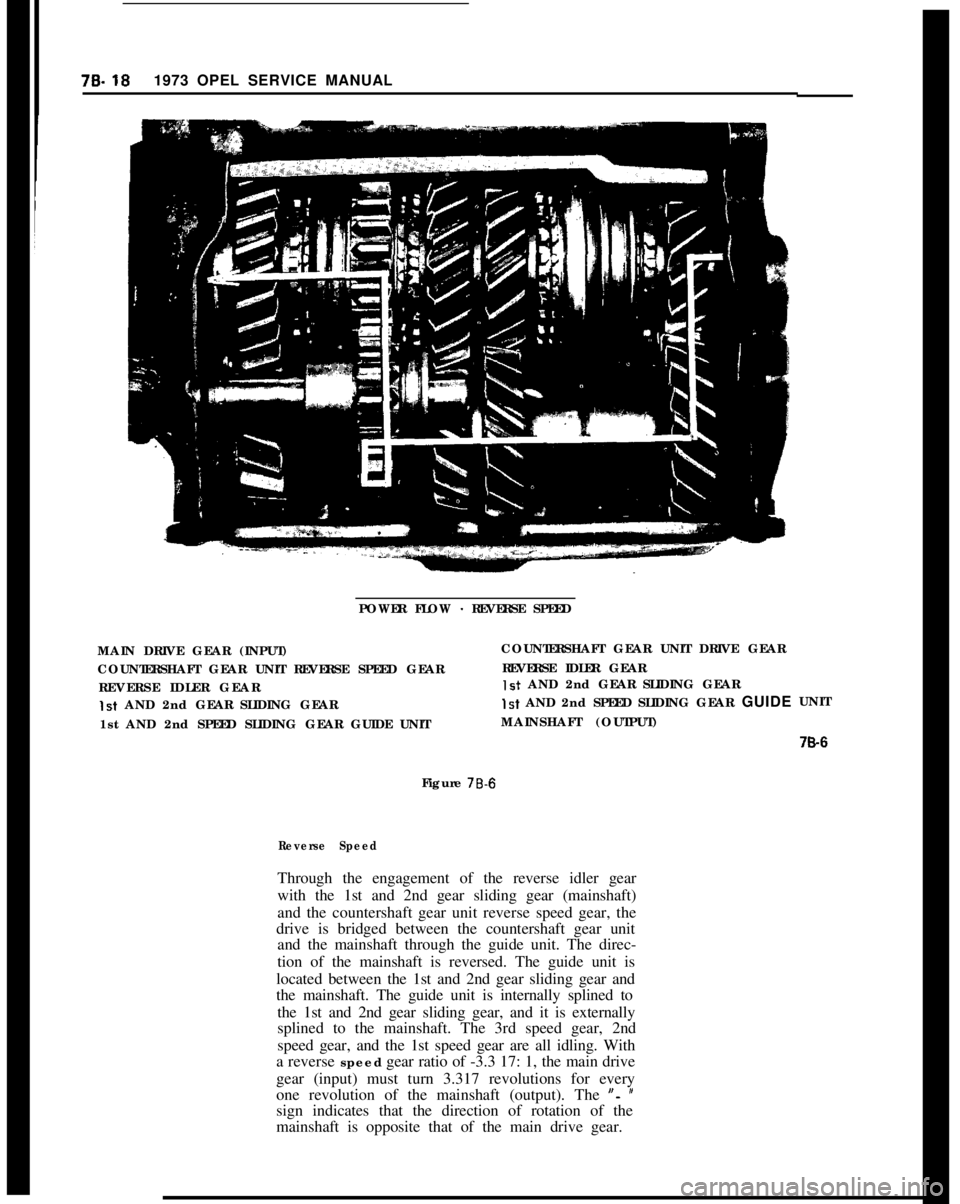

POWER FLOW

- REVERSE SPEED

MAIN DRIVE GEAR (INPUT)COUNTERSHAFT GEAR UNIT DRIVE GEAR

COUNTERSHAFT GEAR UNIT REVERSE SPEED GEARREVERSE IDLER GEAR

REVERSE IDLER GEAR

Is+ AND 2nd GEAR SLIDING GEAR

Is+ AND 2nd GEAR SLIDING GEAR,s+ AND 2nd SPEED SLIDING GEAR GUIDE

1st AND 2nd SPEED SLIDING GEAR GUIDE UNITMAINSHAFT (OUTPUT)

Figure 76.6

Reverse SpeedThrough the engagement of the reverse idler gear

with the 1st and 2nd gear sliding gear (mainshaft)

and the countershaft gear unit reverse speed gear, the

drive is bridged between the countershaft gear unit

and the mainshaft through the guide unit. The direc-

tion of the mainshaft is reversed. The guide unit is

located between the 1st and 2nd gear sliding gear and

the mainshaft. The guide unit is internally splined to

the 1st and 2nd gear sliding gear, and it is externally

splined to the mainshaft. The 3rd speed gear, 2nd

speed gear, and the 1st speed gear are all idling. With

a reverse speed gear ratio of -3.3 17: 1, the main drive

gear (input) must turn 3.317 revolutions for every

one revolution of the mainshaft (output). The “-

’sign indicates that the direction of rotation of the

mainshaft is opposite that of the main drive gear.UNIT756

Page 381 of 625

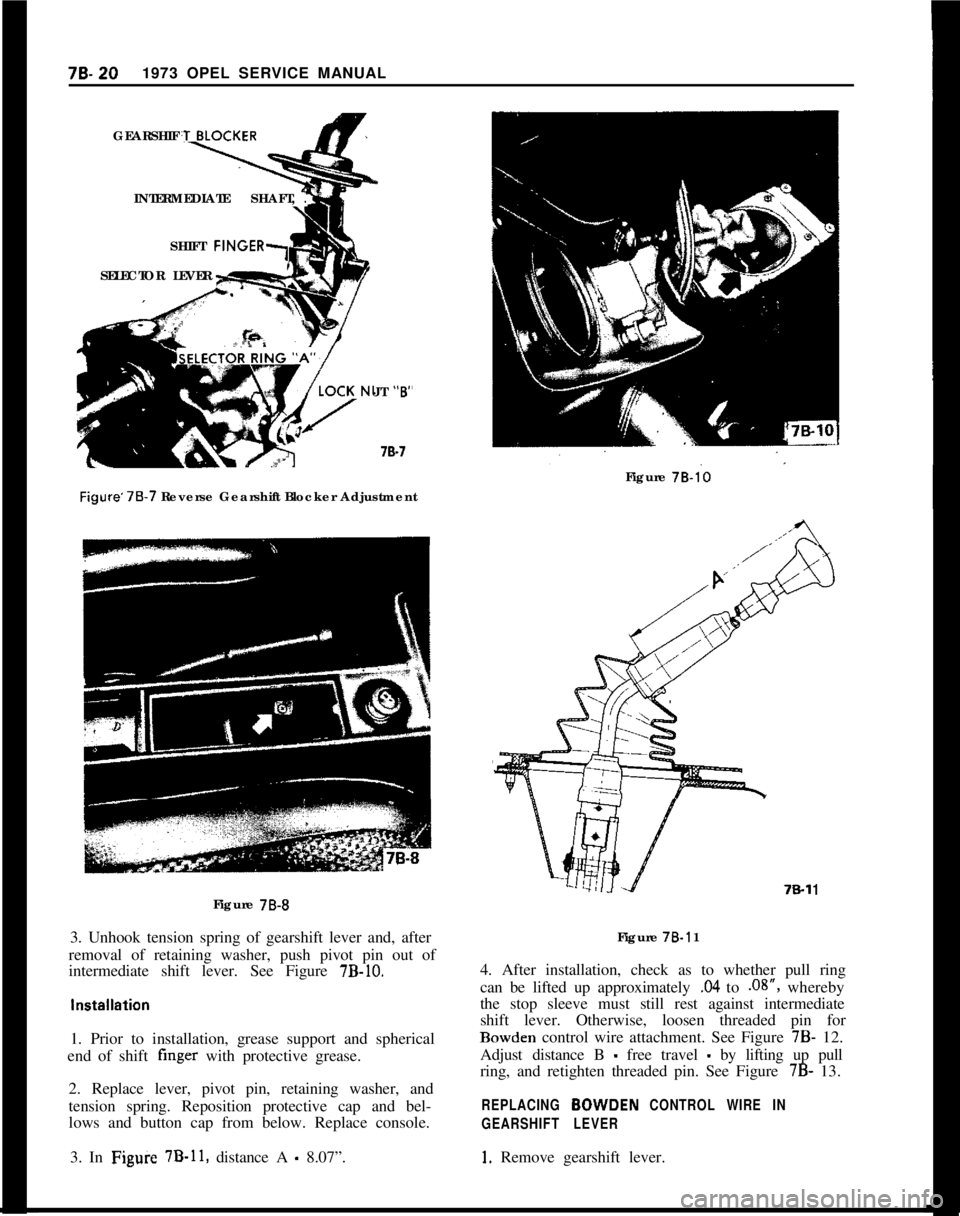

76.201973 OPEL SERVICE MANUAL

GEARSHIF

INTERMEDIATE SHAFT,

.SHIFT

FINGER1SELECTOR LEVER

JT “B’

78-7Figure’7B.7 Reverse Gearshift Blocker Adjustment

Figure

78-B3. Unhook tension spring of gearshift lever and, after

removal of retaining washer, push pivot pin out of

intermediate shift lever. See Figure

7B-10.1. Prior to installation, grease support and spherical

end of shift finger with protective grease.

2. Replace lever, pivot pin, retaining washer, and

tension spring. Reposition protective cap and bel-

lows and button cap from below. Replace console.

3. In

Figuie 7B-11, distance A - 8.07”.Figure 7B-10

7&l 1Figure 78.1 1

4. After installation, check as to whether pull ring

can be lifted up approximately

.04 to .08”, whereby

the stop sleeve must still rest against intermediate

shift lever. Otherwise, loosen threaded pin forBowden control wire attachment. See Figure 7B- 12.

Adjust distance B

- free travel - by lifting up pull

ring, and retighten threaded pin. See Figure 7B- 13.

REPLACING BOWDEN CONTROL WIRE IN

GEARSHIFT LEVER

1. Remove gearshift lever.

Page 383 of 625

78.221973 OPEL SERVICE MANUAL

3. Install new bellows. Adhere to distance A

- 8.07”.

See Figure 7B-I 1.

4. Heat up new gearshift lever knob in boiling water

to 176 degrees F. and push it onto gearshift lever

tube. Adhere to distance A .3”, see Figure

7B-15.The gearshift lever tube end is provided with trans-

verse grooves for which reason the old button cannot

be reused. Install gearshift lever.

REPLACING RUBBER DAMPENING PARTS IN

GEARSHIFT LEVER1. Remove gearshift lever.

2. Knock off gearshift lever button and loosen

threaded pin for Bowden control wire attachment.

3. Remove lower snap ring from gearshift lever tube

and pull tube off shift finger.

4. Take off and replace rubber dampening parts.

5. After installation of tube, tighten Bowden control

wire with threaded pin. Prior to tightening, pull ring

must rest on gearshift lever tube and clamping block

on pull ring. See Figure

7B-15.6. Heat up new gearshift lever knob in boiling water

to 176 degrees F. and push it onto gearshift lever

tube. Adhere to distance A

- .3”, see Figure 7B-15.The gearshift lever tube end is provided with trans-

verse grooves for which reason the old button cannot

be reused.

7. Install gearshift lever.

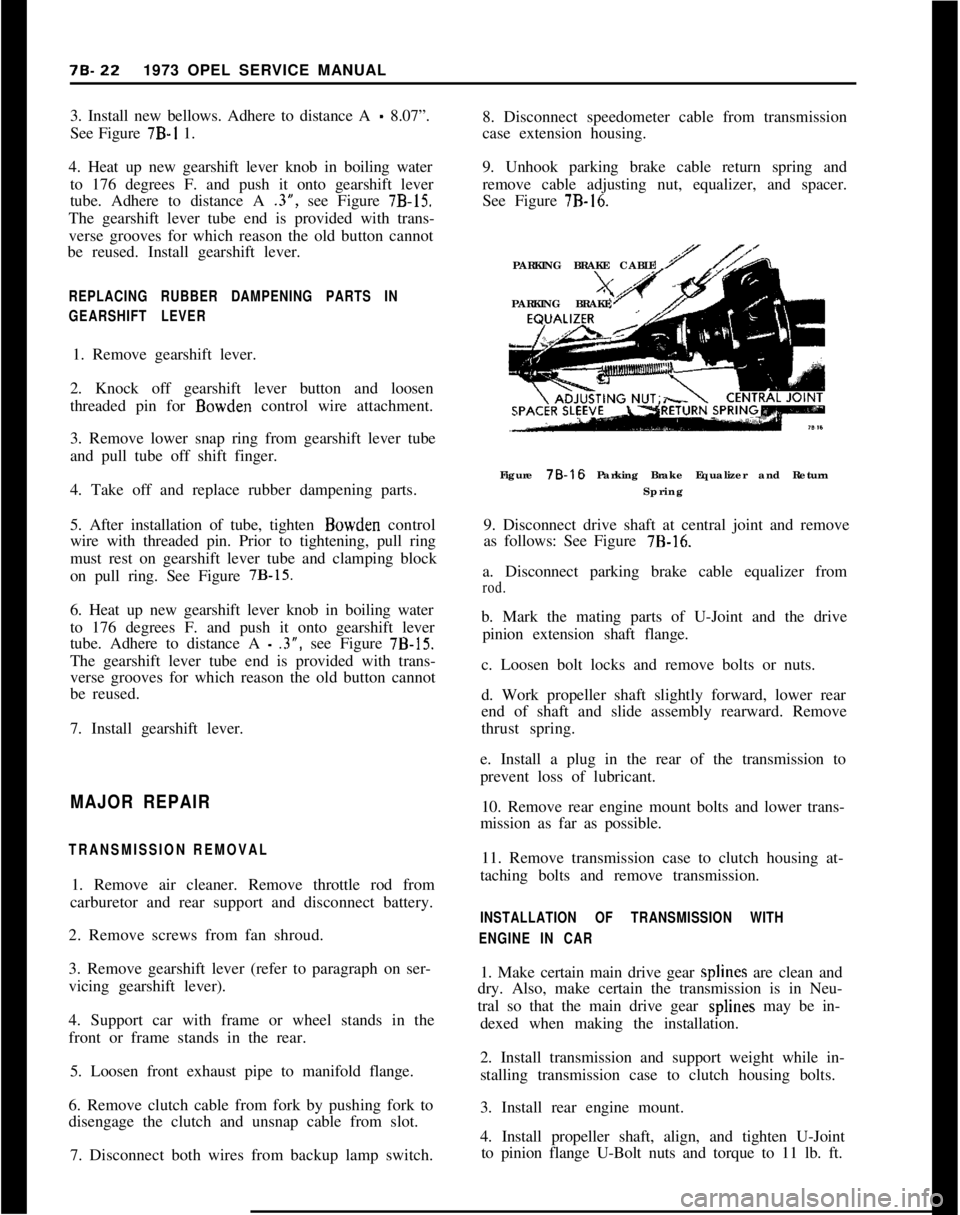

MAJOR REPAIR

TRANSMISSION REMOVAL1. Remove air cleaner. Remove throttle rod from

carburetor and rear support and disconnect battery.

2. Remove screws from fan shroud.

3. Remove gearshift lever (refer to paragraph on ser-

vicing gearshift lever).

4. Support car with frame or wheel stands in the

front or frame stands in the rear.

5. Loosen front exhaust pipe to manifold flange.

6. Remove clutch cable from fork by pushing fork to

disengage the clutch and unsnap cable from slot.

7. Disconnect both wires from backup lamp switch.8. Disconnect speedometer cable from transmission

case extension housing.

9. Unhook parking brake cable return spring and

remove cable adjusting nut, equalizer, and spacer.

See Figure

7B-16.PARKING BRAKE CABLE

PARKING BRAKE

Figure 78-16 Parking Brake Equalizer and Return

Spring

9. Disconnect drive shaft at central joint and remove

as follows: See Figure

7B-16.a. Disconnect parking brake cable equalizer from

rod.b. Mark the mating parts of U-Joint and the drive

pinion extension shaft flange.

c. Loosen bolt locks and remove bolts or nuts.

d. Work propeller shaft slightly forward, lower rear

end of shaft and slide assembly rearward. Remove

thrust spring.

e. Install a plug in the rear of the transmission to

prevent loss of lubricant.

10. Remove rear engine mount bolts and lower trans-

mission as far as possible.

11. Remove transmission case to clutch housing at-

taching bolts and remove transmission.

INSTALLATION OF TRANSMISSION WITH

ENGINE IN CAR1. Make certain main drive gear splines are clean and

dry. Also, make certain the transmission is in Neu-

tral so that the main drive gear splines may be in-

dexed when making the installation.

2. Install transmission and support weight while in-

stalling transmission case to clutch housing bolts.

3. Install rear engine mount.

4. Install propeller shaft, align, and tighten U-Joint

to pinion flange U-Bolt nuts and torque to 11 lb. ft.

Page 385 of 625

78.241973 OPEL SERVICE MANUAL

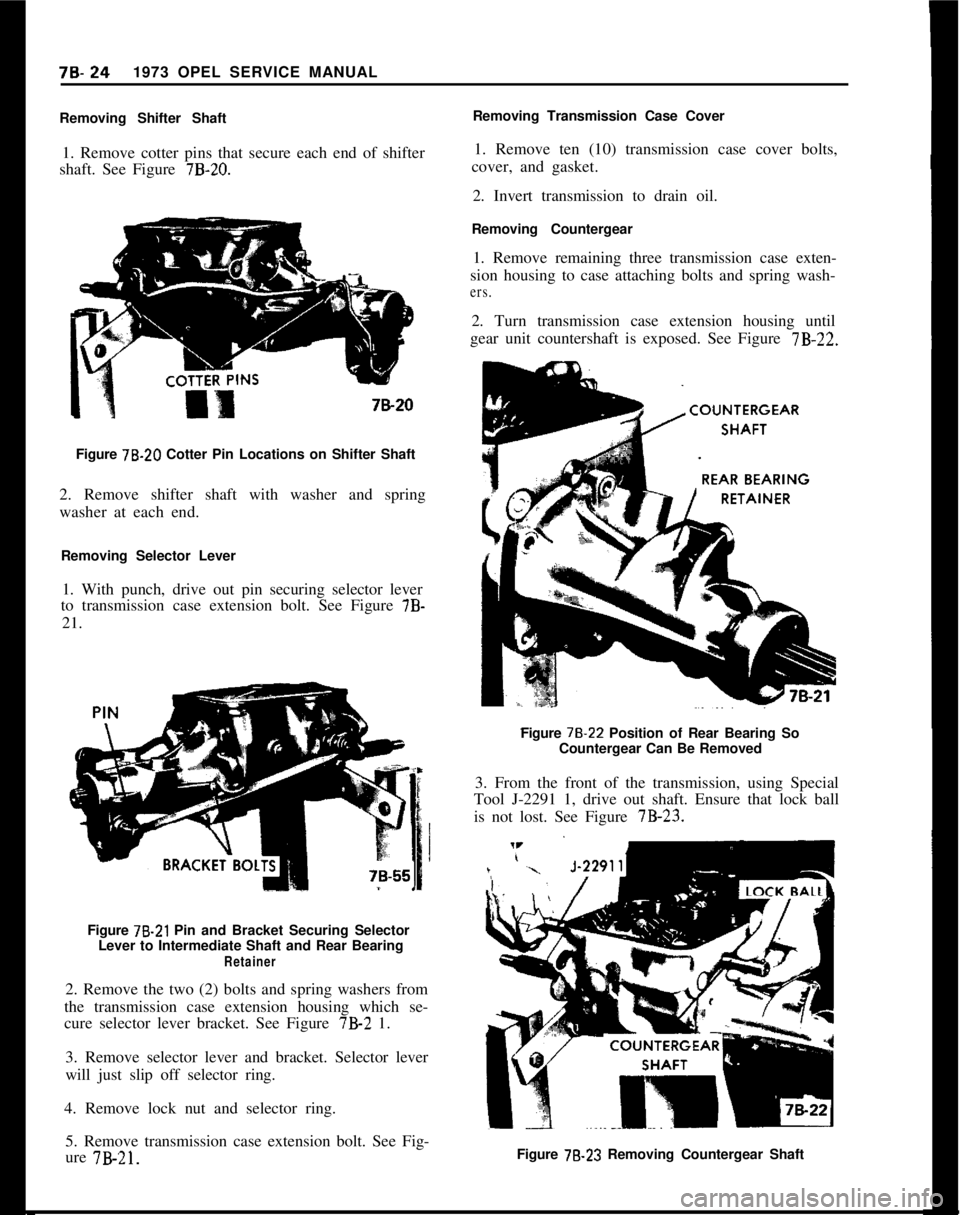

Removing Shifter Shaft

1. Remove cotter pins that secure each end of shifter

shaft. See Figure

7B-20.7&20

Figure 78.20 Cotter Pin Locations on Shifter Shaft

2. Remove shifter shaft with washer and spring

washer at each end.

Removing Selector Lever

1. With punch, drive out pin securing selector lever

to transmission case extension bolt. See Figure 7B-

21.

Figure

78-21 Pin and Bracket Securing Selector

Lever to Intermediate Shaft and Rear Bearing

Retainer2. Remove the two (2) bolts and spring washers from

the transmission case extension housing which se-

cure selector lever bracket. See Figure 7B-2 1.

3. Remove selector lever and bracket. Selector lever

will just slip off selector ring.

4. Remove lock nut and selector ring.

5. Remove transmission case extension bolt. See Fig-

ure 7B-21.Removing Transmission Case Cover

1. Remove ten (10) transmission case cover bolts,

cover, and gasket.

2. Invert transmission to drain oil.

Removing Countergear

1. Remove remaining three transmission case exten-

sion housing to case attaching bolts and spring wash-

ers.2. Turn transmission case extension housing until

gear unit countershaft is exposed. See Figure 7B-22.

Figure

78-22 Position of Rear Bearing So

Countergear Can Be Removed

3. From the front of the transmission, using Special

Tool J-2291 1, drive out shaft. Ensure that lock ball

is not lost. See Figure 7B-23.

Figure

78-23 Removing Countergear Shaft

Page 387 of 625

78.261973 OPEL SERVICE MANUAL

4. Remove both first and second speed shifter yoke

and shifter shaft cam.

Removing Main Drive Gear and Mainshaft

Assembly

1. From front of transmission, pull main drive gear

and needle bearing out of transmission. (May be

necessary to rock main drive gear.)

2. From rear of transmission, pull mainshaft assem-

bly and transmission case extension housing out of

transmission. Gear shifter sleeve will be pulled off

gear shifter sleeve carrier by the third and fourth

speed shifter yoke. Remove sleeve from yoke and

keep sleeve with mainshaft assembly. (Make sure

third and fourth speed shoes are not lost.)

Removing Third and Fourth Gear Shifter Shaft.

1. With main shaft assembly out of transmission

case, drive third and fourth gear shifter shaft out

through hole in front of case with brass drift from

rear of transmission through mainshaft assembly

hole in case.

2. Remove third and fourth speed yoke.

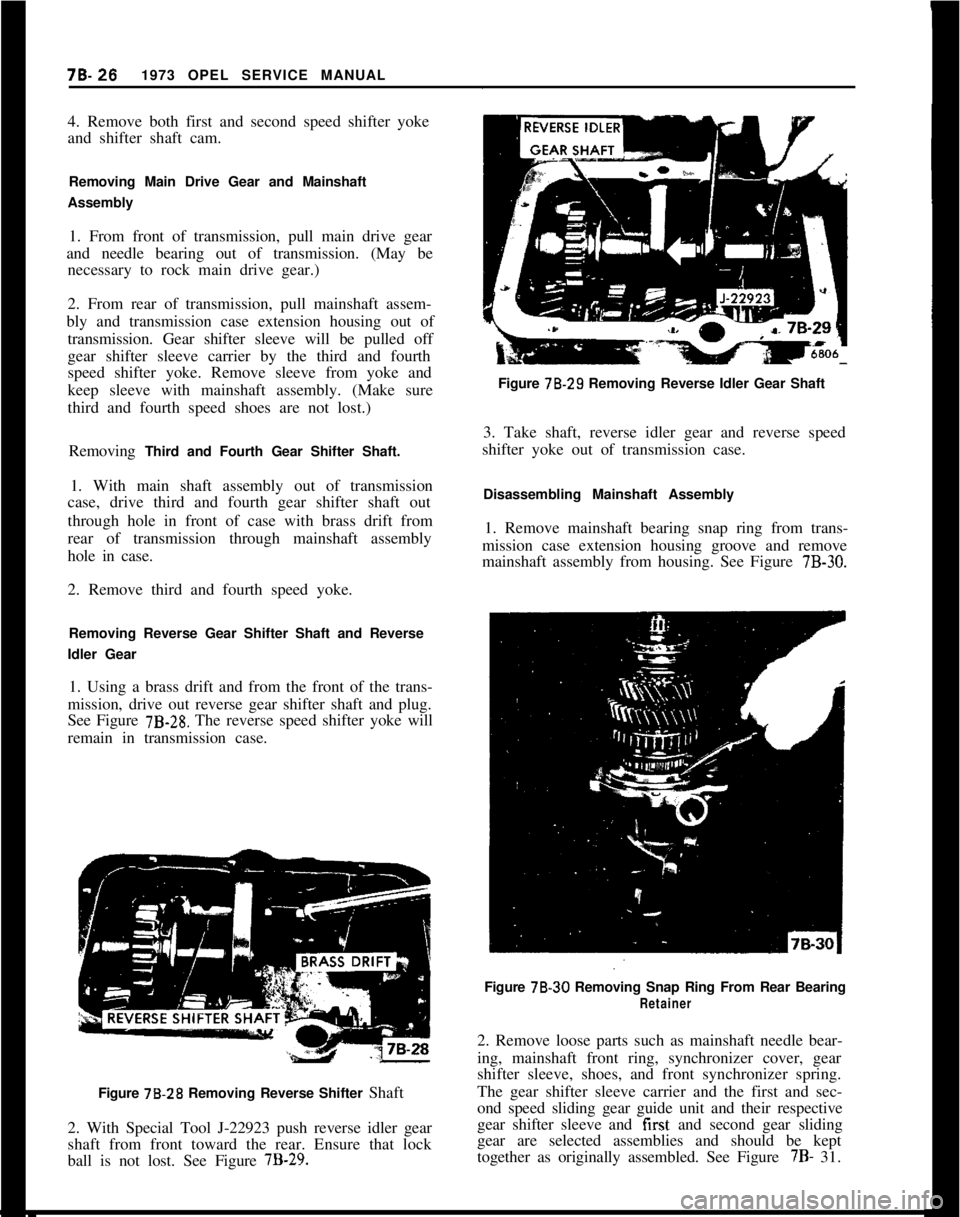

Removing Reverse Gear Shifter Shaft and Reverse

Idler Gear

1. Using a brass drift and from the front of the trans-

mission, drive out reverse gear shifter shaft and plug.

See Figure

7B-28. The reverse speed shifter yoke will

remain in transmission case.

Figure 78.28 Removing Reverse Shifter Shaft

2. With Special Tool J-22923 push reverse idler gear

shaft from front toward the rear. Ensure that lock

ball is not lost. See Figure

7B-29.Figure 78.29 Removing Reverse Idler Gear Shaft

3. Take shaft, reverse idler gear and reverse speed

shifter yoke out of transmission case.

Disassembling Mainshaft Assembly

1. Remove mainshaft bearing snap ring from trans-

mission case extension housing groove and remove

mainshaft assembly from housing. See Figure

7B-30.Figure 78-30 Removing Snap Ring From Rear Bearing

Retainer2. Remove loose parts such as mainshaft needle bear-

ing, mainshaft front ring, synchronizer cover, gear

shifter sleeve, shoes, and front synchronizer spring.

The gear shifter sleeve carrier and the first and sec-

ond speed sliding gear guide unit and their respective

gear shifter sleeve and first and second gear sliding

gear are selected assemblies and should be kept

together as originally assembled. See Figure 7B- 31.