change OPEL ASTRA J 2018 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: ASTRA J, Model: OPEL ASTRA J 2018Pages: 295, PDF Size: 8.41 MB

Page 205 of 295

Vehicle care203

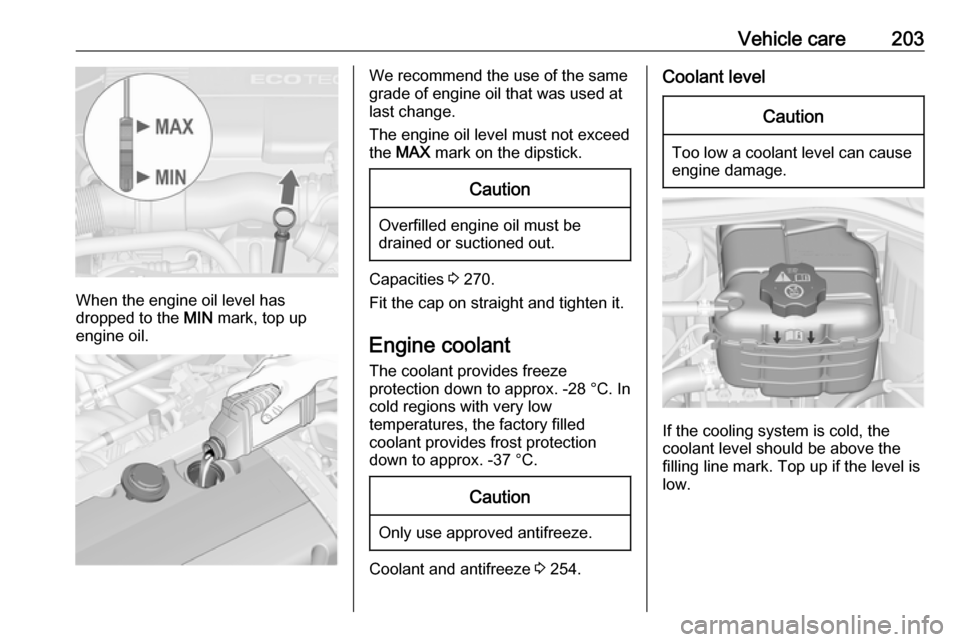

When the engine oil level has

dropped to the MIN mark, top up

engine oil.

We recommend the use of the same

grade of engine oil that was used at

last change.

The engine oil level must not exceed

the MAX mark on the dipstick.Caution

Overfilled engine oil must be

drained or suctioned out.

Capacities 3 270.

Fit the cap on straight and tighten it.

Engine coolant The coolant provides freeze

protection down to approx. -28 °C. In

cold regions with very low

temperatures, the factory filled

coolant provides frost protection

down to approx. -37 °C.

Caution

Only use approved antifreeze.

Coolant and antifreeze 3 254.

Coolant levelCaution

Too low a coolant level can cause

engine damage.

If the cooling system is cold, the

coolant level should be above the

filling line mark. Top up if the level is

low.

Page 213 of 295

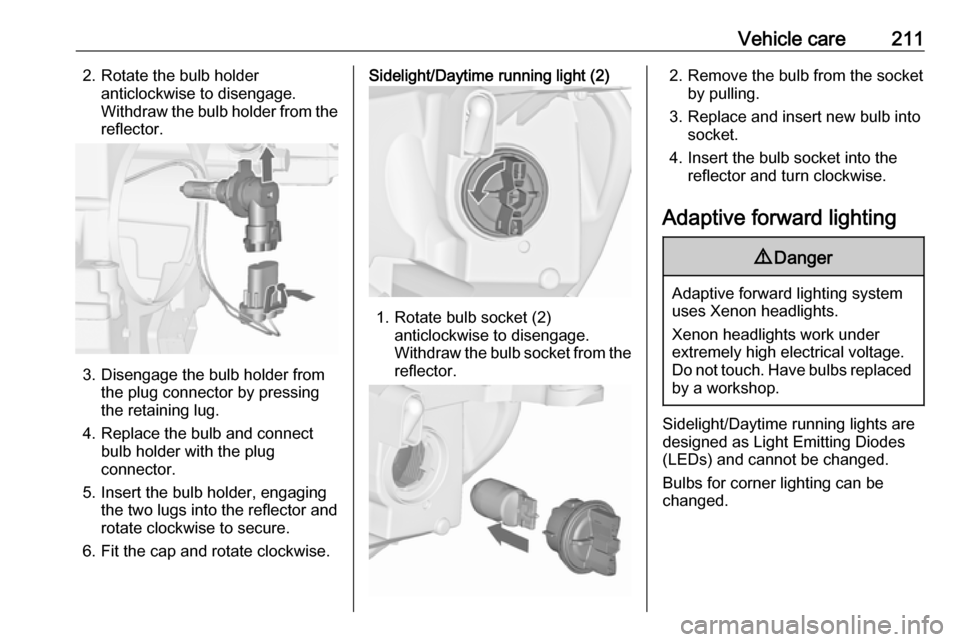

Vehicle care2112. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the reflector.

3. Disengage the bulb holder from the plug connector by pressing

the retaining lug.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

Sidelight/Daytime running light (2)

1. Rotate bulb socket (2) anticlockwise to disengage.

Withdraw the bulb socket from the

reflector.

2. Remove the bulb from the socket by pulling.

3. Replace and insert new bulb into socket.

4. Insert the bulb socket into the reflector and turn clockwise.

Adaptive forward lighting9 Danger

Adaptive forward lighting system

uses Xenon headlights.

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Sidelight/Daytime running lights are

designed as Light Emitting Diodes

(LEDs) and cannot be changed.

Bulbs for corner lighting can be

changed.

Page 219 of 295

Vehicle care2172. Unscrew both plastic securingnuts from the inside by hand.

3. Carefully withdraw the light assembly from the recesses and

remove.

4. Detach wiring plug from bulb carrier.

5. Remove the bulb holder by turning and replace the bulb by

withdrawing or pushing the bulb

slightly into the socket and

rotating anticlockwise:

Tail light/Brake light ( 1)

Turn signal light ( 2)

Version with Light Emitting Diode (LED)

Only turn signal light ( 2) can be

changed.

6. Insert and turn bulb holder clockwise into the tail light

assembly. Connect the wiring

plug with the light assembly. Fit

light assembly with the retaining

pins into the recesses of the

vehicle body and tighten the

plastic securing nuts from the

inside of the load compartment.

Close cover and engage.

Light assembly in the tailgate

1. Open the tailgate and remove the

covers on the respective side.

2. Unscrew three screws.

3. Remove the tail light assembly from tailgate.

4. Remove the bulb holder by turning and replace the bulb by

withdrawing or pushing the bulb

slightly into the socket and rotating anticlockwise:

Page 220 of 295

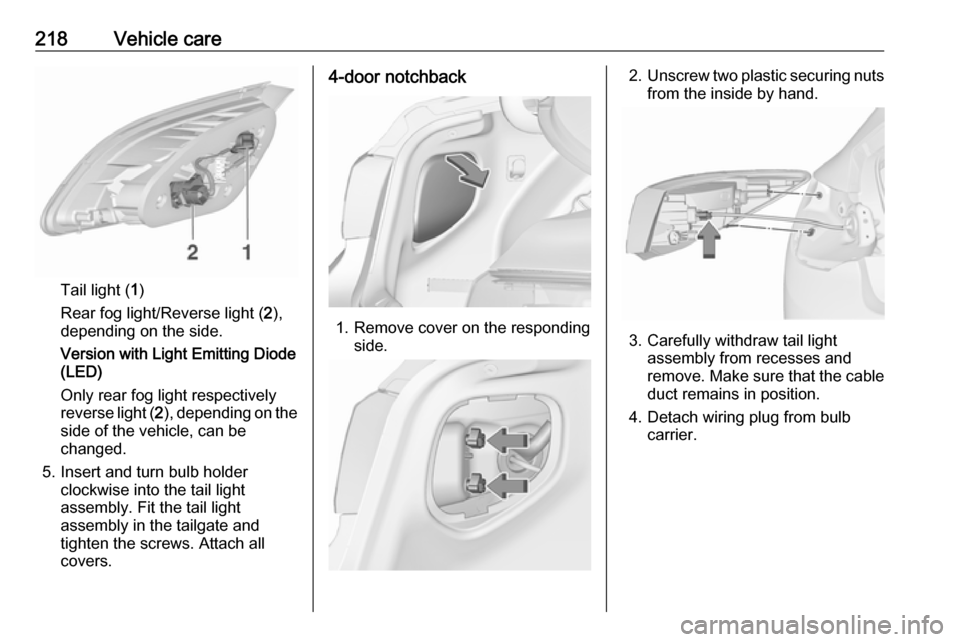

218Vehicle care

Tail light (1)

Rear fog light/Reverse light ( 2),

depending on the side.

Version with Light Emitting Diode

(LED)

Only rear fog light respectively

reverse light ( 2), depending on the

side of the vehicle, can be

changed.

5. Insert and turn bulb holder clockwise into the tail light

assembly. Fit the tail light

assembly in the tailgate and

tighten the screws. Attach all

covers.

4-door notchback

1. Remove cover on the responding side.

2.Unscrew two plastic securing nuts

from the inside by hand.

3. Carefully withdraw tail light assembly from recesses and

remove. Make sure that the cable duct remains in position.

4. Detach wiring plug from bulb carrier.

Page 226 of 295

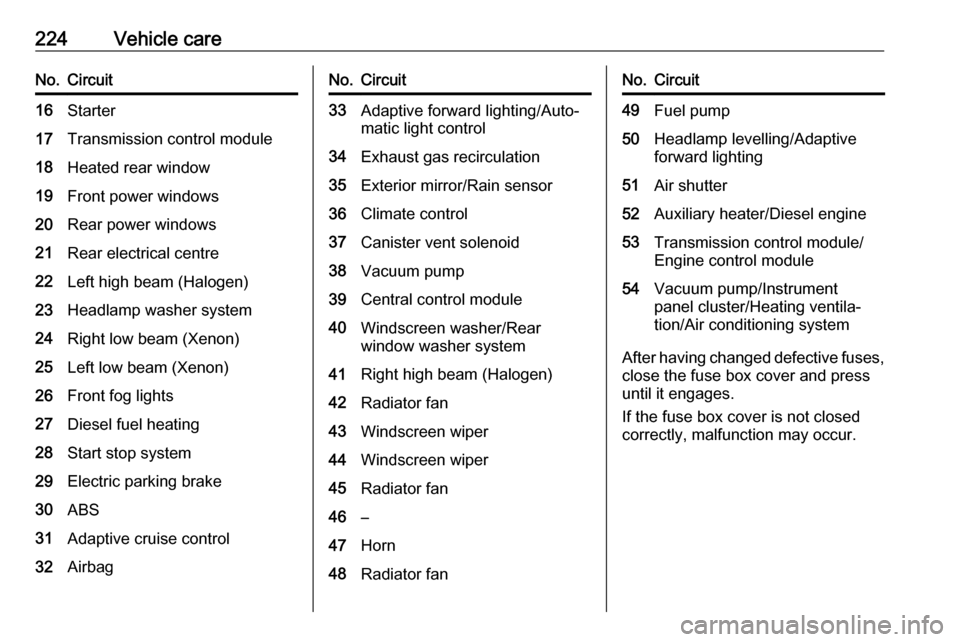

224Vehicle careNo.Circuit16Starter17Transmission control module18Heated rear window19Front power windows20Rear power windows21Rear electrical centre22Left high beam (Halogen)23Headlamp washer system24Right low beam (Xenon)25Left low beam (Xenon)26Front fog lights27Diesel fuel heating28Start stop system29Electric parking brake30ABS31Adaptive cruise control32AirbagNo.Circuit33Adaptive forward lighting/Auto‐

matic light control34Exhaust gas recirculation35Exterior mirror/Rain sensor36Climate control37Canister vent solenoid38Vacuum pump39Central control module40Windscreen washer/Rear

window washer system41Right high beam (Halogen)42Radiator fan43Windscreen wiper44Windscreen wiper45Radiator fan46–47Horn48Radiator fanNo.Circuit49Fuel pump50Headlamp levelling/Adaptive

forward lighting51Air shutter52Auxiliary heater/Diesel engine53Transmission control module/

Engine control module54Vacuum pump/Instrument

panel cluster/Heating ventila‐

tion/Air conditioning system

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 241 of 295

Vehicle care239Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 242.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a

screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 227.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.Alloy wheels with centre wheel

bolt cap: Disengage centre cap by

inserting and pulling the extractor

in the recess of the brand

emblem. Vehicle tools 3 227.

2. Two types of jacks and wheel nut wrenches are possible dependingon the version. Vehicle tools

3 227.

Variant 1a with rigid wheel

wrench:

Page 243 of 295

Vehicle care241

Set the jack to the necessary

height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate

handle until wheel is clear of the ground.

5. Unscrew the wheel nuts.

6. Change the wheel. Spare wheel 3 242.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

Install centre cap on alloy wheels.

11. Install vehicle jacking point cover on versions with sill panelling.

12. Stow the replaced wheel 3 242,

the vehicle tools 3 227 and the

adapter for the locking wheel nuts 3 60.

13. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.Have the defective tyre renewed or repaired as soon as possible.

Jacking position for lifting platform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Page 244 of 295

242Vehicle care

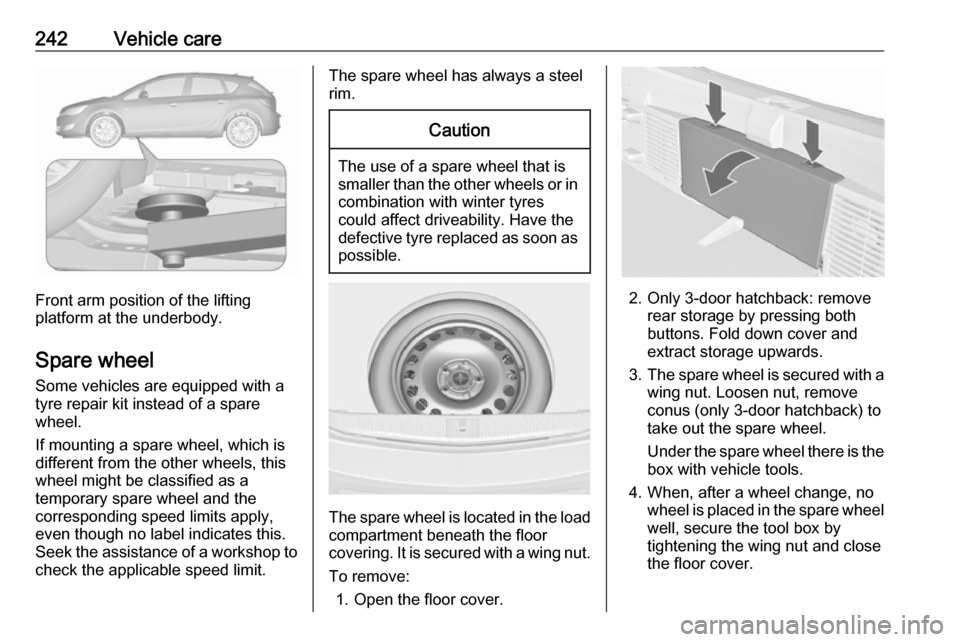

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has always a steel

rim.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

To remove: 1. Open the floor cover.

2. Only 3-door hatchback: remove rear storage by pressing both

buttons. Fold down cover and

extract storage upwards.

3. The spare wheel is secured with a

wing nut. Loosen nut, remove

conus (only 3-door hatchback) to

take out the spare wheel.

Under the spare wheel there is the box with vehicle tools.

4. When, after a wheel change, no wheel is placed in the spare wheel

well, secure the tool box by

tightening the wing nut and close

the floor cover.

Page 256 of 295

254Service and maintenancepollution, presence of airborne sand

and high dust content, driving at high

altitude and large variations of

temperature. Under these severe operating conditions, certain servicework may be required more frequently than the regular service interval.

The international service intervals are

valid for the countries which are not

listed in the European service

intervals.

Service display 3 83.

Confirmations

Confirmation of service is recorded in the Service and Warranty Booklet.

The date and mileage is completed

with the stamp and signature of the

servicing workshop.

Make sure that the Service and

Warranty Booklet is completed

correctly as continuous proof of

service is essential if any warranty or goodwill claims are to be met, and is

also a benefit when selling the

vehicle.Service interval with remaining

engine oil life duration

The service interval is based on

several parameters depending on

usage.

The service display lets you know

when to change the engine oil.

Service display 3 83.Recommended fluids,

lubricants and parts

Recommended fluids andlubricants

Only use products that meet the

recommended specifications.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

aging control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Page 261 of 295

Technical data259Vehicle dataRecommended fluids and lubricants

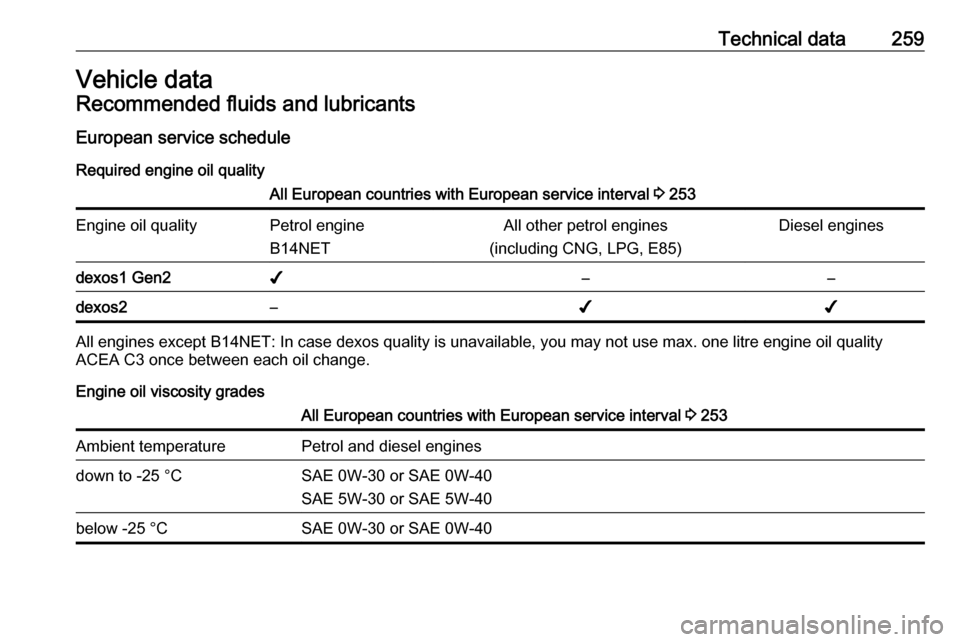

European service schedule Required engine oil qualityAll European countries with European service interval 3 253Engine oil qualityPetrol engine

B14NETAll other petrol engines

(including CNG, LPG, E85)Diesel enginesdexos1 Gen2✔––dexos2–✔✔

All engines except B14NET: In case dexos quality is unavailable, you may not use max. one litre engine oil quality ACEA C3 once between each oil change.

Engine oil viscosity grades

All European countries with European service interval 3 253Ambient temperaturePetrol and diesel enginesdown to -25 °CSAE 0W-30 or SAE 0W-40

SAE 5W-30 or SAE 5W-40below -25 °CSAE 0W-30 or SAE 0W-40