clutch OPEL 1900 1973 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 438 of 625

9. Operation of Controls in Reverse

Reverse Clutch -Applied

Second Clutch Released

Sprag LockedThird Clutch. Applied

Low Band. Released

When the selector leer is moved to the Reverse position on the quadrant, the manual

valve ispositioned to allow Revert oil to pars through the manual

valve into the

Reverse oil passage. The reverse oil applies the reverse clutch. and a portion is directed to the priming valve which acts as a damper until the

line is filled. to effect a smooth and firm apply of the

reverss clutch. At the wne time, reverse oil is directed to the pressure regulator boost control valve

cavity to seat the check ball and prevent reverse oil pasring into the intermediate oil passage. It is then directed to the pressure regulator boast valve forcing

Reverse oil is also directed to act on the end of the

Reverse and Law control valve against the spring to allow detent regulated oil to pass through the valveto the 2 3 shift

valve. The detent regulated oil passes through the 2 3 shift valve and into the third clutch oil passages to apply the third clutch. The third

clutch oil

al= acts on the end of the 3 2 control valve against the spring and modulator oil pressure, clodng off the supply of modulator oil to the 2 3

shift control valve. Third clutch oil at the rwerse and low control valve is closed off from

parring through the valve. and into the servo releal~ parrage.Summary

The

reverse clutch is cm and the third clutch is on. The transmission is in Reverse Range.

Page 440 of 625

h. Operation of Controlr during Detent Downshift Valves in Second Gear Position

Reverse Clutch Released

Second Clutch Applied

Sprag Over RunningThird Clutch Released

Low Band Applied

With the selector in the Drive position. detent downshifts ore possible by fully depressing the accelerator pedal. This causes the mechanical linkage to the

detent

velve to move the detent valve, cutting off moduahor oil to the 3 2 control valve, the 1 2 shift control valve, the 1 2 accumulator valve and the

2 - 3 shift control velve.The mechanical linkage holding the detent nlve open allows the detent regulated oil to pass into the detent oil

passdgeand is directed to the 2 3 shift

control

valve. acting against the spring and governor oil pressure. It is also directed to the 3 2 control valve. acting against the spring, allowing detent oil to

pass through the valve and act on the end of the 2 3 shift control valve to keep the valve bottomed in its bore again* governor oil pressure. Second clutch

oil et the 2 3 shift

valve is closed off from passing into the third clutch passages by the detent oil pressure holding the 2 3 shift valve bottomed in its bore.

Summary

The second clutch is on, the low band is on. The valves are in

wand gear position under detent conditions.

Page 445 of 625

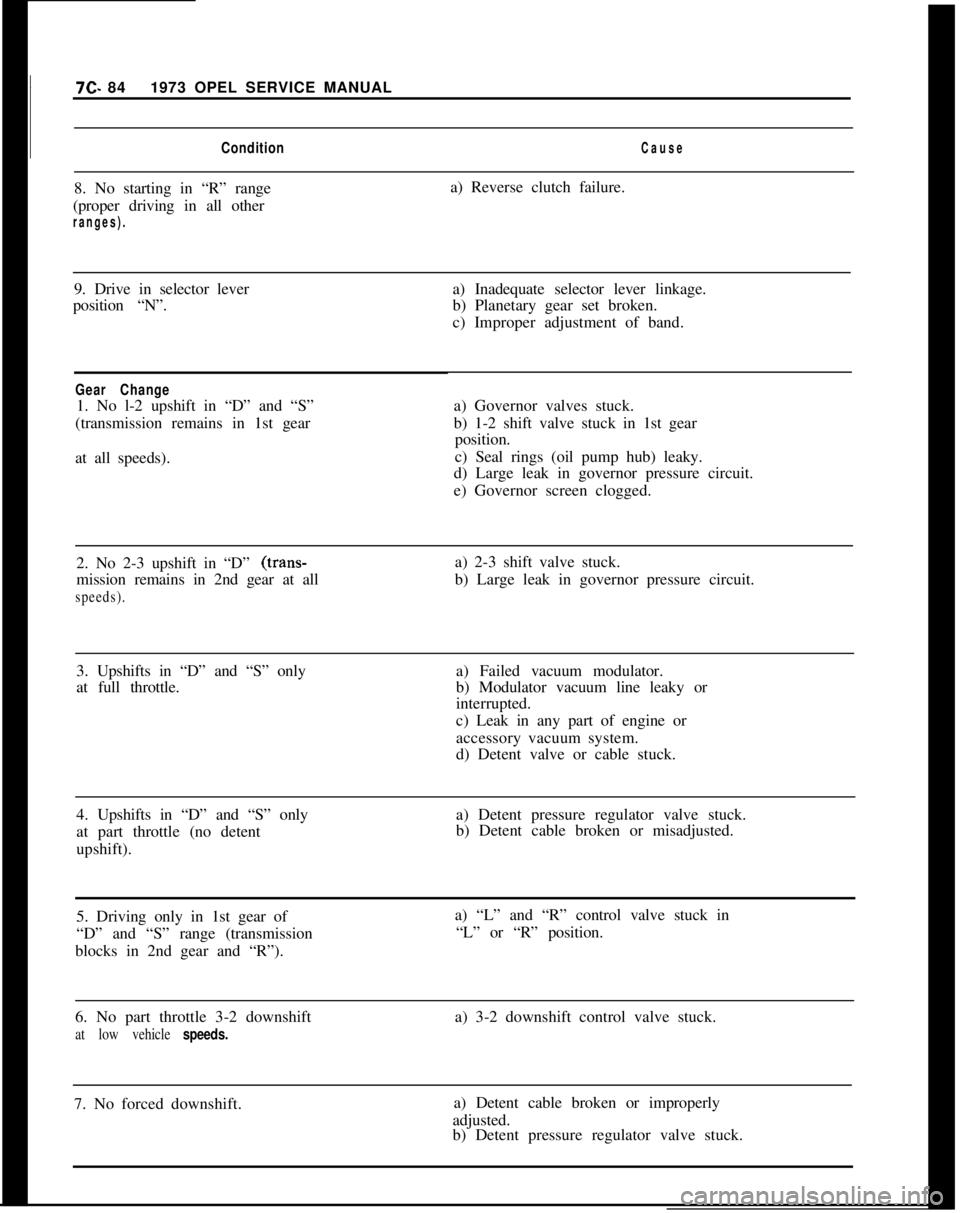

7C. 841973 OPEL SERVICE MANUALConditionCause8. No starting in “R” range

(proper driving in all other

ranges).a) Reverse clutch failure.

9. Drive in selector lever

position “N”.a) Inadequate selector lever linkage.

b) Planetary gear set broken.

c) Improper adjustment of band.

Gear Change1. No l-2 upshift in “D” and “S”

(transmission remains in 1st gear

at all speeds).a) Governor valves stuck.

b) 1-2 shift valve stuck in 1st gear

position.

c) Seal rings (oil pump hub) leaky.

d) Large leak in governor pressure circuit.

e) Governor screen clogged.

2. No 2-3 upshift in “D” (trans-

mission remains in 2nd gear at all

speeds).a) 2-3 shift valve stuck.

b) Large leak in governor pressure circuit.

3. Upshifts in “D” and “S” only

at full throttle.a) Failed vacuum modulator.

b) Modulator vacuum line leaky or

interrupted.

c) Leak in any part of engine or

accessory vacuum system.

d) Detent valve or cable stuck.

4. Upshifts in “D” and “S” only

at part throttle (no detent

upshift).a) Detent pressure regulator valve stuck.

b) Detent cable broken or misadjusted.

5. Driving only in 1st gear of

“D” and “S” range (transmission

blocks in 2nd gear and “R”).a) “L” and “R” control valve stuck in

“L” or “R” position.

6. No part throttle 3-2 downshift

at low vehicle speeds.a) 3-2 downshift control valve stuck.

7. No forced downshift.a) Detent cable broken or improperly

adjusted.

b) Detent pressure regulator valve stuck.

Page 446 of 625

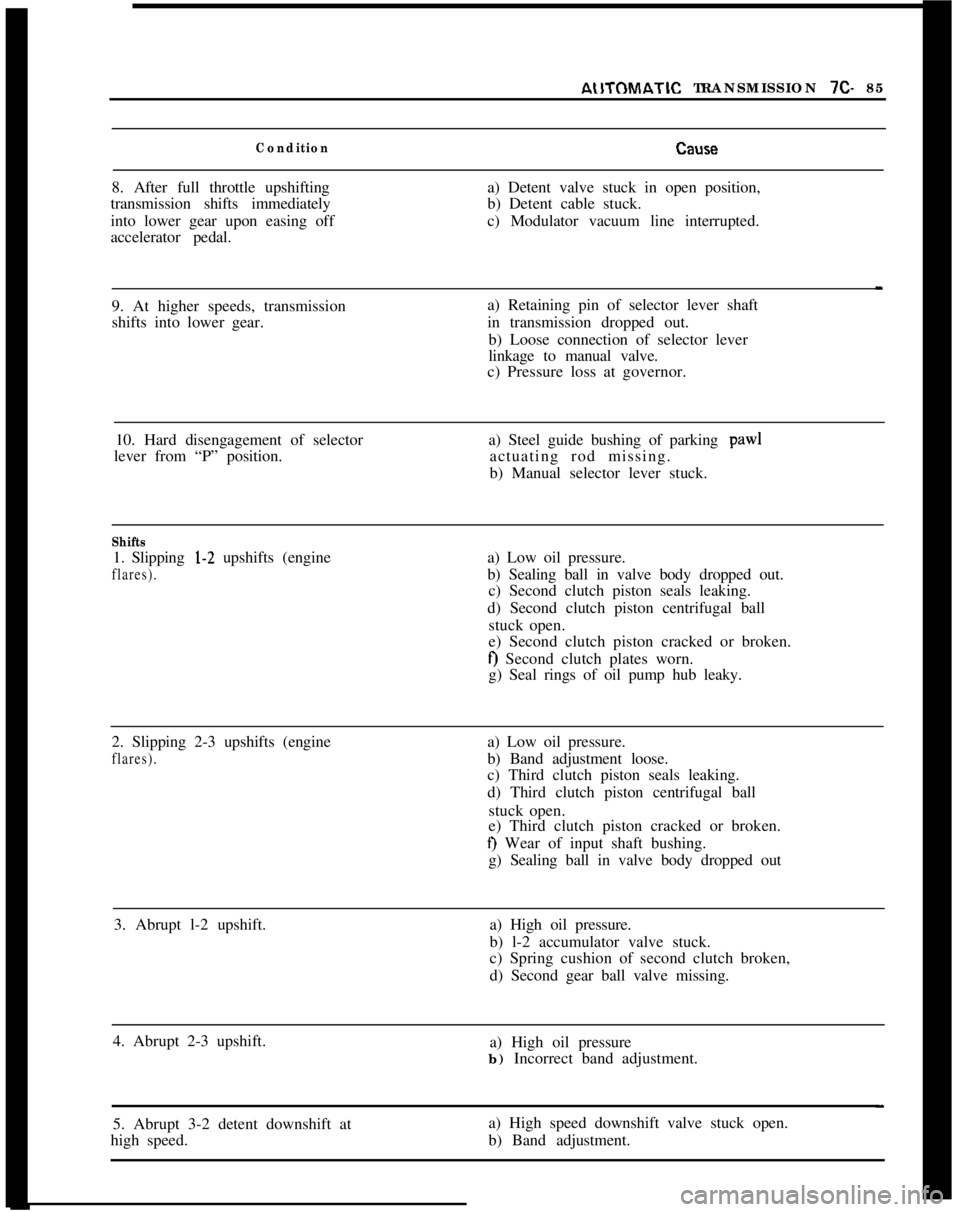

AlITOMATIC TRANSMISSION 7C- 85

ConditionCtSlSl?8. After full throttle upshifting

transmission shifts immediately

into lower gear upon easing off

accelerator pedal.a) Detent valve stuck in open position,

b) Detent cable stuck.

c) Modulator vacuum line interrupted.

9. At higher speeds, transmission

shifts into lower gear.a) Retaining pin of selector lever shaft

in transmission dropped out.

b) Loose connection of selector lever

linkage to manual valve.

c) Pressure loss at governor.

10. Hard disengagement of selector

lever from “P” position.a) Steel guide bushing of parking

paw1actuating rod missing.

b) Manual selector lever stuck.

Shifts1. Slipping l-2 upshifts (engine

flares).a) Low oil pressure.

b) Sealing ball in valve body dropped out.

c) Second clutch piston seals leaking.

d) Second clutch piston centrifugal ball

stuck open.

e) Second clutch piston cracked or broken.

f) Second clutch plates worn.

g) Seal rings of oil pump hub leaky.

2. Slipping 2-3 upshifts (engine

flares).a) Low oil pressure.

b) Band adjustment loose.

c) Third clutch piston seals leaking.

d) Third clutch piston centrifugal ball

stuck open.

e) Third clutch piston cracked or broken.

f) Wear of input shaft bushing.

g) Sealing ball in valve body dropped out

3. Abrupt l-2 upshift.a) High oil pressure.

b) l-2 accumulator valve stuck.

c) Spring cushion of second clutch broken,

d) Second gear ball valve missing.

4. Abrupt 2-3 upshift.

a) High oil pressure

b) Incorrect band adjustment.

5. Abrupt 3-2 detent downshift at

high speed.a) High speed downshift valve stuck open.

b) Band adjustment.

Page 447 of 625

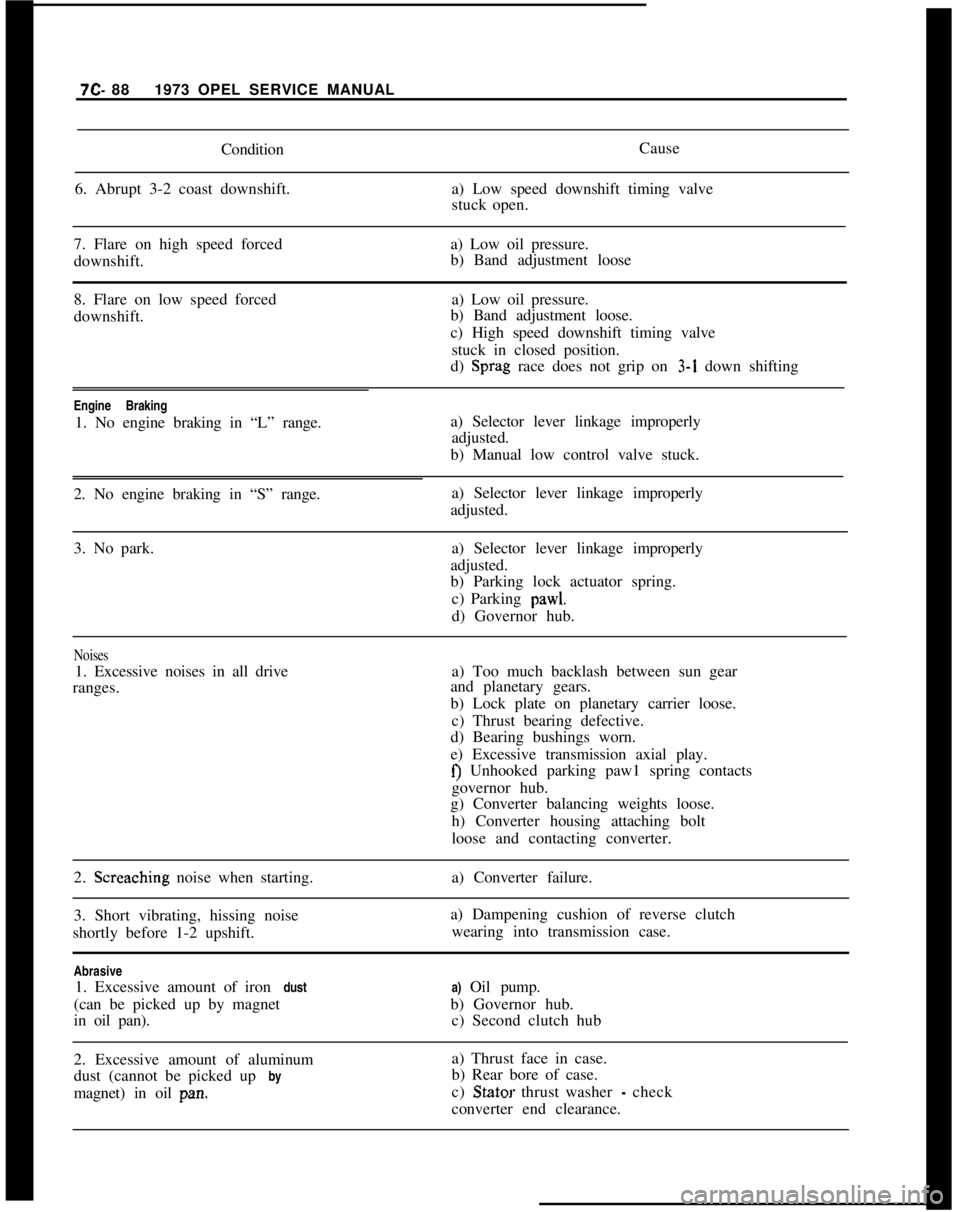

7C- 881973 OPEL SERVICE MANUAL

Condition

6. Abrupt 3-2 coast downshift.Cause

a) Low speed downshift timing valve

stuck open.

7. Flare on high speed forceda) Low oil pressure.

downshift.b) Band adjustment loose

8. Flare on low speed forced

downshift.a) Low oil pressure.

b) Band adjustment loose.

c) High speed downshift timing valve

stuck in closed position.

d) Sprag race does not grip on 3-1 down shifting

Engine Braking

1. No engine braking in “L” range.a) Selector lever linkage improperly

adjusted.

b) Manual low control valve stuck.

2. No engine braking in “S” range.a) Selector lever linkage improperly

adjusted.

3. No park.a) Selector lever linkage improperly

adjusted.

b) Parking lock actuator spring.

c) Parking pawl.

d) Governor hub.

Noises1. Excessive noises in all drive

ranges.a) Too much backlash between sun gear

and planetary gears.

b) Lock plate on planetary carrier loose.

c) Thrust bearing defective.

d) Bearing bushings worn.

e) Excessive transmission axial play.

f) Unhooked parking paw1 spring contacts

governor hub.

g) Converter balancing weights loose.

h) Converter housing attaching bolt

loose and contacting converter.

2. Screaching noise when starting.

3. Short vibrating, hissing noise

shortly before 1-2 upshift.a) Converter failure.

a) Dampening cushion of reverse clutch

wearing into transmission case.

Abrasive

1. Excessive amount of iron dust

(can be picked up by magnet

in oil pan).a) Oil pump.

b) Governor hub.

c) Second clutch hub

2. Excessive amount of aluminum

dust (cannot be picked up by

magnet) in oil pan.a) Thrust face in case.

b) Rear bore of case.

c) Stator thrust washer

- check

converter end clearance.

Page 449 of 625

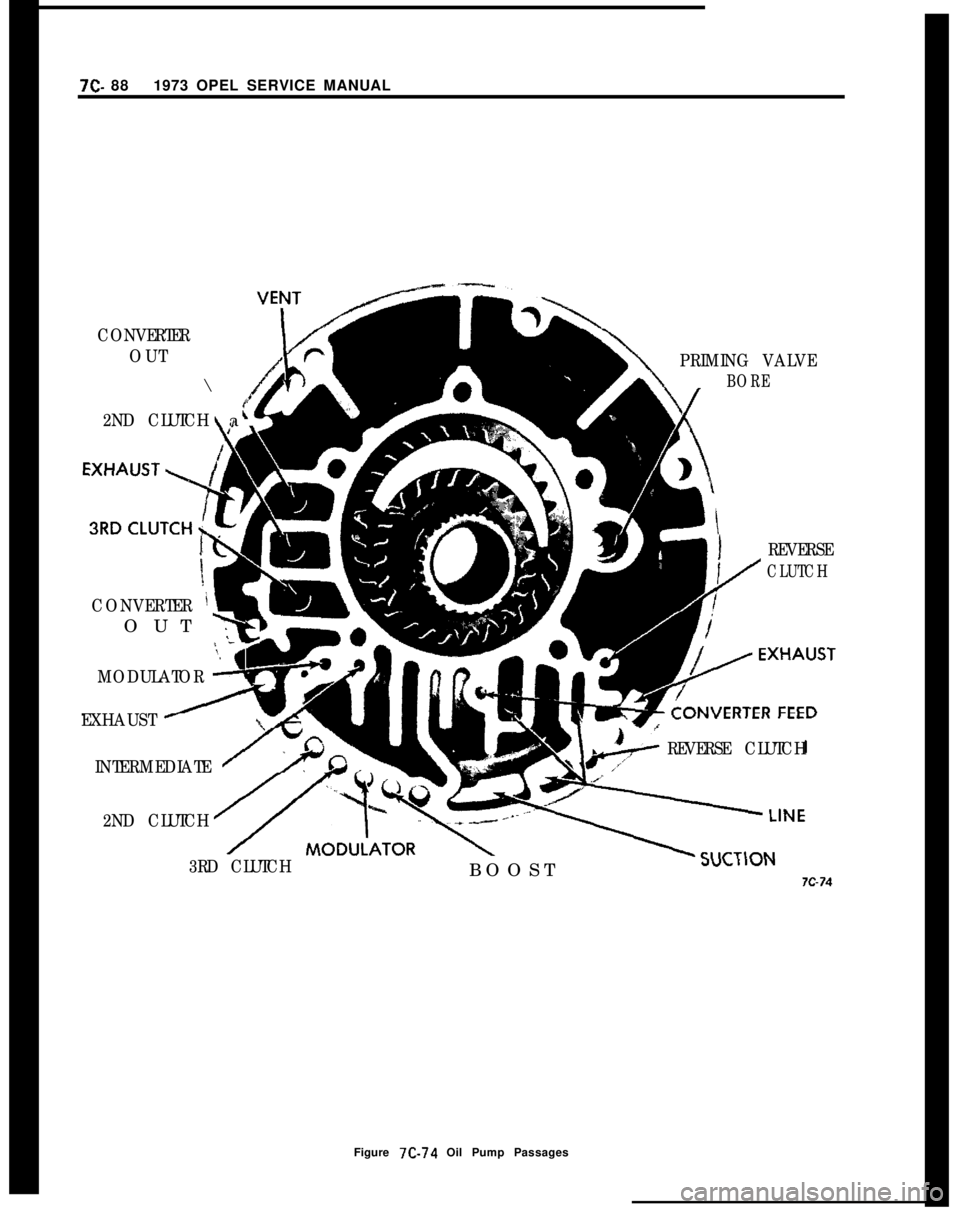

7C- 881973 OPEL SERVICE MANUALCONVERTER

OUT\

/

2ND CLUTCHa!EI1

CONVERTER iOUT

x

PRIMING VALVE

BORE

\

REVERSE

CLUTCH

:. -q

MODULATOR -

EXHAUST

REVERSE CLUTCH

INTERMEDIATE

2ND CLUTCH

3RD CLUTCHBOOST

7674Figure 7C-74 Oil Pump Passages

Page 464 of 625

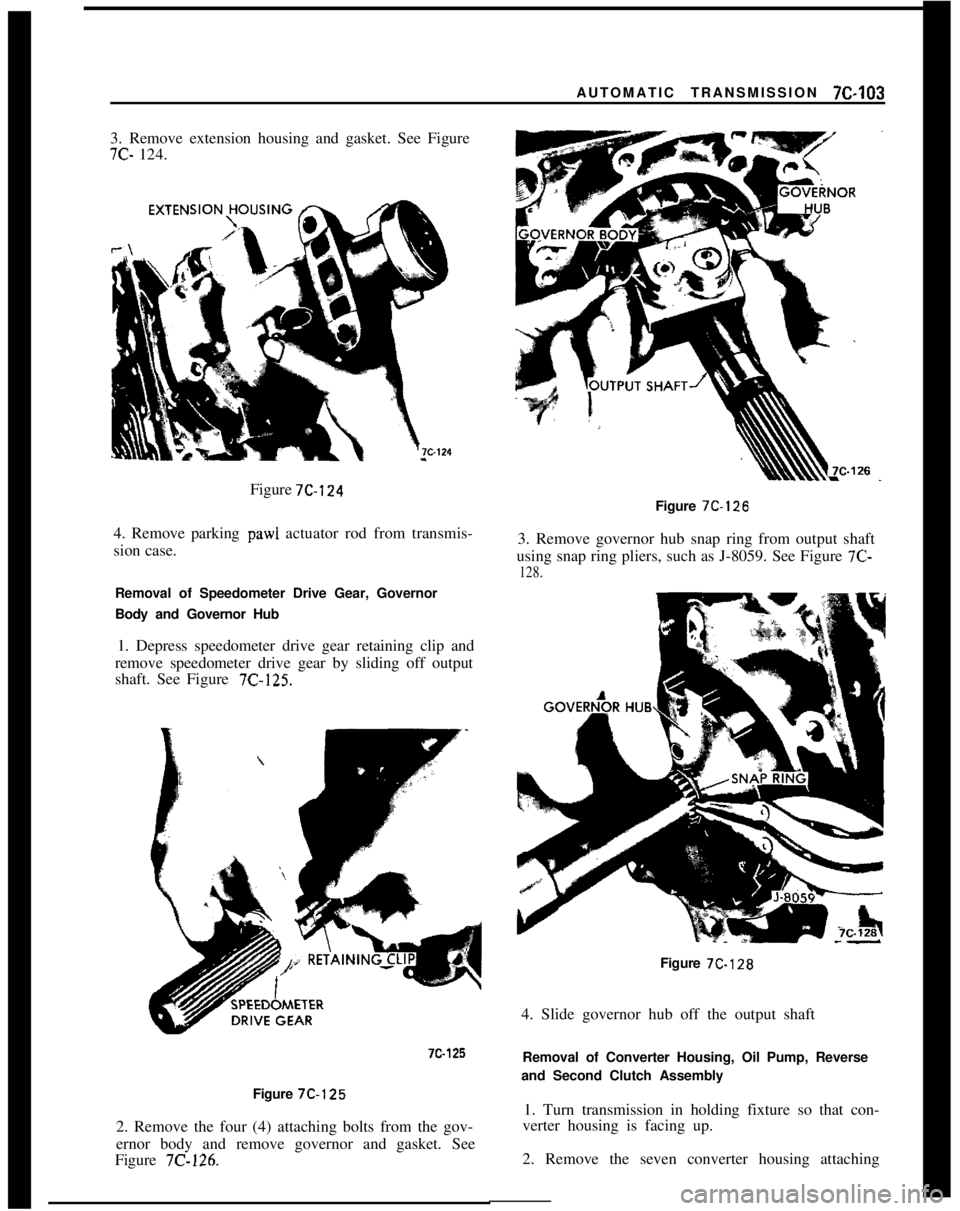

AUTOMATIC TRANSMISSION 712-1033. Remove extension housing and gasket. See Figure7C- 124.

Figure 7C-124

4. Remove parking

paw1 actuator rod from transmis-

sion case.

Removal of Speedometer Drive Gear, Governor

Body and Governor Hub

1. Depress speedometer drive gear retaining clip and

remove speedometer drive gear by sliding off output

shaft. See Figure

7C-125.

7c-125Figure 7C-125

2. Remove the four (4) attaching bolts from the gov-

ernor body and remove governor and gasket. See

Figure

7C-126.Figure 7C-126

3. Remove governor hub snap ring from output shaft

using snap ring pliers, such as J-8059. See Figure 7C-

128.Figure 7C-128

4. Slide governor hub off the output shaft

Removal of Converter Housing, Oil Pump, Reverse

and Second Clutch Assembly

1. Turn transmission in holding fixture so that con-

verter housing is facing up.

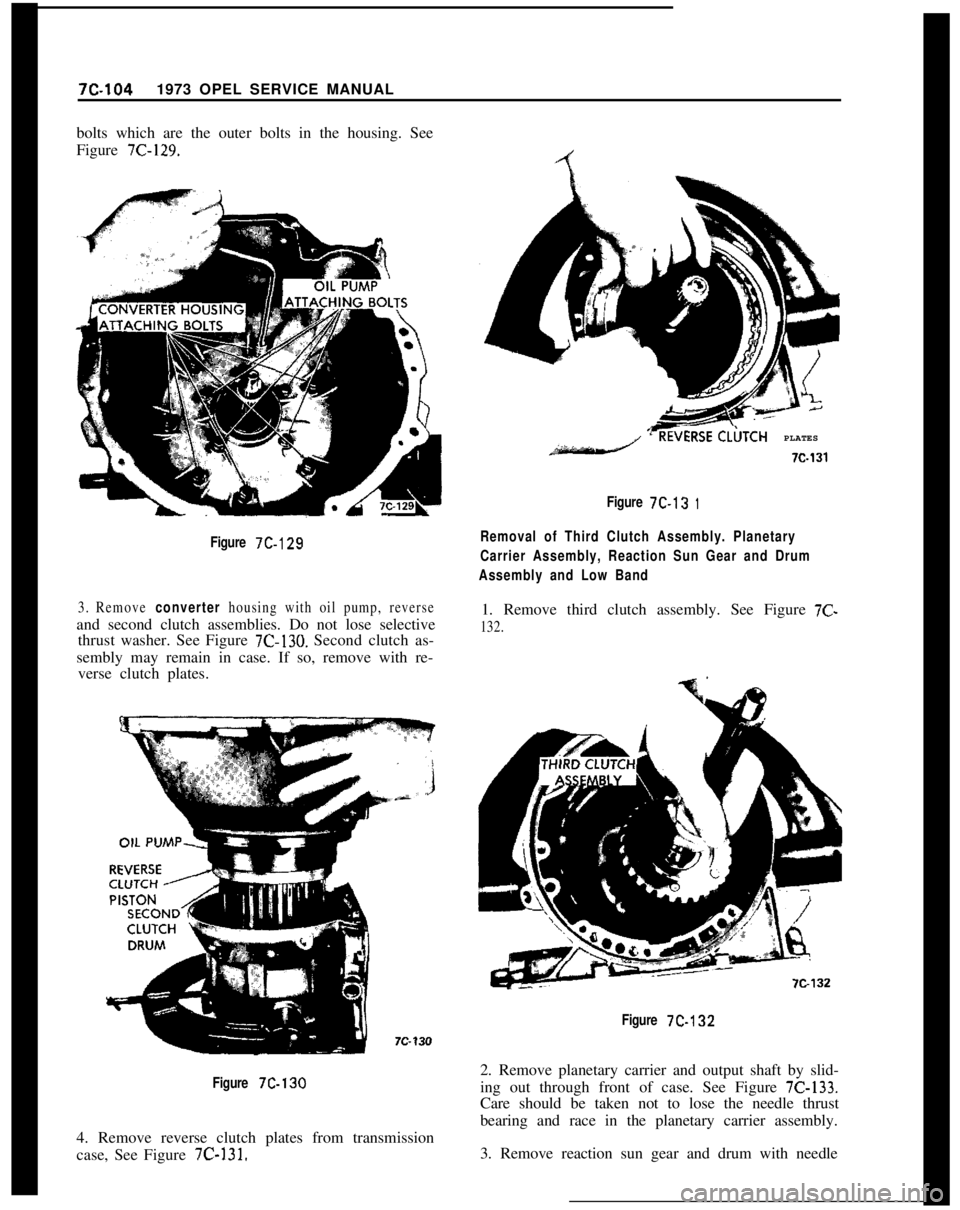

2. Remove the seven converter housing attaching

Page 465 of 625

7C-1041973 OPEL SERVICE MANUAL

bolts which are the outer bolts in the housing. See

Figure 7C-129.

Figure 7C-129

3. Remove converter housing with oil pump, reverseand second clutch assemblies. Do not lose selective

thrust washer. See Figure

7C-130. Second clutch as-

sembly may remain in case. If so, remove with re-

verse clutch plates.

Figure 7C-130

4. Remove reverse clutch plates from transmission

case, See Figure

7C-131.

T%RSE~L~~T~H PLATES

7c-131

Figure

7C-13 I

Removal of Third Clutch Assembly. Planetary

Carrier Assembly, Reaction Sun Gear and Drum

Assembly and Low Band1. Remove third clutch assembly. See Figure 7C-

132.

Figure 7C-132

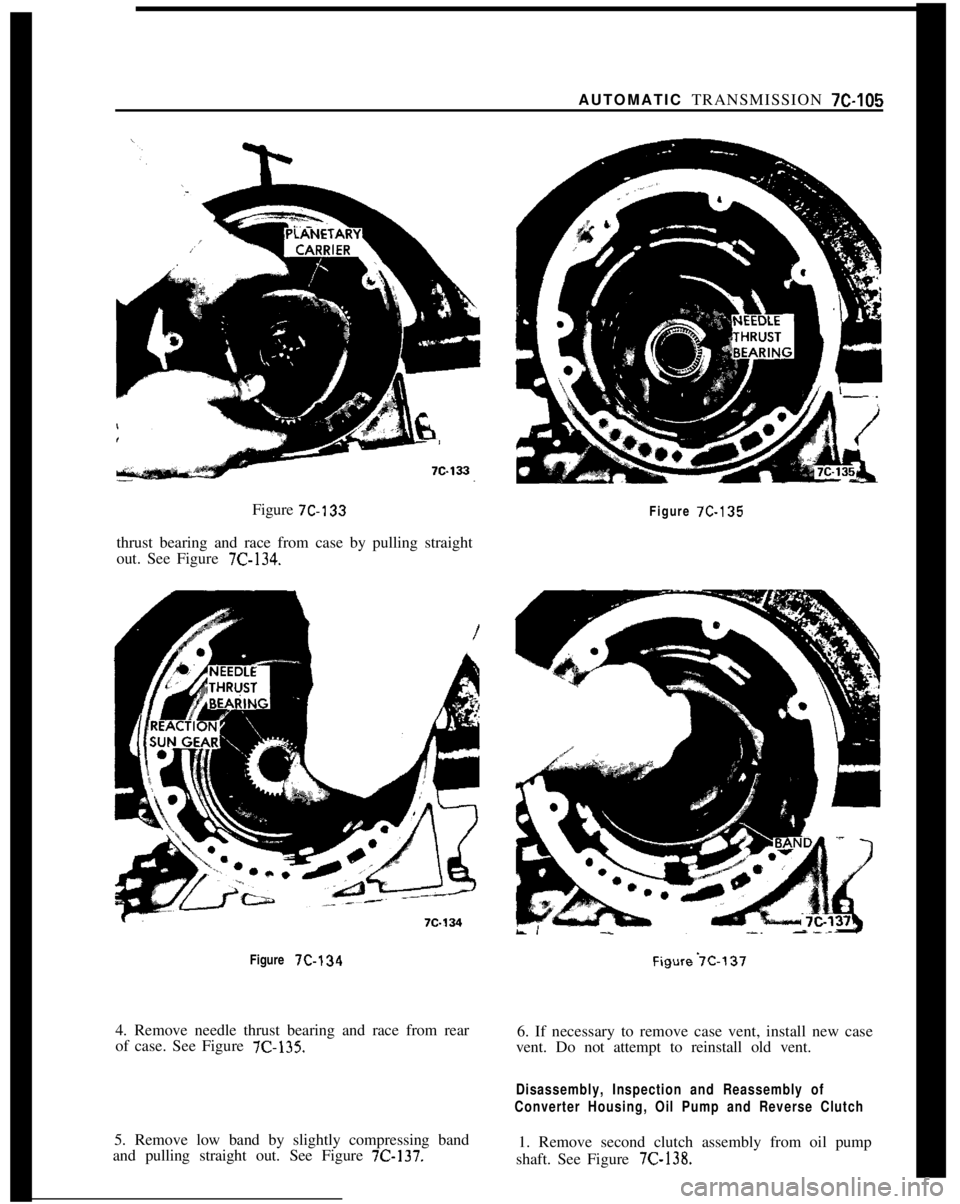

2. Remove planetary carrier and output shaft by slid-

ing out through front of case. See Figure

7C-133.Care should be taken not to lose the needle thrust

bearing and race in the planetary carrier assembly.

3. Remove reaction sun gear and drum with needle

Page 466 of 625

AUTOMATIC TRANSMISSION 7C-105

Figure 7C-133thrust bearing and race from case by pulling straight

out. See Figure

7C-134.Figure

7C-135Figure

7C-1344. Remove needle thrust bearing and race from rear

of case. See Figure

7C-135.5. Remove low band by slightly compressing band

and pulling straight out. See Figure

7C-137.6. If necessary to remove case vent, install new case

vent. Do not attempt to reinstall old vent.

Disassembly, Inspection and Reassembly of

Converter Housing, Oil Pump and Reverse Clutch1. Remove second clutch assembly from oil pump

shaft. See Figure

7C-138.

Page 468 of 625

J-8092

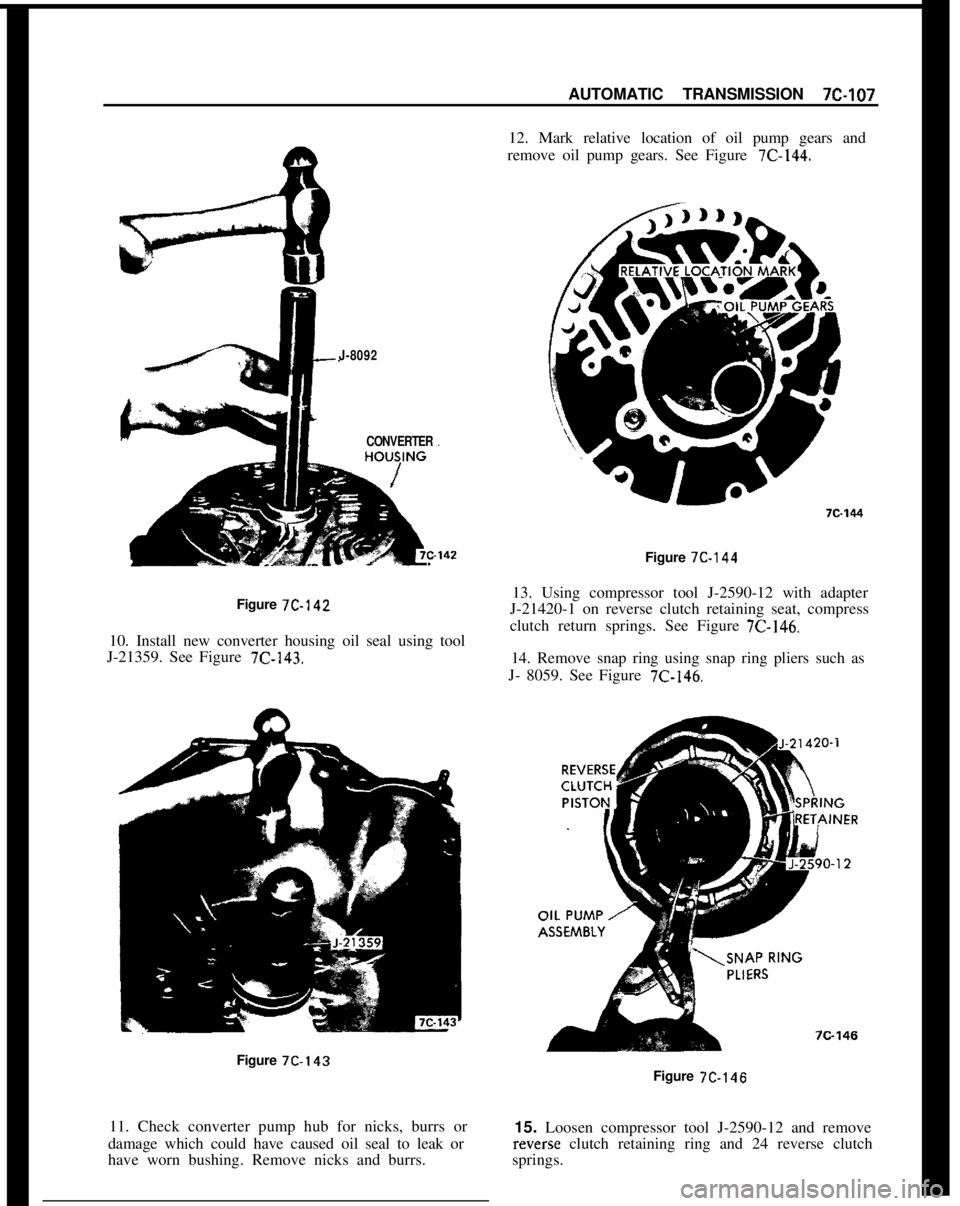

CONVERTERFigure 7C-142

10. Install new converter housing oil seal using tool

J-21359. See Figure

7C-143.12. Mark relative location of oil pump gears and

remove oil pump gears. See Figure

7C-144.AUTOMATIC TRANSMISSION

712.107Figure 7C-144

13. Using compressor tool J-2590-12 with adapter

J-21420-1 on reverse clutch retaining seat, compress

clutch return springs. See Figure

7C-146.14. Remove snap ring using snap ring pliers such as

J- 8059. See Figure

7C-146.Figure 7C-143

Figure 7C-146

11. Check converter pump hub for nicks, burrs or

damage which could have caused oil seal to leak or

have worn bushing. Remove nicks and burrs.15. Loosen compressor tool J-2590-12 and remove

reverse clutch retaining ring and 24 reverse clutch

springs.