brake light OPEL 1900 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 220 of 625

REAR SUSPENSION3F- 53

7. Remove jack stands.

LOWER CONTROL ARM REPLACEMENTRemovalThis operation can be performed with the vehicle

standing at curb height or elevated.

1. Disconnect parking brake cable from support

bracket on control arm.

2. Loosen and remove front and rear control arm

attaching bolts and remove control arm.

installation1. On

1900’s and Manta’s place a load of approxi-

mately 350 lbs. in luggage compartment or on the

GT, place a load of approximately 150

Ibs. on dri-

ver’s seat. Torque control arm attaching nut and

bolts to 18 lb.ft on

GT’s and 23 Ib.ft. on the 1900 -Manta.

2. Connect parking brake cable to support bracket on

control

ranI.

STABILIZER ROD REPLACEMENT

Removal1. Raise and support rear of vehicle.

2. Disconnect stabilizer rod to shackle bolts.

3. Disconnect stabilizer rod to underbody retainers

and work stabilizer rod out from under vehicle.

SPECIFICATIONS

REAR SUSPENSION SPECIFICATIONS

Tightening SpecificationsInstallation1. Work stabilizer rod into position and loosely at-

tach stabilizer to underbody retainers.

2. Connect stabilizer rod to shackles.

3. With the vehicle standing on its wheels or the rear

axle assembly lifted, tighten stabilizer rod to under-

body bracket bolts to 15 lb. ft.

4. Remove jack stands and lower vehicle.

TRACK ROD REPLACEMENT

Removal1. Lift rear of car and suitably support.

2. Disconnect track rod from rear axle and frame

side member.

Installation

1. Loosely connect track rod first to side member and

then to the rear axle.

2. On the

1900 - Manta, load luggage compartment

of vehicle with approximately 350 lbs. or on the GT,

place a load of approximately 150 lbs. on driver’s

seat and tighten track rod attaching bolts to specified

torque.

3. Remove supports (jack stands) and lower vehicle.

Use a reliable torque wrench. Specifications are for clean and lightly-oiled

threads.

Part

Nut

Nut

Nut

Bolt

Nut

Nut

Nut

BoltName

WheelNuts.

.._.._......._........................................................

Control Arm Attaching (GT) .._.._.,,,........,,.,,.......,,......,,,,......

Control Arm Attaching (1 900 - Manta) .,,...._...,,,,_.....,,.,...

Stabilizer Rod to Underbody Retainers ,....._.,.,,.,.....,,,....

Shock Absorber Lower Attachment (GT) . .._.....,._.._.,,,...

Shock Absorber Lower Attachment (1900 Manta) ,,.,

Shock Absorber Upper Attachment. .._.....................

Stabilizer Shackle to Axle Bracket .._._.._,...._..,,.,,.......,,,...

Torque

Lb.Ft.

65

16

23

15

1,5

47

1025

Page 225 of 625

3G- 581873 OPEL SERVICE MANUALTire Wear IrregularitiesAn additional cause of vibrations may sometimes be

tire wear irregularities. These can also produce noise

disturbances, and can be generally corrected by

rotating the tires, Figure

3G-6. Before proceeding

further, locate and correct the cause of the irregular

tire wear. See Figure

3G-7.Use the criss-cross method of rotation of tires only

when all four tires are equally worn. In some in-

stances, it may be necessary to put the truest running

assemblies (those with the lowest tolerances) on the

front of the car.

Wheel Nut Torque end Tightening SpecificationsDuring all wheel installations, it is important to use

the correct procedures for installing wheel nuts and

torquing them uniformly and in proper sequence.

This is important in order to avoid possible distor-

tion of the brake drum or disc, and to minimize

damage to lug and nut threads and wheel stud holes.

To assure uniform tightening of wheel lug nuts, the

following procedure is recommended:

1. Install wheel lug nuts in a criss-cross pattern and

tighten just enough to seat wheel against hub. This

assures proper piloting of the wheel on its hub.

2. Tighten lug nuts uniformly to proper torque of 65

Ib.ft. using criss-cross pattern.

An impact wrench should not be used, as uniform

torque control cannot be maintained.

Summary of Diagnosis end Correction of Tire and

Wheel Vibration1. Inflate all tires to recommended pressure and

road-test car with owner to define problem.

2. Spin front tire/wheel assemblies with wheel driv-

ing equipment. Rear wheels may be spun with tires

off the ground and with one wheel held at a time. The

offending tire may cause vibration that may be felt

by touching the bumper or fender. By process of

elimination, determine offending tire/wheel assem-

bly.

3. Check for tire/wheel unbalance. Balance, if neces-

sary.4. Check each tire/wheel assembly on the car for

radial runout on the tire tread. Wheel and tire assem-

blies exceeding

.050 inches may be considered as

offending assemblies. Offending tire/wheel assemblyshould be deflated and the tire repositioned (indexed)

180 degrees from original location.

5. After repositioning, rebalance tire/wheel assembly

(static and dynamic preferred).

6. Test drive and evaluate correction.

The following procedure should be used to determine

cause of roughness or vibration with car in operation

at various speeds:

I. Jack up all wheels having jack support rear end of

car at center of rear axle housing.

2. With transmission in “Drive”, run engine at vari-

ous car speeds to note speeds at which vibration or

roughness occurs.

3. Remove rear wheels and run engine again at the

critical speeds noted in step 2. If roughness is gone,

the condition is caused by unbalanced wheel and tire

assemblies.

4. If roughness still exists with rear wheels removed,

remove rear brake drums and repeat the running

test. Elimination of the roughness indicates out of

balance brake drums.

5. If roughness still exists with brake drums

removed, run engine with transmission in “Neutral”.

Elimination of the roughness indicates that propeller

shaft is out of balance. Continued roughness indi-

cates an out-of- balance engine.

ABNORMAL TIRE WEAR

General Operating ConditionsAssuming that there is no misalignment condition to

cause abnormal wear, the life of tires depends largely

upon car operation conditions and driving habits.

Tires wear at a much faster rate in some localities

than in others because of road and operating condi-

tions. Some types of roads are much more abrasive

than others. Tire wear is also dependent upon the

number of hills and mountains which the car must

go up and down, the severity of grades, the number

of starts and stops, driging speeds, the amount of rain

and snow, and prevailing temperatures. Tire

wear

increases rapidly with speed, temperature, and loadon tire. Tires used at low speeds, in cool climates, or

with light loads will have longer life than tires used

for high-speed driving in hot climates with heavy

loads.

Driving habits have a very important hearing on tire

life. A careful driver may obtain much greater mile-

age from a set of tires than would be obtained by a

Page 228 of 625

WHEELS AND TIRES3G- 61Cornering Tread WearThe modern independently-sprung automobile al-

lows the driver to negotiate turns at a high rate of

speed with a greater feeling of safety. This fact is

responsible for a comparatively new type of tread

wear that can easily be mistaken for toe or camber

wear.When a car is making a turn, the tires are supposed

to be rolling in a circle. When the turn is made at

high speed, however, centrifugal force acting on the

car causes the tires to be distorted sideways and to

slip or skid on the road surface. This produces a

diagonal cross type of wear, which in severe cases

will result in a fine or sharp edge on each rib of the

tire treads.

Cornering wear can be distinguished from toe or

camber wear by the rounding of the outside shoulder

of the tire and by the roughening of tread surface in

this section denoting severe abrasion. See Figure

3G-7.No alignment or tire pressure cahnge can be made

that will relieve cornering wear. Only the driver can

effect a cure and that is by slowing down on curves.

Heel and Toe Tread WearHeel and toe wear is a saw-tooth effect with one end

of each tread block worn more than the other.

The end which wears is the one that first grips the

road when the brakes are applied. High-speed driv-

ing and excessive “se of the brakes will cause this

type of irregular tire wear. This type of wear will

occur on any type of block tread design. See Figure3G-7.

Heel and toe wear is not so prevalent on the rear tires

because of the propelling action which creates a

counteracting force which wears the opposite end of

the tread block. These two stresses on the rear tires

wear the tread blocks in opposite directions and re-

sult in more even wear while on the front tires, the

braking stress is the only one which is effective. This

may be counteracted by interchanging tires.

A small amount of irregular wear, slightly

saw-toothed in appearance, at the outer segments of tires

is a normal condition and is due to the difference in

circumference between the center and the outer

edges of the tire tread. This saw-toothed appearance,

however, will be exaggerated by underinflation, im-

proper toe-in, or both.Cupped or Scalloped Type Tire Wear

Cupping or scalloping is associated with wear on acar driven mostly at highway speeds without recom-

mended tire rotation. Factors which promote cup-

ping include underinflation, incorrect toe-in setting

or camber setting, and steady highway speeds on

smooth, paved surfaces as opposed to gravel or

rough asphalt.

The following recommendations suggest action that

may be taken to help prevent cupping.

1. Rotate tires as recommended in Figure

3G-6.2. Frequently inspect front tires for irregular wear

due to underinflation, improper toe-in setting, or

camber setting. Regardless of the original cause of

cupped tread wear on either front tire, no alignment

or balance job, however perfect, can prevent future

excessive wear of the spots. Once a front tire acquires

flat or cupped spots, additional wear will continue at

a rapid rate. At the time of correction, however, the

cupped tire should be interchanged with a rear tire

on which the tread runs true. The cupped tire will,

to a certain degree, true itself on a rear wheel.

Although not normally the cause of cupping, the

following factors can contribute to the problem.

Looseness of parts in the suspension system, such as

worn steering knuckle ball joints, loose wheel bear-

ings, inoperative shock absorbers, and any excessive

looseness throughout the steering system all tend to

allow the front wheels to kick around and, if any of

the wheel alignment factors are incorrect, irregular

spotty tire tread wear of one type or another may

result.

Wobble or runout of a tire, either front or rear, due

to bent wheel or to tire being improperly mounted

will cause uneven wear.

MAINTENANCE AND ADJUSTMENTSDEMOUNTING AND MOUNTING

TUBELESS TIRESDue to “se of symmetrical rims, tires must be

mounted over the narrow rim shoulder i.e., over out-

side rim flange.

When demounting a tubeless tire “se care to avoid

damaging the rim-seal ridges on tire beads DO NOT

USE TIRE IRONS TO FORCE BEADS A WA Y

FROM WHEEL RIM FLANGES.

When tire is removed, inspect it carefully to deter-

mine whether loss of air was caused by puncture or

by improper

tit of beads against rim flanges. If im-

proper fit is indicated, check wheel as follows: Do

not reuse dented rims.

Page 234 of 625

PROPELLER SHAFT AND CENTRAL JOINT4A- 3MAJOR REPAIR

PROPELLER SHAFT REMOVAL AND

INSTALLATION

Removal

1. Raise rear of car and support on jack stands at rear

jack brackets.

2. Disconnect parking brake cable equalizer from

rod.3. On the Opel

1900 and Manta, unhook parking

brake cable from floor panel.

4. On the Opel 1900 and Manta, unhook exhaust

system and let it down.

5. Mark the mating parts of the U-joint and the drive

pinion extension shaft flange.

6. Loosen bolt locks and remove bolts or nuts.

7. Work propeller shaft slightly forward, lower rear

end of shaft and slide assembly rearward. Remove

thrust spring from front of propeller shaft.

S. Install plug in transmission extension housing to

prevent loss of lubricant.

installation

CAUTION:

Fasteners in the foJlowing steps are impor-

tant attaching parts in that they could affect the

performance of

vital components and systems, and-

/or could

result in major repair expense. They must

be replaced with one of the

samepart number or with

an equivalent part

ifreplacement becomes oecessary.

Do not use a replacement part of lesser quality or

substitute design. Torque values must be used as

specirid during reassembly to assure proper reten-

tion of these parts.1. Remove plug from rear of transmission.

2. Slide thrust spring onto transmission output shaft

and slide propeller shaft through the oil seal and onto

the transmission output shaft. Make certain trans-

mission rear seal is not damaged.

3. Align rear universal joint and pinion flange locat-

ing marks and secure with respective bolts and lock

plates. Torque bolts to 11

lb.ft. Bend lock plate tangs

to secure bolts or nuts.

4. Connect parking brake cable equalizer to brake

rod and adjust to specifications.

5. On the Opel 1900 and Manta connect parking

brake cable to floor panel.DISASSEMBLY AND ASSEMBLY OF THE

CENTRAL JOINT

Disassembly of Central Joint1. Raise and support rear of car under axle tubes.

2. Release brake line bracket from rear of torque

tube.3. Disconnect parking brake cable equalizer and re-

turn spring from brake rod.

4. On the Opel 1900 and Manta, unhook exhaust

system and let it down.

5. Mark universal joint and flange. Disconnect pro-

peller shaft from flange and support it out of the way.

6. Support torque tube with floor jack using mini-

mum pressure.

7. Remove the central joint bracket to underbody

attaching bolts.

8. Allow floor jack to lower the torque tube.

9. Disconnect torque tube from differential carrier by

removing the attaching bolts.

10. Install pinion flange holder J-8614 and remove

self-locking flange nut. See Figure 4A-2.

FLANGE HOLDER4A-2

Figure 4A-2 Removing Pinion Flange Nut

11. Pull pinion flange using J-8614 adapter. See Fig-

ure 4A-3.

12. Remove drive pinion extension shaft from torque

tube using a soft faced mallet. See Figure 4A- 4.

13. Removal ball bearing from cushion.

14. With torque tube placed in vise remove support

Page 242 of 625

REAR AXLE40- 11

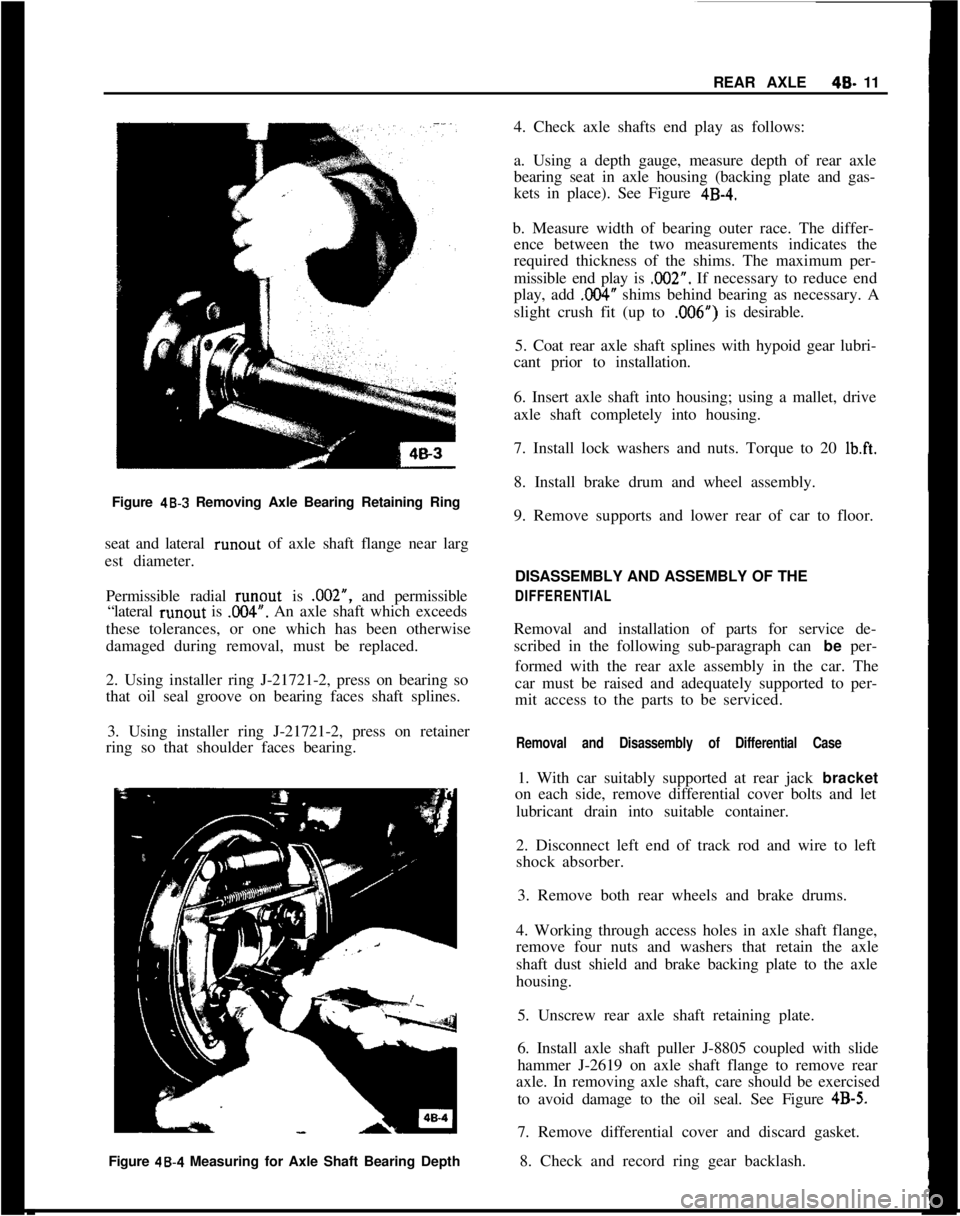

Figure

48-3 Removing Axle Bearing Retaining Ring

seat and lateral runout of axle shaft flange near larg

est diameter.

Permissible radial runout is .002”, and permissible

“lateral runout is

.OO4”. An axle shaft which exceeds

these tolerances, or one which has been otherwise

damaged during removal, must be replaced.

2. Using installer ring J-21721-2, press on bearing so

that oil seal groove on bearing faces shaft splines.

3. Using installer ring J-21721-2, press on retainer

ring so that shoulder faces bearing.

Figure 48.4 Measuring for Axle Shaft Bearing Depth4. Check axle shafts end play as follows:

a. Using a depth gauge, measure depth of rear axle

bearing seat in axle housing (backing plate and gas-

kets in place). See Figure

4B-4.b. Measure width of bearing outer race. The differ-

ence between the two measurements indicates the

required thickness of the shims. The maximum per-

missible end play is .002”. If necessary to reduce end

play, add

,004” shims behind bearing as necessary. A

slight crush fit (up to ,006”) is desirable.

5. Coat rear axle shaft splines with hypoid gear lubri-

cant prior to installation.

6. Insert axle shaft into housing; using a mallet, drive

axle shaft completely into housing.

7. Install lock washers and nuts. Torque to 20

Ib.ft.8. Install brake drum and wheel assembly.

9. Remove supports and lower rear of car to floor.

DISASSEMBLY AND ASSEMBLY OF THE

DIFFERENTIALRemoval and installation of parts for service de-

scribed in the following sub-paragraph can be per-

formed with the rear axle assembly in the car. The

car must be raised and adequately supported to per-

mit access to the parts to be serviced.

Removal and Disassembly of Differential Case1. With car suitably supported at rear jack bracket

on each side, remove differential cover bolts and let

lubricant drain into suitable container.

2. Disconnect left end of track rod and wire to left

shock absorber.

3. Remove both rear wheels and brake drums.

4. Working through access holes in axle shaft flange,

remove four nuts and washers that retain the axle

shaft dust shield and brake backing plate to the axle

housing.

5. Unscrew rear axle shaft retaining plate.

6. Install axle shaft puller J-8805 coupled with slide

hammer J-2619 on axle shaft flange to remove rear

axle. In removing axle shaft, care should be exercised

to avoid damage to the oil seal. See Figure

4B-5.7. Remove differential cover and discard gasket.

8. Check and record ring gear backlash.

Page 261 of 625

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION:

Power

BrakeBooster. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Master

Cylinder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Power

Brake

,UnitTroubleDiagnosis. . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

Checking Brake Booster Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . .Brake Booster Filter Service

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..Vacuum Control Valve Service

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

5A-2

5A-2SA-4SA-5

5A-65A-6

Brake Booster Removal and Installation

. . . . . . . . . . . . . . . . . .Master Cylinder Overhaul

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . . . .SPECIFICATIONS:

General

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SA-6

5A-7

5A-95A. 21973 OPEL SERVICE MANUAL

POWER BRAKE BOOSTER AND MASTER CYLINDER

DESCRIPTION AND OPERATION

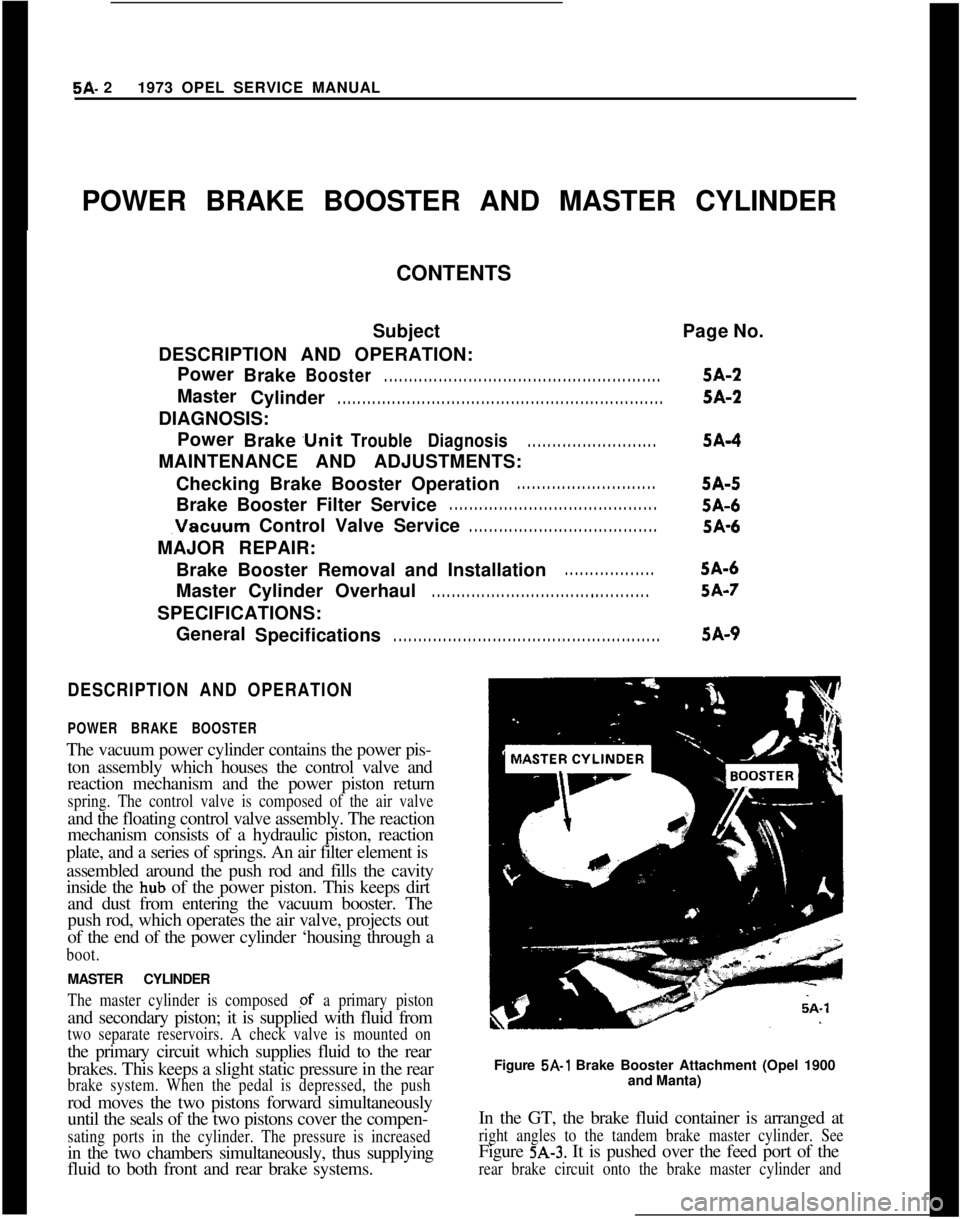

POWER BRAKE BOOSTERThe vacuum power cylinder contains the power pis-

ton assembly which houses the control valve and

reaction mechanism and the power piston return

spring. The control valve is composed of the air valveand the floating control valve assembly. The reaction

mechanism consists of a hydraulic piston, reaction

plate, and a series of springs. An air filter element is

assembled around the push rod and fills the cavity

inside the hub of the power piston. This keeps dirt

and dust from entering the vacuum booster. The

push rod, which operates the air valve, projects out

of the end of the power cylinder ‘housing through a

boot.MASTER CYLINDER

The master cylinder is composed pf a primary pistonand secondary piston; it is supplied with fluid from

two separate reservoirs. A check valve is mounted onthe primary circuit which supplies fluid to the rear

brakes. This keeps a slight static pressure in the rear

brake system. When the pedal is depressed, the pushrod moves the two pistons forward simultaneously

until the seals of the two pistons cover the compen-

sating ports in the cylinder. The pressure is increasedin the two chambers simultaneously, thus supplying

fluid to both front and rear brake systems.Figure

5A-1 Brake Booster Attachment (Opel 1900

and Manta)

In the GT, the brake fluid container is arranged at

right angles to the tandem brake master cylinder. SeeFigure

5A-3. It is pushed over the feed port of the

rear brake circuit onto the brake master cylinder and

Page 265 of 625

5A- 61973 OPEL SERVICE MANUAL

ing on dusty and sandy roads - the filter and sound

deadener should occasionally be replaced. To do so,

brake booster has to be removed without detaching

brake master cylinder.

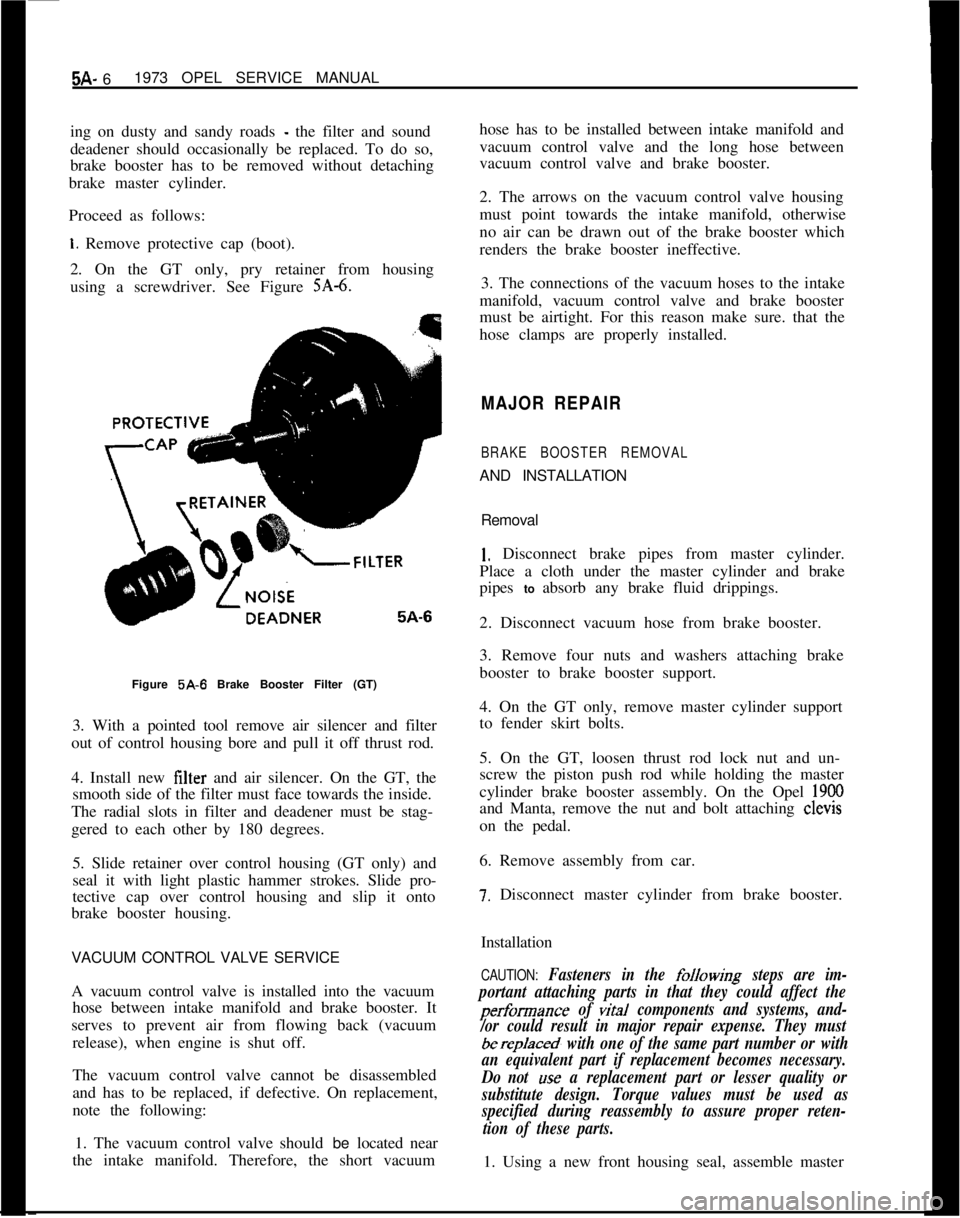

Proceed as follows:

1. Remove protective cap (boot).

2. On the GT only, pry retainer from housing

using a screwdriver. See Figure

SA-6.Figure 5A-6 Brake Booster Filter (GT)

3. With a pointed tool remove air silencer and filter

out of control housing bore and pull it off thrust rod.

4. Install new filter and air silencer. On the GT, the

smooth side of the filter must face towards the inside.

The radial slots in filter and deadener must be stag-

gered to each other by 180 degrees.

5. Slide retainer over control housing (GT only) and

seal it with light plastic hammer strokes. Slide pro-

tective cap over control housing and slip it onto

brake booster housing.

VACUUM CONTROL VALVE SERVICE

A vacuum control valve is installed into the vacuum

hose between intake manifold and brake booster. It

serves to prevent air from flowing back (vacuum

release), when engine is shut off.

The vacuum control valve cannot be disassembled

and has to be replaced, if defective. On replacement,

note the following:

1. The vacuum control valve should be located near

the intake manifold. Therefore, the short vacuumhose has to be installed between intake manifold and

vacuum control valve and the long hose between

vacuum control valve and brake booster.

2. The arrows on the vacuum control valve housing

must point towards the intake manifold, otherwise

no air can be drawn out of the brake booster which

renders the brake booster ineffective.

3. The connections of the vacuum hoses to the intake

manifold, vacuum control valve and brake booster

must be airtight. For this reason make sure. that the

hose clamps are properly installed.

MAJOR REPAIR

BRAKE BOOSTER REMOVALAND INSTALLATION

Removal

1. Disconnect brake pipes from master cylinder.

Place a cloth under the master cylinder and brake

pipes to absorb any brake fluid drippings.

2. Disconnect vacuum hose from brake booster.

3. Remove four nuts and washers attaching brake

booster to brake booster support.

4. On the GT only, remove master cylinder support

to fender skirt bolts.

5. On the GT, loosen thrust rod lock nut and un-

screw the piston push rod while holding the master

cylinder brake booster assembly. On the Opel

1900and Manta, remove the nut and bolt attaching clevis

on the pedal.

6. Remove assembly from car.

7. Disconnect master cylinder from brake booster.

Installation

CAUTION: Fasteners in the folkwing steps are im-

portant attaching parts in that they could affect the

performance of vital components and systems, and-

/or could result in major repair expense. They must

berep/aced, with one of the same part number or with

an equivalent part if replacement becomes necessary.

Do not

use a replacement part or lesser quality or

substitute design. Torque values must be used as

specified during reassembly to assure proper reten-

tion of these parts.1. Using a new front housing seal, assemble master

Page 266 of 625

POWER BRAKE BOOSTER AND MASTER CYLINDER5A- 7cylinder to brake booster and torque nuts to 14

Ib.ft.on the GT and 12

lb.ft. on the Opel 1900 and Manta.

2. Position assembly into brake booster bracket and,

on the GT only, thread piston push rod onto the

thrust rod.

3. Install brake booster to support attaching washers

and nuts and tighten to 11

lb.ft. of torque.

4. On the GT install master cylinder support to inner

fender skirt bolts.

5. Connect vacuum hose to brake booster.

6. By turning the piston push rod on the thrust rod,

(GT only) adjust until the brake pedal free travel is

l/4 inch and tighten the lock nut.

7. Connect brake pipes to master cylinder and bleed

brakes.

MASTER CYLINDER OVERHAUL. GT

Removal of Master Cylinder1. Disconnect the two brake pipes from the master

cylinder.

2. Remove the front support to skirt attaching bolts,

the cylinder to booster retaining nuts and lift out

master cylinder.

Disassembly1. Prior to brake master cylinder disassembly, pour

brake fluid out of brake fluid reservoir, remove reser-

voir from master cylinder and take sealing plugs out

of housing.

2. Screw static pressure valve(s) out of housing.

3. To facilitate disassembly, push piston somewhat

into cylinder and insert a rounded off piece of weld-

ing rod approx.

.12 in. thick into feed port to retain

piston in this position.

4. Remove stop screw and snap ring out of housing

and take out both pistons together with springs.

5. Remove stop screw from piston for rear brake

circuit and remove all component parts. Remove

also all component parts from intermediate piston of

front brake circuit.

Cleaning and Checking1. Clean parts with genuine brake fluid, Delco Su-

preme No. 11, or equivalent. Do not use any other

cleaning solvents. Dry with compressed air. Free up

compensating and feed ports.2. Polish cylinder bore of housing with crocus cloth.

If lapping scores and rust spots are still noticeable,

replace brake master cylinder assembly.

3. Check inner components for damage and replace,

if required. The rubber seals and static pressure valve

always have to be replaced.

Assembly1. Assemble front and rear brake circuit pistons.

Prior to assembly coat rubber seals with brake fluid.

2. Coat cylinder bore, piston sliding surfaces and

seals with brake fluid.

3. Insert preassembled intermediate piston for front

brake circuit together with thrust spring and spring

seat into clyinder bore. The smaller diameter of the

tapered thrust spring must face piston.

4. With a drift, push piston (against spring pres-

sure) into housing and insert a piece of welding rod

into feed port of front brake circuit to retain piston.

5. Install stop screw with new seal ring into housing

and tighten.

6. Insert preassembled piston for rear brake circuit

into cylinder bore and install snap ring into groove

in housing.

7. Check piston fof free movement by moving it to

and fro. If required, place washers under the head of

the stop screw.

8. Lightly push piston into housing and remove

piece of welding rod out of feed port of front brake

circuit.

9. With a rounded off piece of welding rod

(.020 -

,024 in.) check whether compensating ports are free.

10. Screw in new static pressure valve(s).

11. Coat new sealing plugs with brake fluid and in-

sert them into housing. Push twin brake fluid con-

tainer into sealing plugs and install screen and cover

with seal ring.

Installation1. Install master cylinder onto brake booster with

washers and nuts. Torque to 14

lb.ft.2. Attach the front mounting bracket.

3. Install brake lines on master cylinder, and bleed

brakes.

Page 267 of 625

5A- 81973 OPEL SERVICE MANUAL

4. If required, adjust mechanically actuated stop

light switch. Pedal travel of 5/S” to 1” should actu-

ate switch. Add or subtract washers between bracket

and switch to obtain proper adjustment.

5. Road test car for proper brake performance.

MASTER CYLINDER OVERHAUL. OPEL 1900

AND MANTA

Ramoval of Master Cylinder1. Remove master cylinder from brake booster by

disconnecting brake pipes and removing two

self-tightening nuts that secure master cylinder to brake;ia;;ter. Be careful not to loosen the front housing

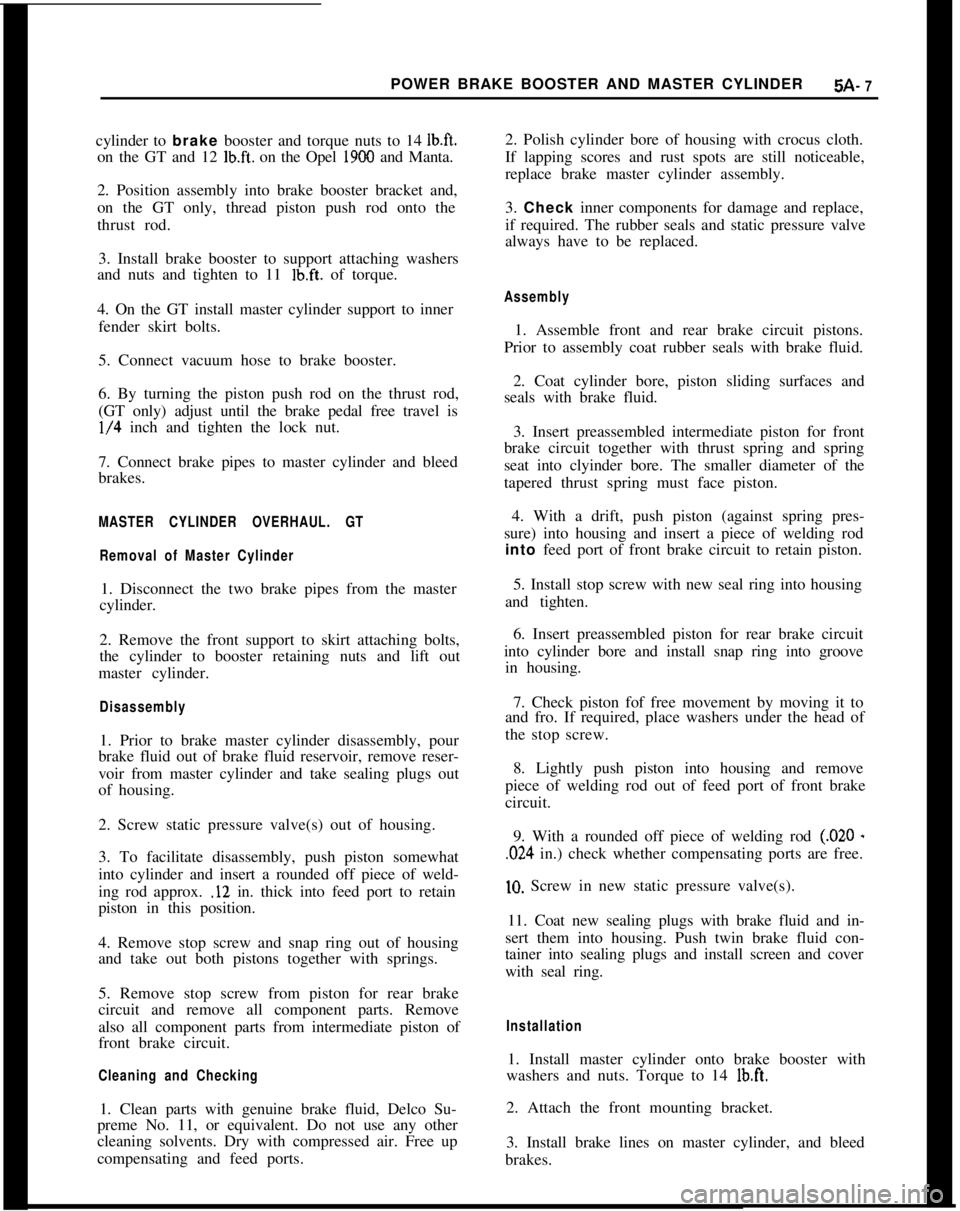

Disassembly1. Prior-to brake master cylinder disassembly, pour

brake fluid out of brake fluid reservoir.

2. Remove reservoir from master cylinder body by

removing reservoir clips with snap ring pliers. See

Figure 5A-7.

Figure

5A-7 Removing Reservoir Clips

3. Remove the piston stop screw which is fitted in

master cylinder body.

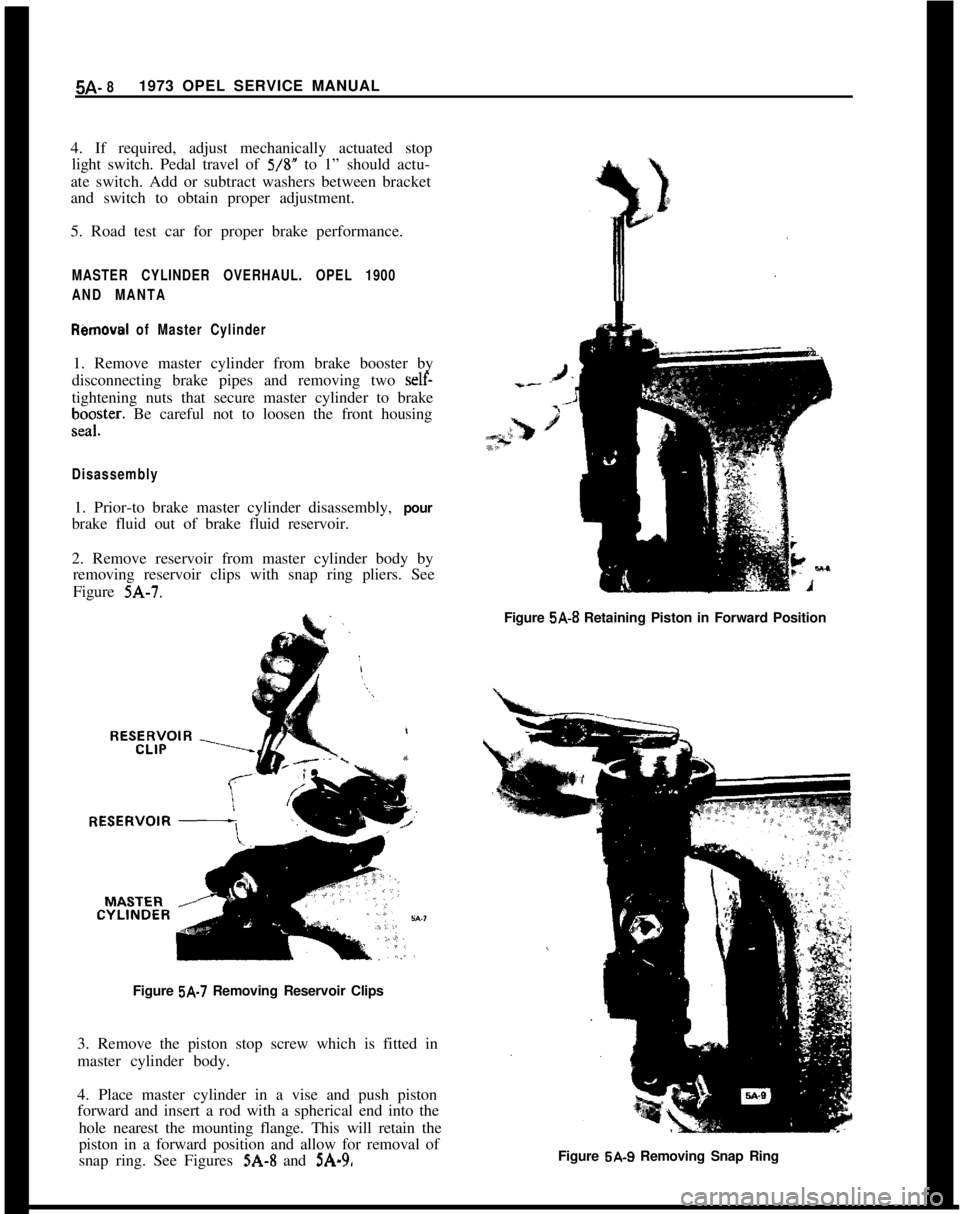

4. Place master cylinder in a vise and push piston

forward and insert a rod with a spherical end into the

hole nearest the mounting flange. This will retain the

piston in a forward position and allow for removal of

snap ring. See Figures

SA-8 and 5A-9,Figure 5A.8 Retaining Piston in Forward Position

Figure 6A-9 Removing Snap Ring

Page 273 of 625

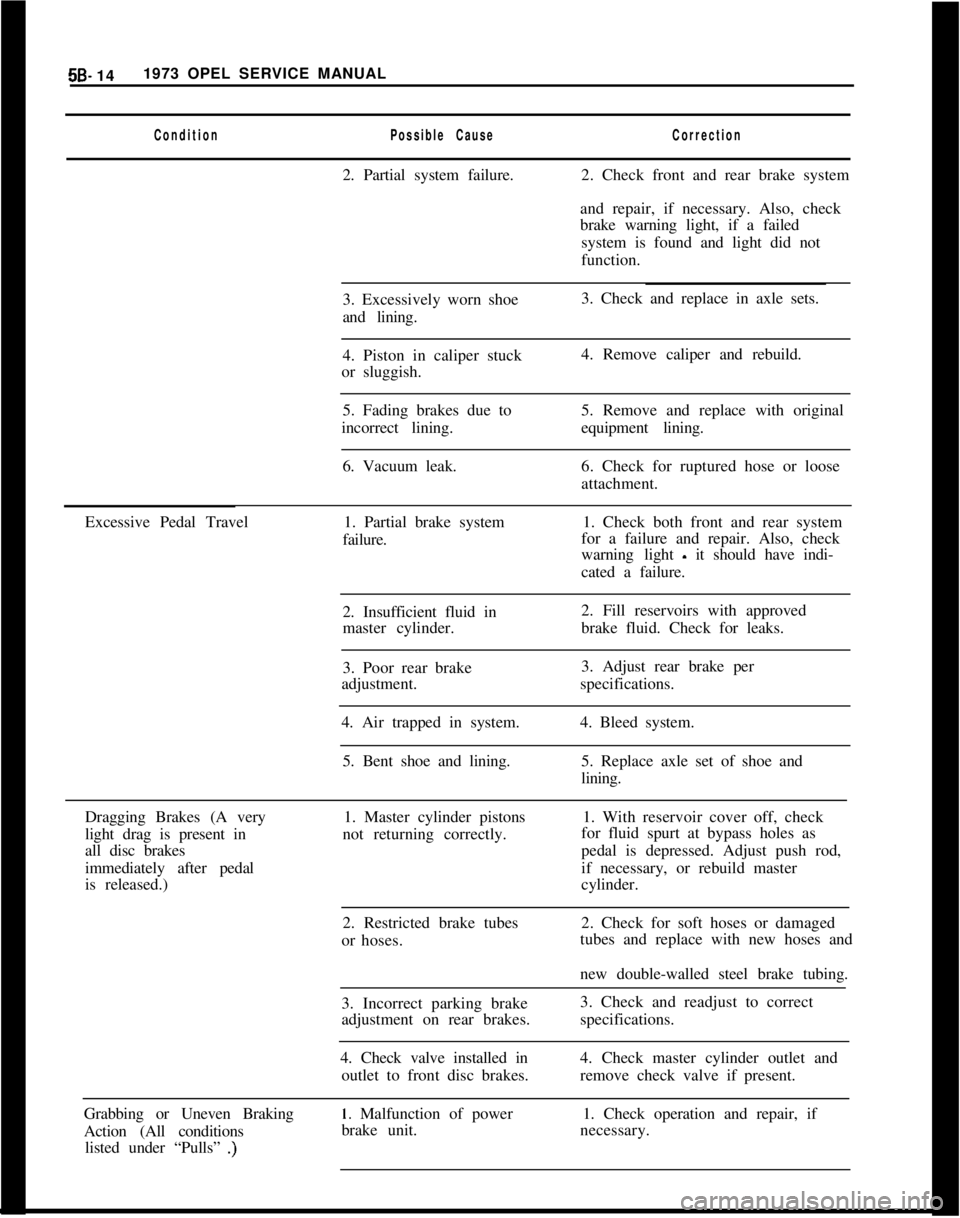

5B- 141973 OPEL SERVICE MANUALConditionPossible CauseCorrection2. Partial system failure.2. Check front and rear brake system

and repair, if necessary. Also, check

brake warning light, if a failed

system is found and light did not

function.

3. Excessively worn shoe

and lining.3. Check and replace in axle sets.

4. Piston in caliper stuck

or sluggish.4. Remove caliper and rebuild.

5. Fading brakes due to

incorrect lining.

6. Vacuum leak.5. Remove and replace with original

equipment lining.

6. Check for ruptured hose or loose

attachment.

Excessive Pedal Travel1. Partial brake system

failure.1. Check both front and rear system

for a failure and repair. Also, check

warning light

- it should have indi-

cated a failure.

2. Insufficient fluid in

master cylinder.

3. Poor rear brake

adjustment.2. Fill reservoirs with approved

brake fluid. Check for leaks.

3. Adjust rear brake per

specifications.

4. Air trapped in system.4. Bleed system.

5. Bent shoe and lining.5. Replace axle set of shoe and

lining.

Dragging Brakes (A very

light drag is present in

all disc brakes

immediately after pedal

is released.)1. Master cylinder pistons

not returning correctly.1. With reservoir cover off, check

for fluid spurt at bypass holes as

pedal is depressed. Adjust push rod,

if necessary, or rebuild master

cylinder.

2. Restricted brake tubes2. Check for soft hoses or damaged

or hoses.tubes and replace with new hoses and

new double-walled steel brake tubing.

3. Incorrect parking brake

adjustment on rear brakes.3. Check and readjust to correct

specifications.

Grabbing or Uneven Braking

Action (All conditions

listed under “Pulls”

.)4. Check valve installed in

outlet to front disc brakes.

1. Malfunction of power

brake unit.4. Check master cylinder outlet and

remove check valve if present.

1. Check operation and repair, if

necessary.