check engine OPEL CALIBRA 1988 Service Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 236 of 525

C16 NZ2, 1.8 and 2.0 litre models, remove the

timing belt. Details are as described in

Chapter 2A.

3Remove timing belt tension roller from oil

pump, where applicable.

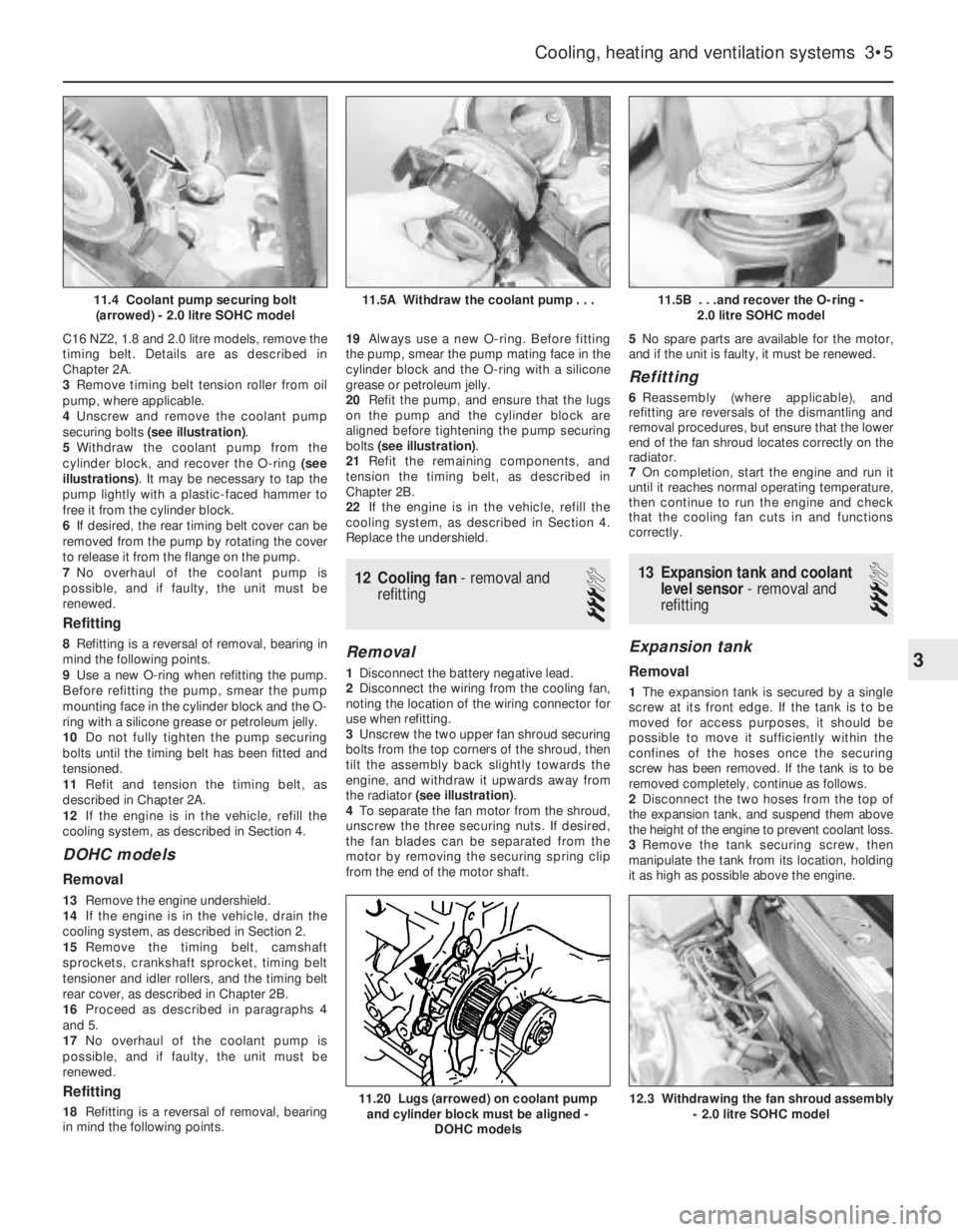

4Unscrew and remove the coolant pump

securing bolts (see illustration).

5Withdraw the coolant pump from the

cylinder block, and recover the O-ring (see

illustrations). It may be necessary to tap the

pump lightly with a plastic-faced hammer to

free it from the cylinder block.

6If desired, the rear timing belt cover can be

removed from the pump by rotating the cover

to release it from the flange on the pump.

7No overhaul of the coolant pump is

possible, and if faulty, the unit must be

renewed.

Refitting

8Refitting is a reversal of removal, bearing in

mind the following points.

9Use a new O-ring when refitting the pump.

Before refitting the pump, smear the pump

mounting face in the cylinder block and the O-

ring with a silicone grease or petroleum jelly.

10Do not fully tighten the pump securing

bolts until the timing belt has been fitted and

tensioned.

11Refit and tension the timing belt, as

described in Chapter 2A.

12If the engine is in the vehicle, refill the

cooling system, as described in Section 4.

DOHC models

Removal

13Remove the engine undershield.

14If the engine is in the vehicle, drain the

cooling system, as described in Section 2.

15Remove the timing belt, camshaft

sprockets, crankshaft sprocket, timing belt

tensioner and idler rollers, and the timing belt

rear cover, as described in Chapter 2B.

16Proceed as described in paragraphs 4

and 5.

17No overhaul of the coolant pump is

possible, and if faulty, the unit must be

renewed.

Refitting

18Refitting is a reversal of removal, bearing

in mind the following points.19Always use a new O-ring. Before fitting

the pump, smear the pump mating face in the

cylinder block and the O-ring with a silicone

grease or petroleum jelly.

20Refit the pump, and ensure that the lugs

on the pump and the cylinder block are

aligned before tightening the pump securing

bolts (see illustration).

21Refit the remaining components, and

tension the timing belt, as described in

Chapter 2B.

22If the engine is in the vehicle, refill the

cooling system, as described in Section 4.

Replace the undershield.

12Cooling fan - removal and

refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect the wiring from the cooling fan,

noting the location of the wiring connector for

use when refitting.

3Unscrew the two upper fan shroud securing

bolts from the top corners of the shroud, then

tilt the assembly back slightly towards the

engine, and withdraw it upwards away from

the radiator (see illustration).

4To separate the fan motor from the shroud,

unscrew the three securing nuts. If desired,

the fan blades can be separated from the

motor by removing the securing spring clip

from the end of the motor shaft.5No spare parts are available for the motor,

and if the unit is faulty, it must be renewed.

Refitting

6Reassembly (where applicable), and

refitting are reversals of the dismantling and

removal procedures, but ensure that the lower

end of the fan shroud locates correctly on the

radiator.

7On completion, start the engine and run it

until it reaches normal operating temperature,

then continue to run the engine and check

that the cooling fan cuts in and functions

correctly.

13Expansion tank and coolant

level sensor -removal and

refitting

3

Expansion tank

Removal

1The expansion tank is secured by a single

screw at its front edge. If the tank is to be

moved for access purposes, it should be

possible to move it sufficiently within the

confines of the hoses once the securing

screw has been removed. If the tank is to be

removed completely, continue as follows.

2Disconnect the two hoses from the top of

the expansion tank, and suspend them above

the height of the engine to prevent coolant loss.

3Remove the tank securing screw, then

manipulate the tank from its location, holding

it as high as possible above the engine.

Cooling, heating and ventilation systems 3•5

11.5B . . .and recover the O-ring -

2.0 litre SOHC model

12.3 Withdrawing the fan shroud assembly

- 2.0 litre SOHC model11.20 Lugs (arrowed) on coolant pump

and cylinder block must be aligned -

DOHC models

11.5A Withdraw the coolant pump . . .11.4 Coolant pump securing bolt

(arrowed) - 2.0 litre SOHC model

3

Page 237 of 525

4Position a container beneath the tank, then

disconnect the bottom hose and allow the

contents of the tank to drain into the

container. Suspend the bottom hose as high

as possible above the engine to prevent

coolant loss.

Refitting

5Refitting is a reversal of removal, but on

completion check and if necessary top-up the

coolant level, as described in Section 4. The

coolant drained from the expansion tank

during removal can be re-used, provided it

has not been contaminated.

Coolant level sensor

6The coolant level sensor, where fitted, is an

integral part of the expansion tank cap. If the

level sensor is faulty, the complete cap

assembly must be renewed.

14Temperature gauge sender -

removal and refitting

2

Removal

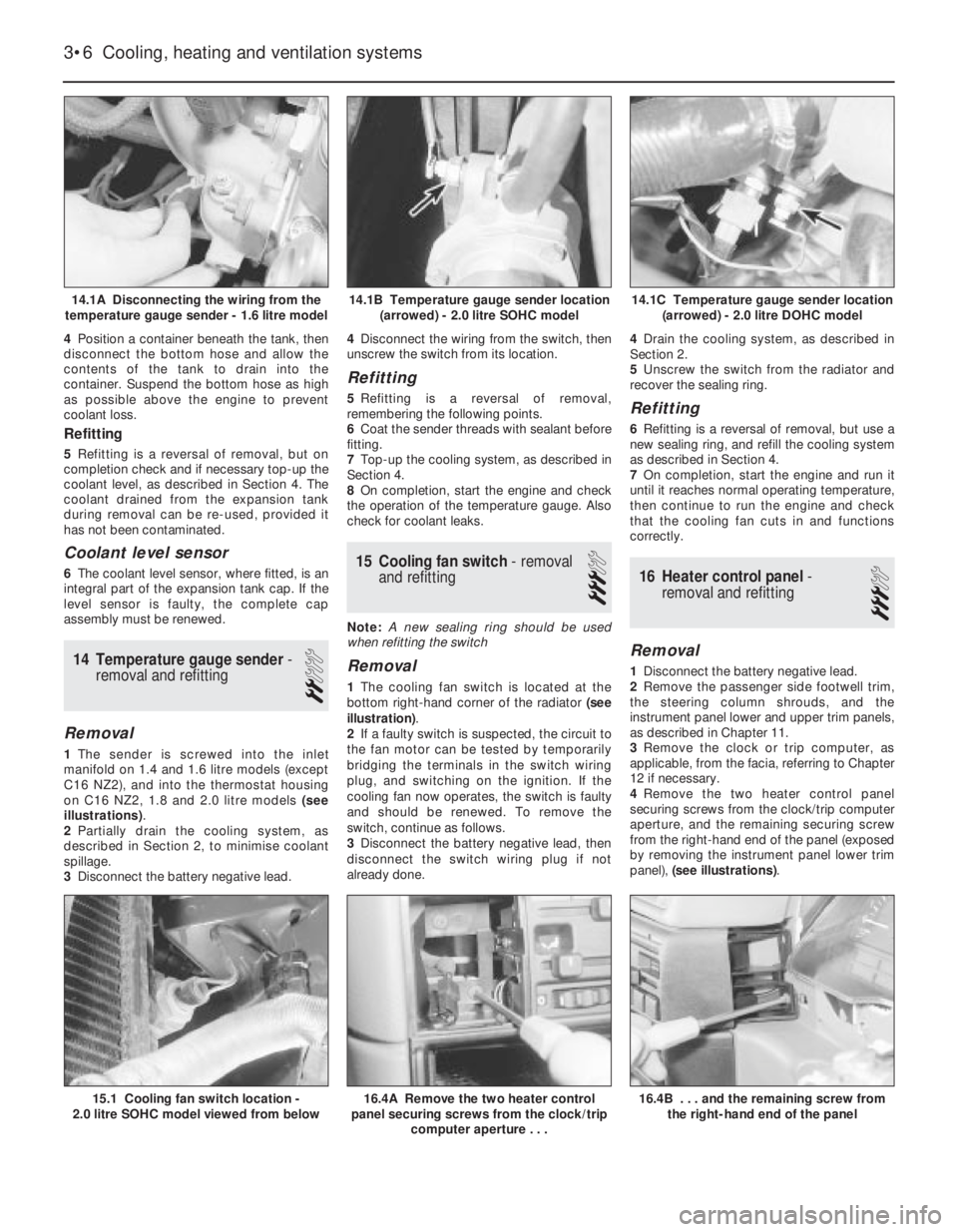

1The sender is screwed into the inlet

manifold on 1.4 and 1.6 litre models (except

C16 NZ2), and into the thermostat housing

on C16 NZ2, 1.8 and 2.0 litre models (see

illustrations).

2Partially drain the cooling system, as

described in Section 2, to minimise coolant

spillage.

3Disconnect the battery negative lead.4Disconnect the wiring from the switch, then

unscrew the switch from its location.

Refitting

5Refitting is a reversal of removal,

remembering the following points.

6Coat the sender threads with sealant before

fitting.

7Top-up the cooling system, as described in

Section 4.

8On completion, start the engine and check

the operation of the temperature gauge. Also

check for coolant leaks.

15Cooling fan switch -removal

and refitting

3

Note: A new sealing ring should be used

when refitting the switch

Removal

1The cooling fan switch is located at the

bottom right-hand corner of the radiator (see

illustration).

2If a faulty switch is suspected, the circuit to

the fan motor can be tested by temporarily

bridging the terminals in the switch wiring

plug, and switching on the ignition. If the

cooling fan now operates, the switch is faulty

and should be renewed. To remove the

switch, continue as follows.

3Disconnect the battery negative lead, then

disconnect the switch wiring plug if not

already done.4Drain the cooling system, as described in

Section 2.

5Unscrew the switch from the radiator and

recover the sealing ring.

Refitting

6Refitting is a reversal of removal, but use a

new sealing ring, and refill the cooling system

as described in Section 4.

7On completion, start the engine and run it

until it reaches normal operating temperature,

then continue to run the engine and check

that the cooling fan cuts in and functions

correctly.

16Heater control panel -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the passenger side footwell trim,

the steering column shrouds, and the

instrument panel lower and upper trim panels,

as described in Chapter 11.

3Remove the clock or trip computer, as

applicable, from the facia, referring to Chapter

12 if necessary.

4Remove the two heater control panel

securing screws from the clock/trip computer

aperture, and the remaining securing screw

from the right-hand end of the panel (exposed

by removing the instrument panel lower trim

panel), (see illustrations).

3•6Cooling, heating and ventilation systems

14.1A Disconnecting the wiring from the

temperature gauge sender - 1.6 litre model14.1C Temperature gauge sender location

(arrowed) - 2.0 litre DOHC model

16.4B . . . and the remaining screw from

the right-hand end of the panel16.4A Remove the two heater control

panel securing screws from the clock/trip

computer aperture . . .15.1 Cooling fan switch location -

2.0 litre SOHC model viewed from below

14.1B Temperature gauge sender location

(arrowed) - 2.0 litre SOHC model

Page 238 of 525

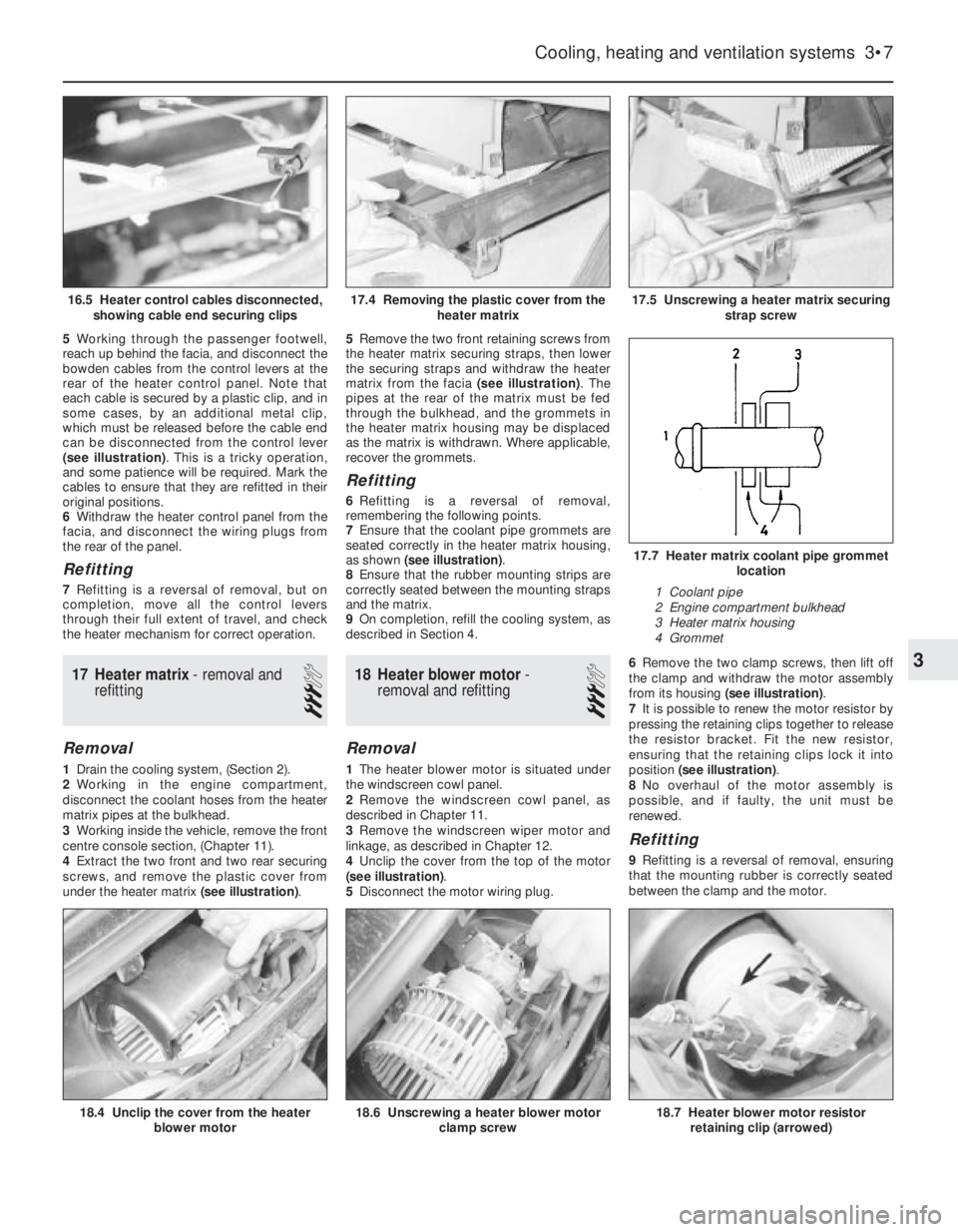

5Working through the passenger footwell,

reach up behind the facia, and disconnect the

bowden cables from the control levers at the

rear of the heater control panel. Note that

each cable is secured by a plastic clip, and in

some cases, by an additional metal clip,

which must be released before the cable end

can be disconnected from the control lever

(see illustration). This is a tricky operation,

and some patience will be required. Mark the

cables to ensure that they are refitted in their

original positions.

6Withdraw the heater control panel from the

facia, and disconnect the wiring plugs from

the rear of the panel.

Refitting

7Refitting is a reversal of removal, but on

completion, move all the control levers

through their full extent of travel, and check

the heater mechanism for correct operation.

17Heater matrix -removal and

refitting

3

Removal

1Drain the cooling system, (Section 2).

2Working in the engine compartment,

disconnect the coolant hoses from the heater

matrix pipes at the bulkhead.

3Working inside the vehicle, remove the front

centre console section, (Chapter 11).

4Extract the two front and two rear securing

screws, and remove the plastic cover from

under the heater matrix (see illustration).5Remove the two front retaining screws from

the heater matrix securing straps, then lower

the securing straps and withdraw the heater

matrix from the facia (see illustration). The

pipes at the rear of the matrix must be fed

through the bulkhead, and the grommets in

the heater matrix housing may be displaced

as the matrix is withdrawn. Where applicable,

recover the grommets.

Refitting

6Refitting is a reversal of removal,

remembering the following points.

7Ensure that the coolant pipe grommets are

seated correctly in the heater matrix housing,

as shown (see illustration).

8Ensure that the rubber mounting strips are

correctly seated between the mounting straps

and the matrix.

9On completion, refill the cooling system, as

described in Section 4.

18Heater blower motor -

removal and refitting

3

Removal

1The heater blower motor is situated under

the windscreen cowl panel.

2Remove the windscreen cowl panel, as

described in Chapter 11.

3Remove the windscreen wiper motor and

linkage, as described in Chapter 12.

4Unclip the cover from the top of the motor

(see illustration).

5Disconnect the motor wiring plug.6Remove the two clamp screws, then lift off

the clamp and withdraw the motor assembly

from its housing (see illustration).

7It is possible to renew the motor resistor by

pressing the retaining clips together to release

the resistor bracket. Fit the new resistor,

ensuring that the retaining clips lock it into

position (see illustration).

8No overhaul of the motor assembly is

possible, and if faulty, the unit must be

renewed.

Refitting

9Refitting is a reversal of removal, ensuring

that the mounting rubber is correctly seated

between the clamp and the motor.

Cooling, heating and ventilation systems 3•7

17.5 Unscrewing a heater matrix securing

strap screw

18.6 Unscrewing a heater blower motor

clamp screw18.7 Heater blower motor resistor

retaining clip (arrowed)18.4 Unclip the cover from the heater

blower motor

17.7 Heater matrix coolant pipe grommet

location

1 Coolant pipe

2 Engine compartment bulkhead

3 Heater matrix housing

4 Grommet

17.4 Removing the plastic cover from the

heater matrix16.5 Heater control cables disconnected,

showing cable end securing clips

3

Page 243 of 525

REF•4General Repair Procedures

Whenever servicing, repair or overhaul work

is carried out on the car or its components, it is

necessary to observe the following procedures

and instructions. This will assist in carrying out

the operation efficiently and to a professional

standard of workmanship.

Joint mating faces and gaskets

When separating components at their

mating faces, never insert screwdrivers or

similar implements into the joint between the

faces in order to prise them apart. This can

cause severe damage which results in oil

leaks, coolant leaks, etc upon reassembly.

Separation is usually achieved by tapping

along the joint with a soft-faced hammer in

order to break the seal. However, note that this

method may not be suitable where dowels are

used for component location.

Where a gasket is used between the mating

faces of two components, ensure that it is

renewed on reassembly, and fit it dry unless

otherwise stated in the repair procedure. Make

sure that the mating faces are clean and dry,

with all traces of old gasket removed. When

cleaning a joint face, use a tool which is not

likely to score or damage the face, and remove

any burrs or nicks with an oilstone or fine file.

Make sure that tapped holes are cleaned

with a pipe cleaner, and keep them free of

jointing compound, if this is being used, unless

specifically instructed otherwise.

Ensure that all orifices, channels or pipes

are clear, and blow through them, preferably

using compressed air.

Oil seals

Oil seals can be removed by levering them

out with a wide flat-bladed screwdriver or

similar implement. Alternatively, a number of

self-tapping screws may be screwed into the

seal, and these used as a purchase for pliers

or some similar device in order to pull the seal

free.

Whenever an oil seal is removed from its

working location, either individually or as part

of an assembly, it should be renewed.

The very fine sealing lip of the seal is easily

damaged, and will not seal if the surface it

contacts is not completely clean and free from

scratches, nicks or grooves.

Protect the lips of the seal from any surface

which may damage them in the course of

fitting. Use tape or a conical sleeve where

possible. Lubricate the seal lips with oil before

fitting and, on dual-lipped seals, fill the space

between the lips with grease.

Unless otherwise stated, oil seals must be

fitted with their sealing lips toward the

lubricant to be sealed.

Use a tubular drift or block of wood of the

appropriate size to install the seal and, if the

seal housing is shouldered, drive the seal

down to the shoulder. If the seal housing is

unshouldered, the seal should be fitted with its

face flush with the housing top face (unless

otherwise instructed).

Screw threads and fastenings

Seized nuts, bolts and screws are quite a

common occurrence where corrosion has set

in, and the use of penetrating oil or releasing

fluid will often overcome this problem if the

offending item is soaked for a while before

attempting to release it. The use of an impact

driver may also provide a means of releasing

such stubborn fastening devices, when used

in conjunction with the appropriate

screwdriver bit or socket. If none of these

methods works, it may be necessary to resort

to the careful application of heat, or the use of

a hacksaw or nut splitter device.

Studs are usually removed by locking two

nuts together on the threaded part, and then

using a spanner on the lower nut to unscrew

the stud. Studs or bolts which have broken off

below the surface of the component in which

they are mounted can sometimes be removed

using a proprietary stud extractor. Always

ensure that a blind tapped hole is completely

free from oil, grease, water or other fluid

before installing the bolt or stud. Failure to do

this could cause the housing to crack due to

the hydraulic action of the bolt or stud as it is

screwed in.

When tightening a castellated nut to accept

a split pin, tighten the nut to the specified

torque, where applicable, and then tighten

further to the next split pin hole. Never slacken

the nut to align the split pin hole, unless stated

in the repair procedure.

When checking or retightening a nut or bolt

to a specified torque setting, slacken the nut

or bolt by a quarter of a turn, and then

retighten to the specified setting. However,

this should not be attempted where angular

tightening has been used.

For some screw fastenings, notably cylinder

head bolts or nuts, torque wrench settings are

no longer specified for the latter stages of

tightening, “angle-tightening” being called up

instead. Typically, a fairly low torque wrench

setting will be applied to the bolts/nuts in

the correct sequence, followed by one or

more stages of tightening through specified

angles.

Locknuts, locktabs and washers

Any fastening which will rotate against a

component or housing in the course of

tightening should always have a washer

between it and the relevant component or

housing.

Spring or split washers should always be

renewed when they are used to lock a critical

component such as a big-end bearing

retaining bolt or nut. Locktabs which are

folded over to retain a nut or bolt should

always be renewed.

Self-locking nuts can be re-used in non-

critical areas, providing resistance can be felt

when the locking portion passes over the bolt

or stud thread. However, it should be noted

that self-locking stiffnuts tend to lose theireffectiveness after long periods of use, and in

such cases should be renewed as a matter of

course.

Split pins must always be replaced with new

ones of the correct size for the hole.

When thread-locking compound is found on

the threads of a fastener which is to be re-

used, it should be cleaned off with a wire

brush and solvent, and fresh compound

applied on reassembly.

Special tools

Some repair procedures in this manual

entail the use of special tools such as a press,

two or three-legged pullers, spring

compressors, etc. Wherever possible, suitable

readily-available alternatives to the

manufacturer’s special tools are described,

and are shown in use. Unless you are highly-

skilled and have a thorough understanding of

the procedures described, never attempt to

bypass the use of any special tool when the

procedure described specifies its use. Not

only is there a very great risk of personal injury,

but expensive damage could be caused to the

components involved.

Environmental considerations

When disposing of used engine oil, brake

fluid, antifreeze, etc, give due consideration to

any detrimental environmental effects. Do not,

for instance, pour any of the above liquids

down drains into the general sewage system,

or onto the ground to soak away. Many local

council refuse tips provide a facility for waste

oil disposal, as do some garages. If none of

these facilities are available, consult your local

Environmental Health Department for further

advice.

With the universal tightening-up of

legislation regarding the emission of

environmentally-harmful substances from

motor vehicles, most current vehicles have

tamperproof devices fitted to the main

adjustment points of the fuel system. These

devices are primarily designed to prevent

unqualified persons from adjusting the fuel/air

mixture, with the chance of a consequent

increase in toxic emissions. If such devices are

encountered during servicing or overhaul, they

should, wherever possible, be renewed or

refitted in accordance with the vehicle

manufacturer’s requirements or current

legislation.

Note: It is

antisocial and

illegal to dump

oil down the

drain. To find

the location of

your local oil

recycling

bank, call this

number free.

Page 247 of 525

REF•8MOTTest Checks

This is a guide to getting your vehicle through the MOT test.

Obviously it will not be possible to examine the vehicle to the same

standard as the professional MOT tester. However, working through

the following checks will enable you to identify any problem areas

before submitting the vehicle for the test.

Where a testable component is in borderline condition, the tester

has discretion in deciding whether to pass or fail it. The basis of such

discretion is whether the tester would be happy for a close relative or

friend to use the vehicle with the component in that condition. If the

vehicle presented is clean and evidently well cared for, the tester may

be more inclined to pass a borderline component than if the vehicle is

scruffy and apparently neglected.

It has only been possible to summarise the test requirements here,

based on the regulations in force at the time of printing. Test standards

are becoming increasingly stringent, although there are some

exemptions for older vehicles. For full details obtain a copy of the Haynes

publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

HandbrakeMTest the operation of the handbrake.

Excessive travel (too many clicks) indicates

incorrect brake or cable adjustment.

MCheck that the handbrake cannot be

released by tapping the lever sideways. Check

the security of the lever mountings.

Footbrake

MDepress the brake pedal and check that it

does not creep down to the floor, indicating a

master cylinder fault. Release the pedal, wait

a few seconds, then depress it again. If the

pedal travels nearly to the floor before firm

resistance is felt, brake adjustment or repair is

necessary. If the pedal feels spongy, there is

air in the hydraulic system which must be

removed by bleeding.MCheck that the brake pedal is secure and in

good condition. Check also for signs of fluid

leaks on the pedal, floor or carpets, which

would indicate failed seals in the brake master

cylinder.

MCheck the servo unit (when applicable) by

operating the brake pedal several times, then

keeping the pedal depressed and starting the

engine. As the engine starts, the pedal will

move down slightly. If not, the vacuum hose or

the servo itself may be faulty.

Steering wheel and column

MExamine the steering wheel for fractures or

looseness of the hub, spokes or rim.

MMove the steering wheel from side to side

and then up and down. Check that the

steering wheel is not loose on the column,

indicating wear or a loose retaining nut.

Continue moving the steering wheel as before,

but also turn it slightly from left to right.

MCheck that the steering wheel is not loose

on the column, and that there is no abnormalmovement of the steering wheel, indicating

wear in the column support bearings or

couplings.

Windscreen and mirrors

MThe windscreen must be free of cracks or

other significant damage within the driver’s

field of view. (Small stone chips are

acceptable.) Rear view mirrors must be

secure, intact, and capable of being adjusted.

1Checks carried out

FROM THE DRIVER’S SEAT

1Checks carried out

FROM THE DRIVER’S

SEAT2Checks carried out

WITH THE VEHICLE

ON THE GROUND3Checks carried out

WITH THE VEHICLE

RAISED AND THE

WHEELS FREE TO

TURN4Checks carried out on

YOUR VEHICLE’S

EXHAUST EMISSION

SYSTEM

Page 249 of 525

REF•10MOTTest Checks

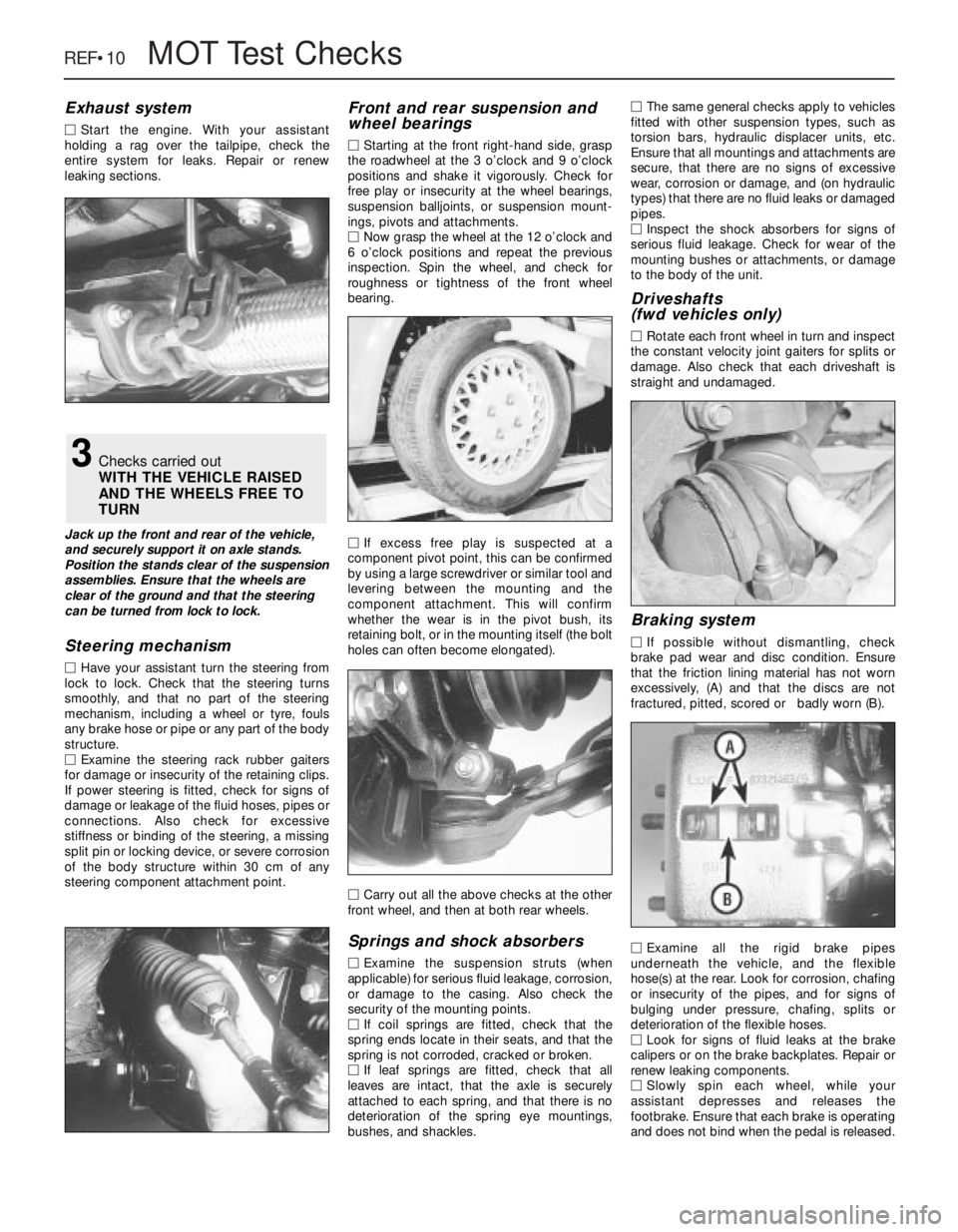

Exhaust system

MStart the engine. With your assistant

holding a rag over the tailpipe, check the

entire system for leaks. Repair or renew

leaking sections.

Jack up the front and rear of the vehicle,

and securely support it on axle stands.

Position the stands clear of the suspension

assemblies. Ensure that the wheels are

clear of the ground and that the steering

can be turned from lock to lock.

Steering mechanism

MHave your assistant turn the steering from

lock to lock. Check that the steering turns

smoothly, and that no part of the steering

mechanism, including a wheel or tyre, fouls

any brake hose or pipe or any part of the body

structure.

MExamine the steering rack rubber gaiters

for damage or insecurity of the retaining clips.

If power steering is fitted, check for signs of

damage or leakage of the fluid hoses, pipes or

connections. Also check for excessive

stiffness or binding of the steering, a missing

split pin or locking device, or severe corrosion

of the body structure within 30 cm of any

steering component attachment point.

Front and rear suspension and

wheel bearings

MStarting at the front right-hand side, grasp

the roadwheel at the 3 o’clock and 9 o’clock

positions and shake it vigorously. Check for

free play or insecurity at the wheel bearings,

suspension balljoints, or suspension mount-

ings, pivots and attachments.

MNow grasp the wheel at the 12 o’clock and

6 o’clock positions and repeat the previous

inspection. Spin the wheel, and check for

roughness or tightness of the front wheel

bearing.

MIf excess free play is suspected at a

component pivot point, this can be confirmed

by using a large screwdriver or similar tool and

levering between the mounting and the

component attachment. This will confirm

whether the wear is in the pivot bush, its

retaining bolt, or in the mounting itself (the bolt

holes can often become elongated).

MCarry out all the above checks at the other

front wheel, and then at both rear wheels.

Springs and shock absorbers

MExamine the suspension struts (when

applicable) for serious fluid leakage, corrosion,

or damage to the casing. Also check the

security of the mounting points.

MIf coil springs are fitted, check that the

spring ends locate in their seats, and that the

spring is not corroded, cracked or broken.

MIf leaf springs are fitted, check that all

leaves are intact, that the axle is securely

attached to each spring, and that there is no

deterioration of the spring eye mountings,

bushes, and shackles.MThe same general checks apply to vehicles

fitted with other suspension types, such as

torsion bars, hydraulic displacer units, etc.

Ensure that all mountings and attachments are

secure, that there are no signs of excessive

wear, corrosion or damage, and (on hydraulic

types) that there are no fluid leaks or damaged

pipes.

MInspect the shock absorbers for signs of

serious fluid leakage. Check for wear of the

mounting bushes or attachments, or damage

to the body of the unit.

Driveshafts

(fwd vehicles only)

MRotate each front wheel in turn and inspect

the constant velocity joint gaiters for splits or

damage. Also check that each driveshaft is

straight and undamaged.

Braking system

MIf possible without dismantling, check

brake pad wear and disc condition. Ensure

that the friction lining material has not worn

excessively, (A) and that the discs are not

fractured, pitted, scored or badly worn (B).

MExamine all the rigid brake pipes

underneath the vehicle, and the flexible

hose(s) at the rear. Look for corrosion, chafing

or insecurity of the pipes, and for signs of

bulging under pressure, chafing, splits or

deterioration of the flexible hoses.

MLook for signs of fluid leaks at the brake

calipers or on the brake backplates. Repair or

renew leaking components.

MSlowly spin each wheel, while your

assistant depresses and releases the

footbrake. Ensure that each brake is operating

and does not bind when the pedal is released.

3Checks carried out

WITH THE VEHICLE RAISED

AND THE WHEELS FREE TO

TURN

Page 250 of 525

MOTTest Checks REF•11

MExamine the handbrake mechanism,

checking for frayed or broken cables,

excessive corrosion, or wear or insecurity of

the linkage. Check that the mechanism works

on each relevant wheel, and releases fully,

without binding.

MIt is not possible to test brake efficiency

without special equipment, but a road test can

be carried out later to check that the vehicle

pulls up in a straight line.

Fuel and exhaust systems

MInspect the fuel tank (including the filler

cap), fuel pipes, hoses and unions. All

components must be secure and free from

leaks.

MExamine the exhaust system over its entire

length, checking for any damaged, broken or

missing mountings, security of the retaining

clamps and rust or corrosion.

Wheels and tyres

MExamine the sidewalls and tread area of

each tyre in turn. Check for cuts, tears, lumps,

bulges, separation of the tread, and exposure

of the ply or cord due to wear or damage.

Check that the tyre bead is correctly seated

on the wheel rim, that the valve is sound andproperly seated, and that the wheel is not

distorted or damaged.

MCheck that the tyres are of the correct size

for the vehicle, that they are of the same size

and type on each axle, and that the pressures

are correct.

MCheck the tyre tread depth. The legal

minimum at the time of writing is 1.6 mm over

at least three-quarters of the tread width.

Abnormal tread wear may indicate incorrect

front wheel alignment.

Body corrosion

MCheck the condition of the entire vehicle

structure for signs of corrosion in load-bearing

areas. (These include chassis box sections,

side sills, cross-members, pillars, and all

suspension, steering, braking system and

seat belt mountings and anchorages.) Any

corrosion which has seriously reduced the

thickness of a load-bearing area is likely to

cause the vehicle to fail. In this case

professional repairs are likely to be needed.

MDamage or corrosion which causes sharp

or otherwise dangerous edges to be exposed

will also cause the vehicle to fail.

Petrol models

MHave the engine at normal operating

temperature, and make sure that it is in good

tune (ignition system in good order, air filter

element clean, etc).

MBefore any measurements are carried out,

raise the engine speed to around 2500 rpm,

and hold it at this speed for 20 seconds. Allowthe engine speed to return to idle, and watch

for smoke emissions from the exhaust

tailpipe. If the idle speed is obviously much

too high, or if dense blue or clearly-visible

black smoke comes from the tailpipe for more

than 5 seconds, the vehicle will fail. As a rule

of thumb, blue smoke signifies oil being burnt

(engine wear) while black smoke signifies

unburnt fuel (dirty air cleaner element, or other

carburettor or fuel system fault).

MAn exhaust gas analyser capable of

measuring carbon monoxide (CO) and

hydrocarbons (HC) is now needed. If such an

instrument cannot be hired or borrowed, a

local garage may agree to perform the check

for a small fee.

CO emissions (mixture)

MAt the time of writing, the maximum CO

level at idle is 3.5% for vehicles first used after

August 1986 and 4.5% for older vehicles.

From January 1996 a much tighter limit

(around 0.5%) applies to catalyst-equipped

vehicles first used from August 1992. If the

CO level cannot be reduced far enough to

pass the test (and the fuel and ignition

systems are otherwise in good condition) then

the carburettor is badly worn, or there is some

problem in the fuel injection system or

catalytic converter (as applicable).

HC emissionsMWith the CO emissions within limits, HC

emissions must be no more than 1200 ppm

(parts per million). If the vehicle fails this test

at idle, it can be re-tested at around 2000 rpm;

if the HC level is then 1200 ppm or less, this

counts as a pass.

MExcessive HC emissions can be caused by

oil being burnt, but they are more likely to be

due to unburnt fuel.

Diesel models

MThe only emission test applicable to Diesel

engines is the measuring of exhaust smoke

density. The test involves accelerating the

engine several times to its maximum

unloaded speed.

Note: It is of the utmost importance that the

engine timing belt is in good condition before

the test is carried out.

M

Excessive smoke can be caused by a dirty

air cleaner element. Otherwise, professional

advice may be needed to find the cause.

4Checks carried out on

YOUR VEHICLE’S EXHAUST

EMISSION SYSTEM

REF

Page 255 of 525

Note:Due to the complexity of the automatic transmission, it is difficult

for the home mechanic to properly diagnose and service this unit. For

problems other than the following, the vehicle should be taken to a

dealer service department or automatic transmission specialist. Do not

be too hasty in removing the transmission if a fault is suspected, as

most of the testing is carried out with the unit still fitted.

Fluid leakage

MAutomatic transmission fluid is usually dark in colour. Fluid leaks

should not be confused with engine oil, which can easily be blown

onto the transmission by airflow.

MTo determine the source of a leak, first remove all built-up dirt and

grime from the transmission housing and surrounding areas using

a degreasing agent, or by steam-cleaning. Drive the vehicle at low

speed, so airflow will not blow the leak far from its source. Raise

and support the vehicle, and determine where the leak is coming

from. The following are common areas of leakage:

a)Fluid pan or “sump” (Chapter 1 and 7B).

b)Dipstick tube (Chapter 1 and 7B).

c)Transmission-to-fluid cooler pipes/unions (Chapter 7B).

Transmission fluid brown, or has burned smell

MTransmission fluid level low, or fluid in need of renewal (Chapter 1).

General gear selection problems

MChapter 7B deals with checking and adjusting the selector cable

on automatic transmissions. The following are common problems

that may be caused by a poorly adjusted cable:a)Engine starting in gears other than Park or Neutral.

b)Indicator panel indicating a gear other than the one actually being

used.

c)Vehicle moves when in Park or Neutral.

d)Poor gear shift quality or erratic gear changes.

MRefer to Chapter 7B for the selector cable adjustment procedure.

Transmission will not downshift (kickdown) with

accelerator pedal fully depressed

MLow transmission fluid level (Chapter 1).

MIncorrect selector cable adjustment (Chapter 7B).

Engine will not start in any gear, or starts in gears

other than Park or Neutral

MIncorrect starter/inhibitor switch adjustment (Chapter 7B).

MIncorrect selector cable adjustment (Chapter 7B).

Transmission slips, shifts roughly, is noisy, or has

no drive in forward or reverse gears

MThere are many probable causes for the above problems, but the

home mechanic should be concerned with only one possibility -

fluid level. Before taking the vehicle to a dealer or transmission

specialist, check the fluid level and condition of the fluid as

described in Chapter 1. Correct the fluid level as necessary, or

change the fluid and filter if needed. If the problem persists,

professional help will be necessary.

Clicking or knocking noise on turns (at slow speed

on full-lock)

MLack of constant velocity joint lubricant, possibly due to damaged

gaiter (Chapter 8).

MWorn outer constant velocity joint (Chapter 8).

Vibration when accelerating or decelerating

MWorn inner constant velocity joint (Chapter 8).

MBent or distorted driveshaft (Chapter 8).

REF•16Fault Finding

Automatic transmission

Driveshafts

Noisy in neutral with engine running

MInput shaft bearings worn (noise apparent with clutch pedal

released, but not when depressed), (Chapter 7A).*

MClutch release bearing worn (noise apparent with clutch pedal

depressed, possibly less when released), (Chapter 6).

Noisy in one particular gear

MWorn, damaged or chipped gear teeth (Chapter 7A).*

Difficulty engaging gears

MClutch fault (Chapter 6).

MWorn or damaged gear linkage (Chapter 7A).

MIncorrectly adjusted gear linkage (Chapter 7A).

MWorn synchroniser units (Chapter 7A).*

Jumps out of gear

MWorn or damaged gear linkage (Chapter 7A).

MIncorrectly adjusted gear linkage (Chapter 7A).MWorn synchroniser units (Chapter 7A).*

MWorn selector forks (Chapter 7A).*

Vibration

MLack of oil (Chapter 1).

MWorn bearings (Chapter 7A).*

Lubricant leaks

MLeaking differential output oil seal (Chapter 7A).

MLeaking housing joint (Chapter 7A).*

MLeaking input shaft oil seal (Chapter 7A).*

* Although the corrective action necessary to remedy the symptoms

described is beyond the scope of the home mechanic, the above

information should be helpful in isolating the cause of the condition.

This should enable the owner can communicate clearly with a

professional mechanic.

Manual transmission

Page 261 of 525

REF•22Glossary of Technical Terms

EEGR valveA valve used to introduce exhaust

gases into the intake air stream.

Electronic control unit (ECU)A computer

which controls (for instance) ignition and fuel

injection systems, or an anti-lock braking

system. For more information refer to the

Haynes Automotive Electrical and Electronic

Systems Manual.

Electronic Fuel Injection (EFI)A computer

controlled fuel system that distributes fuel

through an injector located in each intake port

of the engine.

Emergency brakeA braking system,

independent of the main hydraulic system,

that can be used to slow or stop the vehicle if

the primary brakes fail, or to hold the vehicle

stationary even though the brake pedal isn’t

depressed. It usually consists of a hand lever

that actuates either front or rear brakes

mechanically through a series of cables and

linkages. Also known as a handbrake or

parking brake.

EndfloatThe amount of lengthwise

movement between two parts. As applied to a

crankshaft, the distance that the crankshaft

can move forward and back in the cylinder

block.

Engine management system (EMS)A

computer controlled system which manages

the fuel injection and the ignition systems in

an integrated fashion.

Exhaust manifoldA part with several

passages through which exhaust gases leave

the engine combustion chambers and enter

the exhaust pipe.

FFan clutchA viscous (fluid) drive coupling

device which permits variable engine fan

speeds in relation to engine speeds.Feeler bladeA thin strip or blade of hardened

steel, ground to an exact thickness, used to

check or measure clearances between parts.

Firing orderThe order in which the engine

cylinders fire, or deliver their power strokes,

beginning with the number one cylinder.

Flywheel A heavy spinning wheel in which

energy is absorbed and stored by means of

momentum. On cars, the flywheel is attached

to the crankshaft to smooth out firing

impulses.

Free playThe amount of travel before any

action takes place. The “looseness” in a

linkage, or an assembly of parts, between the

initial application of force and actual

movement. For example, the distance the

brake pedal moves before the pistons in the

master cylinder are actuated.

FuseAn electrical device which protects a

circuit against accidental overload. The typical

fuse contains a soft piece of metal which is

calibrated to melt at a predetermined current

flow (expressed as amps) and break the

circuit.

Fusible linkA circuit protection device

consisting of a conductor surrounded by

heat-resistant insulation. The conductor is

smaller than the wire it protects, so it acts as

the weakest link in the circuit. Unlike a blown

fuse, a failed fusible link must frequently be

cut from the wire for replacement.

GGapThe distance the spark must travel in

jumping from the centre electrode to the sideelectrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

Exhaust manifold

Feeler blade

Adjusting spark plug gap

Gasket

EGR valve

Page 264 of 525

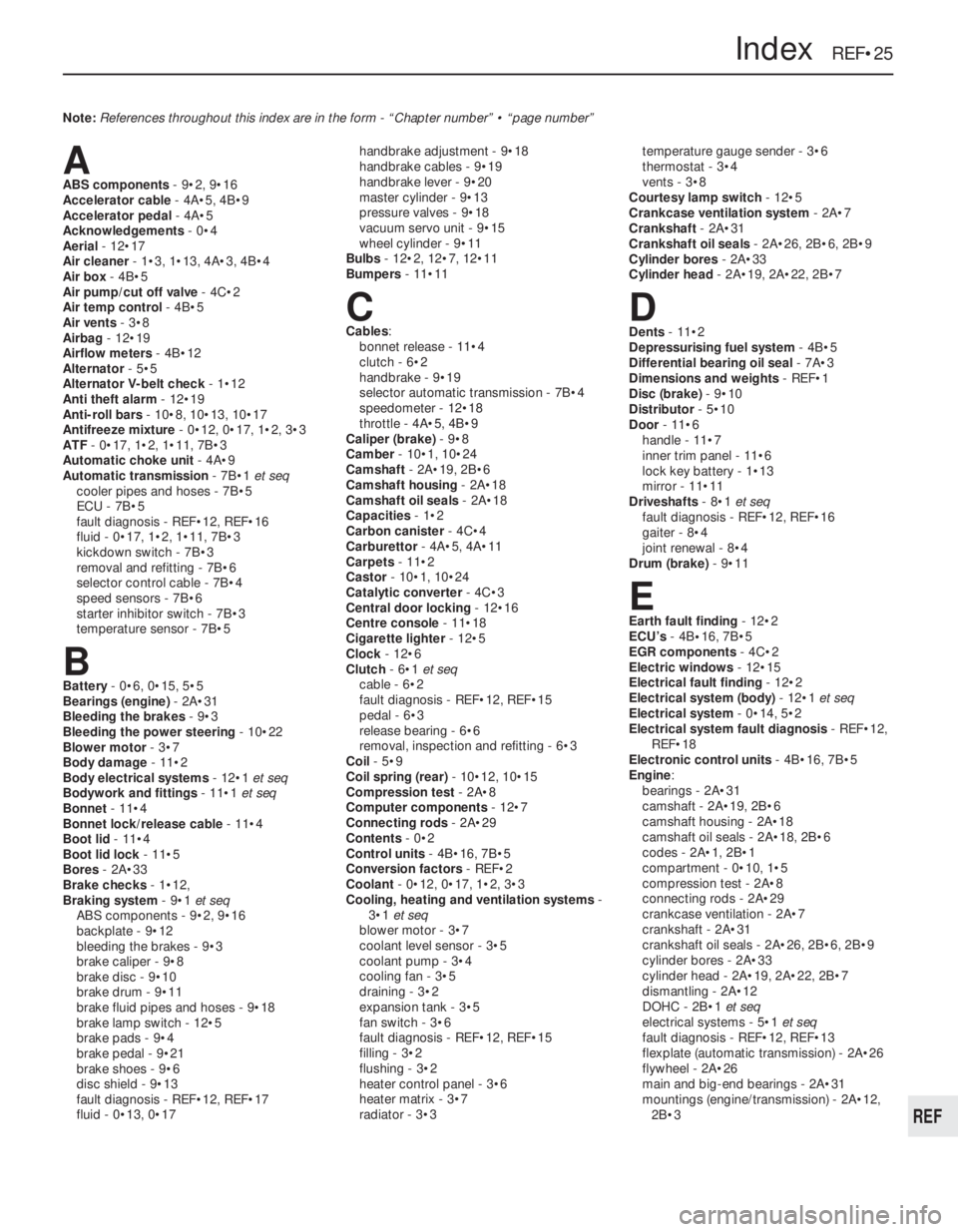

AABS components- 9•2, 9•16

Accelerator cable- 4A•5, 4B•9

Accelerator pedal- 4A•5

Acknowledgements- 0•4

Aerial- 12•17

Air cleaner- 1•3, 1•13, 4A•3, 4B•4

Air box- 4B•5

Air pump/cut off valve- 4C•2

Air temp control- 4B•5

Air vents- 3•8

Airbag- 12•19

Airflow meters- 4B•12

Alternator- 5•5

Alternator V-belt check- 1•12

Anti theft alarm- 12•19

Anti-roll bars- 10•8, 10•13, 10•17

Antifreeze mixture- 0•12, 0•17, 1•2, 3•3

ATF- 0•17, 1•2, 1•11, 7B•3

Automatic choke unit- 4A•9

Automatic transmission- 7B•1 et seq

cooler pipes and hoses - 7B•5

ECU - 7B•5

fault diagnosis - REF•12, REF•16

fluid - 0•17, 1•2, 1•11, 7B•3

kickdown switch - 7B•3

removal and refitting - 7B•6

selector control cable - 7B•4

speed sensors - 7B•6

starter inhibitor switch - 7B•3

temperature sensor - 7B•5

BBattery- 0•6, 0•15, 5•5

Bearings (engine)- 2A•31

Bleeding the brakes- 9•3

Bleeding the power steering- 10•22

Blower motor- 3•7

Body damage- 11•2

Body electrical systems - 12•1 et seq

Bodywork and fittings- 11•1 et seq

Bonnet- 11•4

Bonnet lock/release cable- 11•4

Boot lid- 11•4

Boot lid lock- 11•5

Bores- 2A•33

Brake checks- 1•12,

Braking system- 9•1 et seq

ABS components - 9•2, 9•16

backplate - 9•12

bleeding the brakes - 9•3

brake caliper - 9•8

brake disc - 9•10

brake drum - 9•11

brake fluid pipes and hoses - 9•18

brake lamp switch - 12•5

brake pads - 9•4

brake pedal - 9•21

brake shoes - 9•6

disc shield - 9•13

fault diagnosis - REF•12, REF•17

fluid - 0•13, 0•17handbrake adjustment - 9•18

handbrake cables - 9•19

handbrake lever - 9•20

master cylinder - 9•13

pressure valves - 9•18

vacuum servo unit - 9•15

wheel cylinder - 9•11

Bulbs- 12•2, 12•7, 12•11

Bumpers- 11•11

CCables:

bonnet release - 11•4

clutch - 6•2

handbrake - 9•19

selector automatic transmission - 7B•4

speedometer - 12•18

throttle - 4A•5, 4B•9

Caliper (brake)- 9•8

Camber- 10•1, 10•24

Camshaft- 2A•19, 2B•6

Camshaft housing- 2A•18

Camshaft oil seals- 2A•18

Capacities- 1•2

Carbon canister- 4C•4

Carburettor- 4A•5, 4A•11

Carpets- 11•2

Castor- 10•1, 10•24

Catalytic converter- 4C•3

Central door locking- 12•16

Centre console- 11•18

Cigarette lighter- 12•5

Clock- 12•6

Clutch- 6•1 et seq

cable - 6•2

fault diagnosis - REF•12, REF•15

pedal - 6•3

release bearing - 6•6

removal, inspection and refitting - 6•3

Coil- 5•9

Coil spring (rear)- 10•12, 10•15

Compression test- 2A•8

Computer components- 12•7

Connecting rods- 2A•29

Contents- 0•2

Control units- 4B•16, 7B•5

Conversion factors- REF•2

Coolant- 0•12, 0•17, 1•2, 3•3

Cooling, heating and ventilation systems-

3•1 et seq

blower motor - 3•7

coolant level sensor - 3•5

coolant pump - 3•4

cooling fan - 3•5

draining - 3•2

expansion tank - 3•5

fan switch - 3•6

fault diagnosis - REF•12, REF•15

filling - 3•2

flushing - 3•2

heater control panel - 3•6

heater matrix - 3•7

radiator - 3•3temperature gauge sender - 3•6

thermostat - 3•4

vents - 3•8

Courtesy lamp switch- 12•5

Crankcase ventilation system- 2A•7

Crankshaft- 2A•31

Crankshaft oil seals- 2A•26, 2B•6, 2B•9

Cylinder bores- 2A•33

Cylinder head- 2A•19, 2A•22, 2B•7DDents- 11•2

Depressurising fuel system- 4B•5

Differential bearing oil seal- 7A•3

Dimensions and weights- REF•1

Disc (brake)- 9•10

Distributor- 5•10

Door- 11•6

handle - 11•7

inner trim panel - 11•6

lock key battery - 1•13

mirror - 11•11

Driveshafts- 8•1 et seq

fault diagnosis - REF•12, REF•16

gaiter - 8•4

joint renewal - 8•4

Drum (brake)- 9•11

EEarth fault finding- 12•2

ECU’s - 4B•16, 7B•5

EGR components- 4C•2

Electric windows- 12•15

Electrical fault finding- 12•2

Electrical system (body)- 12•1 et seq

Electrical system- 0•14, 5•2

Electrical system fault diagnosis- REF•12,

REF•18

Electronic control units- 4B•16, 7B•5

Engine:

bearings - 2A•31

camshaft - 2A•19, 2B•6

camshaft housing - 2A•18

camshaft oil seals - 2A•18, 2B•6

codes - 2A•1, 2B•1

compartment - 0•10, 1•5

compression test - 2A•8

connecting rods - 2A•29

crankcase ventilation - 2A•7

crankshaft - 2A•31

crankshaft oil seals - 2A•26, 2B•6, 2B•9

cylinder bores - 2A•33

cylinder head - 2A•19, 2A•22, 2B•7

dismantling - 2A•12

DOHC - 2B•1 et seq

electrical systems - 5•1 et seq

fault diagnosis - REF•12, REF•13

flexplate (automatic transmission) - 2A•26

flywheel - 2A•26

main and big-end bearings - 2A•31

mountings (engine/transmission) - 2A•12,

2B•3

Index REF•25

REF

Note:References throughout this index are in the form - “Chapter number” • “page number”