check engine OPEL ANTARA 2017.5 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: ANTARA, Model: OPEL ANTARA 2017.5Pages: 225, PDF Size: 6.2 MB

Page 134 of 225

132Driving and operatingIf AdBlue is not refilled within a certaindistance, further level warnings are

shown in the Driver Information

Centre, depending on the current

AdBlue level.

Subsequent requests to refill AdBlue

and finally the announcement that an engine restart will be prevented are

displayed in the Driver Information

Centre.

Note

These restrictions are a legal

requirement.At an AdBlue range of 900 km, the following warning messages are

alternately displayed in the Driver

Information Centre:

● AdBlue Low Refill Now

● Engine Restart Prevented in

900 km

Additionally, control indicator Y

flashes continuously.

Engine restarts prevented

Before the prevention of an engine

restart, the following warning

messages are alternately displayed in the Driver Information Centre:

● AdBlue Empty Refill Now

● Engine Will Not Restart

These messages indicate that after

switching off the ignition, an engine

restart will be prohibited.

Additionally, control indicator Y

flashes continuously.

After the prevention of an engine

start, a warning message (e.g. "Refill

AdBlue To Start Vehicle") is displayed

in the Driver Information Centre

reminding the driver that AdBlue level

is insufficient.

To allow the engine to be restarted,

the tank should be filled with at least

10 litres of AdBlue.

High emission warningsIf the exhaust emission rises above a

certain value, warnings similar to the

range warnings as described above

will be displayed in the Driver

Information Centre.

Requests to have the exhaust system checked and finally the

announcement that an engine restart

will be prevented are displayed in the

Driver Information Centre.

Page 136 of 225

134Driving and operatingFilling station9Danger

Follow the operating and safety

instructions of the filling station

when refilling AdBlue.

1. Switch off engine and remove key

from ignition switch.

2. Disengage the cover using a suitable screwdriver and remove.

3. Unscrew protective capanticlockwise from the filler neck.

4. Fully insert the pump nozzle intothe filler neck and switch it on.

5. When refilling is complete, mount the protective cap and turn

clockwise until it engages.

6. Replace the cover by inserting the

right side first.

AdBlue canister Note

Only use the designated AdBlue

canisters for refilling, to prevent a

topping-up of too much AdBlue.

Additionally, the fumes in the tank

are captured in the canister and do

not emerge.

Note

Since AdBlue has a limited

durability, check the date of expiry

before refilling.

1. Switch off engine and remove key

from ignition switch.

2. Disengage the cover using a suitable screwdriver and remove.

3. Unscrew protective cap anticlockwise from the filler neck.

Page 143 of 225

Driving and operating141you might in a conventional vehicle.

Strong crosswinds can affect the

normal steering of the vehicle. Drive

slower under strong crosswind

conditions.

Off-road driving ● Avoid protruding objects (such as

rocks or tree stumps) that may

damage the underbody and tyres of your vehicle.

● Test the brakes after operating in

mud, to clear excess mud from

the braking surfaces.

● Grip the steering wheel when travelling over rough terrain.

Terrain conditions can cause

rapid and unexpected movement in the steering.

The ground clearance, ramp angle,

angle of approach and departure and wading depth need to be considered,

especially in hilly conditions and

when wading, to prevent the vehicle

becoming stuck and possibly

damaged.

Vehicle dimensions 3 209.

Towing the vehicle 3 196.Driving through water

Do not exceed the maximum wading

depth 3 209.

Check the depth of water: choose the

lowest entry and departure angles

before entering. Maintain a steady

engine speed, to help prevent water

from entering the exhaust system, but do not exceed 5 km/h, to avoid

splashing the water.

Drive with the flow wherever possible,

not against it. If you have to drive

against the flow, try to drive at an

angle to it, so that the leading corner

of the vehicle will help deflect water

from the engine compartment. Avoid

splashing the water - if the ignition

system becomes wet, the engine may

stall.

Avoid water entering the air intake

system 3 120. If water enters the air

intake system, engine seizure with severe costly damage may result.

Test the brakes after leaving the

water - wet brakes are less effective

than dry ones. Perform the service

operations for wading , involving

checks for water contamination, at

the earliest opportunity.Service checks after wading

Check for the ingress of water into the following:

● Brake fluid reservoir

● Air cleaner element

● Engine

● Transmission

● Axles

● Interior of vehicle

Renew any lubricating oil or hydraulic

fluid that has a milky appearance,

indicating contamination with water.

Cleaning

Clean the vehicle thoroughly and as

soon as possible after driving off-

road.

Do not let mud remain dry on any part

of the vehicle as it becomes abrasive and can damage paint, glass, seals,

bearings and brake components. If

left to build up, mud can seriously

affect the airflow through and over

mechanical components and cause

localised overheating and failure of

parts, especially in the engine

compartment.

Page 144 of 225

142Driving and operatingEnsure the radiator core and the areabetween the radiator and intercooler/

oil cooler (where installed) is cleaned, to maintain proper cooling air flow.Check the radiator and cooler cores

for blockage (sand, silt etc.).

Check the tyre treads.

Clean and check the mechanical

parts of the vehicle, particularly the

following areas:

● Driveshafts, including sealing bellows

● Front brake calipers, pads and discs

● Front suspension

● Clutch fork sealing bellows

● Rear brake calipers, pads and discs

● Rear suspension

● Fuel tank and underguard

● Breathers, axles and fuel tank

● Load sensing valve

● Transfer box and underguard

● Engine oil pan and underguardObserve the following: ● Do not spray high-pressure water

directly at the vehicle seals

● The wheels must be removed to clean all mud and stones from the

brake calipers and to check

brake pad wear

● The areas on the upper side of the underguards must be clearedof stones, to prevent damage to

the engine oil pan and the fuel

tankBrakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek

the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 85.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.

Page 145 of 225

Driving and operating143ABS starts to regulate brake pressure

as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting off, the system performs a self-test which may be audible.

Control indicator u 3 85.

Fault9 Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS

are no longer available. During

hard braking, the vehicle can nolonger be steered and may

swerve.

You can continue driving, provided

you drive with care and anticipation.

Have the cause of the fault remedied

by a workshop.

Parking brake

Electrical parking brake

Applying when vehicle is stationary

Pull switch m, the electrical parking

brake operates automatically with

adequate force. For maximum force,

e.g. parking with a trailer or on

inclines, pull switch m twice.

The electrical parking brake can

always be activated, even if the

ignition is off.

Do not operate electrical parking

brake system too often without

engine running as this will discharge

the battery.

Before leaving the vehicle, check the

electrical parking brake status.

Control indicator m 3 85.

Releasing

Switch on ignition. Keep foot brake

depressed and then push switch m.

If the foot brake is not depressed

when attempting to release electrical

parking brake, a warning chime will

sound and control indicator -

illuminates in the instrument cluster

3 90.

Page 155 of 225

Driving and operating153Adjust tyre pressure to the value

specified for full load 3 212.

Trailer towing Trailer loadsThe permissible trailer loads are

vehicle-dependent and engine-

dependent maximum values which

must not be exceeded. The actual

trailer load is the difference between

the actual gross weight of the trailer

and the actual coupling socket load

with the trailer coupled.

When the trailer load is being

checked, therefore, only the trailer

wheels - and not the jockey wheel -

must be standing on the weighing

apparatus.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12%.

The permitted trailer load applies up

to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases

as altitude increases due to the airbecoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than

8%, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is specified on the identification plate3 205.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (80 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.When measuring the vertical coupling

load, ensure the drawbar of the

loaded trailer is at the same height as it will be when the trailer is coupled

with the towing vehicle loaded. This is

particularly important for trailers with

tandem axle.

Rear axle load

When the trailer is coupled and the

towing vehicle is fully loaded

(including all occupants), the

permissible rear axle load (see

identification plate or vehicle

documents) must not be exceeded.

National regulations regarding

maximum speeds for vehicles towing a trailer must be observed.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Page 157 of 225

Driving and operating155Check that the coupling ball bar is

correctly attached:

● Green marking must be visible on

lever.

● Coupling ball bar must be seated

firmly in coupling housing.

Coupling ball bar must be locked and key must be removed.9 Warning

Towing a trailer is permitted only

when the coupling ball bar is fitted correctly. If the coupling ball bar

cannot be properly attached, seek the assistance of a workshop.

Eye for break-away stopping cable

In the case of trailers with brakes,

attach the break-away stopping cable

to the eye - not to the coupling ball

bar.

Dismounting the coupling ball bar

Unlock coupling ball bar and remove

key. Push lever to the left, towards the

coupling ball bar and turn it

downwards. Pull coupling ball bar out of coupling housing.

Remove any rust or dirt from area

around the coupling housing and

coupling ball bar connection before

inserting sealing plug in the hole.

Place the coupling ball bar in the bag supplied, fasten it with the strap and

stow it below the floor cover in the

load compartment.

Do not use steam-jet cleaners or

other high-pressure cleaners to clean

the coupling ball bar.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep

steering wheel as still as possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Control 3 145.

Page 158 of 225

156Vehicle careVehicle careGeneral Information...................157

Accessories and vehicle modifications .......................... 157

Vehicle storage ........................157

End-of-life vehicle recovery .....158

Vehicle checks ........................... 158

Performing work ......................158

Bonnet ..................................... 158

Engine oil ................................. 159

Engine coolant ......................... 160

Power steering fluid .................161

Washer fluid ............................ 161

Brakes ..................................... 161

Brake fluid ............................... 162

Clutch fluid ............................... 162

Vehicle battery ......................... 162

Diesel fuel filter ........................164

Diesel fuel system bleeding .....165

Wiper blade replacement ........165

Bulb replacement .......................165

Headlights ............................... 165

Halogen headlights ..................166

Xenon headlights .....................167

Fog lights ................................. 168

Tail lights ................................. 169Side turn signal lights ..............170

Centre high-mounted brake light ......................................... 170

Number plate light ...................170

Interior lights ............................ 170

Instrument panel illumination ...171

Electrical system ........................171

Fuses ....................................... 171

Engine compartment fuse box . 173

Instrument panel fuse box .......176

Vehicle tools .............................. 179

Tools ........................................ 179

Wheels and tyres .......................181

Winter tyres ............................. 181

Tyre designations ....................181

Tyre pressure .......................... 182

Tyre pressure monitoring system .................................... 183

Tread depth ............................. 186

Changing tyre and wheel size . 186

Wheel covers ........................... 187

Tyre chains .............................. 187

Tyre repair kit .......................... 187

Wheel changing .......................190

Spare wheel ............................ 193

Jump starting ............................. 194

Towing ....................................... 196

Towing the vehicle ...................196

Towing another vehicle ...........197Appearance care .......................198

Exterior care ............................ 198

Interior care ............................. 200

Page 159 of 225

Vehicle care157General Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the

electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, well ventilated place. Engage first or

reverse gear or move selector

lever to P. Prevent the vehicle

from rolling.

● Do not apply the electrical parking brake.● Open the bonnet, close all doorsand lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.

Page 160 of 225

158Vehicle careEnd-of-life vehicle recoveryInformation on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system and Xenon

headlights use extremely high

voltage. Do not touch.

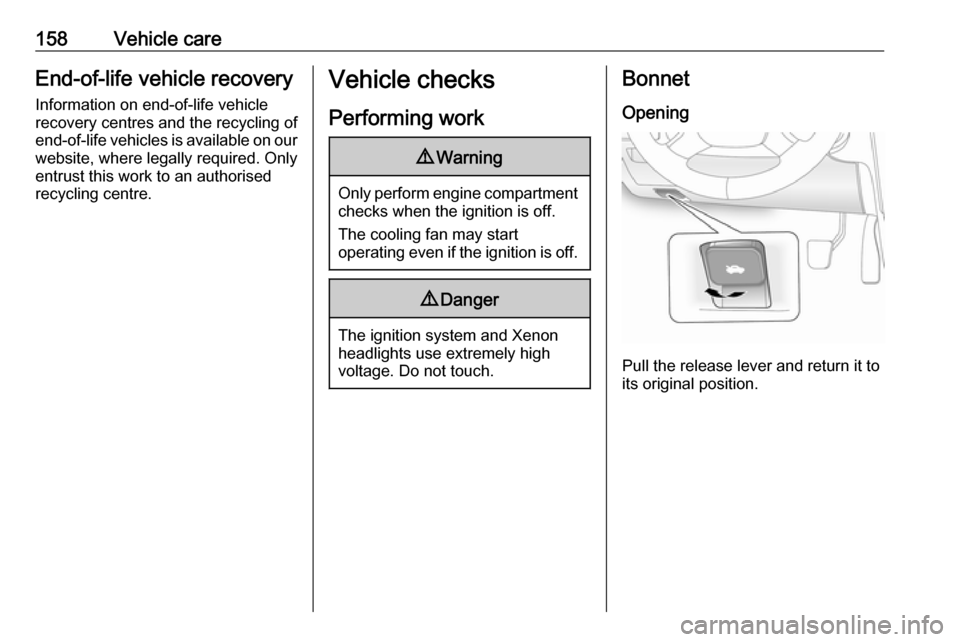

Bonnet

Opening

Pull the release lever and return it to

its original position.