tyre pressure OPEL ANTARA 2014 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2014, Model line: ANTARA, Model: OPEL ANTARA 2014Pages: 217, PDF Size: 6.04 MB

Page 13 of 217

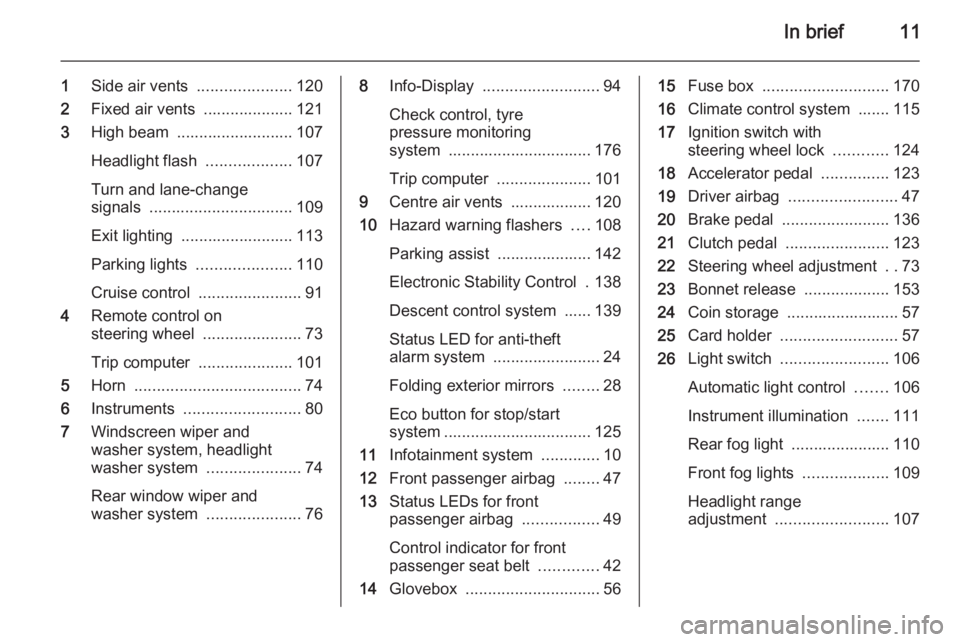

In brief11

1Side air vents .....................120

2 Fixed air vents .................... 121

3 High beam .......................... 107

Headlight flash ...................107

Turn and lane-change

signals ................................ 109

Exit lighting ......................... 113

Parking lights .....................110

Cruise control ....................... 91

4 Remote control on

steering wheel ......................73

Trip computer .....................101

5 Horn ..................................... 74

6 Instruments .......................... 80

7 Windscreen wiper and

washer system, headlight

washer system .....................74

Rear window wiper and

washer system .....................768Info-Display .......................... 94

Check control, tyre

pressure monitoring

system ................................ 176

Trip computer .....................101

9 Centre air vents .................. 120

10 Hazard warning flashers ....108

Parking assist ..................... 142

Electronic Stability Control . 138

Descent control system ...... 139

Status LED for anti-theft

alarm system ........................ 24

Folding exterior mirrors ........28

Eco button for stop/start

system ................................. 125

11 Infotainment system .............10

12 Front passenger airbag ........47

13 Status LEDs for front

passenger airbag .................49

Control indicator for front

passenger seat belt .............42

14 Glovebox .............................. 5615Fuse box ............................ 170

16 Climate control system ....... 115

17 Ignition switch with

steering wheel lock ............124

18 Accelerator pedal ...............123

19 Driver airbag ........................ 47

20 Brake pedal ........................ 136

21 Clutch pedal ....................... 123

22 Steering wheel adjustment ..73

23 Bonnet release ...................153

24 Coin storage ......................... 57

25 Card holder .......................... 57

26 Light switch ........................ 106

Automatic light control .......106

Instrument illumination .......111

Rear fog light ...................... 110

Front fog lights ...................109

Headlight range

adjustment ......................... 107

Page 19 of 217

![OPEL ANTARA 2014 Owners Manual In brief17

Automatic transmissionP=parkR=reverseN=neutralD=drive

Manual mode: move selector lever

from D to the left.

<=higher gear]=lower gear

The selector lever can only be moved

out of P when the OPEL ANTARA 2014 Owners Manual In brief17

Automatic transmissionP=parkR=reverseN=neutralD=drive

Manual mode: move selector lever

from D to the left.

<=higher gear]=lower gear

The selector lever can only be moved

out of P when the](/img/37/58214/w960_58214-18.png)

In brief17

Automatic transmissionP=parkR=reverseN=neutralD=drive

Manual mode: move selector lever

from D to the left.

<=higher gear]=lower gear

The selector lever can only be moved

out of P when the ignition is on and

the foot brake is applied. To engage

P or R, push the release button.

Automatic transmission 3 129.

Starting off

Check before starting off ■ Tyre pressure and condition 3 176,

3 207.

■ Engine oil level and fluid levels 3 153.

■ All windows, mirrors, exterior lighting and number plates are free

from dirt, snow and ice and are

operational.

■ Proper position of mirrors, seats, and seat belts 3 27, 3 35,

3 42.

■ Brake function at low speed, particularly if the brakes are wet.Starting the engine

■ Turn key to position ACC

■ move the steering wheel slightly to release the steering wheel lock

■ manual transmission in neutral

■ operate clutch and brake pedals ■ automatic transmission in P or N

■ do not accelerate

■ diesel engines: turn key to ON for

preheating and wait until control

indicator ! extinguishes

■ turn key to START and release

Starting the engine 3 124.

Page 74 of 217

72Storage

To calculate the EC kerb weight,

enter the data for your vehicle in the

Weights table at the front of this

manual.

The EC kerb weight includes

weights for the driver (68 kg),

luggage (7 kg) and all fluids (tank

90 % full).

Optional equipment and

accessories increase the kerb

weight.

■ Driving with a roof load increases the sensitivity of the vehicle to

cross-winds and has a detrimental

effect on vehicle handling due to the vehicle's higher centre of

gravity. Distribute the load evenly

and secure it properly with retaining

straps. Adjust the tyre pressure and

vehicle speed according to the load conditions. Check and retighten the

straps frequently.

Do not drive faster than 120 km/h.

The permissible roof load is

100 kg. The roof load is the

combined weight of the roof rack

and the load.

Page 102 of 217

100Instruments and controls

■ During automatic self-cleaning ofthe diesel particle filter 3 128.

■ In vehicles equipped with engine overspeed warning; when vehicle

speed exceeds 120 km/h 3 91.

When the vehicle is parked and/ or the driver's door is opened ■ When the key is in the ignition switch.

■ With exterior lights on.

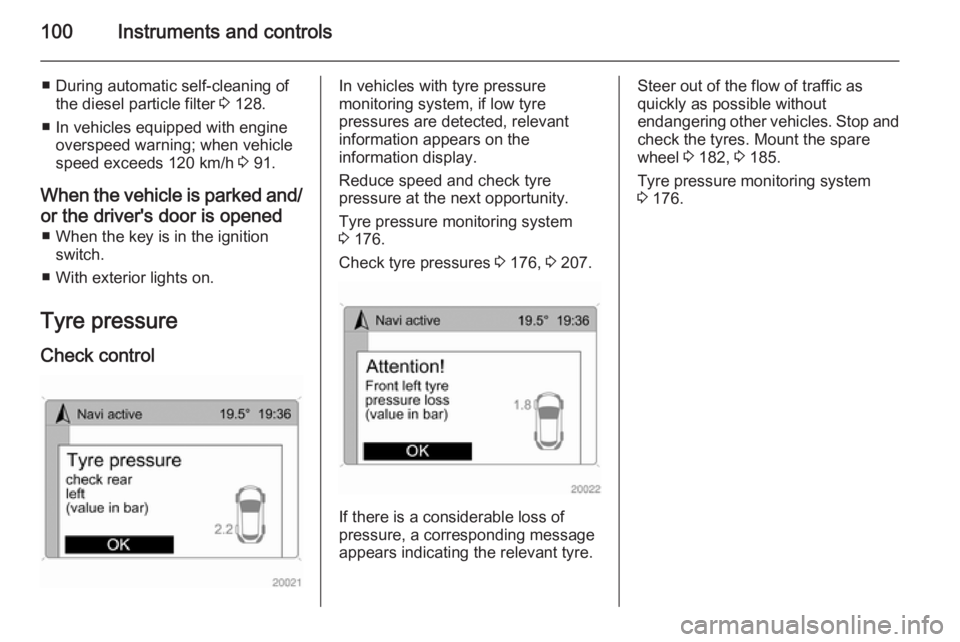

Tyre pressure

Check controlIn vehicles with tyre pressure

monitoring system, if low tyre

pressures are detected, relevant

information appears on the

information display.

Reduce speed and check tyre

pressure at the next opportunity.

Tyre pressure monitoring system

3 176.

Check tyre pressures 3 176, 3 207.

If there is a considerable loss of

pressure, a corresponding message

appears indicating the relevant tyre.

Steer out of the flow of traffic as

quickly as possible without

endangering other vehicles. Stop and

check the tyres. Mount the spare

wheel 3 182, 3 185.

Tyre pressure monitoring system 3 176.

Page 136 of 217

134Driving and operatingDrive systems

All-wheel drive All-wheel drive is an active-on-

demand system that engages

automatically, with no action required

by the driver. Depending on the

driving environment, the vehicle

switches between two-wheel drive and four-wheel drive, to give the

vehicle more traction and stability

when necessary.

If the front wheels begin to slip, the

rear wheels will automatically begin to drive the vehicle as required. More

torque is transferred to the wheels

that have the most traction, so the

vehicle has optimum grip at all times. There may be a slight engagement

noise during hard use.

As well as enabling the vehicle to be

driven off-road, this system also

enables the vehicle to be driven on

normal roads without incurring

excessive tyre and drivetrain wear or

causing poor control.Ensure tyres (including the spare) are

inflated to the correct pressure

3 207 and are suitable for the

prevailing road conditions. For

optimum system performance, the

vehicle's tyres should not have

varying degrees of wear.

If control indicator B flashes in the

instrument cluster during driving, All- wheel drive is temporarily disabled. If B flashes continuously, there is a fault

in the system; seek the assistance of

a workshop.

All-wheel drive control indicator B

3 86.

On-road driving The increased traction of All-wheel

drive vehicles offers greater driving

control in adverse road conditions,

particularly heavy snow and ice.

However, All-wheel drive vehicles are

not "skid-proof" and do not decrease

stopping distances.

All-wheel drive vehicles have a higher

centre of gravity than conventional

vehicles. Always approach curves at

an appropriate driving speed. Do notattempt to go as fast through turns as

you might in a conventional vehicle.

Strong crosswinds can affect the normal steering of the vehicle. Drive

slower under strong crosswind

conditions.

Off-road driving ■ Avoid protruding objects (such as rocks or tree stumps) that maydamage the underbody and tyres of

your vehicle.

■ Test the brakes after operating in mud, to clear excess mud from the

braking surfaces.

■ Grip the steering wheel when travelling over rough terrain.

Terrain conditions can cause rapid

and unexpected movement in the

steering.

The ground clearance, ramp angle,

angle of approach and departure and wading depth need to be considered,

especially in hilly conditions and

when wading, to prevent the vehicle

becoming stuck and possibly

damaged.

Vehicle dimensions 3 204.

Page 140 of 217

138Driving and operating

Fault

Failure mode of electrical parking

brake is indicated by control indicator

j 3 86.

In the event of a fault, to apply

electrical parking brake: pull and hold the switch m for a few seconds. If

control indicator m illuminates,

electrical parking brake has been

applied successfully.

To release electrical parking brake:

push and hold the switch m for a few

seconds. If control indicator m

extinguishes, electrical parking brake has been released successfully.

If control indicator m flashes:

electrical parking brake is not fully

applied or released. When m is

continuously flashing, with ignition

switched on depress brake pedal,

release electrical parking brake and

retry applying.

If m continues to flash, do not drive

the vehicle. If necessary, place

wedge blocks or equivalent in front of and behind wheels to prevent vehiclemovement. Seek the assistance of a

workshop to have the cause of the

fault remedied.

Brake assist

If the brake pedal is depressed

quickly and forcefully, maximum

brake force is automatically applied

(full braking).

Maintain steady pressure on the brake pedal for as long as full braking is required. Maximum brake force is

automatically reduced when the

brake pedal is released.

Hill start assist The system helps prevent unintendedmovement when driving away on

inclines.

When releasing the foot brake after

stopping on an incline, the brakes

remain on for a further 2 seconds. The brakes release automatically as soon

as the vehicle begins to accelerate.Ride control systems

Electronic Stability Control Electronic Stability Control (ESC)

improves driving stability when

necessary, regardless of the type of

road surface or tyre grip. It also

prevents the drive wheels from

spinning.

As soon as the vehicle starts to

swerve (understeer/oversteer),

engine output is reduced and the wheels are braked individually. This

considerably improves the driving

stability of the vehicle on slippery road

surfaces.

ESC is operational as soon as control indicators b and t extinguish in the

instrument cluster after switching on the ignition.

When ESC is active b flashes 3 87.

Page 149 of 217

Driving and operating147Trailer hitch

General information

The coupling ball bar is kept in a bag,

fastened with a strap and is stowed

below the floor cover in the load

compartment.

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

Control indicator á illuminates in the

instrument cluster when a trailer is

connected to the vehicle 3 91.

Driving characteristics and

towing tips In the case of trailers with brakes,

attach the break-away stopping cable

to the eye - not to the coupling ball

bar.If no eye is available, loop cable

around coupling ball bar. Ensure

cable is crossed under the vertical

coupling socket to ensure the trailer

nose cannot drop to the ground if it

becomes separated from the trailer

hitch. Do not allow the cable to drag

along the ground and always allow

enough slack to permit full turning.

Follow the instructions supplied with

the towing equipment.

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the coupling ball, is being used to reduce snaking movements. For trailers with

low driving stability, the use of a

friction-type stabiliser is strongly

recommended.

Do not drive faster than 80 km/h, even in countries where higher speeds are

permitted. When driving uphill, do not drive faster than 30 km/h in 1st gear,

or 50 km/h in 2nd gear.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 207.

Trailer towing Trailer loads

The permissible trailer loads are

vehicle-dependent and engine-

dependent maximum values which

must not be exceeded. The actual

trailer load is the difference between

the actual gross weight of the trailer

and the actual coupling socket load

with the trailer coupled.

When the trailer load is being

checked, therefore, only the trailer

wheels - and not the jockey wheel -

must be standing on the weighing

apparatus.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12 %.

Page 153 of 217

Vehicle care151Vehicle careGeneral Information...................151

Vehicle checks ........................... 152

Bulb replacement .......................160

Electrical system ........................166

Vehicle tools .............................. 173

Wheels and tyres .......................175

Jump starting ............................. 187

Towing ....................................... 188

Appearance care .......................190General Information

Accessories and vehicle

modifications

We recommend the use of genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

■ Wash and wax the vehicle.

■ Have the wax in the engine compartment and underbody

checked.

■ Clean and preserve the rubber seals.

■ Change the engine oil.

■ Drain the washer fluid reservoir.

■ Check the coolant antifreeze and corrosion protection.

■ Adjust tyre pressure to the value specified for full load.

■ Park the vehicle in a dry, well ventilated place. Engage first orreverse gear or move selector lever

to P. Prevent the vehicle from

rolling.

■ Do not apply the electrical parking brake.

Page 154 of 217

152Vehicle care

■ Open the bonnet, close all doorsand lock the vehicle.

■ Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are not functional, e.g. anti-theft alarm

system.

Putting back into operation When the vehicle is to be put back into

operation:

■ Connect the clamp to the negative terminal of the vehicle battery.

Activate the electronics of the

power windows.

■ Check tyre pressure.

■ Fill up the washer fluid reservoir.

■ Check the engine oil level.

■ Check the coolant level.

■ Fit the number plate if necessary.End-of-life vehicle

recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system and Xenon

headlights use extremely high

voltage. Do not touch.

Page 178 of 217

176Vehicle care

V=up to 240 km/hW=up to 270 km/h

Tyre pressureCheck the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Use the valve cap key to make

unscrewing the valve caps easier.

The valve cap key is located on the

inside of the tank flap.

Tyre pressure 3 207.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

The tyre pressure tables show all

possible tyre combinations 3 207.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure shall be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Tyre pressure monitoring

system The tyre pressure monitoring system

checks the pressure of all four wheels

once per minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure. If

wheels without sensors are mounted,

the tyre pressure monitoring system

is not operational. Retrofitting of

sensors is possible.

Note

In countries where the tyre pressure monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.