oil type OPEL 1900 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 323 of 625

66.321973 OPEL SERVICE MANUAL

COOLING SYSTEM

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Cooling System and Water Pump

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Checking and Filling Cooling System

. . . . . . . . . . . . . . . . . . . . . . . .Draining

andFlushingCoolingSystem. . . . . . . . . . . . . . . . . . . . . .Conditioning the Cooling System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Using and Testing Anti-Freeze Solutions

. . . . . . . . . . . . . . . . . .Fan Belt Adjustment or Replacement

. . . . . . . . . . . . . . . . . . . . . . . .Radiator Thermostat Inspection and Test

. . . . . . . . . . . . . . . .MAJOR REPAIR:

Water Pump Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Radiator

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Cooling System Capacities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

68-32

6B-32

68-32

68-33

68-33

68-33

68-33

68-34

68-34

6B-35

DESCRIPTION AND OPERATION

COOLING SYSTEM AND WATER PUMPThe coiling system is of the conventional pressurized

type. A centrifugal pump arranged in timing case

serves to circulate the coolant.

When the thermostat is closed, the coolant will re-

turn to the pump via a by-pass for swift and uniform

warming up of the engine the coolant circulates

through the radiator, only when the engine has

reached normal operating temperature.

The heater system branches off the cooling system

ahead of thermostat in flow direction so that the

heater is in operation before engine has reached full

operating temperature.

MAINTENANCE AND ADJUSTMENTS

Checking and Filling Cooling SystemThe coolant level should be checked only when the

engine is cold and only enough coolant should be

added to bring the level halfway between core andtank top. It is unnecessary and undesirable to remove

the radiator cap and check the coolant level each

time the car stops at a filling station for gasoline or

oil, since the engine is usually hot at such times.

WARNING: Never remove the radiator cap quickly

when engine is HOT Sudden release of cooling

sys-

tern pressure may cause the coolant to boil and some

of it may be ejected from the radiator

filler neck,

resulting in

inl’ury to persons or damage to the car

finish.If it is necessary at any time to remove the radiator

cap when engine is hot, rotate the cap counterclock-

wise until first stop is reached. Leave cap in this

position until all pressure in cooling system has been

released, then turn cap past the first stop and remove

it.

Draining and Flushing

Cooling SystemThe cooling system should be completely drained

and the recommended coolant installed every two (2)

years.To drain the cooling system, remove radiator cap,

remove lower radiator hose from the lower tank and

Page 324 of 625

COOLING SYSTEM6B- 33

remove drain plug on right.side of cylinder block. Set

heater temperature control valve at full heat posi-

tion. After the cooling system is drained, and plugs

reinstalled, fill the system with clean water. Run the

engine long enough to open the thermostat for com-

plete circulation through the system, then com-

pletely drain the cooling system before sediment has

a chance to settle.

Conditioning the Cooling System

“Rust Inhibitor and Stop Leak”, or equivalent listed

under Group 8.800 is recommended for use in the

cooling system, particularly when preparing for in-

stallation of anti-freeze solution. This material stops

small seepage leaks, has rust preventive properties

and its soluble oil is effective in eliminating a squeal-

ing noise which sometimes develops at the water

pump seal washer. Instructions for its application are

printed on the conditioner bottle.

It is very important to make certain that the cooling

system is properly prepared before an anti-freeze so-

lution is installed, otherwise loss of solution through

leakage may occur or seepage may result in damage

to the engine. The cooling system should be drained

and flushed as described under Draining and Flush-

ing Cooling System. All joints should be checked for

leakage and corrected, and the conditioner described

above should be added with the anti-freeze solution.

Inspect the water pump, radiator core, heater and

defroster cores, water jacket plugs, and edge of cylin-

der head gaskets for evidence of water leaks. Tighten

all hose clamps in the cooling and heating systems

and replace any deteriorated hoses.

Using and Testing Anti-Freeze

Solutions

Inhibited year around (ethylene glycol type) engine

coolant solution which is formulated to withstand

two full calendar years of normal operation without

draining or adding inhibitors should be used at all

times. Freeze protection should be provided to pro-

tect against corrosion. When adding solution due to

loss of coolant for any reason or in areas where tem-

peratures lower than minus 20 degrees F. may be

encountered, a sufficient amount of any of the sev-

eral brands of year around coolant (Ethylene Glycol

base) compatible to GM Specification 1899-M avail-

able on the market should be used. Water or alcohol

base coolants are not recommended for this vehicle

at any time.

If for any reason water only is used as a coolant in

an emergency, it is extremely important that Buick

Heavy Duty Cooling System Protector and Water

Pump Lubricant or equivalent be added to the cool-

ing system as soon as possible. If any other cooling

System protector is used, be certain it is labeled toindicate that it meets General Motors Specification

GM 1894-M. It should be recognized that this is only

a temporary measure. The manufacture intends that

permanent type coolant solution be used year around

in the cooling system.

The cooling system should be completely drained

and the recommended coolant installed every two (2)years.It is advisable to test the anti-freeze solution at inter-

vals during the winter to make certain that the solu-

tion has not been weakened. Use only hydrometers

which are calibrated to read both the specific gravity

and the temperature, and have a table or other means

of converting the freezing point at various tempera-

tures of solution. Disregarding the temperature of

the solution when making the test may cause an error

as large as 30 degrees F. Care must be exercised to

use the correct float or table for the particular type

of anti-freeze being tested.

Fan Belt Adjustment or Replacement

A tight fan belt will cause rapid wear of the alterna-

tor and water pump bearings. A loose belt will slip

and wear excessively and will cause noise, engine

over-heating, and unsteady alternator output. A fan

belt which is cracked or frayed, or which is worn so

that it bottoms in the pulleys should be replaced. The

fan belt may be replaced by loosening the alternator

brace at alternator, slightly loosening the alternator

mounting bolts and moving alternator inward to pro-

vide maximum slack in the belt.

The alternator must be moved outward to adjust the

fan belt. After the generator brace and mounting

bolts are securely tightened, the fan belt tension

should be 45 lb. using Tensioner J-23600.

WARNING: Zfa

fan blade is bent or damaged in any

way, no attempt should be made to repair and reuse

the damaged part. A bent or damaged fan assembly

should always be replaced with a new

fal. assembly.

It is essential that fan assemblies remain in proper

balance and proper balance cannot be assured once

a fan assembly has been bent or damaged. A fan

assembly that is not in proper balance could fail and

fly apart during subsequent

we creating an ex-

tremely dangerous condition.

Radiator Thermostat Inspection and Test

A sticking radiator thermostat will prevent the cool-

ing system from functioning properly. If the thermo-

stat sticks in the open position, the engine will warm

up very slowly. If the thermostat sticks in the closed

position, the engine will overheat.

The thermostat may be removed for inspection and

Page 325 of 625

6B- 341973 OPEL SERVICE MANUAL

test by partially draining the cooling system and dis-

connecting the water outlet housing from the ther-

mostat housing which is mounted on the right front

side of cylinder head.

The standard thermostat valve should start to open

at 189 degrees F and fully open at approximately 212

degrees F. If thermostat does not operate at specified

temperatures, it should be replaced as it cannot be

repaired.MAJOR REPAIR

WATER PUMP REPAIRSThe water pump bearing outer race is shrunk fit into

the water pump cover. For this reason the cover,

shaft bearing, and hub are not repairable.

Water Pump RemovalOpel radiators do not have a drain plug. Drain radia-

tor by first, loosening radiator cap, then remove

lower hose from lower radiator tank.

1. Drain coolant into a clean container. Remove

radiator and shroud.

2. Remove fan belt.

3. Remove fan blade and pulley on water pump shaft.

4. Disconnect inlet hose and heater hose from water

pump. Remove bolts, pump assembly and gasket

from timing chain cover.

5. Check pump shaft bearing for end play or rough-

ness in operation. If bearings are not in serviceable

condition, the assembly must be replaced.

Water Pump Installation1. Make sure the gasket surfaces on pump and timing

chain covers are clean. Install pump assembly with

new gasket. Bolts must be tightened uniformly.

Torque to 11 lb. ft.

2. Install radiator and shroud. Connect radiator hose

to pump inlet and heater hose to nipple.

3. Install fan pulley and fan blade, tighten attaching

bolts securely. Install belts and adjust for proper

tension.4. Fill cooling system and check

,for leaks at pump

and hose joints.

RADIATOR REMOVAL AND INSTALLATION

RemovalI. Loosen radiator cap, then remove lower radiator

hose and drain radiator coolant into suitable con-

tainer.

2. On vehicles with automatic transmission, unscrew

oil lines from connectors on lower radiator tank and

plug lines. On GT models with automatic transmis-

sion the lines have to be disconnected at the coupling

before removing from the tank. It is essential that no

dirt enters the oil lines. When unscrewing oil lines,

hold connectors on lower radiator tank with pliers to

avoid leakages. Ensure that no dirt enters oil cooler.

3. Remove lower attaching nut and slide radiator

upward and out of engine compartment.

Installation1. Install radiat,or into engine compartment and se-

cure lower attaching nut.

2. On vehicles with automatic transmissions, fasten

oil cooler lines to lower radiator tank. It is essential

that no dirt enters the oil lines. When tightening oil

lines, hold connectors on lower radiator tank with

pliers to avoid leakages. Ensure that no dirt enters oil

cooler. Torque to 1 I-15

lbs.ft.3. Install lower radiator hose and add collected coo-

lant.

All Opels are provided with a radiator initial fill of

an antifreeze solution containing corrosion inhibitor.

The antifreeze has either a glycol or glycerin base

and protects the engine against freezing, down to

minus 22 degrees F. (minus 30 degrees C.). Before

the start of the cold season, coolant must be checked

with a hydrometer and if necessary, brought to the

necessary specific gravity by adding anti-freeze with

a glycol or glycerin base. As the specific gravities of

all anti- freeze solutions having a glycol or glycerin

base are practically the same, the hydrometer can be

used for all these types. Because of the tolerances of

the hydrometer, or slight differences in specific

gravity, variations of plus or minus 5 degrees can be

expected. Coolant must be checked at a temperature

of plus 68 degrees F. (plus 20 degrees C.)

Page 409 of 625

7C- 481973 OPEL SERVICE MANUAL

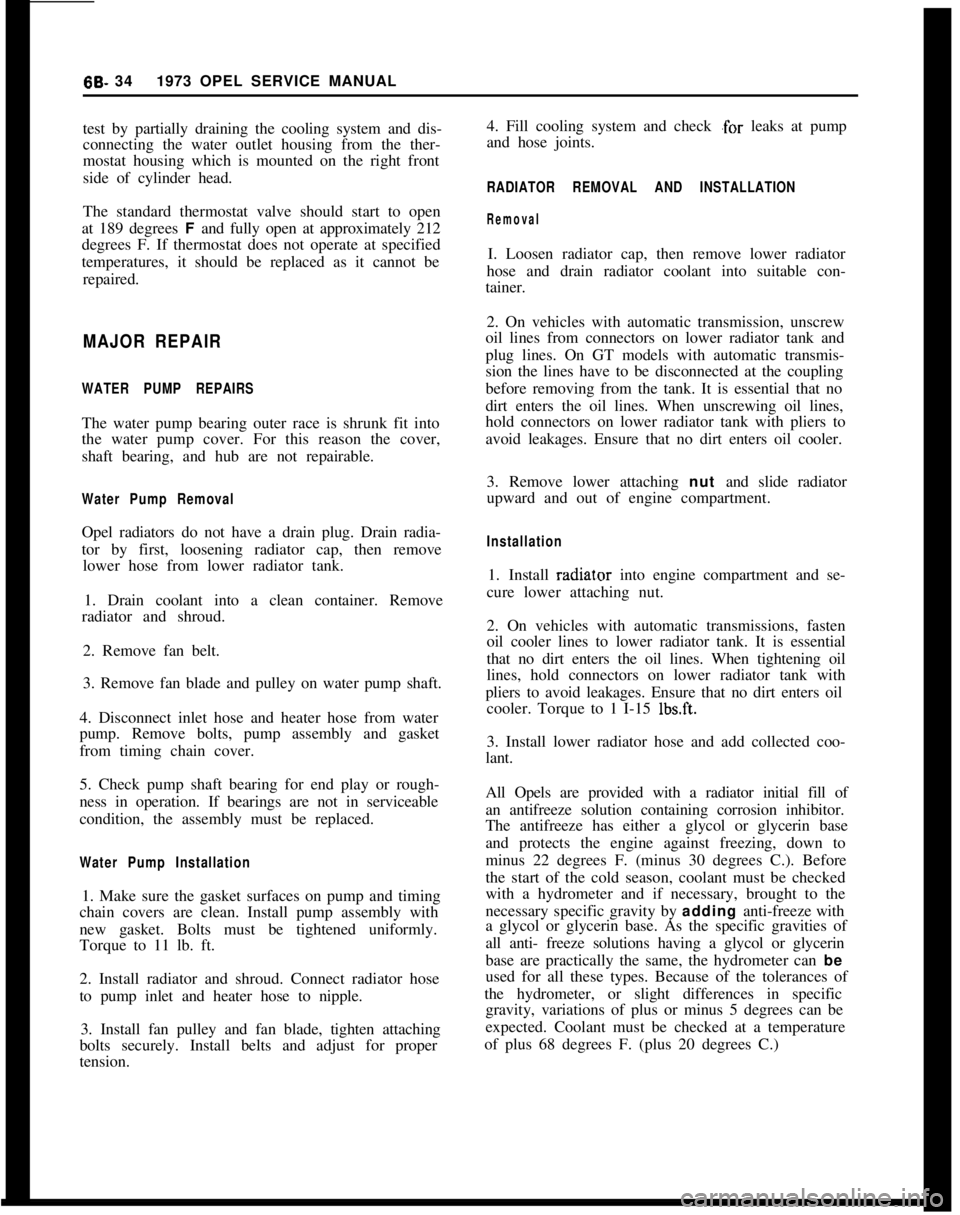

INPUT SUNRING

GEAR ASSY.GEARPLANETARY

CARRIERASSY.REACTION SUNtow

GEAR 8 DRUMBAND

Figure 7C-25Planetary Gears

The planetary pinion shafts which support the plane-

tary pinions are secured to the planetary carrier by

means of a lock plate at the rear of the planetary

carrier preventing the pinion shafts from rotating or

working loose. The lock plate is secured to the car-

rier by screws.

The planetary carrier is welded to the output shaft,

therefore, the directional movement of the carrier

delivers the transmission’s torque to the output shaft.

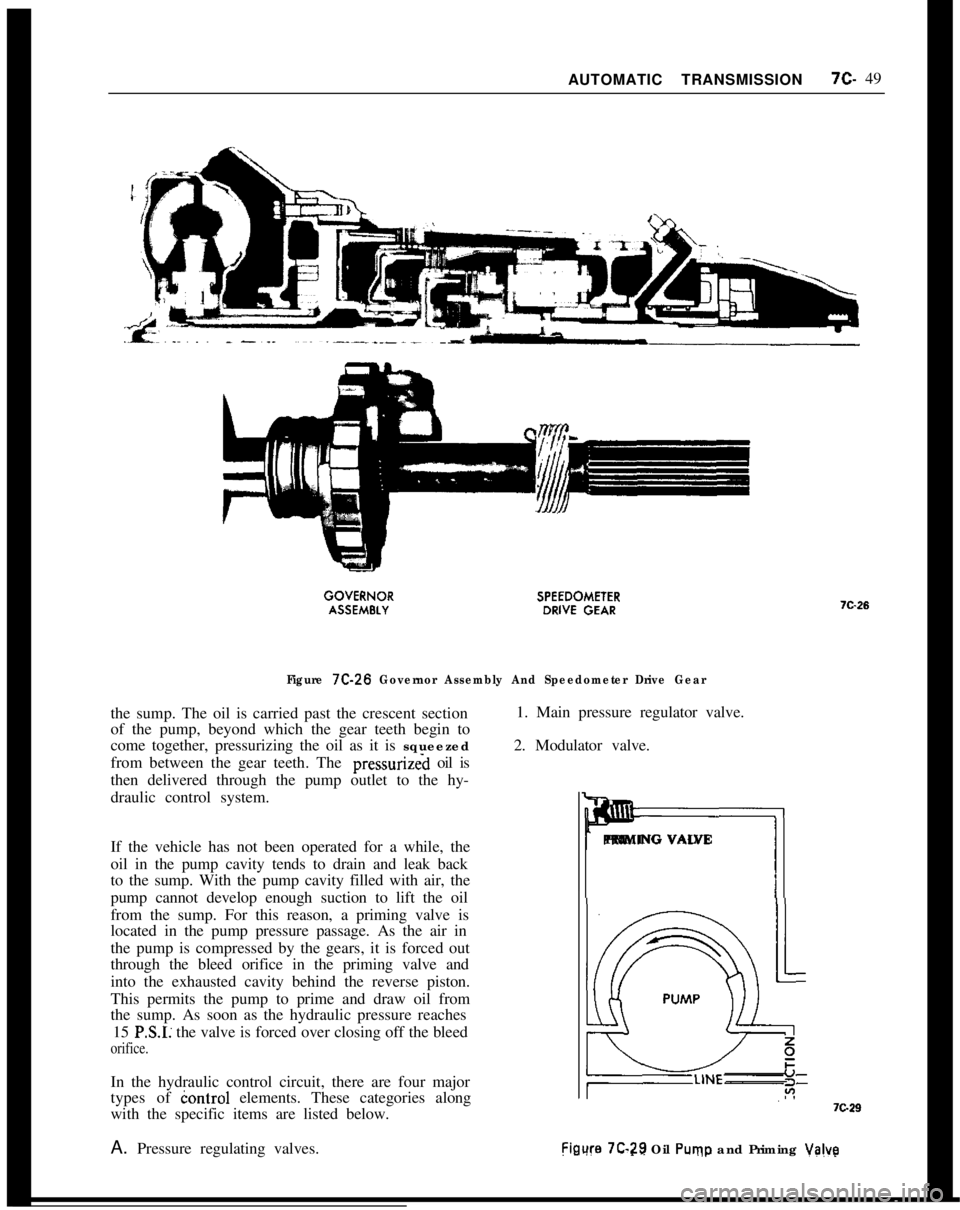

The governor hub is splined to, and driven by, the

output shaft. See Figure 7C-26. A governor body is

bolted to the governor hub. The speedometer drive

gear is also driven by the output shaft, and is secured

to the shaft by a retaining clip.

MECHANICAL OPERATIONThe following information describes how engine

torque is transmitted through the Opel Three Speed

automatic transmission for each selected position on

the quadrant. In every case, with the engine running,

torque is transmitted via the flex plate and converter7G25

cover to

tht? pump member of the converter. The

converter is always tilled with oil from the transmis-

sion’s oil pump, and the converter pump member

transmits the torque through oil to the driven mem-

ber of the converter. Power to the transmission is

then transmitted via the input shaft and third clutch

drum. See Figures

7C-48 through 7C-52.

HYDRAULIC CONTROL UNITS AND VALVESPreviously, the mechanical aspects of the transmis-

sion operation have been described, including refer-

ence to various clutches and the low band being

applied. The following describes, in detail, the hy-

draulic system that applies the clutches and band,

and which controls the manually selected and auto-

matic shifts.

A hydraulic pressure system requires a source of

clean hydraulic fluid and a pump to pressurize the

fluid. Opel Three Speed Automatic transmission uses

a gear type pump which draws oil through a screen

located in the sump. See Figure

7C-29. Since the

pump drive gear is keyed to the converter pump hub,

it turns whenever the engine is operating and turns

the driven gear, which causes the oil to be lifted from

Page 410 of 625

AUTOMATIC TRANSMISSION7c- 49Figure 7C-26 Governor Assembly And Speedometer Drive Gearthe sump. The oil is carried past the crescent section

of the pump, beyond which the gear teeth begin to

come together, pressurizing the oil as it is squeezed

from between the gear teeth. The pressurizeh oil is

then delivered through the pump outlet to the hy-

draulic control system.1. Main pressure regulator valve.

2. Modulator valve.

mPRIMING VALVE

If the vehicle has not been operated for a while, the

oil in the pump cavity tends to drain and leak back

to the sump. With the pump cavity filled with air, the

pump cannot develop enough suction to lift the oil

from the sump. For this reason, a priming valve is

located in the pump pressure passage. As the air in

the pump is compressed by the gears, it is forced out

through the bleed orifice in the priming valve and

into the exhausted cavity behind the reverse piston.

This permits the pump to prime and draw oil from

the sump. As soon as the hydraulic pressure reaches

15

PSI: the valve is forced over closing off the bleed

orifice.PRIMING VALVE

In the hydraulic control circuit, there are four major

types of iontrol elements. These categories along

with the specific items are listed below.

A. Pressure regulating valves.

Fieure 7C-7.9 Oil Puvp and Priming Valve

Page 495 of 625

7C-1341973 OPEL SERVICE MANUAL

Figure 7C-232

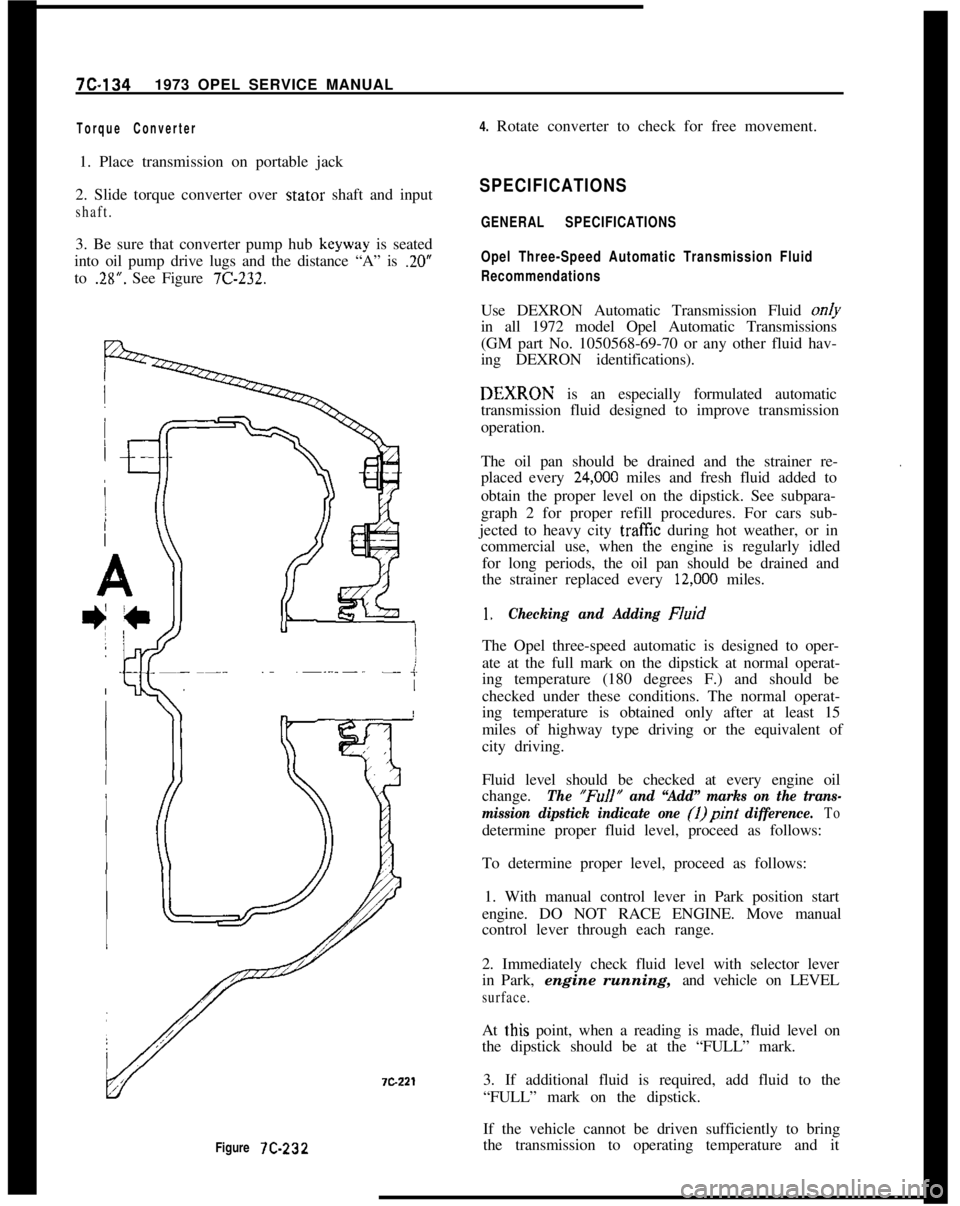

Torque Converter4. Rotate converter to check for free movement.

1. Place transmission on portable jack

2. Slide torque converter over stator shaft and input

shaft.3. Be sure that converter pump hub keyway is seated

into oil pump drive lugs and the distance “A” is

.20”to

.28”. See Figure 7C-232.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Opel Three-Speed Automatic Transmission Fluid

RecommendationsUse DEXRON Automatic Transmission Fluid on/y

in all 1972 model Opel Automatic Transmissions

(GM part No. 1050568-69-70 or any other fluid hav-

ing DEXRON identifications).DEXIRON is an especially formulated automatic

transmission fluid designed to improve transmission

operation.

The oil pan should be drained and the strainer re-

placed every

24,ooO miles and fresh fluid added to

obtain the proper level on the dipstick. See subpara-

graph 2 for proper refill procedures. For cars sub-

jected to heavy city

traff%z during hot weather, or in

commercial use, when the engine is regularly idled

for long periods, the oil pan should be drained and

the strainer replaced every

12,ooO miles.

.

1.Checking and Adding FluidThe Opel three-speed automatic is designed to oper-

ate at the full mark on the dipstick at normal operat-

ing temperature (180 degrees F.) and should be

checked under these conditions. The normal operat-

ing temperature is obtained only after at least 15

miles of highway type driving or the equivalent of

city driving.

Fluid level should be checked at every engine oil

change.

The “FuIl” and “Add” marks on the trans-

mission dipstick indicate one (1)pint

difference. Todetermine proper fluid level, proceed as follows:

To determine proper level, proceed as follows:

1. With manual control lever in Park position start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

2. Immediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL

surface.At

t,his point, when a reading is made, fluid level on

the dipstick should be at the “FULL” mark.

3. If additional fluid is required, add fluid to the

“FULL” mark on the dipstick.

If the vehicle cannot be driven sufficiently to bring

the transmission to operating temperature and it

Page 533 of 625

9B-24 1973 OPEL SERVICE MANUAL

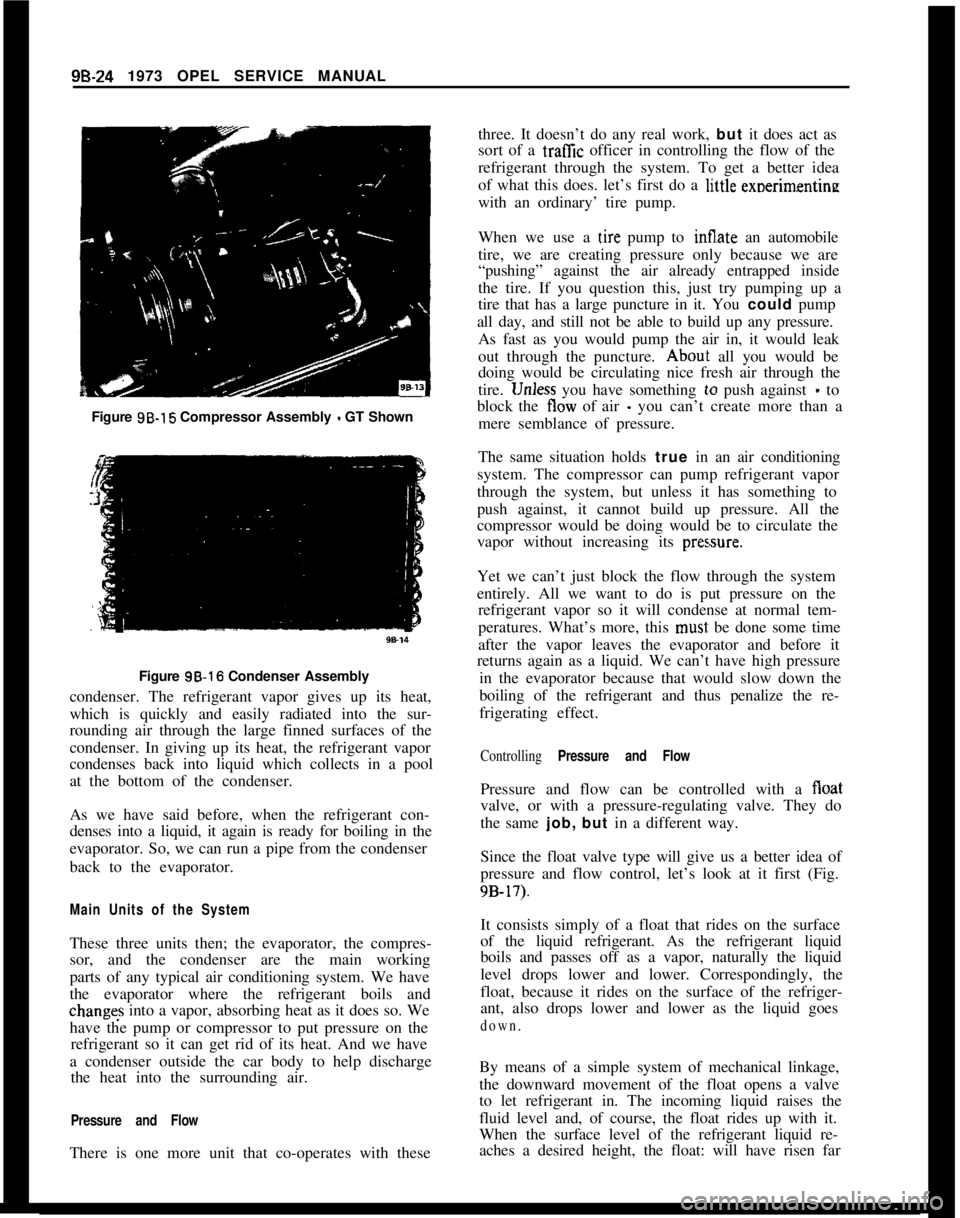

Figure 9B-15 Compressor Assembly - GT Shown

Figure 3B-16 Condenser Assembly

condenser. The refrigerant vapor gives up its heat,

which is quickly and easily radiated into the sur-

rounding air through the large finned surfaces of the

condenser. In giving up its heat, the refrigerant vapor

condenses back into liquid which collects in a pool

at the bottom of the condenser.

As we have said before, when the refrigerant con-

denses into a liquid, it again is ready for boiling in the

evaporator. So, we can run a pipe from the condenser

back to the evaporator.

Main Units of the SystemThese three units then; the evaporator, the compres-

sor, and the condenser are the main working

parts of any typical air conditioning system. We have

the evaporator where the refrigerant boils andchanges into a vapor, absorbing heat as it does so. We

have the pump or compressor to put pressure on the

refrigerant so it can get rid of its heat. And we have

a condenser outside the car body to help discharge

the heat into the surrounding air.

Pressure and FlowThere is one more unit that co-operates with thesethree. It doesn’t do any real work, but it does act as

sort of a traffic officer in controlling the flow of the

refrigerant through the system. To get a better idea

of what this does. let’s first do a li,ttle exoerimentine

with an ordinary’ tire pump.

When we use a

t,ire pump to Sate an automobile

tire, we are creating pressure only because we are

“pushing” against the air already entrapped inside

the tire. If you question this, just try pumping up a

tire that has a large puncture in it. You could pump

all day, and still not be able to build up any pressure.

As fast as you would pump the air in, it would leak

out through the puncture.

Abou~t all you would be

doing would be circulating nice fresh air through the

tire.

1Jnless you have something lo push against - to

block the tlow of air

- you can’t create more than a

mere semblance of pressure.

The same situation holds true in an air conditioning

system. The compressor can pump refrigerant vapor

through the system, but unless it has something to

push against, it cannot build up pressure. All the

compressor would be doing would be to circulate the

vapor without increasing its

pres,sure.Yet we can’t just block the flow through the system

entirely. All we want to do is put pressure on the

refrigerant vapor so it will condense at normal tem-

peratures. What’s more, this

musi: be done some time

after the vapor leaves the evaporator and before it

returns again as a liquid. We can’t have high pressure

in the evaporator because that would slow down the

boiling of the refrigerant and thus penalize the re-

frigerating effect.

Controlling Pressure and FlowPressure and flow can be controlled with a float

valve, or with a pressure-regulating valve. They do

the same job, but in a different way.

Since the float valve type will give us a better idea of

pressure and flow control, let’s look at it first (Fig.

9B-17).It consists simply of a float that rides on the surface

of the liquid refrigerant. As the refrigerant liquid

boils and passes off as a vapor, naturally the liquid

level drops lower and lower. Correspondingly, the

float, because it rides on the surface of the refriger-

ant, also drops lower and lower as the liquid goes

down.By means of a simple system of mechanical linkage,

the downward movement of the float opens a valve

to let refrigerant in. The incoming liquid raises the

fluid level and, of course, the float rides up with it.

When the surface level of the refrigerant liquid re-

aches a desired height, the float: will have risen far

Page 534 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 2596.15

Figure 95.17 Float Type Flow Valve

enough to close the valve and stop the flow of refrig-

erant liquid.

For the sake of simplicity, we have described the

float and valve action as being in a sort of definite

wide open or tight shut condition. Actually, though,

the liquid level falls rather slowly as the refrigerant

boils away. Likewise, the float goes down gradually

and gradually opens the valve just a crack. New

refrigerant liquid barely seeps in through the

“cracked” valve. At such a slow rate of flow, it raises

the liquid level in the evaporator very slowly.

With that in mind, it is easy to see how it would be

possible for a stabilized condition to exist. By that,

we mean a condition wherein the valve would be/

DIAPHRAGMACTUATINGBACK.UP PLATE

PINS \

t

>IAPHRAGM \

/

BoDyEQUALIZER\4]

PASSAGE

‘!!!ISEATSCkEEN:ARRIAGEORIFICE

AGE SPRINGIER ELEMENT:MOB”LBSPRING SEAT

OUTLET

W-16opened barely enough to allow just exactly the right

amount of refrigerant liquid to enter the freezer to

take the place of that leaving as a vapor.

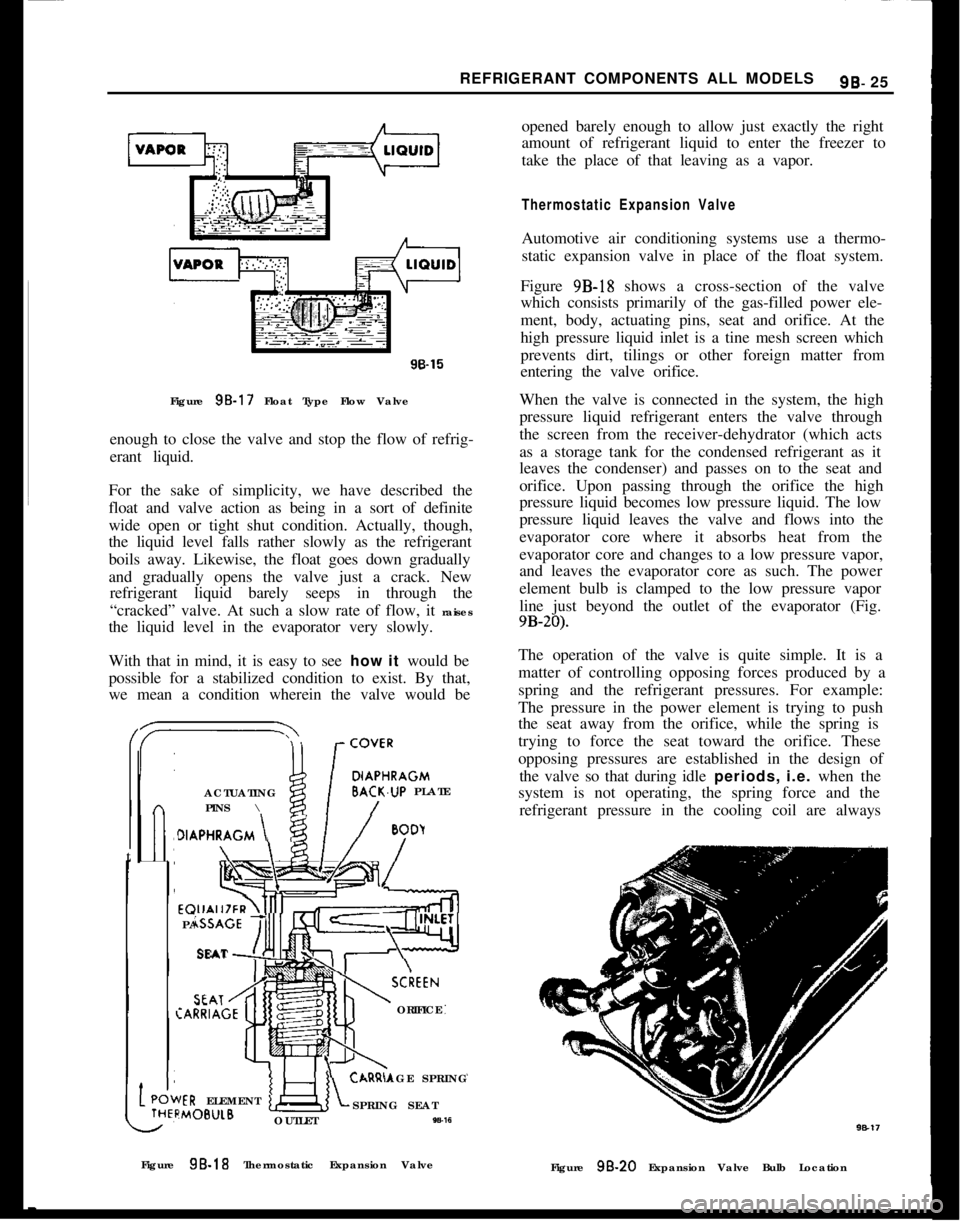

Thermostatic Expansion ValveAutomotive air conditioning systems use a thermo-

static expansion valve in place of the float system.

Figure 9B-18 shows a cross-section of the valve

which consists primarily of the gas-filled power ele-

ment, body, actuating pins, seat and orifice. At the

high pressure liquid inlet is a tine mesh screen which

prevents dirt, tilings or other foreign matter from

entering the valve orifice.

When the valve is connected in the system, the high

pressure liquid refrigerant enters the valve through

the screen from the receiver-dehydrator (which acts

as a storage tank for the condensed refrigerant as it

leaves the condenser) and passes on to the seat and

orifice. Upon passing through the orifice the high

pressure liquid becomes low pressure liquid. The low

pressure liquid leaves the valve and flows into the

evaporator core where it absorbs heat from the

evaporator core and changes to a low pressure vapor,

and leaves the evaporator core as such. The power

element bulb is clamped to the low pressure vapor

line just beyond the outlet of the evaporator (Fig.

9B-20).The operation of the valve is quite simple. It is a

matter of controlling opposing forces produced by a

spring and the refrigerant pressures. For example:

The pressure in the power element is trying to push

the seat away from the orifice, while the spring is

trying to force the seat toward the orifice. These

opposing pressures are established in the design of

the valve so that during idle periods, i.e. when the

system is not operating, the spring force and the

refrigerant pressure in the cooling coil are always

Figure 9B-18 Thermostatic Expansion Valve

Figure

98.20 Expansion Valve Bulb Location

Page 535 of 625

98-26 1973 OPEL SERVICE MANUAL

greater than the opposing pressure in the power ele-

ment. Therefore, the valve remains closed. When the

compressor is started, it will reduce the pressure and

temperature of the refrigerant in the cooling coil to

a point where the vapor pressure in the power ele-

ment becomes the stronger. The seat then moves off

the orifice and liquid starts to flow through the valve

orifice into the cooling coil.

The purpose of the power element is to help deter-

mine the quantity of liquid that is being metered into

the cooling coil. As the temperature of the low pres-

sure line changes at the bulb, the pressure of

the

vapor in the power element changes, resulting in a

change of the position of the seat. For example, if the

cooling coil gets more liquid than is required, the

temperature of the low pressure line is reduced and

the resultant lowering of the bulb temperature

reduces the pressure of the vapor in the power ele-

ment, allowing the seat to move closer to the orifice.

This immediately reduces the amount of liquid leav-

ing the valve. Under normal operation, the power

element provides accurate control of the quantity of

refrigerant to the cooling coil.

To employ our tire pump analogy once more for

clarity, it is the same situation that would exist if you were inflating a tire with a very slow leak. Providing

you pumped the air into the tire as fast as it leaked

out, you would be able to maintain pressure even

though the air would merely be circulating through the tire and leaking out through the puncture.

To Sum Up

So far, we’ve discussed only what each unit in an air

conditioning system does. We’ve learned that the

evaporator is the unit in which liquid refrigerant

soaks up heat from the air, the compressor is a pump

for squeezing this heat out of the vapor, the con-

denser is a radiator for getting rid of the heat, and the

thermostatic expansion valve is a device for regulat-

ing the pressure on the refrigerant. Now, let’s

find

out how the temperature of the cooled air is con-

trolled.

METHOD OF TEMPERATURE CONTROL

To achieve temperature control, the compressor is

run intermittently, automatically turning on and off

as necessary to maintain proper temperature.

Thermostatic Switch

The compressor can be started and stopped au-

tomatically through the use of an electro-magnetic

clutch and a thermostat affected by variations of temperature.

The job is usually done by a gas bulb thermostat (Fig.

9B-21).

Figure 9B-21 Thermostatic Switch Schematic

With the gas bulb type of thermostat, a highly expan-

sive gas is sealed into a metallic bulb which is located

in the air stream as it leaves the evaporator. A small

tube leads from the bulb to a bellows operated switch. As air temperature rises, the gas inside the

bulb expands, travels through the tube to the bellows

and closes the electrical switch that engages the com-

pressor clutch.

Of course, as soon as the compressor starts running,

the temperature begins to go down. As the air being

cooled gets colder, the gas in the thermostat bulb

begins to reduce the pressure on the switch bellows.

This

Ilips “off’ the switch and disengages the com-

pressor clutch.

REFRIGERANTS

No matter how scientifically refrigerating machinery

is built or how

efftciently it runs, it alone cannot

remove heat. The only thing that carries heat out of

a refrigerator cabinet or an automobile is the sub-

stance we call the refrigerant.

There are many refrigerants known to man. In fact,

any liquid that can boil at temperatures somewhere

near the freezing point of water can be used.

But a boiling point below the temperature at which

ice forms is not the only thing that makes a good

refrigerant. A refrigerant should also be non-

poiso-

nowand non-explosive to be safe. Besides that, we

want a refrigerant that is non-corrosive and one that

will mix with oil.

Since Nature did not provide an ideal refrigerant,

chemists went to work to see if they could do any

better. They did! But it wasn’t as simple as that.

At first, they tried to improve existing natural refrig-

erants. But after exploring innumerable trails along

Page 540 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 31

When adding oil, the container should be exception-

ally clean and dry due to the fact that the refrigera-

tion oil in the container is as moisture-free as it is

possible to make it. Therefore, it will quickly absorb

any moisture with which it comes in contact. For this

same reason the oil container should not be opened

until ready for use and it should be capped immedi-

ately afte;r use.

When it is necessary to open a system, have every-

thing you will need ready and handy so that as little

time as possible will be required to perform the oper-

ation. Don’t leave the system open any longer than

is necessary.

Finally, after the operation has been completed and

the system sealed again, air and moisture should be

evacuated from the system before recharging.

THE PRIMARY CAUSES OF SYSTEM FAILURES

LeaksA shortage of refrigerant causes oil to be trapped in

the evaporator. Oil may be lost with the refrigerant

at point of leakage. Both of these can cause compres-

sor seizure.

Oil circulates in the system with the refrigerant; in

solution with the liquid and in globules with the

vapor. It leaves the compressor by the action of the

pistons and mixes with the refrigerant liquid in the

condenser. The oil then enters the evaporator with

the liquid and, with the evaporator properly flooded,

is returned to the compressor through the low pres-

sure line. Some of the oil returns as globules in the

vapor, but more important, it is swept as a liquid

along the walls of the tubing by the velocity of the

vapor. If the evaporator is starved, the oil cannot

return in sut?icient quantities to keep the compressor

properly lubricated.

High Temperature and PressureAn increase in temperature causes an increase in

pressure. This accelerates chemical instability due to

existing contaminants in the system, and initiates

chemical instability in clean systems. Other results

are brittle hoses,

“0” ring gaskets, and valve dia-

phragms with possible decomposition, broken com-

pressor discharge reeds, and seized compressor

bearings.

A fundamental law of nature accounts for the fact

that when a substance, such as a refrigerant, is in-

creased in temperature, its pressure is also increased.

Any chemical reactions caused by contaminants al-

ready in the system are greatly accelerated as the

temperature increases. A 15 degree rise in tempera-

ture doubles the chemical action. Even in a goodclean system, heat alone can start a chain of harmful

chemical reactions.

While temperature alone can cause the synthetic rub-

ber parts to become brittle and possibly to decom-

pose, the increased pressure can cause them to

rupture or blow.

As the temperature and pressure increases the stress

and strain on the compressor discharge reeds also

increases. This can result in broken reeds. Due to the

effect of the contaminants caused by high tempera-

ture and pressure, compressor bearings can be

caused to seize.

High temperature and pressure are also caused by air

in the system.

Air in the SYstemAir results from a discharged system or careless ser-

vicing procedures. This reduces system capacity and

efficiency and causes oxidation of oil into gum and

varnish.

When a leak causes the system to become dis-

charged, the resulting vacuum within the system will

cause air to be drawn in. Air in the system is a

non-condensable gas and will build up in the con-

denser as it would in an air compressor tank. The

resultant heat produced will contribute to the condi-

tions discussed previously.

Many systems are contaminated and also reduced in

capacity and efficiency by servicemen who either do

not know or are careless regarding proper servicing

procedures.

Too frequently, systems which have been open to the

atmosphere during service operations have not been

properly purged or evacuated. Air is also introduced

into the system by unpurged gauge and charging

lines. Remember that any air in the system is too

much air.

Poor ConnectionsHose clamp type fittings must be properly made.

Hoses should be installed over the sealing flanges and

with the end of the hose at the stop flange. The hose

should never extend beyond the stop flange. Locate

the clamp properly and torque as recommended. Be

especially careful that the sealing flanges are not

nicked or scored or a future leak will result.

When compression fittings are used, over tightening

can cause physical damage to the “0” ring gasket

and will result in leaks. The use of torque and back-

ing wrenches is highly recommended. When making

a connection with compression fittings, the gaskets

should always be first placed over the tube before