info OPEL ASTRA K 2017.5 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: ASTRA K, Model: OPEL ASTRA K 2017.5Pages: 311, PDF Size: 9.21 MB

Page 262 of 311

260Vehicle careto indicate that the sensor

identification code has been

matched to the left side rear

wheel, and the tyre pressure

sensor matching process is no

longer active.

12. Turn off the ignition.

13. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

information label.

14. Ensure the tyre loading status is set according to the selected

pressure 3 115.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

The legally permissible minimumtread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle

modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.

Furthermore, the advanced parking

assist must be calibrated 3 199.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

Page 266 of 311

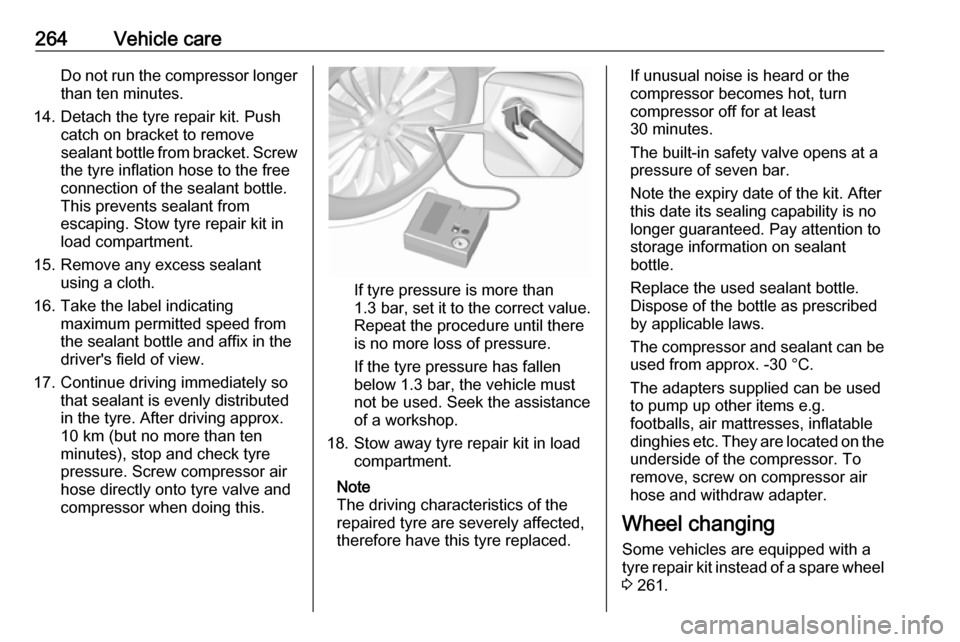

264Vehicle careDo not run the compressor longerthan ten minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw

the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than 1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the

underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 261.

Page 267 of 311

Vehicle care265Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 267.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. one cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a

screwdriver and remove. For alloy

wheels, place a soft cloth

underneath the screwdriver. Pull

off the wheel cover. Vehicle tools

3 253.

2. Fold out the wheel wrench and

install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Page 279 of 311

Service and maintenance277Service and

maintenanceGeneral information ...................277

Service information ..................277

Recommended fluids, lubricants and parts .................................... 278

Recommended fluids and lubricants ................................ 278General information

Service information In order to ensure economical and

safe vehicle operation and to

maintain the value of your vehicle, it

is of vital importance that all

maintenance work is carried out at the proper intervals as specified.

The detailed, up-to-date service

schedule for your vehicle is available

at the workshop.

Service display 3 108.

European service intervals Maintenance of your vehicle is

required every 30,000 km or after one year, whichever occurs first, unless

otherwise indicated in the service

display.

A shorter service interval can be valid

for severe driving behaviour, e.g. for

taxis and police vehicles.

The European service intervals are

valid for the following countries:Andorra, Austria, Belgium, Bosnia-

Herzegovina, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany,

Greece, Greenland, Hungary,

Iceland, Ireland, Italy, Latvia,

Liechtenstein, Lithuania,

Luxembourg, Macedonia, Malta,

Monaco, Montenegro, Netherlands,

Norway, Poland, Portugal, Romania,

San Marino, Serbia, Slovakia,

Slovenia, Spain, Sweden,

Switzerland, United Kingdom.

Service display 3 108.

International service intervals

Maintenance of your vehicle is

required every 15,000 km or after one year, whichever occurs first, unless

otherwise indicated in the service

display.

Severe operating conditions exist if

one or more of the following

circumstances occur frequently: Cold

starting, stop and go operation, trailer operation, mountain driving, driving

on poor and sandy road surfaces,

increased air pollution, presence of

airborne sand and high dust content,

Page 280 of 311

278Service and maintenancedriving at high altitude and large

variations of temperature. Under

these severe operating conditions,

certain service work may be required more frequently than the regular

service interval.

The international service intervals are

valid for the countries which are not

listed in the European service

intervals.

Service display 3 108.

Confirmations Confirmation of service is recorded inthe Service and warranty booklet.

The date and mileage is completed

with the stamp and signature of the

servicing workshop.

Make sure that the Service and

warranty booklet is completed

correctly as continuous proof of

service is essential if any warranty or goodwill claims are to be met, and is

also a benefit when selling the

vehicle.Service interval with remaining

engine oil life duration

The service interval is based on

several parameters depending on

usage.

The service display lets you know

when to change the engine oil.

Service display 3 108.Recommended fluids,

lubricants and parts

Recommended fluids andlubricants

Only use products that meet the

recommended specifications.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

aging control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Page 281 of 311

Service and maintenance279Dexos is the newest engine oil quality

that provides optimum protection for

gasoline and diesel engines. If it is

unavailable, engine oils of other listed qualities have to be used.

Recommendations for gasoline

engines are also valid for

Compressed Natural Gas (CNG),

Liquified Petroleum Gas (LPG) and

Ethanol (E85) fuelled engines.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 282.

Topping up engine oil

Engine oils of different manufacturers

and brands can be mixed as long as

they comply with the required engine

oil quality and viscosity.

Use of engine oil with only

ACEA A1/B1 or only A5/B5 quality is

prohibited, since it can cause long-

term engine damage under certain

operating conditions.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 282.Additional engine oil additives

The use of additional engine oil

additives could cause damage and

invalidate the warranty.

Engine oil viscosity grades

The SAE viscosity grade gives

information of the thickness of the oil.

Multigrade oil is indicated by two

figures, e.g. SAE 5W-30. The first

figure, followed by a W, indicates the

low temperature viscosity and the

second figure the high temperature viscosity.

Select the appropriate viscosity grade depending on the minimum ambient

temperature 3 282.

All of the recommended viscosity grades are suitable for high ambient

temperatures.

Coolant and antifreeze

Use only organic acid type-long life

coolant (LLC) antifreeze approved for

the vehicle. Consult a workshop.

The system is factory filled with

coolant designed for excellent

corrosion protection and frost

protection down to approx. -28 °C. Innorthern countries with very low

temperatures the factory filled coolant

provides frost protection down to

approx. -37 °C. This concentration

should be maintained all year round.

The use of additional coolant

additives that intend to give additional corrosion protection or seal against

minor leaks can cause function

problems. Liability for consequences

resulting from the use of additional coolant additives will be rejected.

Washer fluid Use only washer fluid approved for

the vehicle to prevent damage of wiper blades, paintwork, plastic and

rubber parts. Consult a workshop.

Brake and clutch fluid

Over time, brake fluid absorbs

moisture which will reduce braking

effectiveness. The brake fluid should

therefore be replaced at the specified interval.

Page 283 of 311

Technical data281Information on identification label:1:manufacturer2:type approval number3:vehicle identification number4:permissible gross vehicle weightrating in kg5:permissible gross train weight

in kg6:maximum permissible front axle

load in kg7:maximum permissible rear axle

load in kg8:vehicle-specific or country-

specific data

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its

maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the front axle load.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

The technical data tables show the

engine identifier code. Engine data

3 285.

To identify the respective engine,

refer to the engine power in the EEC

Certificate of Conformity provided

with your vehicle or other national

registration documents.

Page 291 of 311

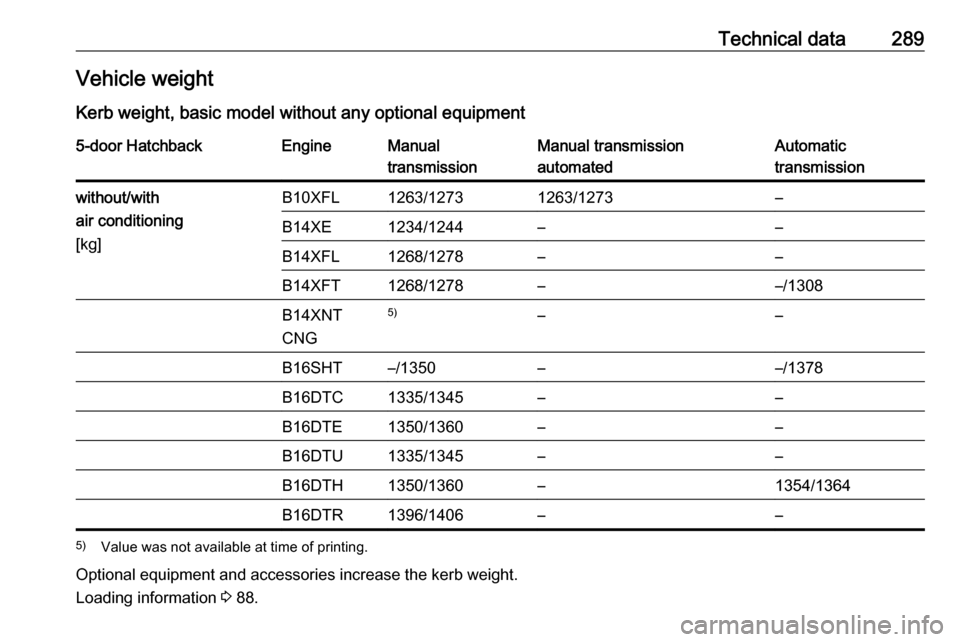

Technical data289Vehicle weightKerb weight, basic model without any optional equipment5-door HatchbackEngineManual

transmissionManual transmission

automatedAutomatic

transmissionwithout/with

air conditioning

[kg]B10XFL1263/12731263/1273–B14XE1234/1244––B14XFL1268/1278––B14XFT1268/1278––/1308B14XNT

CNG5)––B16SHT–/1350––/1378B16DTC1335/1345––B16DTE1350/1360––B16DTU1335/1345––B16DTH1350/1360–1354/1364B16DTR1396/1406––5) Value was not available at time of printing.

Optional equipment and accessories increase the kerb weight.

Loading information 3 88.

Page 292 of 311

![OPEL ASTRA K 2017.5 Owners Manual 290Technical dataKerb weight, basic model without any optional equipmentSports TourerEngineManual transmissionManual transmission automatedAutomatic transmissionwithout/with air conditioning

[kg]B10XF OPEL ASTRA K 2017.5 Owners Manual 290Technical dataKerb weight, basic model without any optional equipmentSports TourerEngineManual transmissionManual transmission automatedAutomatic transmissionwithout/with air conditioning

[kg]B10XF](/img/37/18781/w960_18781-291.png)

290Technical dataKerb weight, basic model without any optional equipmentSports TourerEngineManual transmissionManual transmission automatedAutomatic transmissionwithout/with air conditioning

[kg]B10XFL1278/12881278/1288–B14XE1263/1273––B14XFL–/1322––B14XFT1312/1322–1340/1350B14XNT

CNG5)––B16SHT–/1393––B16DTC1378/1388––B16DTE1393/1403––B16DTU1393/1403––B16DTH1393/1403–1415/1425B16DTR1393/1411–1425/14435) Value was not available at time of printing.

Optional equipment and accessories increase the kerb weight.

Loading information 3 88.

Page 299 of 311

Customer information297Customer

informationCustomer information ................297

Declaration of conformity .........297

Collision damage repair ...........299

Software acknowledgement ....299

Software update ......................301

Registered trademarks ............301

Vehicle data recording and pri‐

vacy ........................................... 302

Event data recorders ...............302

Radio Frequency Identification (RFID) ..................................... 303Customer information

Declaration of conformity

Radio transmission systems

This vehicle has systems that

transmit and/or receive radio waves subject to Directive 1999/5/EC or

2014/53/EU. These systems are in compliance with the essential

requirements and other relevant

provisions of Directive 1999/5/EC or 2014/53/EU. Copies of the original

Declarations of Conformity can be

obtained on our website.