OPEL ANTARA 2017.5 Manual user

Manufacturer: OPEL, Model Year: 2017.5, Model line: ANTARA, Model: OPEL ANTARA 2017.5Pages: 225, PDF Size: 6.2 MB

Page 181 of 225

Vehicle care179FuseCircuitRR HEAT SEATRear seat

heatingRUN 2Power battery

key on runRUN/CRNKRun crankRVCRear view

cameraRVS/HVAC/DLCExterior

mirrors, climate

control, data

link connectionSCRPMSelective cata‐

lytic reduction

power moduleSDM (BATT)Safety Diag‐

nosis Module

(Battery)SDM (IGN 1)Safety Diag‐

nosis Module

(Ignition)SPARE-FuseCircuitS/ROOF/

FOLDING

MIRRORSunroof, folding

mirrorS/ROOF BATTSunroof batterySSPSPower steeringSTR/WHL SWSteering wheelTRLRTrailerTRLR BATTTrailer batteryXBCMExport Body

Control Module

After changing of defective fuses

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

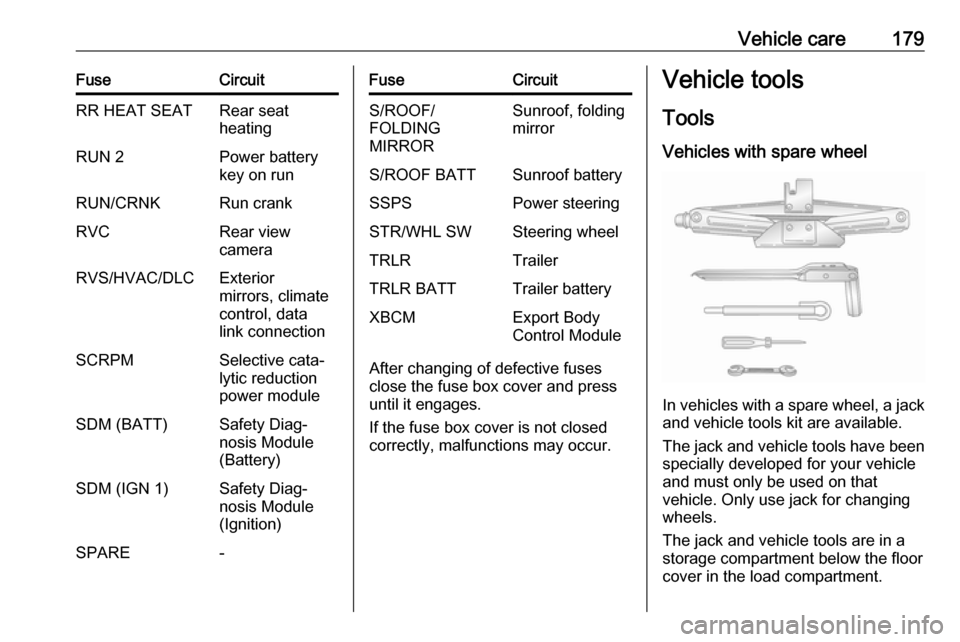

Vehicle tools

Tools

Vehicles with spare wheel

In vehicles with a spare wheel, a jack and vehicle tools kit are available.

The jack and vehicle tools have been

specially developed for your vehicle

and must only be used on that

vehicle. Only use jack for changing

wheels.

The jack and vehicle tools are in a

storage compartment below the floor

cover in the load compartment.

Page 182 of 225

180Vehicle careTo remove the jack and vehicle tools,open the tailgate.

Push both levers on the floor cover

towards the handle and pull up the

cover by the handle.

Where present, hang the hook to the

upper part of the tailgate opening.

Remove wing bolt from the jack by

rotating it anticlockwise and remove

the jack and wheel wrench bag.

Remove straps holding the bag

containing the wheel wrench.

Remove wheel wrench from the bag.

Wheel changing 3 190.

Spare wheel 3 193.

Vehicles with tyre repair kit

In vehicles with a tyre repair kit, there may not be a jack and vehicle tool kit.

The tyre repair kit is in a storage

compartment below the floor cover in the load compartment.

Page 183 of 225

Vehicle care181

To remove the tyre repair kit, open thetailgate and pull the floor cover handle

upwards 3 68.

Caution

Do not allow objects to protrude

above the top of the rear floor

storage compartment, to avoid

damage to the storage area and

the load compartment floor.

Tyre repair kit 3 187.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

If winter tyres are installed that have

not been approved for your vehicle,

Electronic Stability Control (ESC)

system performance may be affected 3 145. Seek the assistance of a

workshop regarding availability of

approved winter tyres.If winter tyres are in use, the

temporary spare wheel may still be

fitted with a summer tyre. Vehicle

driveability could be affected,

especially on slippery road surfaces.

Spare wheel 3 193.

Tyre designations E.g. 235/65 R 17 104 H235:Tyre width, in mm65:Cross-section ratio (tyre height

to tyre width), %R:Belt type: RadialRF:Type: RunFlat17:Wheel diameter, in inches104:Load index e.g. 91 is

equivalent to 618 kgH:Speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of your vehicle.

Page 184 of 225

182Vehicle careThe maximum speed is achievable atkerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 208.

Tyre pressure

Check the pressure of cold tyres at least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Use the valve cap key to make

unscrewing the valve caps easier.

The valve cap key is located on the

inside of the tank flap.

Tyre pressure 3 212.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 207.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 212.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

Page 185 of 225

Vehicle care183The tyre pressure value displayed in

the Info-Display shows the real tyre

pressure. A cooled down tyre will

show a decreased value, which does

not indicate an air leak.

Tyre pressure monitoring system

The tyre pressure monitoring system

checks the pressure of all four wheels

once per minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure. If

wheels without sensors are mounted,

the tyre pressure monitoring system

is not operational.

Note

In countries where the tyre pressure monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The tyre pressure sensors monitor

the air pressure in the tyres and

transmit tyre pressure readings to a

receiver located in the vehicle.

Each tyre, including the spare, should be checked monthly when cold and

inflated to the recommended inflation

pressure 3 212.

Low tyre pressure conditionA detected low tyre pressure

condition is indicated by control

indicator w 3 88.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 212.

When the system detects a

malfunction, w will flash for approx.

one minute and then remain

continuously illuminated. This

sequence will continue upon

subsequent vehicle start-ups as long as the malfunction exists.

When w is illuminated, the system

may not be able to detect or signal low tyre pressure as intended.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching

a low tyre pressure condition. Check

tyre pressure.

Page 186 of 225

184Vehicle careTyre pressures in Info-Display

The current tyre pressures can be

shown in the menu item Tyres in the

Board Computer menu. Press BC on

the Infotainment system and select

the menu item.

The tyre pressure monitoring system

automatically detects the vehicle

load. A corresponding message may appear on the Info-Display if

inconsistent tyre pressures are

detected. In some versions, the

message is displayed in abbreviated

form.

For example, the following messages can be displayed:

A graphic indicating the left rear tyre

is shown together with the current tyre

pressure; slight pressure deviation.

Reduce speed. Check tyre pressure

at next opportunity with an

appropriate gauge and correct if

necessary.

On the Colour-Info-Display, this

message will appear in yellow.A graphic indicating the front left tyre

is shown together with the current tyre

pressure; significant pressure

deviation or direct pressure loss.

Steer out of the flow of traffic as

quickly as possible without

endangering other vehicles. Stop and

check the tyres. Mount the spare

wheel if necessary 3 190.

On the Colour-Info-Display, this

message will appear in red.

Acknowledgement of warnings 3 92,

3 94.

Vehicle messages 3 99.

Page 187 of 225

Vehicle care185If the tyre pressure is to be reduced or

increased, switch off the ignition. Tyre

pressures 3 182, 3 212.

General information The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved tyre repair kits can be used.

Tyre repair kit 3 187.

Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

The tyre pressure monitoring system

valve cores and sealing rings must be

replaced each time the tyres are

changed.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new tyre/wheel position after

rotating the tyres or replacing one or

more of the tyre pressure sensors.The tyre pressure sensor matching

process should also be performed

after replacing a spare tyre with a

road tyre containing a tyre pressure

sensor. The control indicator w and

the warning message should

extinguish at the next ignition cycle.

The sensors are matched to the tyre/

wheel positions, using a TPMS

relearn tool, in the following order:

● left front tyre

● right front tyre

● right rear tyre

● left rear tyre

Consult your workshop for service or

to purchase a relearn tool.

There are two minutes to match the

first tyre/wheel position, and

five minutes overall to match all four

tyre/wheel positions. If it takes longer, the matching process stops and must

be restarted.The tyre pressure sensor matching

process is as follows:

1. Apply the electrical parking brake 3 143 ; on vehicles with automatic

transmission move the selector

lever to position P.

2. Turn the ignition on 3 125.

3. Initiate the TPMS Learn Mode by simultaneously pressing p and

q on the radio remote control,

- or -

Press INFO on the Infotainment

system until a tyre learn message appears on the Info-display.

Press and hold OK.

The horn sounds twice and the left front turn signal also illuminates

as confirmation that Learn Mode

has been enabled.

4. Start with the left front tyre. 5. Place the relearn tool against the tyre sidewall, near the valve stem.

Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

Page 188 of 225

186Vehicle carematched to this tyre and wheel

position. The next relevant turn

signal illuminates.

6. Proceed to the right front tyre, and

repeat the procedure in Step 5.

7. Proceed to the right rear tyre, and

repeat the procedure in Step 5.

8. Proceed to the left rear tyre, and repeat the procedure in Step 5.

The horn sounds twice to indicate

the sensor identification code has been matched, and the tyre

pressure sensor matching

process is no longer active.

9. Turn off the ignition.

10. Set all four tyres to the recommended inflation pressure

3 212.

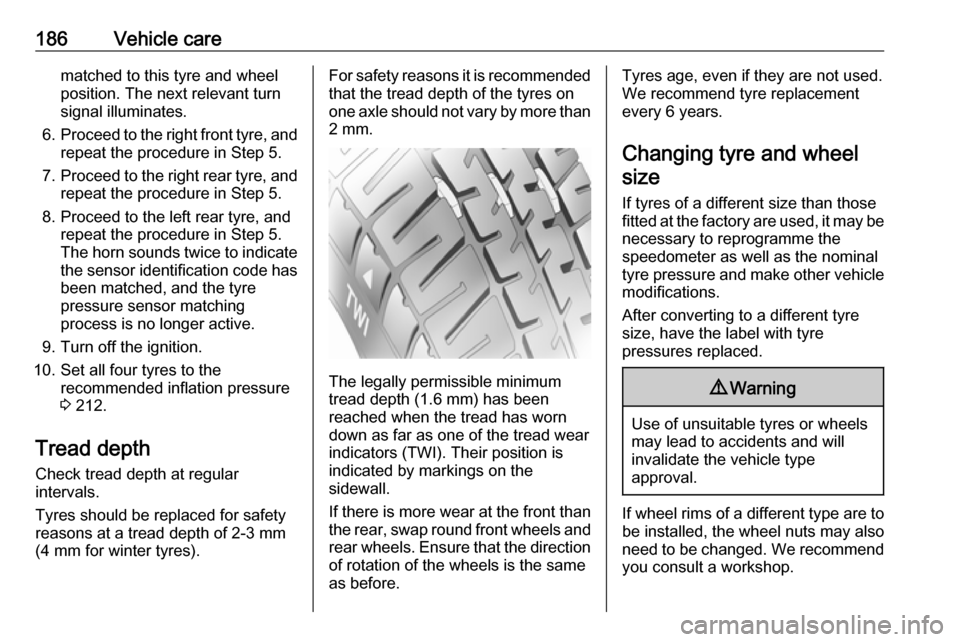

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels. Ensure that the direction

of rotation of the wheels is the same

as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

If wheel rims of a different type are to

be installed, the wheel nuts may also

need to be changed. We recommend you consult a workshop.

Page 189 of 225

Vehicle care187Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre chains

Tyre chains are only permitted on the

front wheels.

They must be fitted to the tyres

symmetrically in order to achieve a

concentric fit.

9 Warning

Damage may lead to tyre blowout.

Special snow chains are only

permitted when they are designed

with a rotating chain belt on the tyre

tread, no chain links on the wheel

inboard sides and the chains add no

more than 12 mm to the tyre tread.

For further information regarding

correct snow chain usage for the tyre

size, contact a specialised vehicle

parts dealer or snow chain

manufacture. Tyre chains are only

permitted on tyres of size

235/60 R17 and 235/55 R18.General

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread or

sidewall can be repaired with the tyre

repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at the tyre's sidewall near the rim

cannot be repaired with the tyre repair kit.

In vehicles with a tyre repair kit, there may not be a jack and vehicle tool kit.

Vehicle tools 3 179.

Temporary spare wheel 3 193.

Page 190 of 225

188Vehicle care9Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the electrical parking brake

3 143 and engage first gear, reverse

gear or P.

The tyre repair kit is in a storage

compartment below the floor cover in the load compartment.

To remove the tyre repair kit, open the

tailgate.

Pull the floor cover handle upwards

3 68.

Vehicle tools 3 179.

Caution

Do not allow objects to protrude

above the top of the rear floor

storage compartment, to avoid

damage to the storage area and

the load compartment floor.

1. Release the sealant filler hose 1

and the power plug 2.

2. Unscrew valve cap from defective

tyre.

Screw the sealant filler hose onto

the tyre valve.

3. Connect the power plug to the power outlet. Unplug all items

from other power outlets.

4. Switch on ignition. To avoid discharging the battery, werecommend running the engine.5. Turn the selector switch anticlockwise to the sealant +

air position.