service OPEL 1900 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 451 of 625

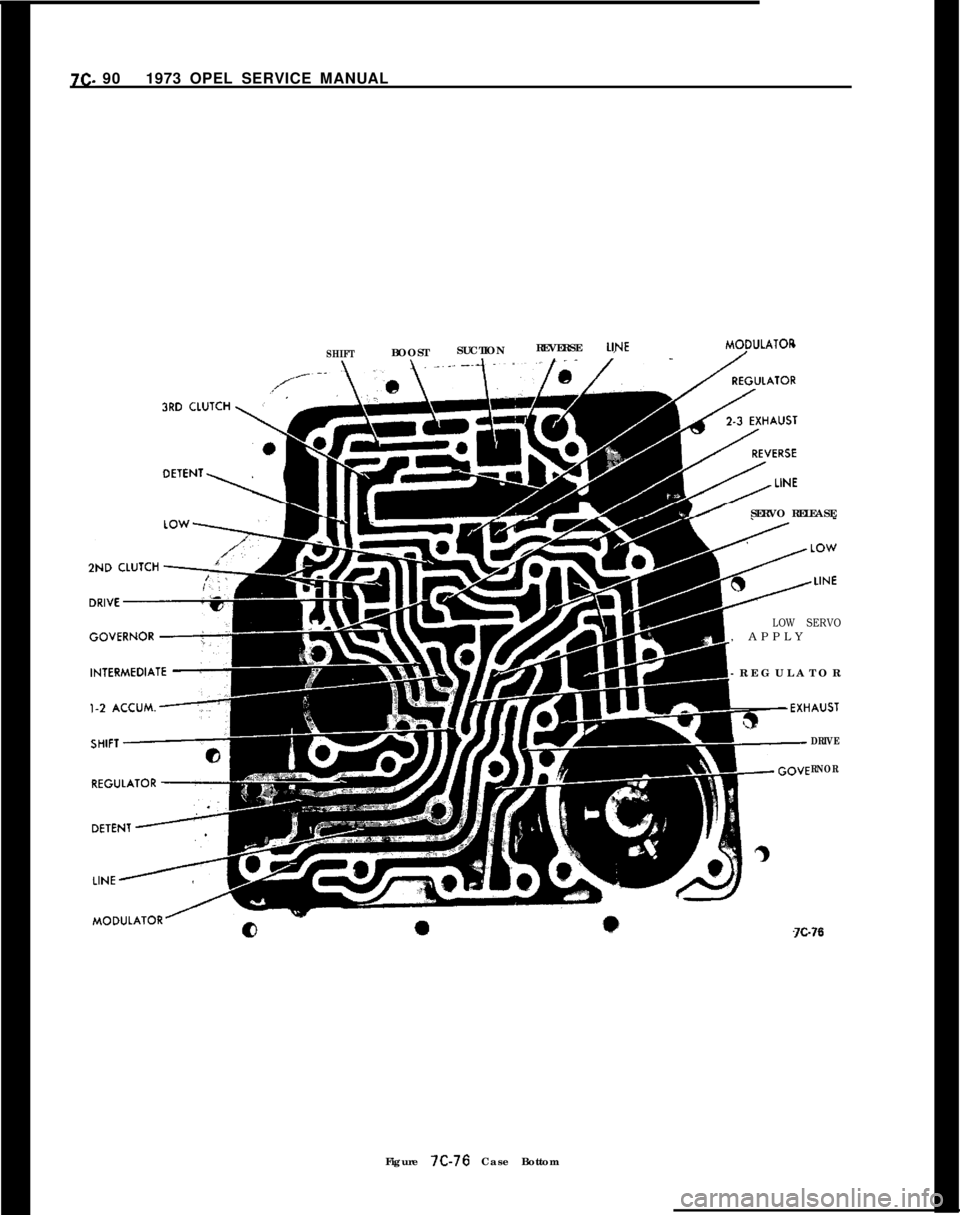

7C. 901973 OPEL SERVICE MANUALSHIFTBOOSTSUCTIONREVERSE ,UNEMO/DULATORSERVO RELEASE

LOW SERVO, APPLY

-REGULATOR

DRIVE

RNOR7076

Figure 7C-76 Case Bottom

Page 453 of 625

7C- 92

1973 OPEL SERVICE MANUAL

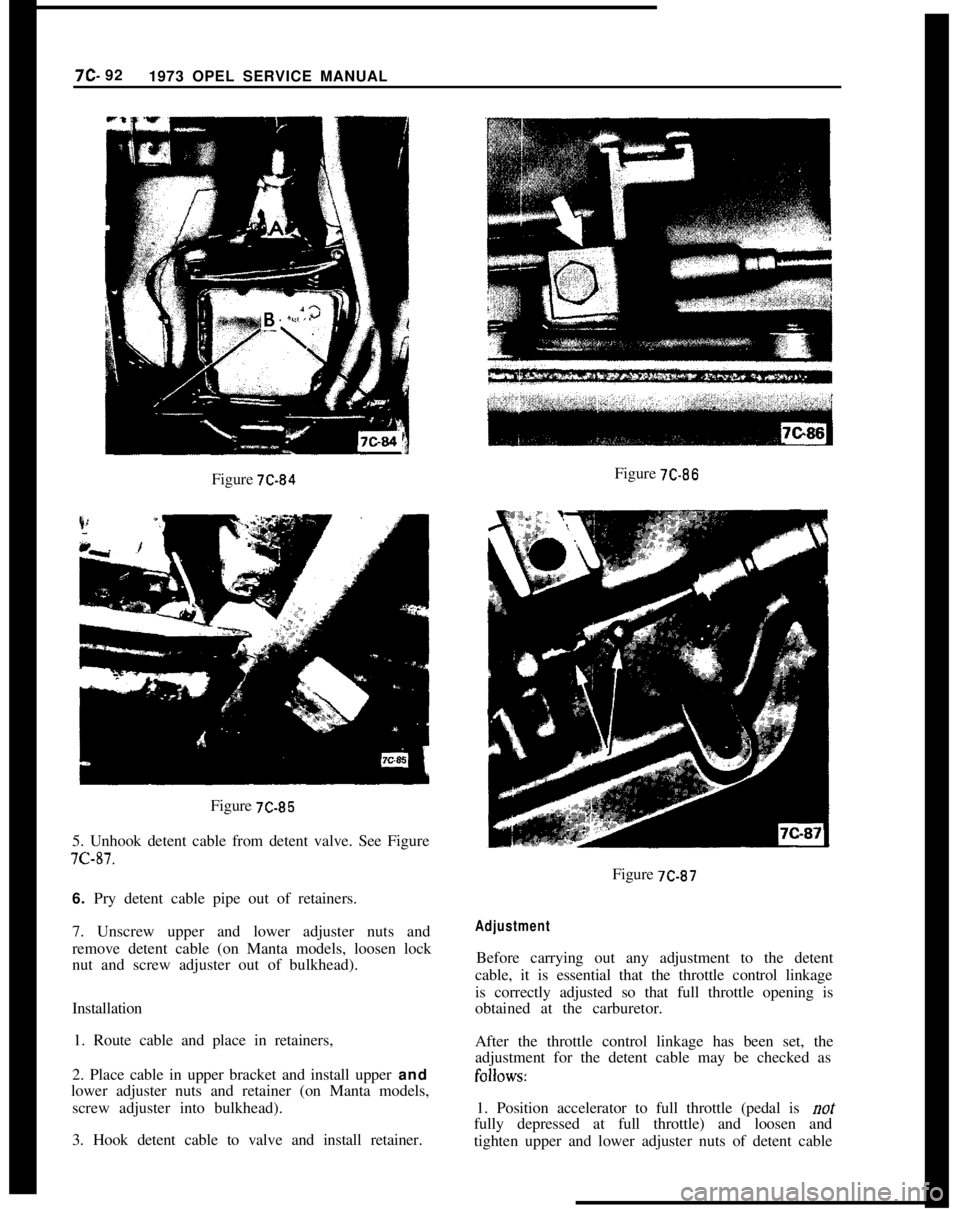

Figure 7C-84Figure

7C-855. Unhook detent cable from detent valve. See Figure7c-87.

6. Pry detent cable pipe out of retainers.

7. Unscrew upper and lower adjuster nuts and

remove detent cable (on Manta models, loosen lock

nut and screw adjuster out of bulkhead).

Installation

1. Route cable and place in retainers,

2. Place cable in upper bracket and install upper and

lower adjuster nuts and retainer (on Manta models,

screw adjuster into bulkhead).

3. Hook detent cable to valve and install retainer.Figure

7C-86Figure

7C.87

AdjustmentBefore carrying out any adjustment to the detent

cable, it is essential that the throttle control linkage

is correctly adjusted so that full throttle opening is

obtained at the carburetor.

After the throttle control linkage has been set, the

adjustment for the detent cable may be checked as

FOllOWS:1. Position accelerator to full throttle (pedal is nol

fully depressed at full throttle) and loosen and

tighten upper and lower adjuster nuts of detent cable

Page 455 of 625

7C. 941973 OPEL SERVICE MANUAL

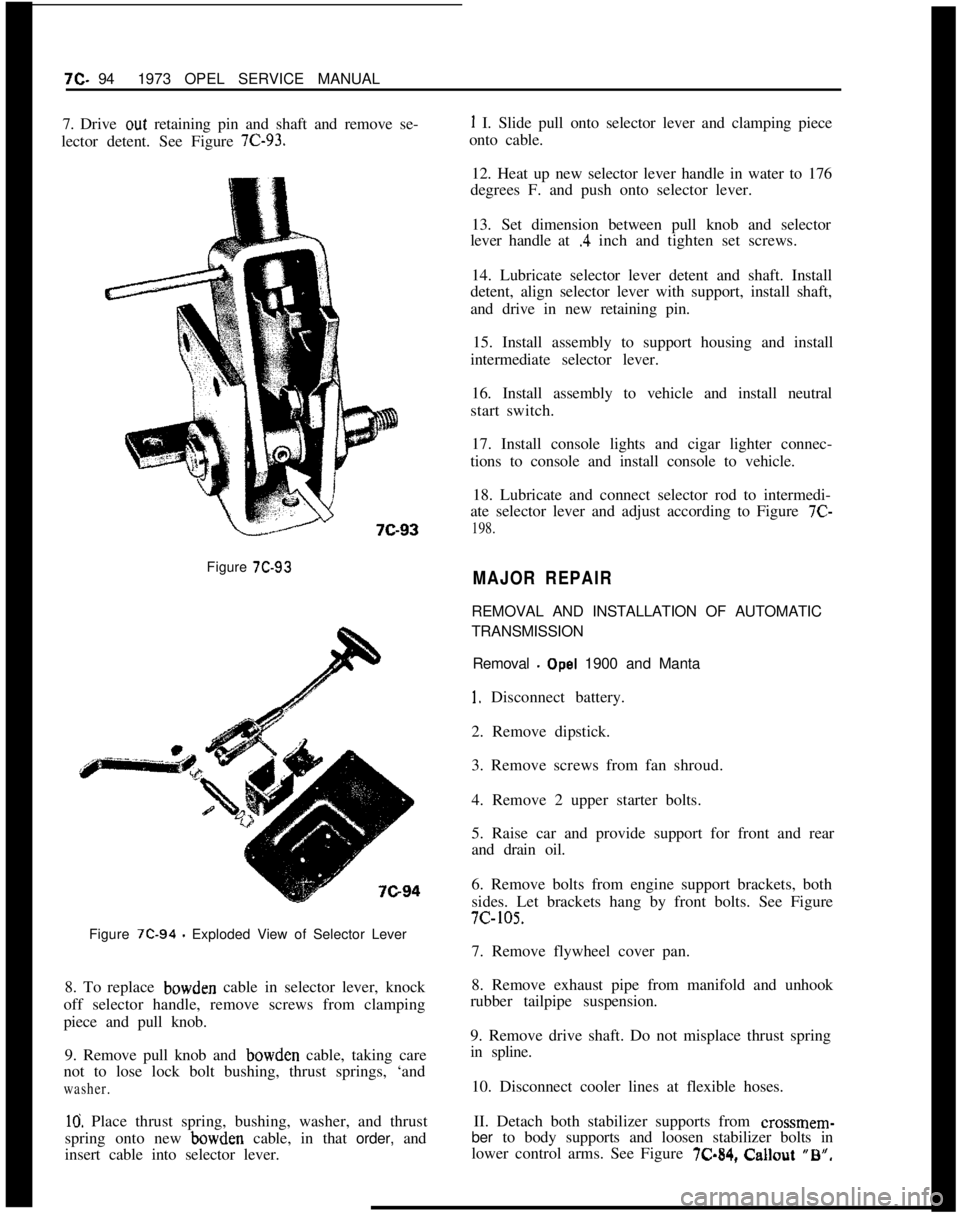

7. Drive out retaining pin and shaft and remove se-

lector detent. See Figure 7C-93.Figure

7C-93Figure

7C-94 - Exploded View of Selector Lever

8. To replace bowden cable in selector lever, knock

off selector handle, remove screws from clamping

piece and pull knob.

9. Remove pull knob and bowden cable, taking care

not to lose lock bolt bushing, thrust springs, ‘and

washer.

10. Place thrust spring, bushing, washer, and thrust

spring onto new bowden cable, in that order, and

insert cable into selector lever.

1 I. Slide pull onto selector lever and clamping piece

onto cable.

12. Heat up new selector lever handle in water to 176

degrees F. and push onto selector lever.

13. Set dimension between pull knob and selector

lever handle at

.4 inch and tighten set screws.

14. Lubricate selector lever detent and shaft. Install

detent, align selector lever with support, install shaft,

and drive in new retaining pin.

15. Install assembly to support housing and install

intermediate selector lever.

16. Install assembly to vehicle and install neutral

start switch.

17. Install console lights and cigar lighter connec-

tions to console and install console to vehicle.

18. Lubricate and connect selector rod to intermedi-

ate selector lever and adjust according to Figure 7C-

198.

MAJOR REPAIRREMOVAL AND INSTALLATION OF AUTOMATIC

TRANSMISSION

Removal

- Opel 1900 and Manta

I. Disconnect battery.

2. Remove dipstick.

3. Remove screws from fan shroud.

4. Remove 2 upper starter bolts.

5. Raise car and provide support for front and rear

and drain oil.

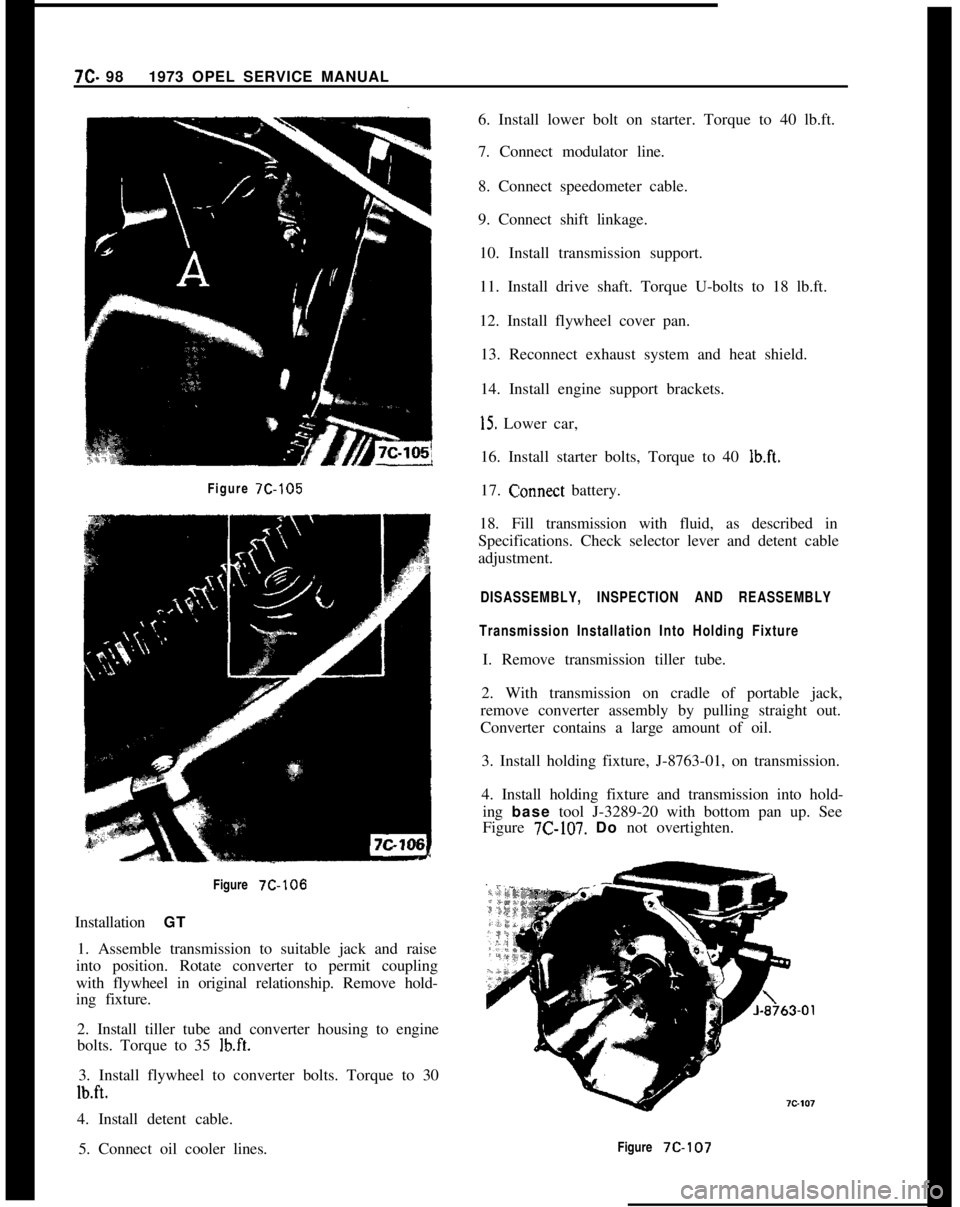

6. Remove bolts from engine support brackets, both

sides. Let brackets hang by front bolts. See Figure7c-105.

7. Remove flywheel cover pan.

8. Remove exhaust pipe from manifold and unhook

rubber tailpipe suspension.

9. Remove drive shaft. Do not misplace thrust spring

in spline.

10. Disconnect cooler lines at flexible hoses.

II. Detach both stabilizer supports from

crossmem-ber to body supports and loosen stabilizer bolts in

lower control arms. See Figure X-84, Callout “B”,

Page 457 of 625

7C- 961973 OPEL SERVICE MANUAL

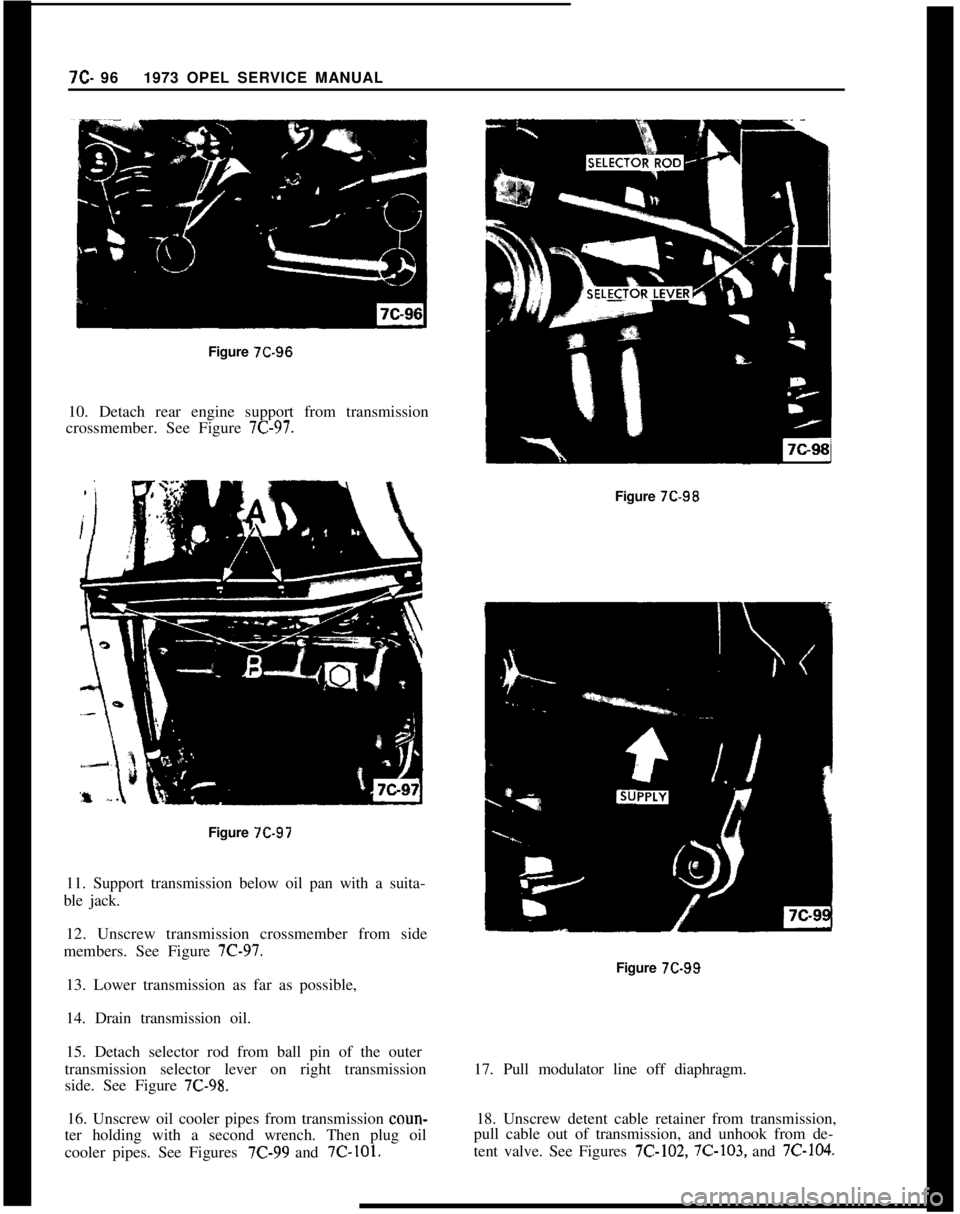

Figure 7C-96

10. Detach rear engine support from transmission

crossmember. See Figure 7C-97.Figure 7C-98

Figure

7C-9711. Support transmission below oil pan with a suita-

ble jack.

12. Unscrew transmission crossmember from side

members. See Figure

7C-97.13. Lower transmission as far as possible,

14. Drain transmission oil.

15. Detach selector rod from ball pin of the outer

transmission selector lever on right transmission

side. See Figure

7C-98.16. Unscrew oil cooler pipes from transmission cow-

ter holding with a second wrench. Then plug oil

cooler pipes. See Figures 7C-99 and

7C-101.Figure 7C-99

17. Pull modulator line off diaphragm.

18. Unscrew detent cable retainer from transmission,

pull cable out of transmission, and unhook from de-

tent valve. See Figures 7C-102, 7C-103, and 7C-104.

Page 459 of 625

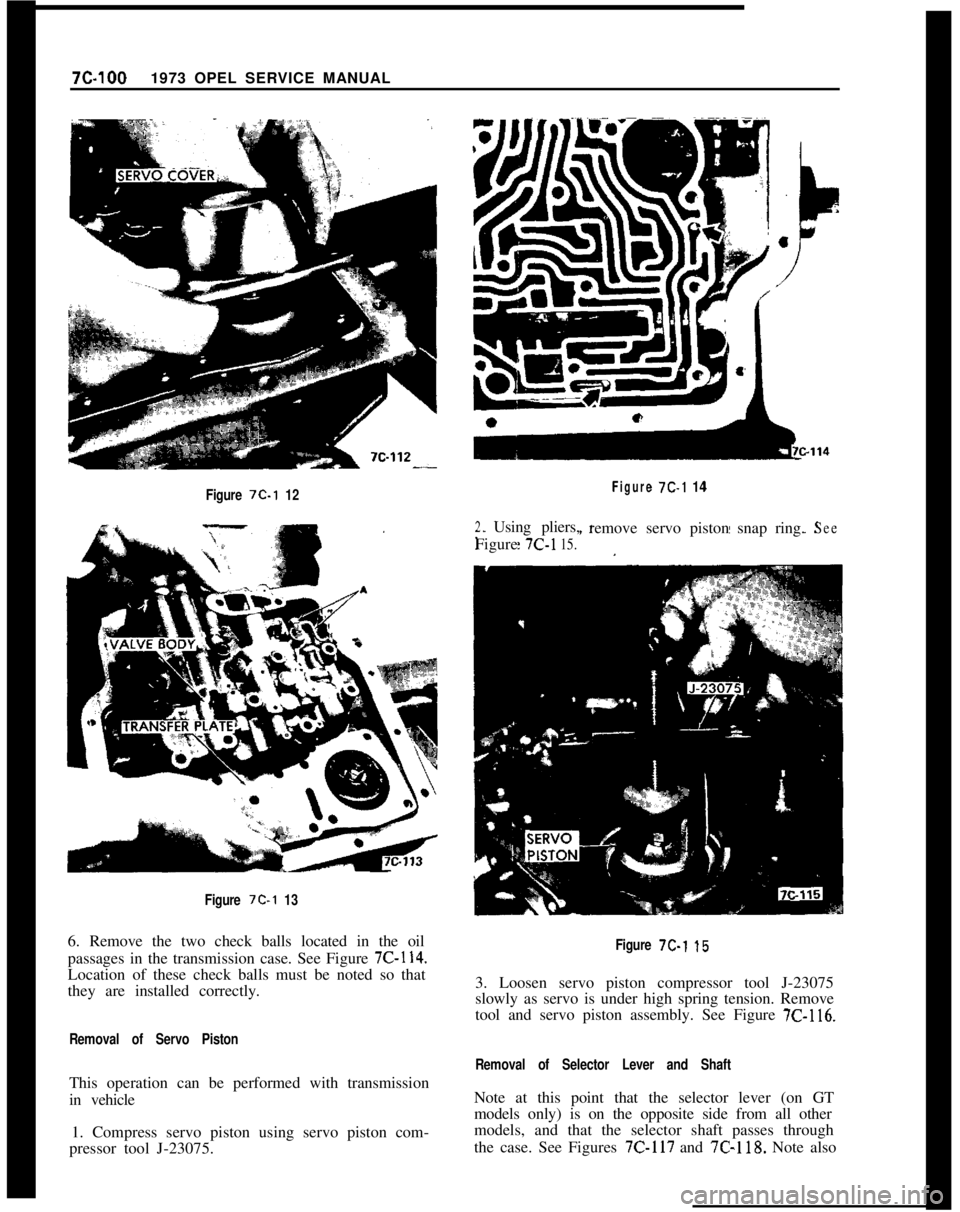

7C- 981973 OPEL SERVICE MANUAL

Figure 7C-105Figure

7C-106Installation GT

1. Assemble transmission to suitable jack and raise

into position. Rotate converter to permit coupling

with flywheel in original relationship. Remove hold-

ing fixture.

2. Install tiller tube and converter housing to engine

bolts. Torque to 35

lb.ft.3. Install flywheel to converter bolts. Torque to 30

lb.ft.4. Install detent cable.

5. Connect oil cooler lines.6. Install lower bolt on starter. Torque to 40 lb.ft.

7. Connect modulator line.

8. Connect speedometer cable.

9. Connect shift linkage.

10. Install transmission support.

11. Install drive shaft. Torque U-bolts to 18 lb.ft.

12. Install flywheel cover pan.

13. Reconnect exhaust system and heat shield.

14. Install engine support brackets.

15. Lower car,

16. Install starter bolts, Torque to 40

lb.ft.17.

C:onnect battery.

18. Fill transmission with fluid, as described in

Specifications. Check selector lever and detent cable

adjustment.

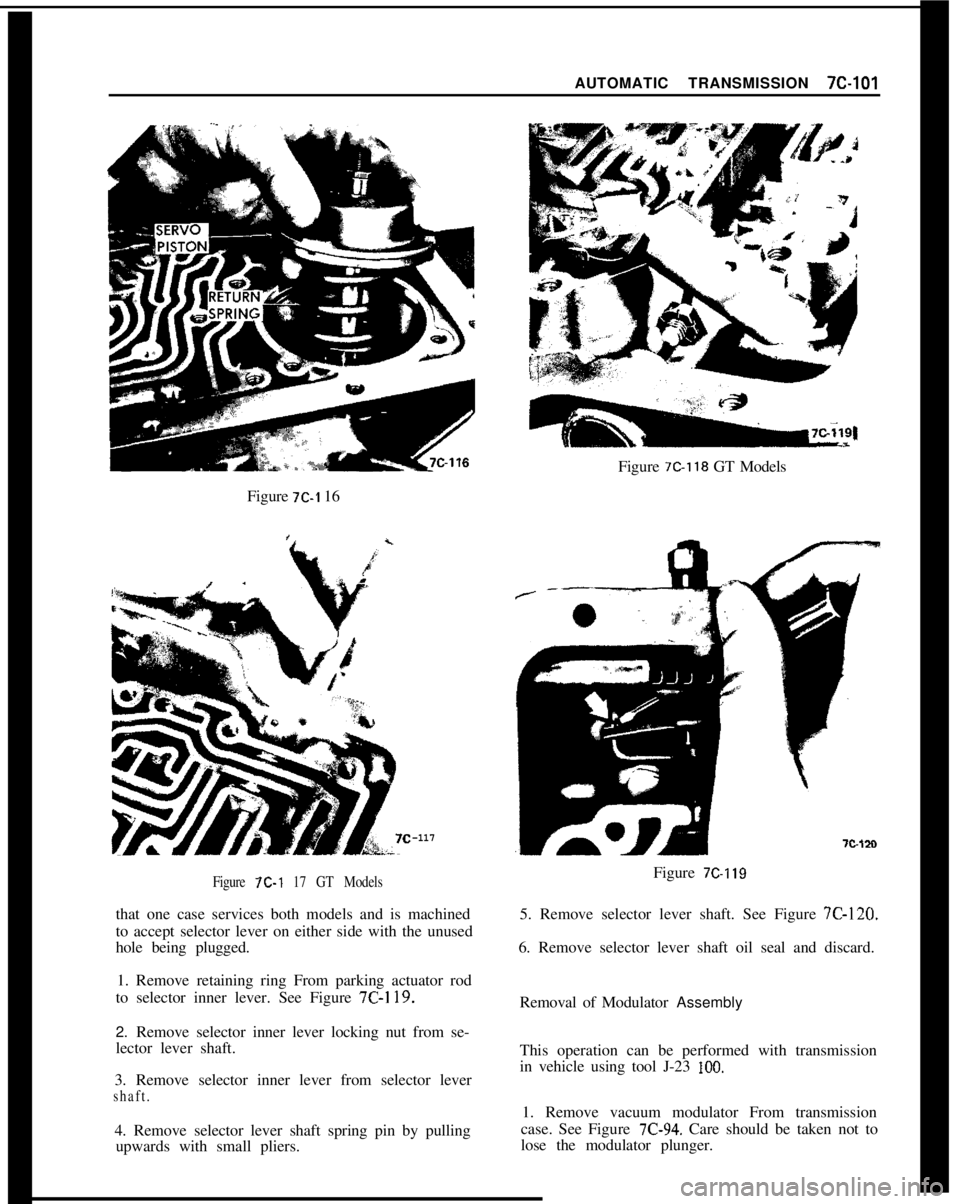

DISASSEMBLY, INSPECTION AND REASSEMBLY

Transmission Installation Into Holding FixtureI. Remove transmission tiller tube.

2. With transmission on cradle of portable jack,

remove converter assembly by pulling straight out.

Converter contains a large amount of oil.

3. Install holding fixture, J-8763-01, on transmission.

4. Install holding fixture and transmission into hold-

ing base tool J-3289-20 with bottom pan up. See

Figure

7C-107. Do not overtighten.

Figure

7C-107

Page 461 of 625

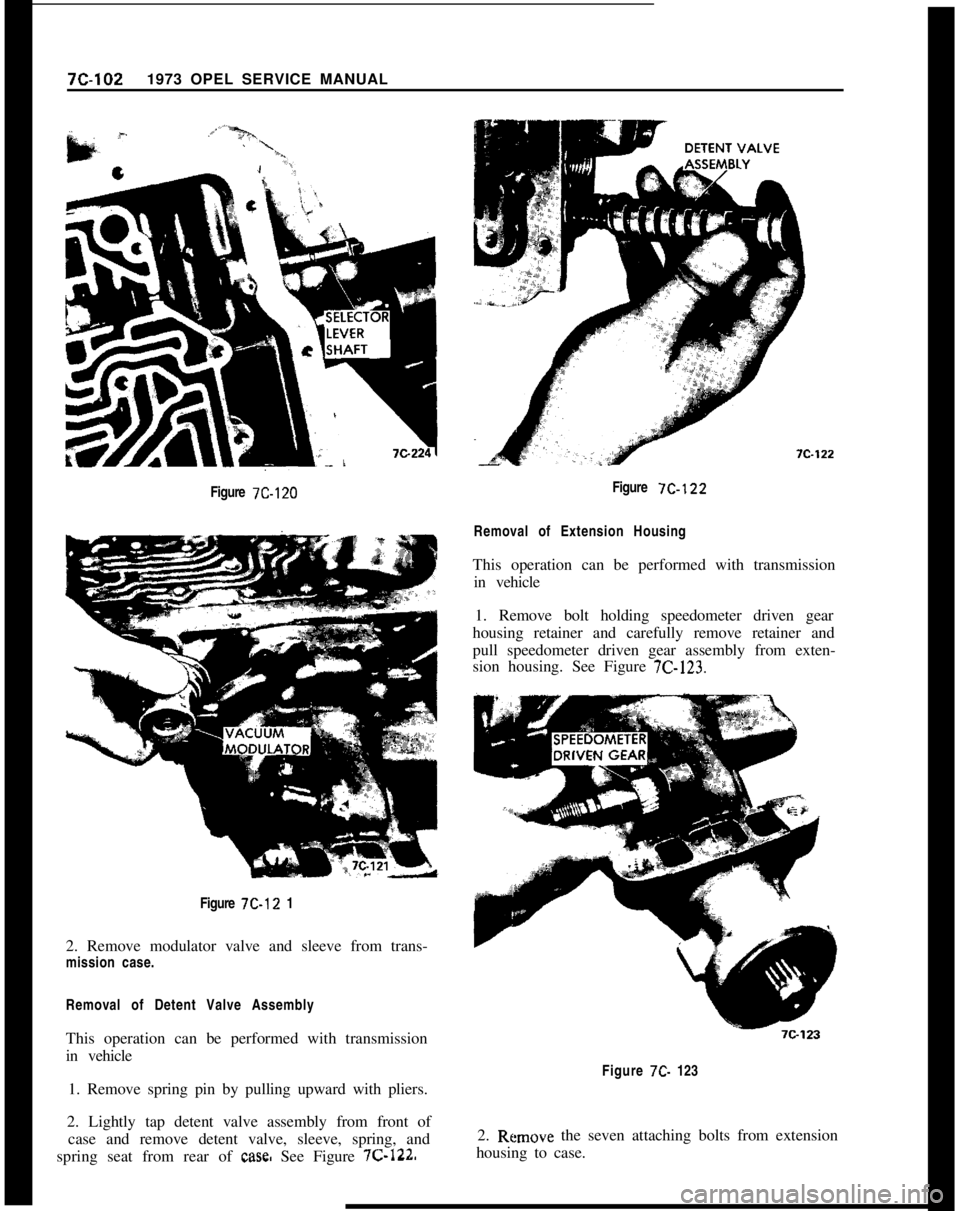

7C-1001973 OPEL SERVICE MANUALFigure 7C-1 12

Figure

7C-1 136. Remove the two check balls located in the oil

passages in the transmission case. See Figure

7C-114.Location of these check balls must be noted so that

they are installed correctly.

Removal of Servo PistonThis operation can be performed with transmission

in vehicle

1. Compress servo piston using servo piston com-

pressor tool J-23075.

Figure7C-1 14

2.Using pliers,

remove servo pistonsnap ring.SeeFigure

X-1 15.

Figure

7C-1 153. Loosen servo piston compressor tool J-23075

slowly as servo is under high spring tension. Remove

tool and servo piston assembly. See Figure

7C-116.

Removal of Selector Lever and ShaftNote at this point that the selector lever (on GT

models only) is on the opposite side from all other

models, and that the selector shaft passes through

the case. See Figures 7C-117 and 7C-118. Note also

Page 462 of 625

AUTOMATIC TRANSMISSION 7C-101

Figure 7C-1 16

-117Figure

7C-118 GT Models

Figure 7C-1 17 GT Modelsthat one case services both models and is machined

to accept selector lever on either side with the unused

hole being plugged.

1. Remove retaining ring From parking actuator rod

to selector inner lever. See Figure 7C-119.

2. Remove selector inner lever locking nut from se-

lector lever shaft.

3. Remove selector inner lever from selector lever

shaft.4. Remove selector lever shaft spring pin by pulling

upwards with small pliers.Figure

7C-1195. Remove selector lever shaft. See Figure 7C-120.

6. Remove selector lever shaft oil seal and discard.

Removal of Modulator Assembly

This operation can be performed with transmission

in vehicle using tool J-23

100.1. Remove vacuum modulator From transmission

case. See Figure

7C-94. Care should be taken not to

lose the modulator plunger.

Page 463 of 625

7C-1021973 OPEL SERVICE MANUAL

Figure 7C-120Figure 7C-122

Figure 7C-12 1

2. Remove modulator valve and sleeve from trans-

mission case.

Removal of Detent Valve Assembly

This operation can be performed with transmission

in vehicle

1. Remove spring pin by pulling upward with pliers.

2. Lightly tap detent valve assembly from front of

case and remove detent valve, sleeve, spring, and

spring seat from rear of easel See Figure 7C-122,Removal of Extension Housing

This operation can be performed with transmission

in vehicle

1. Remove bolt holding speedometer driven gear

housing retainer and carefully remove retainer and

pull speedometer driven gear assembly from exten-

sion housing. See Figure

7C-123.Figure

7C- 123

2. Remove the seven attaching bolts from extension

housing to case.

Page 465 of 625

7C-1041973 OPEL SERVICE MANUAL

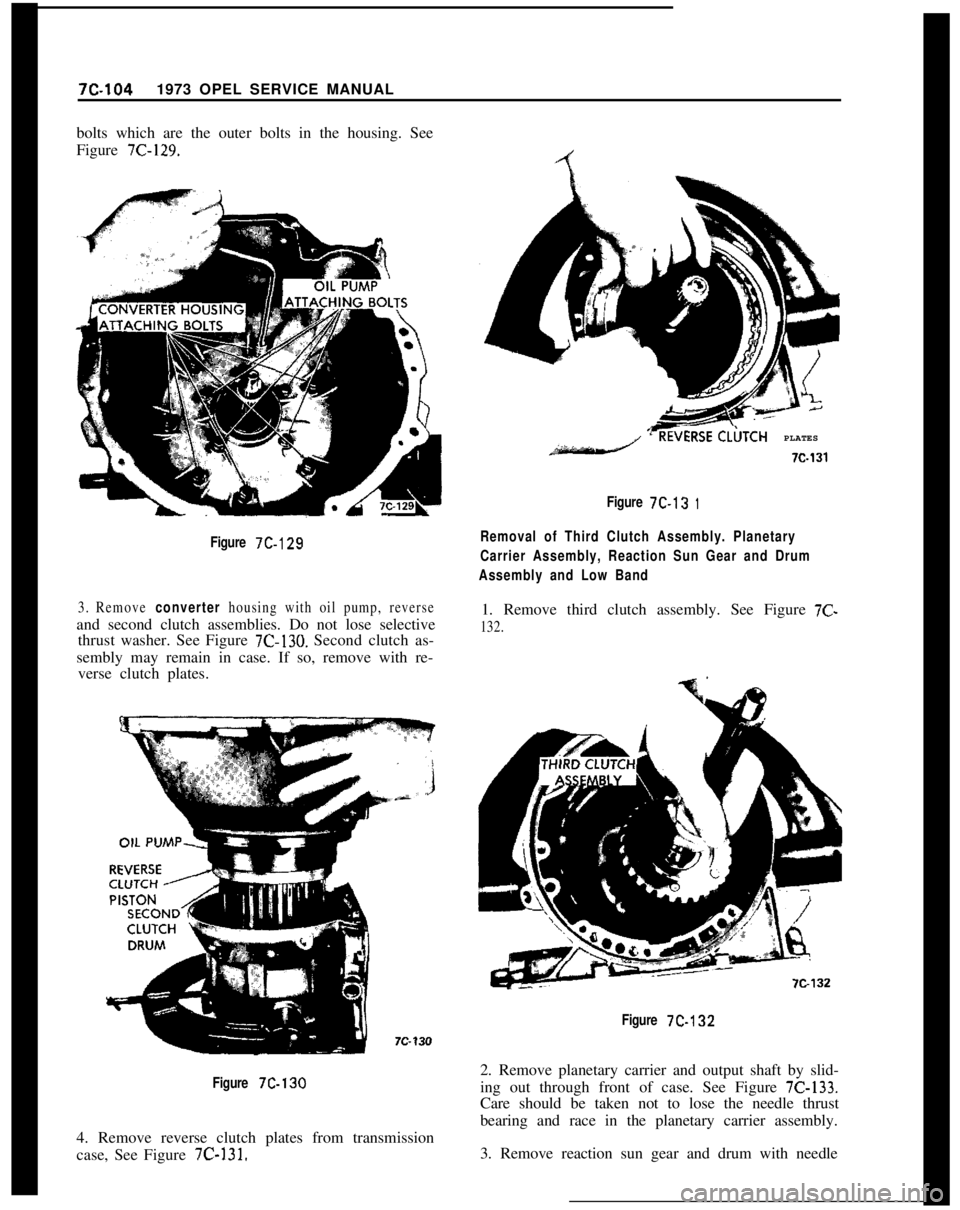

bolts which are the outer bolts in the housing. See

Figure 7C-129.

Figure 7C-129

3. Remove converter housing with oil pump, reverseand second clutch assemblies. Do not lose selective

thrust washer. See Figure

7C-130. Second clutch as-

sembly may remain in case. If so, remove with re-

verse clutch plates.

Figure 7C-130

4. Remove reverse clutch plates from transmission

case, See Figure

7C-131.

T%RSE~L~~T~H PLATES

7c-131

Figure

7C-13 I

Removal of Third Clutch Assembly. Planetary

Carrier Assembly, Reaction Sun Gear and Drum

Assembly and Low Band1. Remove third clutch assembly. See Figure 7C-

132.

Figure 7C-132

2. Remove planetary carrier and output shaft by slid-

ing out through front of case. See Figure

7C-133.Care should be taken not to lose the needle thrust

bearing and race in the planetary carrier assembly.

3. Remove reaction sun gear and drum with needle

Page 467 of 625

7C-1061973 OPEL SERVICE MANUAL

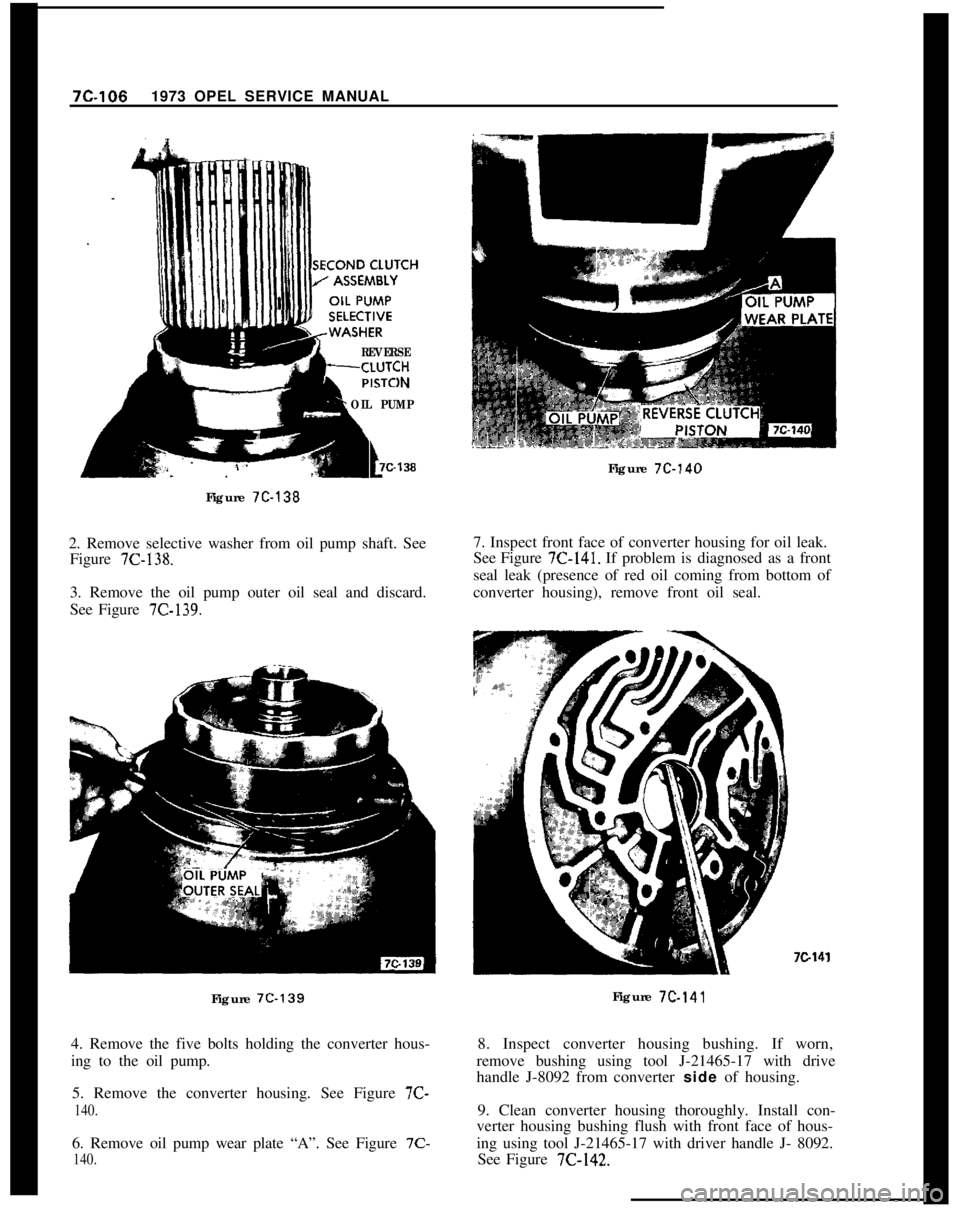

Figure 7C-138

!LREVERSEZH

)N

OIL PUMP

t7c-1382. Remove selective washer from oil pump shaft. See

Figure

7C-138.3. Remove the oil pump outer oil seal and discard.

See Figure

7C-139.Figure 7’2.139

4. Remove the five bolts holding the converter hous-

ing to the oil pump.

5. Remove the converter housing. See Figure 7C-

140.6. Remove oil pump wear plate “A”. See Figure 7C-

140.Figure

7C-1407. Inspect front face of converter housing for oil leak.

See Figure

7C-141. If problem is diagnosed as a front

seal leak (presence of red oil coming from bottom of

converter housing), remove front oil seal.

7c141Figure

7C-1418. Inspect converter housing bushing. If worn,

remove bushing using tool J-21465-17 with drive

handle J-8092 from converter side of housing.

9. Clean converter housing thoroughly. Install con-

verter housing bushing flush with front face of hous-

ing using tool J-21465-17 with driver handle J- 8092.

See Figure

7C-142.