OPEL ASTRA 1991 Electronic Workshop Manual

Manufacturer: OPEL, Model Year: 1991, Model line: ASTRA, Model: OPEL ASTRA 1991Pages: 1070, PDF Size: 41.39 MB

Page 1061 of 1070

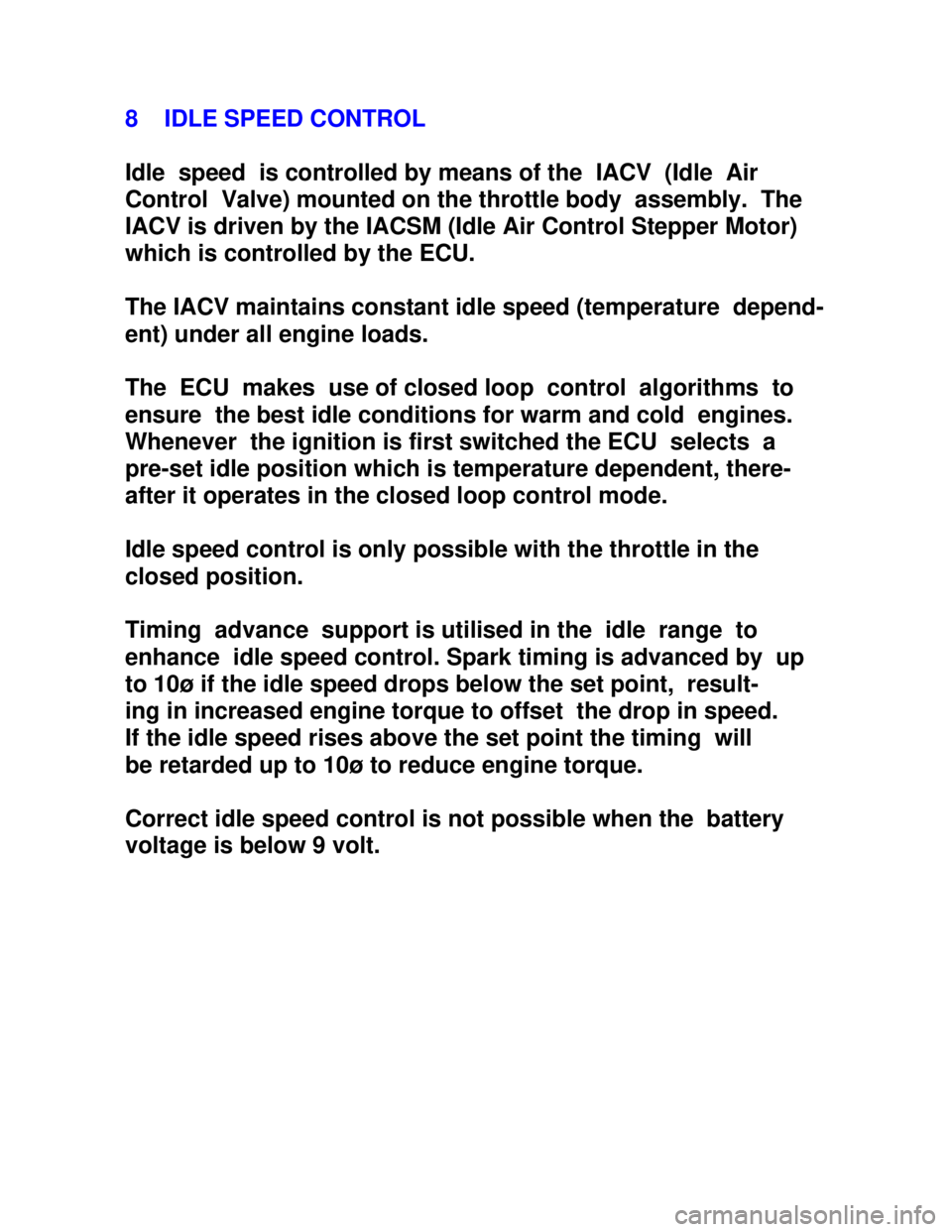

Downloaded from www.Manualslib.com manuals search engine 8 IDLE SPEED CONTROL

Idle speed is controlled by means of the IACV (Idle Air

Control Valve) mounted on the throttle body assembly. The

IACV is driven by the IACSM (Idle Air Control Stepper Motor)

which is controlled by the ECU.

The IACV maintains constant idle speed (temperature depend-

ent) under all engine loads.

The ECU makes use of closed loop control algorithms to

ensure the best idle conditions for warm and cold engines.

Whenever the ignition is first switched the ECU selects a

pre-set idle position which is temperature dependent, there-

after it operates in the closed loop control mode.

Idle speed control is only possible with the throttle in the

closed position.

Timing advance support is utilised in the idle range to

enhance idle speed control. Spark timing is advanced by up

to 10ø if the idle speed drops below the set point, result-

ing in increased engine torque to offset the drop in speed.

If the idle speed rises above the set point the timing will

be retarded up to 10ø to reduce engine torque.

Correct idle speed control is not possible when the battery

voltage is below 9 volt.

Page 1062 of 1070

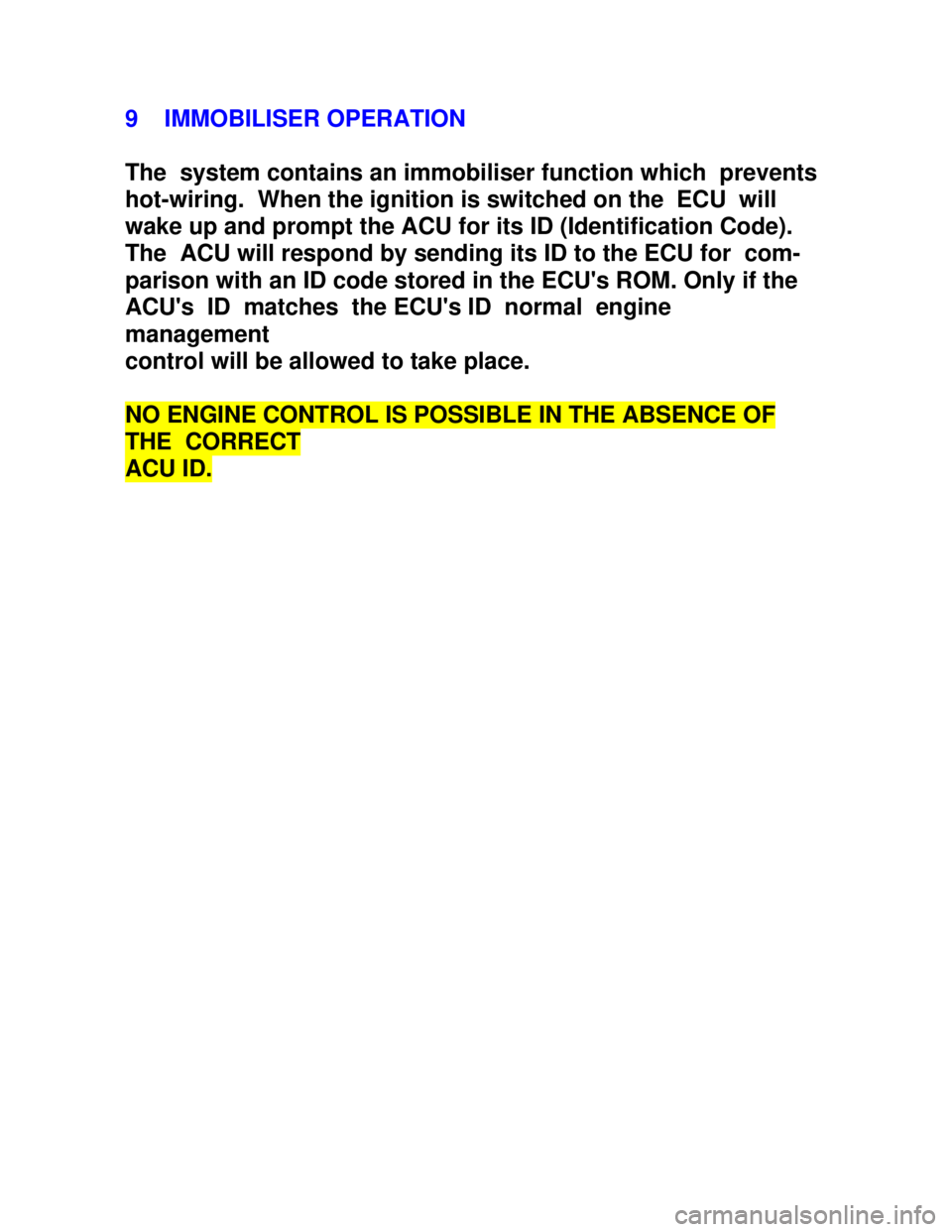

Downloaded from www.Manualslib.com manuals search engine 9 IMMOBILISER OPERATION

The system contains an immobiliser function which prevents

hot-wiring. When the ignition is switched on the ECU will

wake up and prompt the ACU for its ID (Identification Code).

The ACU will respond by sending its ID to the ECU for com-

parison with an ID code stored in the ECU's ROM. Only if the

ACU's ID matches the ECU's ID normal engine

management

control will be allowed to take place.NO ENGINE CONTROL IS POSSIBLE IN THE ABSENCE OFTHE CORRECTACU ID.

Page 1063 of 1070

Downloaded from www.Manualslib.com manuals search engine 10 DEFAULT MODE SELECTION

When the ECU detects a faulty signal from one of its sensors

it will substitute a default signal value to enable the

vehicle to be driven with degraded performance (see para-

graph 10.1).

Faulty sensor Substitute value/sensor

_____________________________________________________

______

EWT Warm engine - 100 øC

MAT 31 øC

Fuel map selector Zero percent enrichment

Timing map selector Map T1 - RON 87D

TPS Idle speed - 1,000 to

2,000 r.p.m.

MAP TPS and idle speed -

1,000 to 2,000 r.p.m.

Disable distributor

bypass operation and

fix spark timing at

10ø BTDC

CO potentiometer Zero percent

Page 1064 of 1070

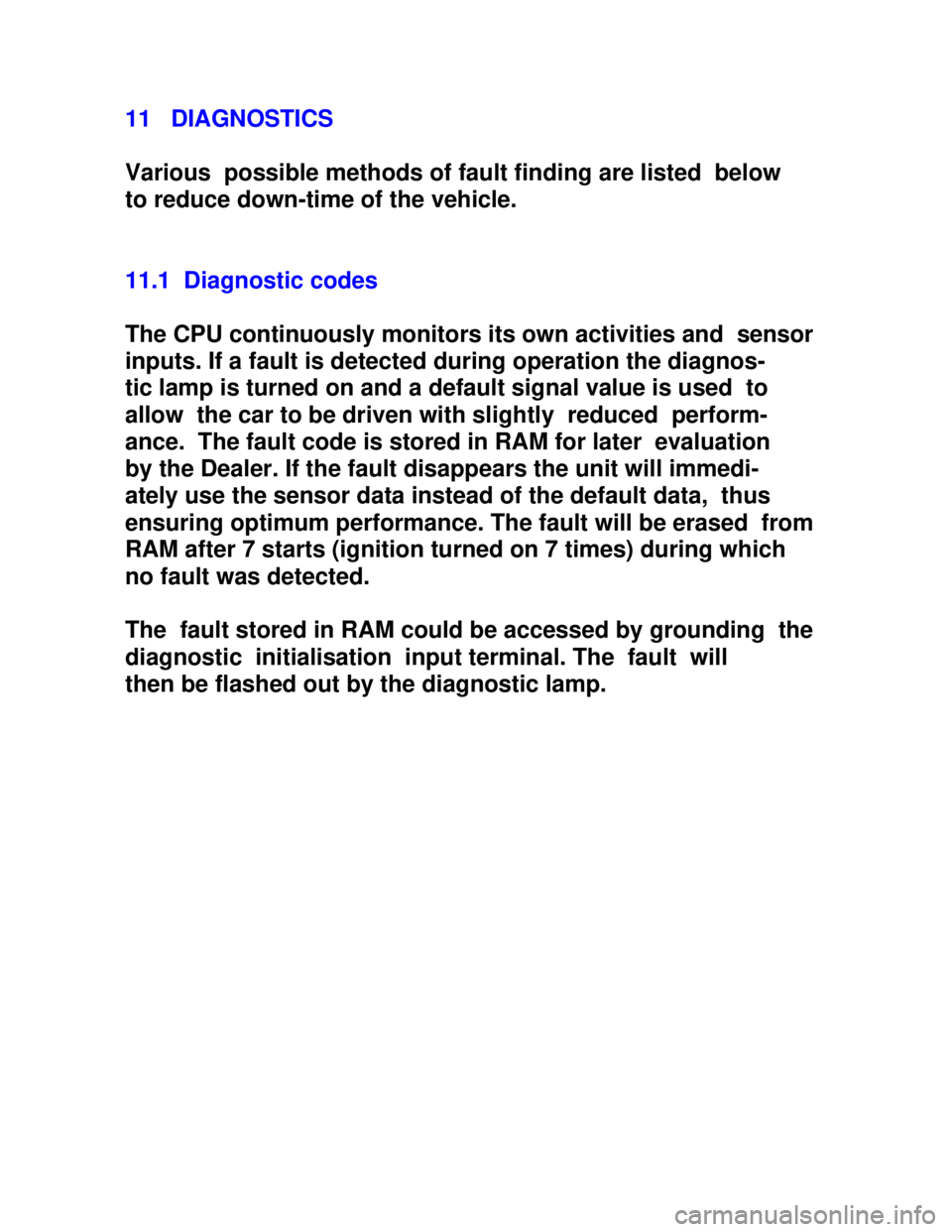

Downloaded from www.Manualslib.com manuals search engine 11 DIAGNOSTICS

Various possible methods of fault finding are listed below

to reduce down-time of the vehicle.

11.1 Diagnostic codes

The CPU continuously monitors its own activities and sensor

inputs. If a fault is detected during operation the diagnos-

tic lamp is turned on and a default signal value is used to

allow the car to be driven with slightly reduced perform-

ance. The fault code is stored in RAM for later evaluation

by the Dealer. If the fault disappears the unit will immedi-

ately use the sensor data instead of the default data, thus

ensuring optimum performance. The fault will be erased from

RAM after 7 starts (ignition turned on 7 times) during which

no fault was detected.

The fault stored in RAM could be accessed by grounding the

diagnostic initialisation input terminal. The fault will

then be flashed out by the diagnostic lamp.

Page 1065 of 1070

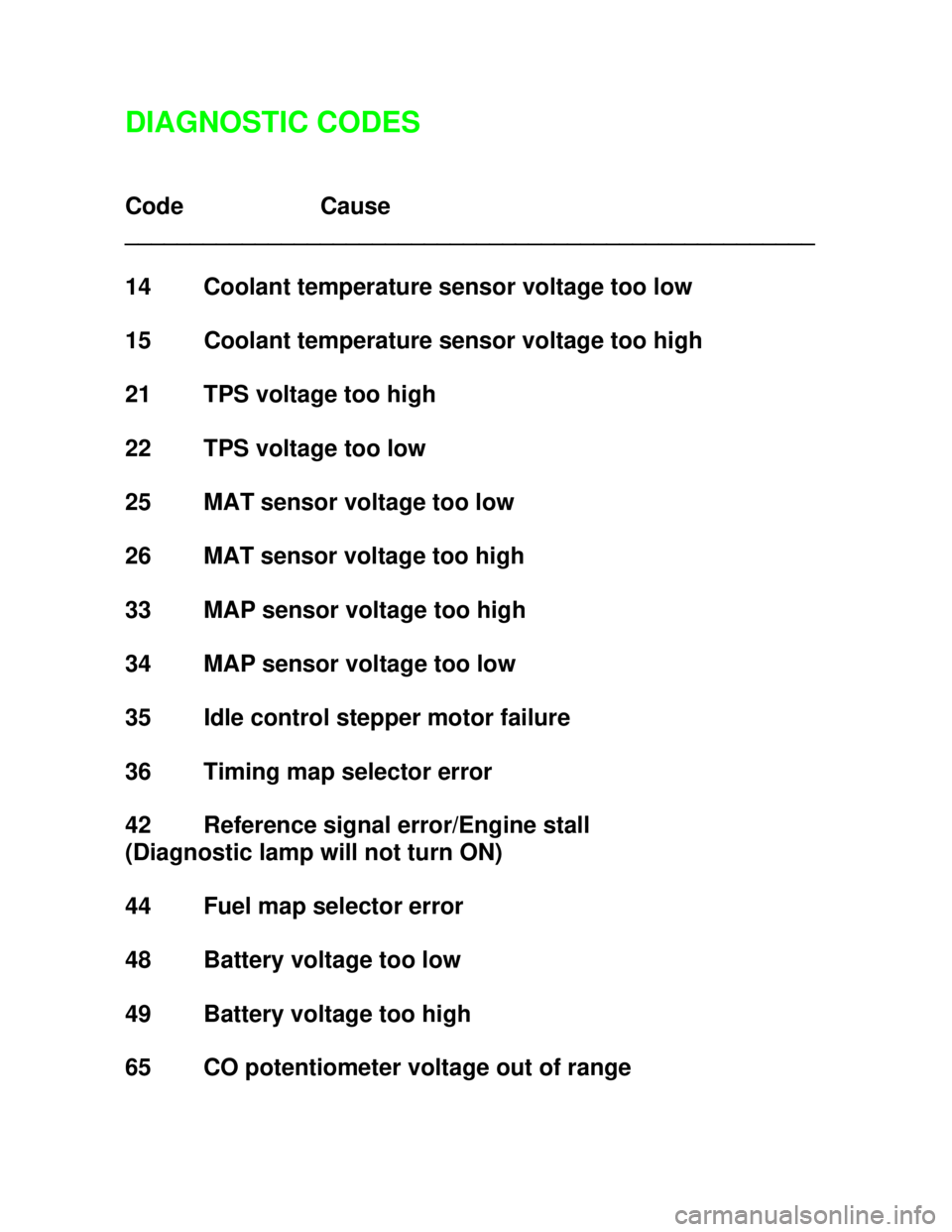

Downloaded from www.Manualslib.com manuals search engine DIAGNOSTIC CODES

Code Cause

_____________________________________________________

14 Coolant temperature sensor voltage too low

15 Coolant temperature sensor voltage too high

21 TPS voltage too high

22 TPS voltage too low

25 MAT sensor voltage too low

26 MAT sensor voltage too high

33 MAP sensor voltage too high

34 MAP sensor voltage too low

35 Idle control stepper motor failure

36 Timing map selector error

42 Reference signal error/Engine stall

(Diagnostic lamp will not turn ON)

44 Fuel map selector error

48 Battery voltage too low

49 Battery voltage too high

65 CO potentiometer voltage out of range

Page 1066 of 1070

Downloaded from www.Manualslib.com manuals search engine 11.2 Volt- and ohmmeter

No repair work inside the ECU's is possible and

recommended.

A multimeter could however be used to ensure that the fol-

lowing inputs to the ECU are present:

11.2.1 Battery voltage:

11.2.2 The voltage measured between terminals

26B (pos) and 25B (neg) should be equal to the battery

voltage (6 and 16 VDC).

11.2.2 Ignition voltage: The voltage between terminal 22B

and

power ground should be equal to the battery voltage with

the ignition turned on.

11.2.3 TPS supply voltage: The voltage between terminal

09B

and signal ground should be between 4.6 and 5.2 volt.

11.2.4 TPS input signal voltage: The voltage between terminal

05B and signal ground should be:

Closed throttle 0.3 < VTPS < 1.0

Part load 1.0 < VTPS < 3.11

WOT 3.11 < VTPS < 5.2

Page 1067 of 1070

Downloaded from www.Manualslib.com manuals search engine 11.2.5 CO potentiometer supply voltage: The voltage

between

terminal 23B and signal ground should be between 4.7 and

5.2 volt.

11.2.6 MAP sensor supply voltage: The voltage between

terminal

24B and signal ground should be between 4.7 and 5.2 volt.

11.2.7 MAP sensor signal voltage: The voltage between

terminal

15B and signal ground with ignition on should be:

MAP signal voltage Manifold absolute pressure

_____________________________________________________

___

1.00 20 kPa

2.00 40 kPa

3.00 60 kPa

4.00 80 kPa

4.50 90 kPa

5.00 100 kPa

A general tolerance of +/- 5% exists on the above voltages.

Page 1068 of 1070

Downloaded from www.Manualslib.com manuals search engine 11.2.8 Timing map selector: The resistance between terminal

19B and 22B measured on the harness connector with the

ECU removed should be:

97 RON - 470 ohm

93 RON - 220 ohm

87 RON - 4,700 ohm

87D RON - 5,600 ohm

11.2.9 Fuel mixture selector: The resistance between terminal

18B and 11A measured on the harness connector with the

ECU removed should be:

-15% - 274 ohm

-10% - 340 ohm

-05% - 412 ohm

+05% - 619 ohm

+10% - 768 ohm

+15% - 931 ohm

+20% - 1180 ohm

+25% - 1500 ohm

Page 1069 of 1070

Downloaded from www.Manualslib.com manuals search engine 11.2.10 EWT sensor: The resistance between terminal 16B and

11A

on the harness connector with the ECU removed should be:

EWT øC Resistance (ohm)

-20 19,700

-0 5,640

+20 2,410

40 1,177

60 565

80 308

100 186

Page 1070 of 1070

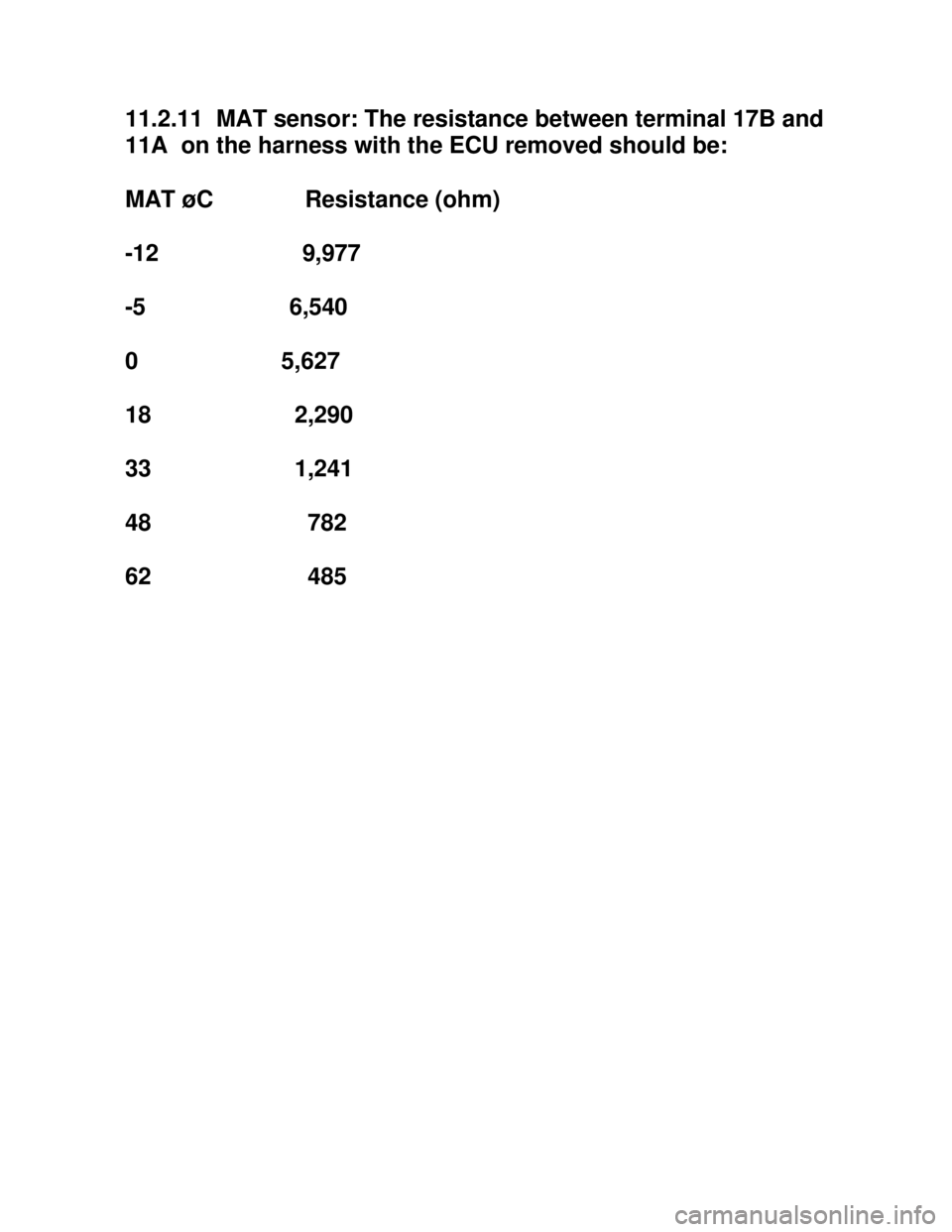

Downloaded from www.Manualslib.com manuals search engine 11.2.11 MAT sensor: The resistance between terminal 17B and

11A on the harness with the ECU removed should be:

MAT øC Resistance (ohm)

-12 9,977

-5 6,540

0 5,627

18 2,290

33 1,241

48 782

62 485