check engine OPEL CALIBRA 1988 Service Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 222 of 525

cylinder head for wear. If excessive wear is

evident, the cylinder head must be renewed.

Also check the valve lifter oil holes in the

cylinder head for obstructions.

3Starting with number 1 valve lifter, carefully

pull the collar from the top of the valve lifter

cylinder. It should be possible to remove the

collar by hand -if a tool is used, take care not

to distort the collar.

4Withdraw the plunger from the cylinder, and

recover the spring.5Using a small screwdriver, carefully prise

the cap from the base of the plunger. Recover

the spring and ball from under the cap, taking

care not to lose them as the cap is removed.

6Carefully clean all the components using

paraffin or solvent, paying particular attention

to the machined surfaces of the cylinder

(internal surfaces), and piston (external

surfaces). Thoroughly dry all the components

using a lint-free cloth. Carefully examine the

springs for damage or distortion -thecomplete valve lifter must be renewed if the

springs are not in perfect condition.

7Lubricate the components sparingly with

clean engine oil of the correct grade, then

reassemble as follows.

8Invert the plunger, and locate the ball on its

seat in the base of the plunger (see

illustration).

9Locate the smaller spring on its seat in the

plunger cap, then carefully refit the cap and

spring, ensuring that the spring locates on the

ball. Carefully press around the flange of the

cap, using a small screwdriver if necessary,

until the flange is securely located in the

groove in the base of the plunger (see

illustrations).

10Locate the larger spring over the plunger

cap, ensuring that the spring is correctly

seated, and slide the plunger and spring

assembly into the cylinder (see illustrations).

11Slide the collar over the top of the

plunger, and carefully compress the plunger

by hand, until the collar can be pushed down

to engage securely with the groove in the

cylinder (see illustration).

12Repeat the above procedures on the

remaining valve lifters.

SOHC engine procedures 2A•25

24.11 Slide the collar (1) over the top of

the plunger and engage with the

groove (2) in the cylinder24.10B . . .then slide the plunger and

spring assembly into the cylinder

24.9B Locate the cap flange in the plunger

groove24.9A Spring (1) located in plunger cap,

and ball (2) located on seat in plunger

24.10A Locate the spring over the

plunger cap . . .

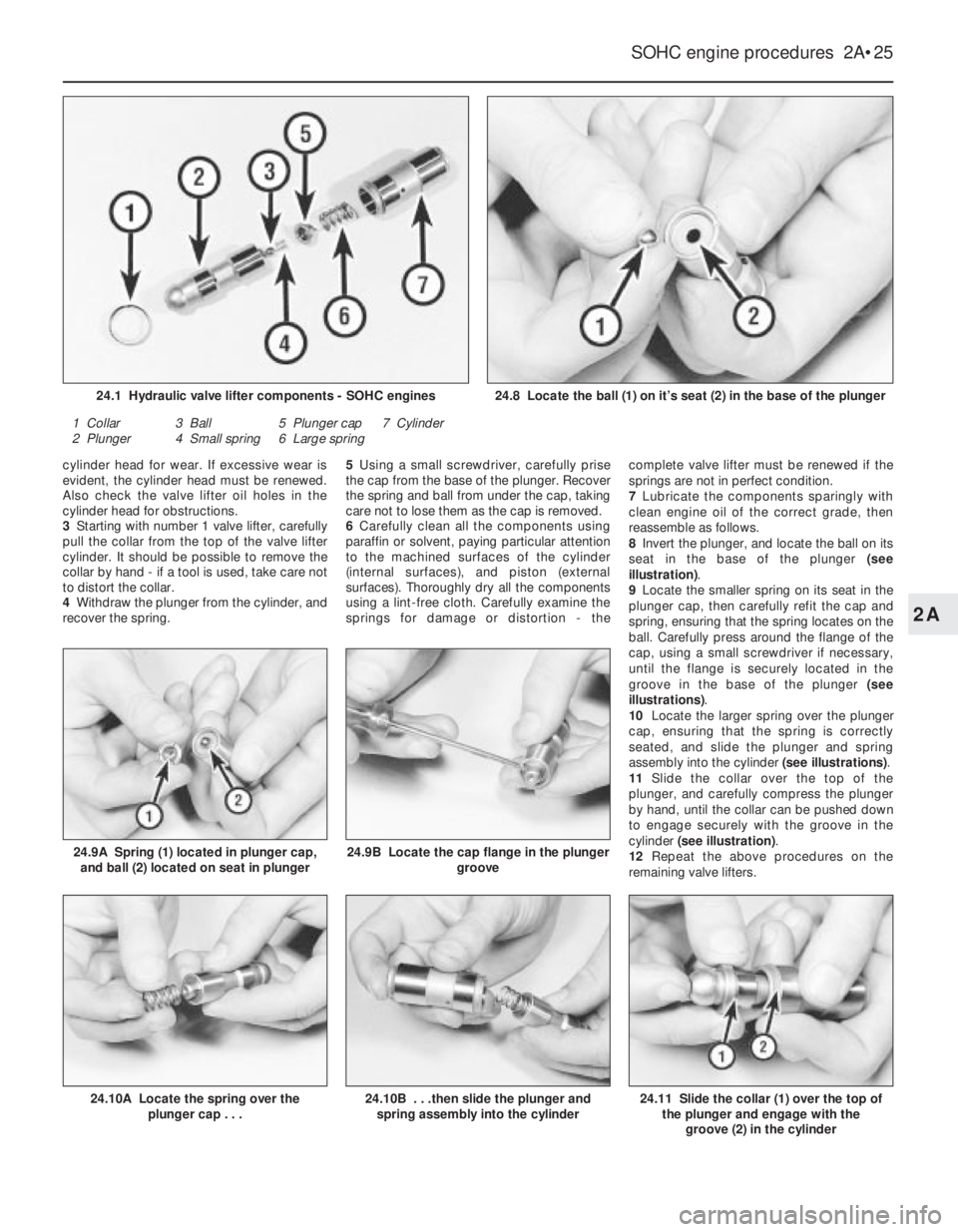

24.8 Locate the ball (1) on it’s seat (2) in the base of the plunger24.1 Hydraulic valve lifter components - SOHC engines

1 Collar

2 Plunger3 Ball

4 Small spring5 Plunger cap

6 Large spring7 Cylinder

2A

Page 223 of 525

25Flywheel -removal, inspection

and refitting

4

Note: New flywheel securing bolts must he

used on refitting. Certain models are fitted

with a ‘Pot type’ flywheel. Although, it has a

deeply recessed surface for the clutch disc,

the operations below are the same.

Removal

1If not already done, remove the clutch,

(Chapter 6), and the starter motor, (Chapter 5).

2If the engine is in the vehicle, remove the

clutch release bearing and its guide sleeve, as

described in Chapter 6.

3Although the flywheel bolt holes are offset

so that the flywheel can only be fitted in one

position, it will make refitting easier if

alignment marks are made between the

flywheel and the end of the crankshaft.

4Prevent the flywheel from turning by

jamming the ring gear teeth using a large

screwdriver or similar tool. Access is most

easily obtained through the starter motor

aperture if the engine is in the vehicle.

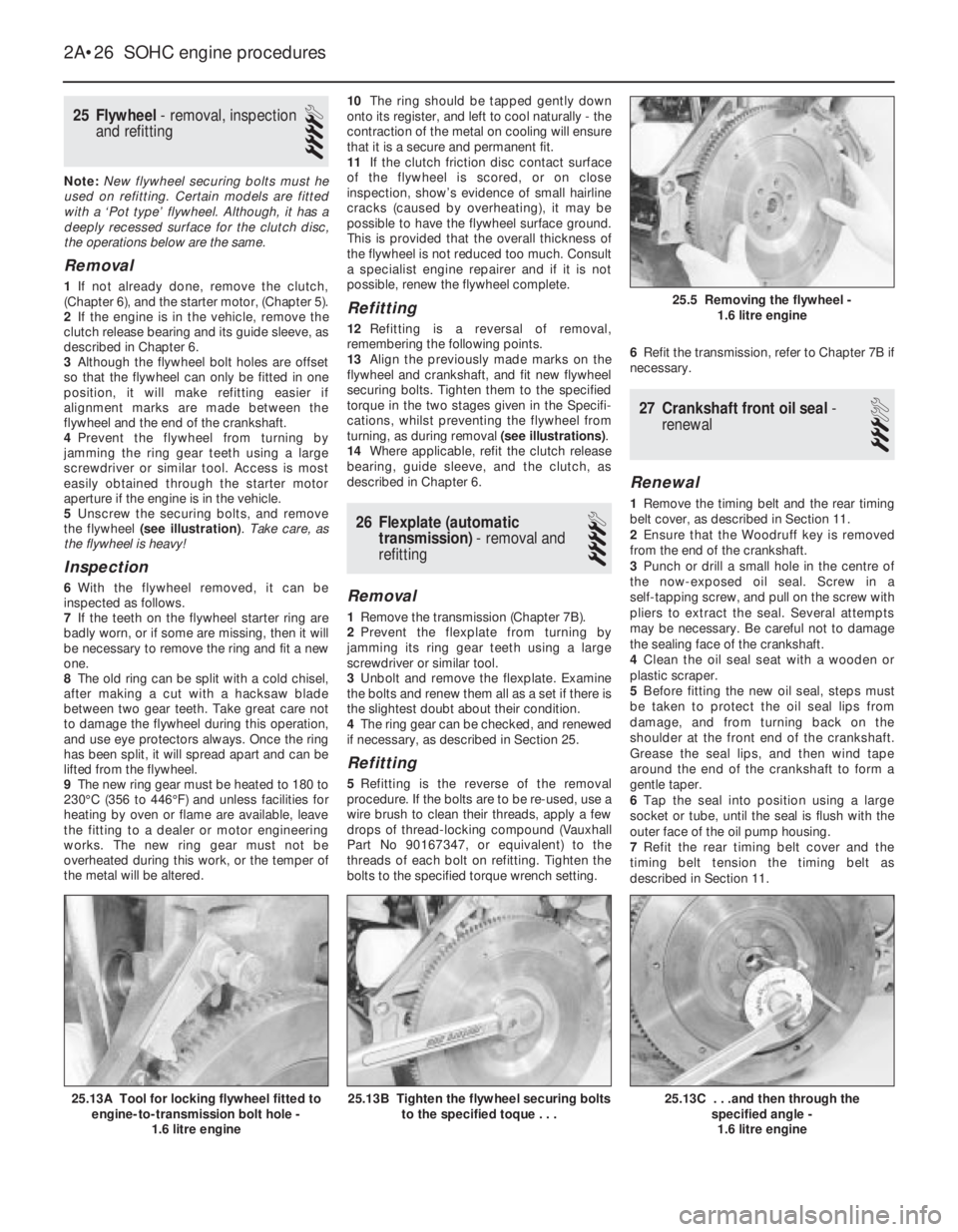

5Unscrew the securing bolts, and remove

the flywheel (see illustration). Take care, as

the flywheel is heavy!

Inspection

6With the flywheel removed, it can be

inspected as follows.

7If the teeth on the flywheel starter ring are

badly worn, or if some are missing, then it will

be necessary to remove the ring and fit a new

one.

8The old ring can be split with a cold chisel,

after making a cut with a hacksaw blade

between two gear teeth. Take great care not

to damage the flywheel during this operation,

and use eye protectors always. Once the ring

has been split, it will spread apart and can be

lifted from the flywheel.

9The new ring gear must be heated to 180 to

230°C (356 to 446°F) and unless facilities for

heating by oven or flame are available, leave

the fitting to a dealer or motor engineering

works. The new ring gear must not be

overheated during this work, or the temper of

the metal will be altered.10The ring should be tapped gently down

onto its register, and left to cool naturally -the

contraction of the metal on cooling will ensure

that it is a secure and permanent fit.

11If the clutch friction disc contact surface

of the flywheel is scored, or on close

inspection, show’s evidence of small hairline

cracks (caused by overheating), it may be

possible to have the flywheel surface ground.

This is provided that the overall thickness of

the flywheel is not reduced too much. Consult

a specialist engine repairer and if it is not

possible, renew the flywheel complete.

Refitting

12Refitting is a reversal of removal,

remembering the following points.

13Align the previously made marks on the

flywheel and crankshaft, and fit new flywheel

securing bolts. Tighten them to the specified

torque in the two stages given in the Specifi-

cations, whilst preventing the flywheel from

turning, as during removal (see illustrations).

14Where applicable, refit the clutch release

bearing, guide sleeve, and the clutch, as

described in Chapter 6.

26Flexplate (automatic

transmission) -removal and

refitting

4

Removal

1Remove the transmission (Chapter 7B).

2Prevent the flexplate from turning by

jamming its ring gear teeth using a large

screwdriver or similar tool.

3Unbolt and remove the flexplate. Examine

the bolts and renew them all as a set if there is

the slightest doubt about their condition.

4The ring gear can be checked, and renewed

if necessary, as described in Section 25.

Refitting

5Refitting is the reverse of the removal

procedure. If the bolts are to be re-used, use a

wire brush to clean their threads, apply a few

drops of thread-locking compound (Vauxhall

Part No 90167347, or equivalent) to the

threads of each bolt on refitting. Tighten the

bolts to the specified torque wrench setting.6Refit the transmission, refer to Chapter 7B if

necessary.

27Crankshaft front oil seal -

renewal

3

Renewal

1Remove the timing belt and the rear timing

belt cover, as described in Section 11.

2Ensure that the Woodruff key is removed

from the end of the crankshaft.

3Punch or drill a small hole in the centre of

the now-exposed oil seal. Screw in a

self-tapping screw, and pull on the screw with

pliers to extract the seal. Several attempts

may be necessary. Be careful not to damage

the sealing face of the crankshaft.

4Clean the oil seal seat with a wooden or

plastic scraper.

5Before fitting the new oil seal, steps must

be taken to protect the oil seal lips from

damage, and from turning back on the

shoulder at the front end of the crankshaft.

Grease the seal lips, and then wind tape

around the end of the crankshaft to form a

gentle taper.

6Tap the seal into position using a large

socket or tube, until the seal is flush with the

outer face of the oil pump housing.

7Refit the rear timing belt cover and the

timing belt tension the timing belt as

described in Section 11.

2A•26SOHC engine procedures

25.13C . . .and then through the

specified angle -

1.6 litre engine25.13B Tighten the flywheel securing bolts

to the specified toque . . .25.13A Tool for locking flywheel fitted to

engine-to-transmission bolt hole -

1.6 litre engine

25.5 Removing the flywheel -

1.6 litre engine

Page 226 of 525

Inspection

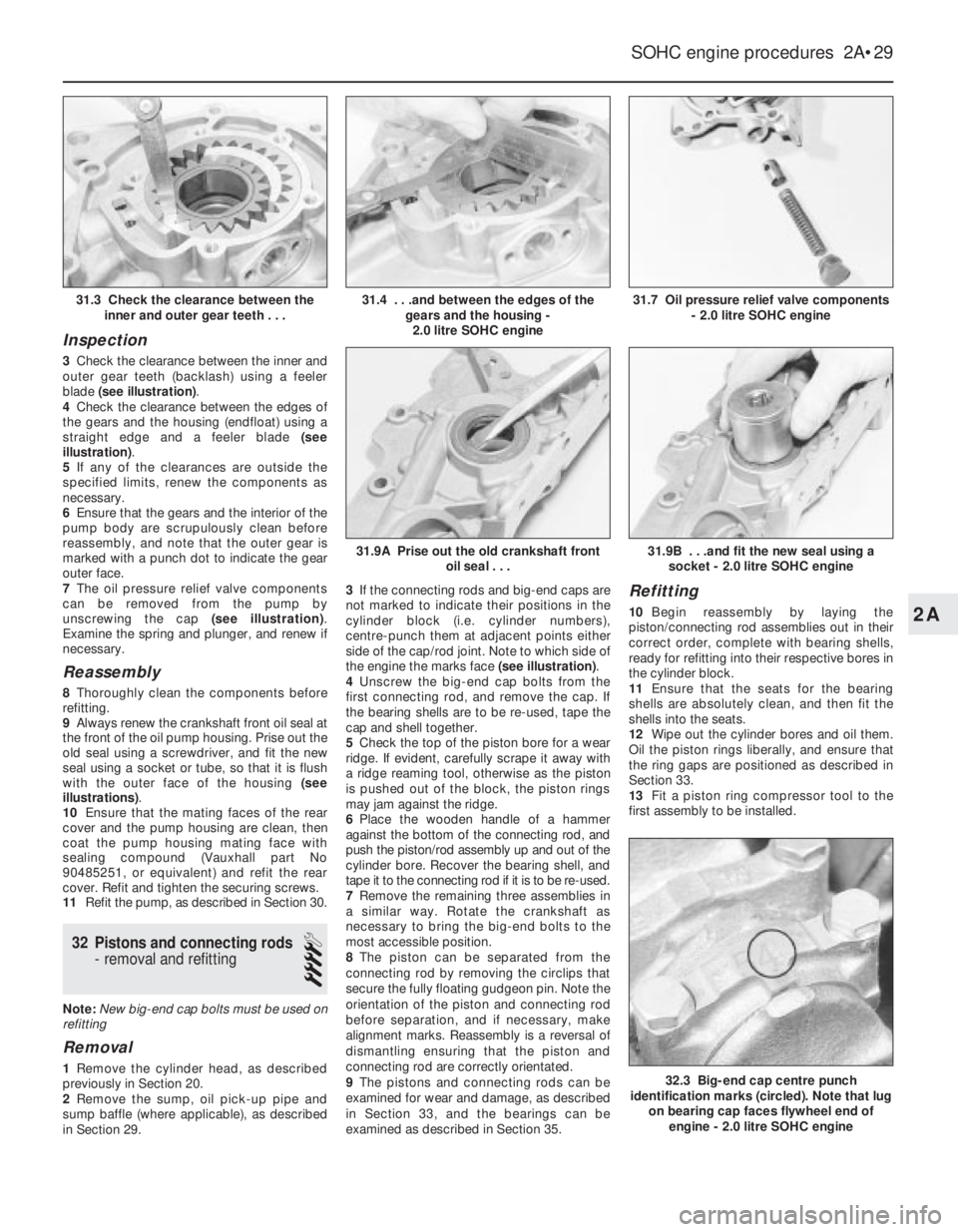

3Check the clearance between the inner and

outer gear teeth (backlash) using a feeler

blade (see illustration).

4Check the clearance between the edges of

the gears and the housing (endfloat) using a

straight edge and a feeler blade (see

illustration).

5If any of the clearances are outside the

specified limits, renew the components as

necessary.

6Ensure that the gears and the interior of the

pump body are scrupulously clean before

reassembly, and note that the outer gear is

marked with a punch dot to indicate the gear

outer face.

7The oil pressure relief valve components

can be removed from the pump by

unscrewing the cap (see illustration).

Examine the spring and plunger, and renew if

necessary.

Reassembly

8Thoroughly clean the components before

refitting.

9Always renew the crankshaft front oil seal at

the front of the oil pump housing. Prise out the

old seal using a screwdriver, and fit the new

seal using a socket or tube, so that it is flush

with the outer face of the housing (see

illustrations).

10Ensure that the mating faces of the rear

cover and the pump housing are clean, then

coat the pump housing mating face with

sealing compound (Vauxhall part No

90485251, or equivalent) and refit the rear

cover. Refit and tighten the securing screws.

11Refit the pump, as described in Section 30.

32Pistons and connecting rods

- removal and refitting

4

Note: New big-end cap bolts must be used on

refitting

Removal

1Remove the cylinder head, as described

previously in Section 20.

2Remove the sump, oil pick-up pipe and

sump baffle (where applicable), as described

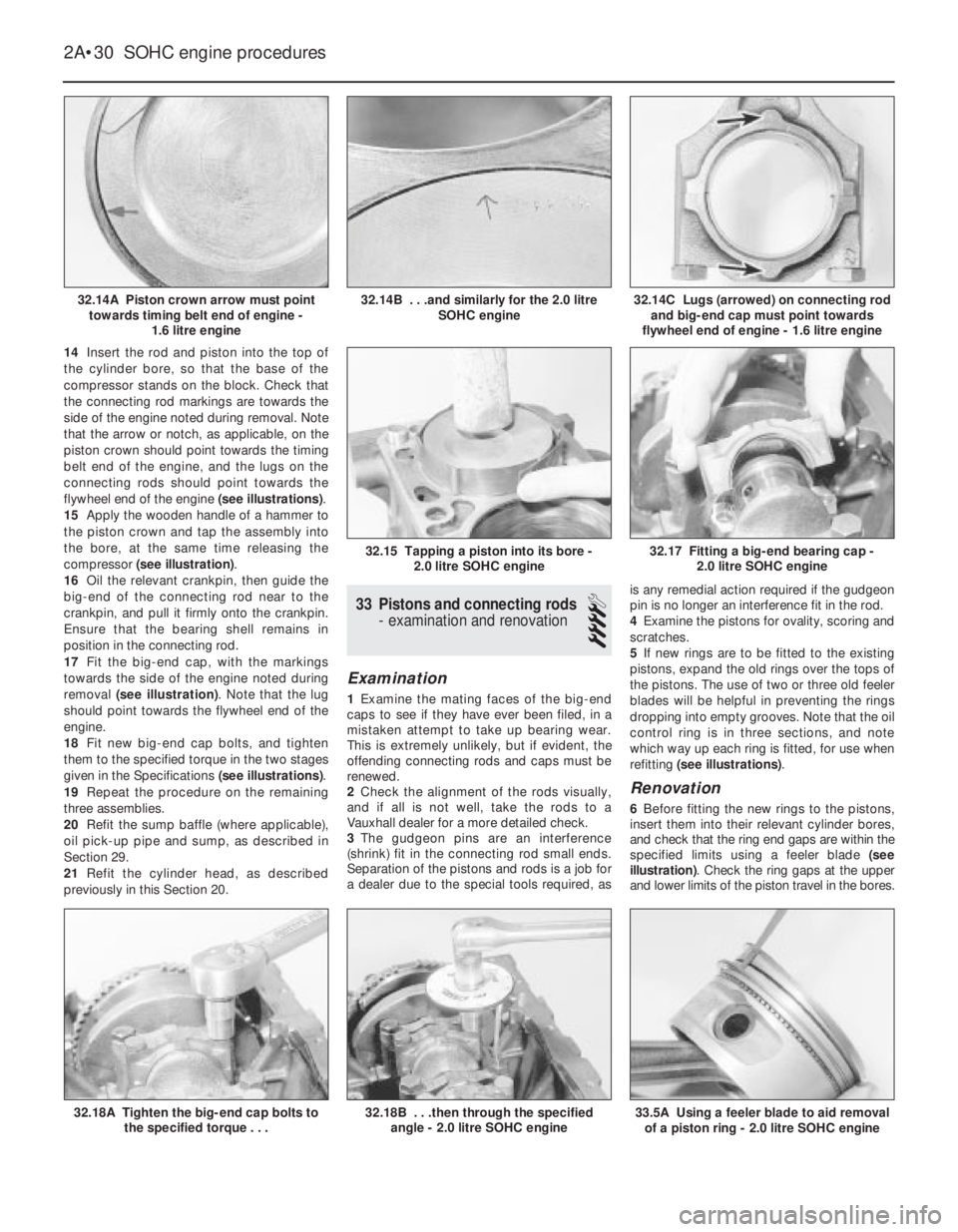

in Section 29.3If the connecting rods and big-end caps are

not marked to indicate their positions in the

cylinder block (i.e. cylinder numbers),

centre-punch them at adjacent points either

side of the cap/rod joint. Note to which side of

the engine the marks face (see illustration).

4Unscrew the big-end cap bolts from the

first connecting rod, and remove the cap. If

the bearing shells are to be re-used, tape the

cap and shell together.

5Check the top of the piston bore for a wear

ridge. If evident, carefully scrape it away with

a ridge reaming tool, otherwise as the piston

is pushed out of the block, the piston rings

may jam against the ridge.

6Place the wooden handle of a hammer

against the bottom of the connecting rod, and

push the piston/rod assembly up and out of the

cylinder bore. Recover the bearing shell, and

tape it to the connecting rod if it is to be re-used.

7Remove the remaining three assemblies in

a similar way. Rotate the crankshaft as

necessary to bring the big-end bolts to the

most accessible position.

8The piston can be separated from the

connecting rod by removing the circlips that

secure the fully floating gudgeon pin. Note the

orientation of the piston and connecting rod

before separation, and if necessary, make

alignment marks. Reassembly is a reversal of

dismantling ensuring that the piston and

connecting rod are correctly orientated.

9The pistons and connecting rods can be

examined for wear and damage, as described

in Section 33, and the bearings can be

examined as described in Section 35.

Refitting

10Begin reassembly by laying the

piston/connecting rod assemblies out in their

correct order, complete with bearing shells,

ready for refitting into their respective bores in

the cylinder block.

11Ensure that the seats for the bearing

shells are absolutely clean, and then fit the

shells into the seats.

12Wipe out the cylinder bores and oil them.

Oil the piston rings liberally, and ensure that

the ring gaps are positioned as described in

Section 33.

13Fit a piston ring compressor tool to the

first assembly to be installed.

SOHC engine procedures 2A•29

31.7 Oil pressure relief valve components

- 2.0 litre SOHC engine

32.3 Big-end cap centre punch

identification marks (circled). Note that lug

on bearing cap faces flywheel end of

engine - 2.0 litre SOHC engine

31.9B . . .and fit the new seal using a

socket - 2.0 litre SOHC engine31.9A Prise out the old crankshaft front

oil seal . . .

31.4 . . .and between the edges of the

gears and the housing -

2.0 litre SOHC engine31.3 Check the clearance between the

inner and outer gear teeth . . .

2A

Page 227 of 525

14Insert the rod and piston into the top of

the cylinder bore, so that the base of the

compressor stands on the block. Check that

the connecting rod markings are towards the

side of the engine noted during removal. Note

that the arrow or notch, as applicable, on the

piston crown should point towards the timing

belt end of the engine, and the lugs on the

connecting rods should point towards the

flywheel end of the engine (see illustrations).

15Apply the wooden handle of a hammer to

the piston crown and tap the assembly into

the bore, at the same time releasing the

compressor (see illustration).

16Oil the relevant crankpin, then guide the

big-end of the connecting rod near to the

crankpin, and pull it firmly onto the crankpin.

Ensure that the bearing shell remains in

position in the connecting rod.

17Fit the big-end cap, with the markings

towards the side of the engine noted during

removal (see illustration). Note that the lug

should point towards the flywheel end of the

engine.

18Fit new big-end cap bolts, and tighten

them to the specified torque in the two stages

given in the Specifications (see illustrations).

19Repeat the procedure on the remaining

three assemblies.

20Refit the sump baffle (where applicable),

oil pick-up pipe and sump, as described in

Section 29.

21Refit the cylinder head, as described

previously in this Section 20.

33Pistons and connecting rods

-examination and renovation

4

Examination

1Examine the mating faces of the big-end

caps to see if they have ever been filed, in a

mistaken attempt to take up bearing wear.

This is extremely unlikely, but if evident, the

offending connecting rods and caps must be

renewed.

2Check the alignment of the rods visually,

and if all is not well, take the rods to a

Vauxhall dealer for a more detailed check.

3The gudgeon pins are an interference

(shrink) fit in the connecting rod small ends.

Separation of the pistons and rods is a job for

a dealer due to the special tools required, asis any remedial action required if the gudgeon

pin is no longer an interference fit in the rod.

4Examine the pistons for ovality, scoring and

scratches.

5If new rings are to be fitted to the existing

pistons, expand the old rings over the tops of

the pistons. The use of two or three old feeler

blades will be helpful in preventing the rings

dropping into empty grooves. Note that the oil

control ring is in three sections, and note

which way up each ring is fitted, for use when

refitting (see illustrations).

Renovation

6Before fitting the new rings to the pistons,

insert them into their relevant cylinder bores,

and check that the ring end gaps are within the

specified limits using a feeler blade (see

illustration). Check the ring gaps at the upper

and lower limits of the piston travel in the bores.

2A•30SOHC engine procedures

32.14A Piston crown arrow must point

towards timing belt end of engine -

1.6 litre engine32.14C Lugs (arrowed) on connecting rod

and big-end cap must point towards

flywheel end of engine - 1.6 litre engine

33.5A Using a feeler blade to aid removal

of a piston ring - 2.0 litre SOHC engine32.18B . . .then through the specified

angle - 2.0 litre SOHC engine32.18A Tighten the big-end cap bolts to

the specified torque . . .

32.17 Fitting a big-end bearing cap -

2.0 litre SOHC engine32.15 Tapping a piston into its bore -

2.0 litre SOHC engine

32.14B . . .and similarly for the 2.0 litre

SOHC engine

Page 228 of 525

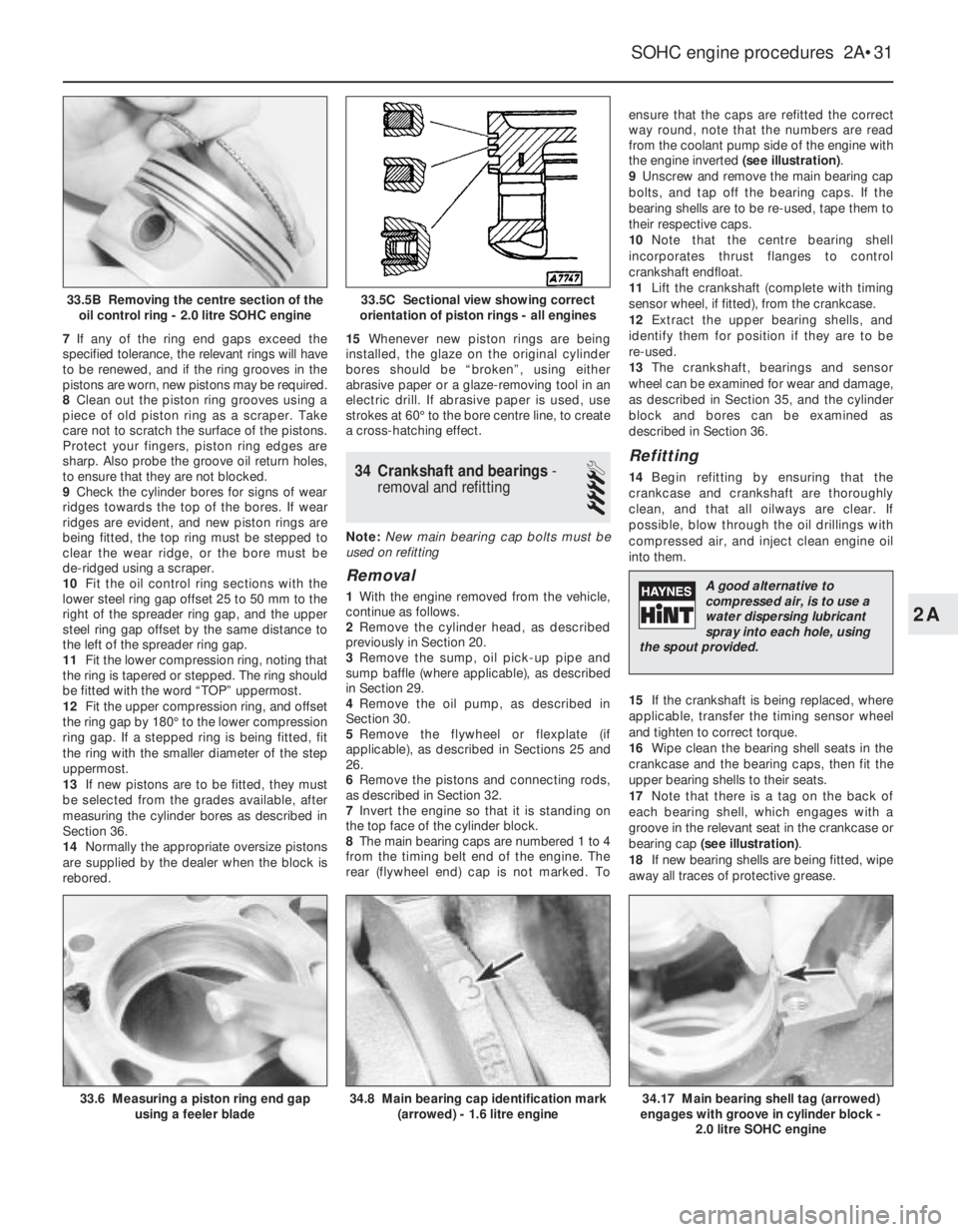

7If any of the ring end gaps exceed the

specified tolerance, the relevant rings will have

to be renewed, and if the ring grooves in the

pistons are worn, new pistons may be required.

8Clean out the piston ring grooves using a

piece of old piston ring as a scraper. Take

care not to scratch the surface of the pistons.

Protect your fingers, piston ring edges are

sharp. Also probe the groove oil return holes,

to ensure that they are not blocked.

9Check the cylinder bores for signs of wear

ridges towards the top of the bores. If wear

ridges are evident, and new piston rings are

being fitted, the top ring must be stepped to

clear the wear ridge, or the bore must be

de-ridged using a scraper.

10Fit the oil control ring sections with the

lower steel ring gap offset 25 to 50 mm to the

right of the spreader ring gap, and the upper

steel ring gap offset by the same distance to

the left of the spreader ring gap.

11Fit the lower compression ring, noting that

the ring is tapered or stepped. The ring should

be fitted with the word “TOP” uppermost.

12Fit the upper compression ring, and offset

the ring gap by 180°to the lower compression

ring gap. If a stepped ring is being fitted, fit

the ring with the smaller diameter of the step

uppermost.

13If new pistons are to be fitted, they must

be selected from the grades available, after

measuring the cylinder bores as described in

Section 36.

14Normally the appropriate oversize pistons

are supplied by the dealer when the block is

rebored.15Whenever new piston rings are being

installed, the glaze on the original cylinder

bores should be “broken”, using either

abrasive paper or a glaze-removing tool in an

electric drill. If abrasive paper is used, use

strokes at 60°to the bore centre line, to create

a cross-hatching effect.

34Crankshaft and bearings -

removal and refitting

4

Note: New main bearing cap bolts must be

used on refitting

Removal

1With the engine removed from the vehicle,

continue as follows.

2Remove the cylinder head, as described

previously in Section 20.

3Remove the sump, oil pick-up pipe and

sump baffle (where applicable), as described

in Section 29.

4Remove the oil pump, as described in

Section 30.

5Remove the flywheel or flexplate (if

applicable), as described in Sections 25 and

26.

6Remove the pistons and connecting rods,

as described in Section 32.

7Invert the engine so that it is standing on

the top face of the cylinder block.

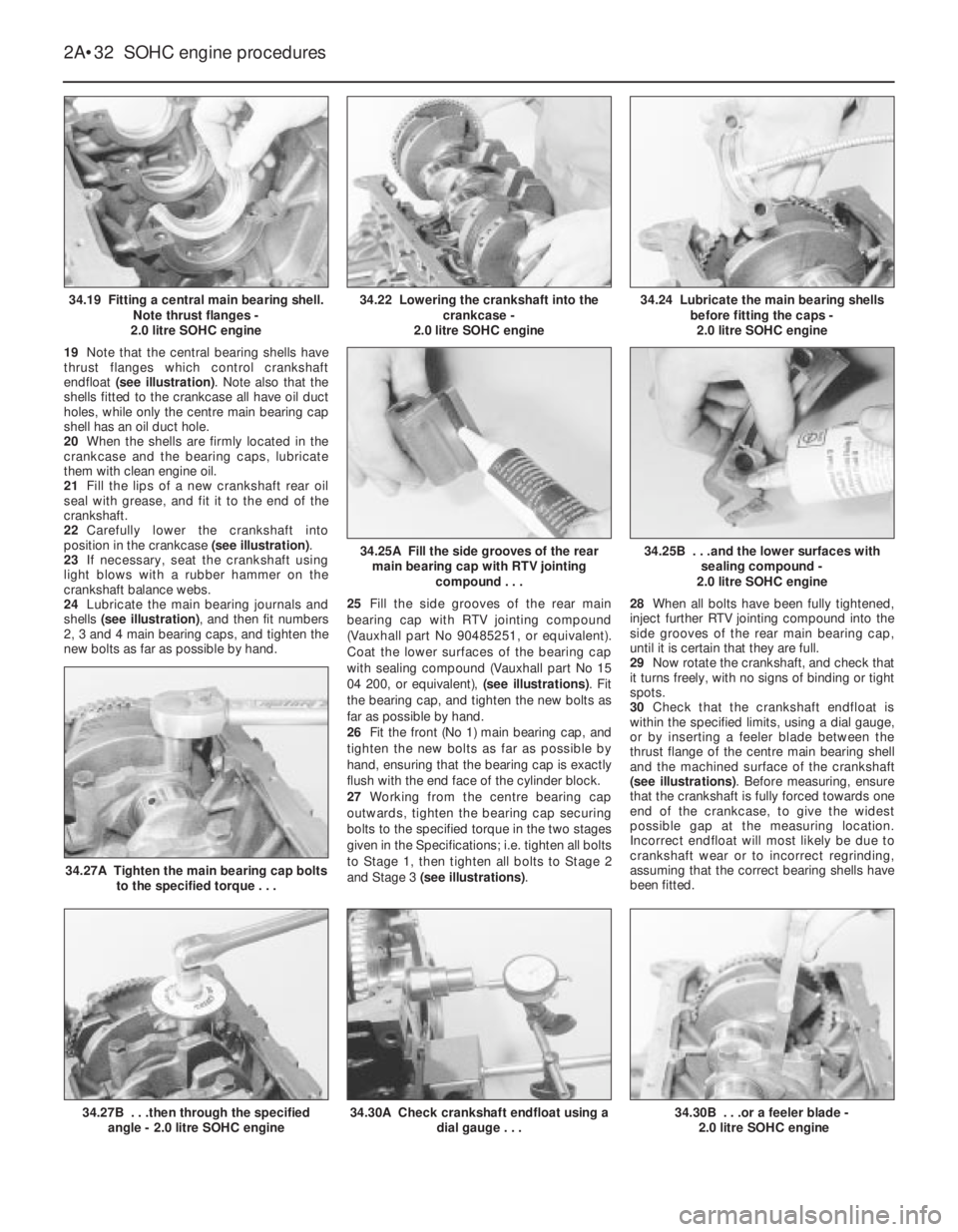

8The main bearing caps are numbered 1 to 4

from the timing belt end of the engine. The

rear (flywheel end) cap is not marked. Toensure that the caps are refitted the correct

way round, note that the numbers are read

from the coolant pump side of the engine with

the engine inverted (see illustration).

9Unscrew and remove the main bearing cap

bolts, and tap off the bearing caps. If the

bearing shells are to be re-used, tape them to

their respective caps.

10Note that the centre bearing shell

incorporates thrust flanges to control

crankshaft endfloat.

11Lift the crankshaft (complete with timing

sensor wheel, if fitted), from the crankcase.

12Extract the upper bearing shells, and

identify them for position if they are to be

re-used.

13The crankshaft, bearings and sensor

wheel can be examined for wear and damage,

as described in Section 35, and the cylinder

block and bores can be examined as

described in Section 36.

Refitting

14Begin refitting by ensuring that the

crankcase and crankshaft are thoroughly

clean, and that all oilways are clear. If

possible, blow through the oil drillings with

compressed air, and inject clean engine oil

into them.

15If the crankshaft is being replaced, where

applicable, transfer the timing sensor wheel

and tighten to correct torque.

16Wipe clean the bearing shell seats in the

crankcase and the bearing caps, then fit the

upper bearing shells to their seats.

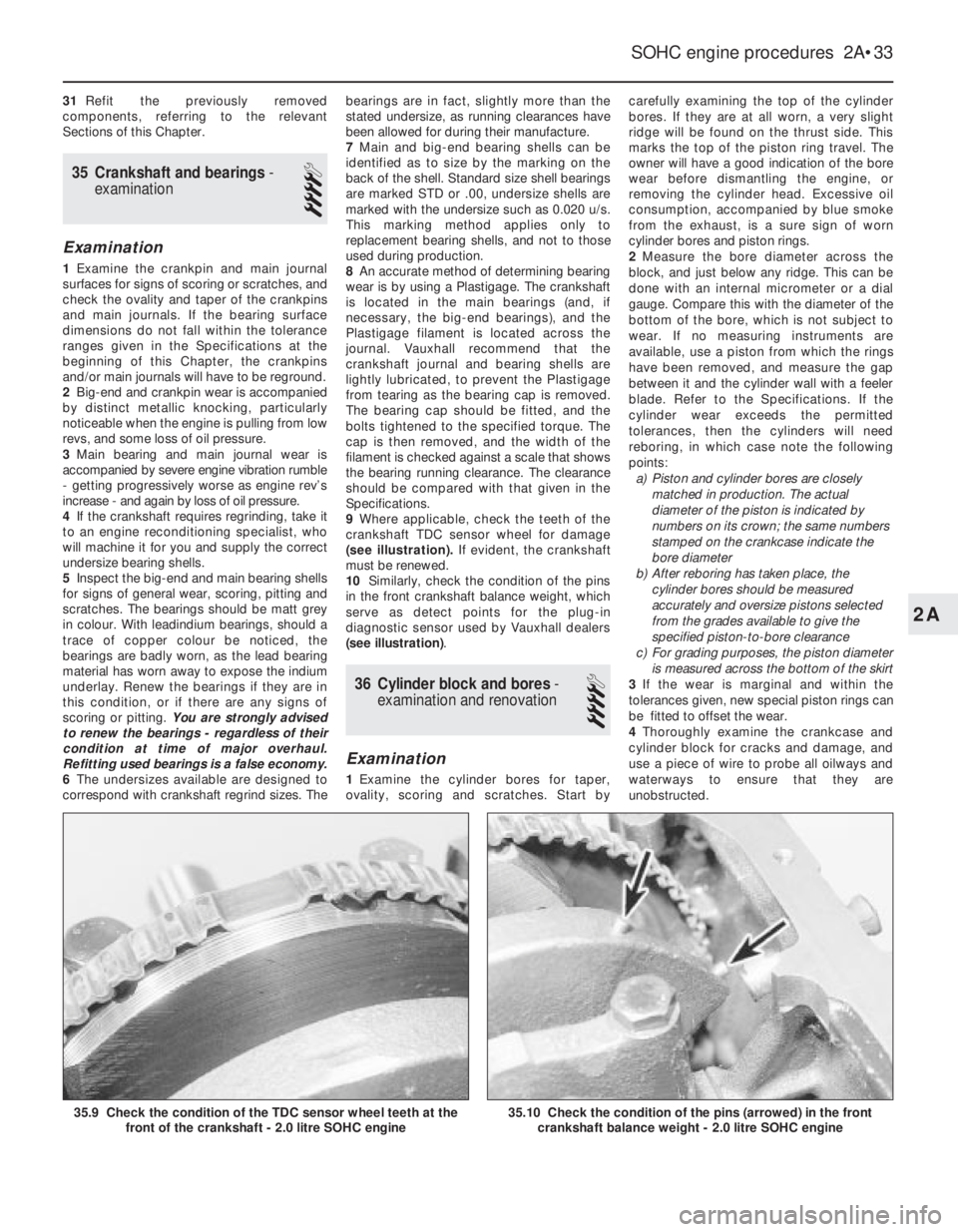

17Note that there is a tag on the back of

each bearing shell, which engages with a

groove in the relevant seat in the crankcase or

bearing cap (see illustration).

18If new bearing shells are being fitted, wipe

away all traces of protective grease.

SOHC engine procedures 2A•31

33.6 Measuring a piston ring end gap

using a feeler blade34.8 Main bearing cap identification mark

(arrowed) - 1.6 litre engine34.17 Main bearing shell tag (arrowed)

engages with groove in cylinder block -

2.0 litre SOHC engine

33.5C Sectional view showing correct

orientation of piston rings - all engines33.5B Removing the centre section of the

oil control ring - 2.0 litre SOHC engine

2A

A good alternative to

compressed air, is to use a

water dispersing lubricant

spray into each hole, using

the spout provided.

Page 229 of 525

19Note that the central bearing shells have

thrust flanges which control crankshaft

endfloat (see illustration). Note also that the

shells fitted to the crankcase all have oil duct

holes, while only the centre main bearing cap

shell has an oil duct hole.

20When the shells are firmly located in the

crankcase and the bearing caps, lubricate

them with clean engine oil.

21Fill the lips of a new crankshaft rear oil

seal with grease, and fit it to the end of the

crankshaft.

22Carefully lower the crankshaft into

position in the crankcase (see illustration).

23If necessary, seat the crankshaft using

light blows with a rubber hammer on the

crankshaft balance webs.

24Lubricate the main bearing journals and

shells (see illustration), and then fit numbers

2, 3 and 4 main bearing caps, and tighten the

new bolts as far as possible by hand.25Fill the side grooves of the rear main

bearing cap with RTV jointing compound

(Vauxhall part No 90485251, or equivalent).

Coat the lower surfaces of the bearing cap

with sealing compound (Vauxhall part No 15

04 200, or equivalent), (see illustrations). Fit

the bearing cap, and tighten the new bolts as

far as possible by hand.

26Fit the front (No 1) main bearing cap, and

tighten the new bolts as far as possible by

hand, ensuring that the bearing cap is exactly

flush with the end face of the cylinder block.

27Working from the centre bearing cap

outwards, tighten the bearing cap securing

bolts to the specified torque in the two stages

given in the Specifications; i.e. tighten all bolts

to Stage 1, then tighten all bolts to Stage 2

and Stage 3 (see illustrations).28When all bolts have been fully tightened,

inject further RTV jointing compound into the

side grooves of the rear main bearing cap,

until it is certain that they are full.

29Now rotate the crankshaft, and check that

it turns freely, with no signs of binding or tight

spots.

30Check that the crankshaft endfloat is

within the specified limits, using a dial gauge,

or by inserting a feeler blade between the

thrust flange of the centre main bearing shell

and the machined surface of the crankshaft

(see illustrations). Before measuring, ensure

that the crankshaft is fully forced towards one

end of the crankcase, to give the widest

possible gap at the measuring location.

Incorrect endfloat will most likely be due to

crankshaft wear or to incorrect regrinding,

assuming that the correct bearing shells have

been fitted.

2A•32SOHC engine procedures

34.19 Fitting a central main bearing shell.

Note thrust flanges -

2.0 litre SOHC engine34.24 Lubricate the main bearing shells

before fitting the caps -

2.0 litre SOHC engine

34.30B . . .or a feeler blade -

2.0 litre SOHC engine

34.27A Tighten the main bearing cap bolts

to the specified torque . . .

34.27B . . .then through the specified

angle - 2.0 litre SOHC engine34.30A Check crankshaft endfloat using a

dial gauge . . .

34.25B . . .and the lower surfaces with

sealing compound -

2.0 litre SOHC engine34.25A Fill the side grooves of the rear

main bearing cap with RTV jointing

compound . . .

34.22 Lowering the crankshaft into the

crankcase -

2.0 litre SOHC engine

Page 230 of 525

31Refit the previously removed

components, referring to the relevant

Sections of this Chapter.

35Crankshaft and bearings -

examination

4

Examination

1Examine the crankpin and main journal

surfaces for signs of scoring or scratches, and

check the ovality and taper of the crankpins

and main journals. If the bearing surface

dimensions do not fall within the tolerance

ranges given in the Specifications at the

beginning of this Chapter, the crankpins

and/or main journals will have to be reground.

2Big-end and crankpin wear is accompanied

by distinct metallic knocking, particularly

noticeable when the engine is pulling from low

revs, and some loss of oil pressure.

3Main bearing and main journal wear is

accompanied by severe engine vibration rumble

- getting progressively worse as engine rev’s

increase - and again by loss of oil pressure.

4If the crankshaft requires regrinding, take it

to an engine reconditioning specialist, who

will machine it for you and supply the correct

undersize bearing shells.

5Inspect the big-end and main bearing shells

for signs of general wear, scoring, pitting and

scratches. The bearings should be matt grey

in colour. With leadindium bearings, should a

trace of copper colour be noticed, the

bearings are badly worn, as the lead bearing

material has worn away to expose the indium

underlay. Renew the bearings if they are in

this condition, or if there are any signs of

scoring or pitting. You are strongly advised

to renew the bearings - regardless of their

condition at time of major overhaul.

Refitting used bearings is a false economy.

6The undersizes available are designed to

correspond with crankshaft regrind sizes. Thebearings are in fact, slightly more than the

stated undersize, as running clearances have

been allowed for during their manufacture.

7Main and big-end bearing shells can be

identified as to size by the marking on the

back of the shell. Standard size shell bearings

are marked STD or .00, undersize shells are

marked with the undersize such as 0.020 u/s.

This marking method applies only to

replacement bearing shells, and not to those

used during production.

8An accurate method of determining bearing

wear is by using a Plastigage. The crankshaft

is located in the main bearings (and, if

necessary, the big-end bearings), and the

Plastigage filament is located across the

journal. Vauxhall recommend that the

crankshaft journal and bearing shells are

lightly lubricated, to prevent the Plastigage

from tearing as the bearing cap is removed.

The bearing cap should be fitted, and the

bolts tightened to the specified torque. The

cap is then removed, and the width of the

filament is checked against a scale that shows

the bearing running clearance. The clearance

should be compared with that given in the

Specifications.

9Where applicable, check the teeth of the

crankshaft TDC sensor wheel for damage

(see illustration). If evident, the crankshaft

must be renewed.

10Similarly, check the condition of the pins

in the front crankshaft balance weight, which

serve as detect points for the plug-in

diagnostic sensor used by Vauxhall dealers

(see illustration).

36Cylinder block and bores -

examination and renovation

4

Examination

1Examine the cylinder bores for taper,

ovality, scoring and scratches. Start bycarefully examining the top of the cylinder

bores. If they are at all worn, a very slight

ridge will be found on the thrust side. This

marks the top of the piston ring travel. The

owner will have a good indication of the bore

wear before dismantling the engine, or

removing the cylinder head. Excessive oil

consumption, accompanied by blue smoke

from the exhaust, is a sure sign of worn

cylinder bores and piston rings.

2Measure the bore diameter across the

block, and just below any ridge. This can be

done with an internal micrometer or a dial

gauge. Compare this with the diameter of the

bottom of the bore, which is not subject to

wear. If no measuring instruments are

available, use a piston from which the rings

have been removed, and measure the gap

between it and the cylinder wall with a feeler

blade. Refer to the Specifications. If the

cylinder wear exceeds the permitted

tolerances, then the cylinders will need

reboring, in which case note the following

points:

a)Piston and cylinder bores are closely

matched in production. The actual

diameter of the piston is indicated by

numbers on its crown; the same numbers

stamped on the crankcase indicate the

bore diameter

b)After reboring has taken place, the

cylinder bores should be measured

accurately and oversize pistons selected

from the grades available to give the

specified piston-to-bore clearance

c)For grading purposes, the piston diameter

is measured across the bottom of the skirt

3If the wear is marginal and within the

tolerances given, new special piston rings can

be fitted to offset the wear.

4Thoroughly examine the crankcase and

cylinder block for cracks and damage, and

use a piece of wire to probe all oilways and

waterways to ensure that they are

unobstructed.

SOHC engine procedures 2A•33

35.10 Check the condition of the pins (arrowed) in the front

crankshaft balance weight - 2.0 litre SOHC engine35.9 Check the condition of the TDC sensor wheel teeth at the

front of the crankshaft - 2.0 litre SOHC engine

2A

Page 231 of 525

5Note that the rubber plug located next to

the bellhousing flange on the cylinder block

covers the aperture for the installation of a

diagnostic TDC sensor. The sensor, when

connected to a monitoring unit, indicates TDC

from the position of the pins set into the

crankshaft balance weight.

37Examination and renovation

-general

4

General

1With the engine completely stripped, clean all

components and examine them for wear. Each

component should be checked, and where

necessary renewed or renovated, as described

in the relevant Sections of this Chapter.

2Renew main and big-end bearing shells as

a matter of course, unless it is known that

they have had little wear, and are in perfect

condition.

3If in doubt whether to renew a component

that is still just serviceable, consider the time

and effort that will be incurred should the

component fail at an early date after rebuild.

Obviously, the age and expected life of the

vehicle must influence the standards applied.4Gaskets, oil seals and O-rings must all be

renewed as a matter of routine. Flywheel,

cylinder head, and main and big-end bearing

cap bolts must be renewed, because of the

high stress to which they are subjected.

5Renew the engine core plugs while they are

easily accessible, if they show signs of

leakage. Knock out the old plugs with a

hammer and chisel or punch. Clean the plug

seats, smear the new plugs with sealing

compound, and tap them squarely into

position.

38Initial start-up after major

overhaul or repair

2

1Make a final check to ensure that

everything has been reconnected to the

engine, and that no rags or tools have been

left in the engine compartment.

2Check that oil and coolant levels are

correct.

3Start the engine. This may take a little longer

than usual, as fuel is pumped to the engine.

4Check that the oil pressure warning lamp

goes out when the engine starts. This may

take a few seconds as the new oil filter fills

with oil.5Run the engine at a fast tickover, and check

for leaks of oil, fuel and coolant. If a new

camshaft has been fitted, pay careful

attention to the running-in procedure given in

Section 18, paragraphs 17 and 18. Where

applicable, check the power steering and/or

automatic transmission fluid cooler unions for

leakage. Some smoke and odd smells may be

experienced, as assembly lubricants and

sealers burn off the various components.

6Bring the engine to normal operating

temperature. Check the ignition timing, idle

speed and the mixture (where applicable), as

described in Chapter 4A or 4B.

7Allow the engine to cool, then recheck the

oil and coolant levels. Top-up if necessary

8If new bearings, pistons, etc., have been

fitted, the engine should be run-in at reduced

speeds and loads for the first 500 miles (800

km) or so. It is beneficial to change the engine

oil and filter after this mileage.

2A•34SOHC engine procedures

Page 233 of 525

1General description

Engine cooling is achieved by a

conventional pump-assisted system, in which

the coolant is pressurised. The system

consists of a radiator, a coolant pump driven

by the engine timing belt, an electric cooling

fan, a thermostat, an expansion tank, and

connecting hoses. Hoses also carry coolant to

and from the heater matrix, which provides

heat for the ventilation and heating system.

The system works in the following way.

Cold coolant from one side of the radiator,

which is mounted at the front of the engine

compartment, passes to the coolant pump,

which forces the coolant through the coolant

passages in the cylinder block and cylinder

head. The coolant absorbs heat from the

engine, and then returns to the radiator

through the heater matrix. As the coolant

flows across the radiator it is cooled, and the

cycle is repeated.

Air flows through the radiator, to cool the

coolant as a result of the vehicle’s forward

motion. However, if the coolant temperature

exceeds a given figure, a

temperature-sensitive switch in the radiator

switches on the electric fan, to increase the

airflow through the radiator. The fan only

operates when necessary, with a consequent

reduction in noise and energy consumption.

To reduce the time taken for the engine to

warm up when starting from cold, the

thermostat, located in the cylinder head

outlet, prevents coolant flowing to the radiator

until the temperature has risen sufficiently.

Instead, the outflow from the cylinder head

bypasses the radiator, and is redirected

around the engine. When the temperature

reaches a given figure, the thermostat opens,

to allow coolant to flow to the radiator. The

thermostat is operated by the expansion of a

temperature sensitive wax capsule.

An expansion tank is incorporated in the

system, to allow for coolant expansion. The

system is topped up through a filler cap on

the expansion tank.

Note that later models may be fitted with

self-tensioning spring clamps to secure the

cooling system (including heater) hoses.

These clamps can be released by squeezing

together their free ends using a large pair of

self-grip pliers or similar so that the clamp can

be moved up the hose, clear of the union.

Check that the clamp is securely seated, and

check for leaks on reassembly.

2Cooling system -draining

2

1With the vehicle parked on level ground,

remove the expansion tank filler cap. If the

engine is warm, cover the filler cap with a

thick cloth, and unscrew the cap slowly, to

gradually relieve the system pressure. Take

care to avoid scalding by steam or coolant

escaping from the pressurised system.

2On DOHC models, remove the engine

undershield, with reference to Chapter 11.

3Position a container beneath the radiator

bottom hose connection, then slacken the

hose clip and ease the hose from the radiator

stub. If the hose joint has not been disturbed

for some time, it will be necessary to

manipulate the hose to break the joint. Allow

the coolant to drain into the container.

4As no cylinder block drain plug is fitted, and

the radiator bottom hose may be situated

halfway up the radiator, the system cannot be

drained completely. Care should therefore be

taken when refilling the system to maintain

antifreeze strength.

5If the coolant has been drained for a reason

other than renewal, then provided it is clean

and less than two years old, it can be re-used.

6If the coolant has been drained for renewal,

and is badly contaminated, the coolant

system should be flushed as described in

Section 4. As the system cannot be drained

completely, it is advisable to flush the system

whenever the coolant is renewed, to minimise

the impurities remaining in the system.

3Cooling system -flushing

2

1If coolant renewal has been neglected, or if

the antifreeze mixture has become diluted,

then in time the cooling system will gradually

lose efficiency, as the coolant passages

become restricted due to rust, scale deposits

and other sediment. To restore coolant

system efficiency, it is necessary to flush the

system clean.

2The radiator should be flushed

independently of the engine, to avoid

unnecessary contamination.

3To flush the radiator, disconnect the top

hose at the radiator, then insert a garden hose

into the radiator top inlet. Direct a flow of

clean water through the radiator, and continue

flushing until clean water emerges from the

radiator bottom outlet (the bottom hose

should have been disconnected to drain the

system). If after a reasonable period, the water

still does not run clear, the radiator can be

flushed with a good proprietary cleaning

agent. It is important that the manufacturer’s

instructions are followed carefully. If the

contamination is particularly bad, insert the

hose in the radiator bottom outlet, and flush

the radiator in reverse.

4To flush the engine, continue as follows.

1.4 and 1.6 litre models (except

C16 NZ2)

5Remove the thermostat as described in

Section 9, then temporarily refit the

thermostat cover.

6With the radiator top and bottom hoses

disconnected from the radiator, insert a

garden hose into the radiator bottom hose.

Direct a flow of clean water through the

engine, and continue flushing until clean water

emerges from the radiator top hose.

7On completion of flushing, refit the

thermostat, and reconnect the hoses.

C16 NZ2, 1.8 and 2.0 litre

models

8Remove the thermostat and cover

assembly, as described in Section 9.

9With the radiator bottom hose

disconnected from the radiator, insert a

garden hose into the radiator bottom hose.

Direct a flow of clean water through the

engine, and continue flushing until clean water

emerges from the thermostat housing. It is

advisable to place a sheet of plastic under the

thermostat housing to deflect water away

from the engine and surrounding components

during the flushing process.

10On completion of flushing, refit the

thermostat and cover assembly, reconnect

the hoses and remove the sheet of plastic.

4Cooling system -filling

2

1Before attempting to fill the cooling system,

make sure that all hoses and clips are in good

condition, and that the clips are tight. Note

that an antifreeze mixture must be used all

year round, to prevent corrosion of the alloy

engine components -refer to Section 5.

2On 1.4 and 1.6 litre models (except C16

NZ2), disconnect the wire and unscrew the

coolant temperature sender from the inlet

manifold.

3Remove the expansion tank cap, and fill the

system by slowly pouring the coolant into the

expansion tank to prevent air locks from

forming.

4If the coolant is being renewed, begin by

pouring in a couple of pints of water, followed

by the correct quantity of antifreeze (see

Section 5), then top-up with more water.

5On 1.4 and 1.6 litre models (except C16

NZ2), refit the coolant temperature sender

when coolant free of air bubbles emerges

from the orifice in the inlet manifold.

6Top-up the coolant level to the “COLD” (or

“KALT”) mark on the expansion tank, then refit

the expansion tank cap.

7Start the engine and run it until it reaches

normal operating temperature, then stop the

engine and allow it to cool.

8Check for leaks, particularly around

disturbed components. Check the coolant

3•2Cooling, heating and ventilation systems

When renewing any hoses,

use a little soapy water as a

lubricant, or soften the hose

in hot water. Do not use oil or

grease, as this may attack the rubber.

Page 234 of 525

level in the expansion tank, and top-up if

necessary. Note that the system must be cold

before an accurate level is indicated in the

expansion tank. If the expansion tank cap is

removed while the engine is still warm, cover

the cap with a thick cloth and unscrew the

cap slowly, to gradually relieve the system

pressure. Take care to avoid scalding by

steam or coolant escaping from the

pressurised system.

9On DOHC models, refit the engine

undershield on completion.

5Coolant mixture -general

1It is important to use an antifreeze mixture

in the cooling system all year round, to

prevent corrosion of the alloy engine

components. The coolant mixture should be

made up from clean, preferably soft, tap

water, and a good quality antifreeze

containing corrosion inhibitor. Ensure that the

antifreeze is ethylene glycol based, as the

cheaper methanol based types evaporate

over a period of time.

2The proportions of water and antifreeze

used will depend on the degree of protection

required. A coolant mixture containing 25%

antifreeze should be regarded as the

minimum strength required to maintain good

anti-corrosion properties. Details of the

degree of protection provided against freezing

will be supplied with the antifreeze by the

manufacturers. For absolute protection, use a

50% antifreeze mixture.

3The coolant mixture should be renewed

every two years, as the corrosion inhibitors

will deteriorate with time.

4Before filling the system with fresh coolant,

drain and flush the system, as described in

Sections 2 and 3, and check that all hoses are

secure and that the clips are tight. Antifreeze

has a searching action, and will leak morerapidly than plain water.

5Refill the system as described in Section 4.

All future topping-up should be carried out

using a coolant mixture of the same

proportions as that used to initially fill the

system.

6Do not use antifreeze in the windscreen

wash system, as it will attack the vehicle

paintwork. Note that antifreeze is poisonous,

and must be handled with due care.

6Radiator (manual

transmission) -removal and

refitting

3

Removal

1The radiator can be removed complete with

the coolant fan and shroud if there is no need

to disturb the fan. If desired, the fan and its

shroud can be removed from the radiator,

with reference to Section 12.

2Drain the cooling system, as described in

Section 2.

3Disconnect the radiator top hose and the

expansion tank at the radiator.

4Disconnect the battery negative lead, then

disconnect the wiring from the cooling fan

switch, located at the bottom right-hand side

of the radiator.5Disconnect the cooling fan wiring

connector, noting its location for use when

refitting.

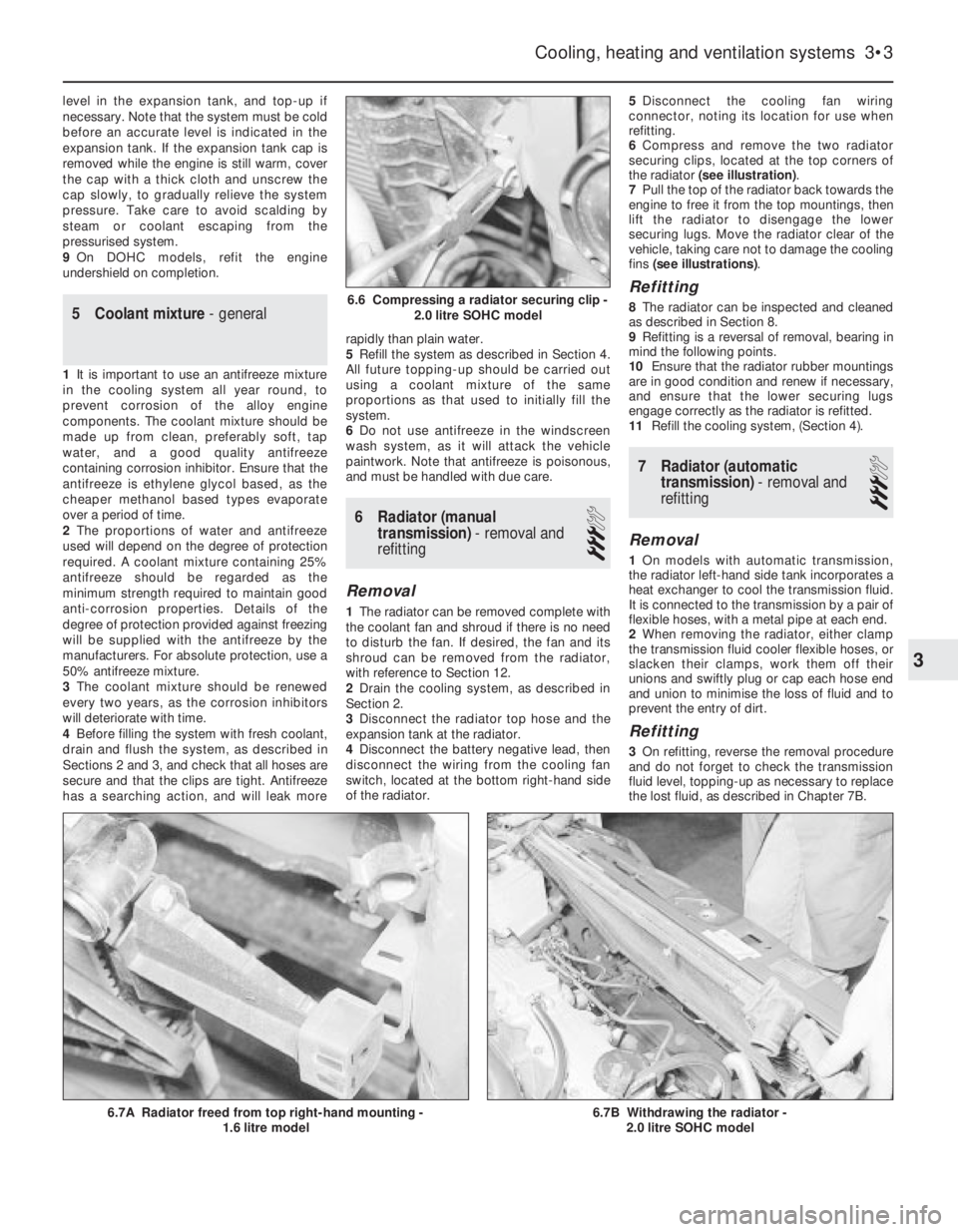

6Compress and remove the two radiator

securing clips, located at the top corners of

the radiator (see illustration).

7Pull the top of the radiator back towards the

engine to free it from the top mountings, then

lift the radiator to disengage the lower

securing lugs. Move the radiator clear of the

vehicle, taking care not to damage the cooling

fins (see illustrations).

Refitting

8The radiator can be inspected and cleaned

as described in Section 8.

9Refitting is a reversal of removal, bearing in

mind the following points.

10Ensure that the radiator rubber mountings

are in good condition and renew if necessary,

and ensure that the lower securing lugs

engage correctly as the radiator is refitted.

11Refill the cooling system, (Section 4).

7Radiator (automatic

transmission) -removal and

refitting

3

Removal

1On models with automatic transmission,

the radiator left-hand side tank incorporates a

heat exchanger to cool the transmission fluid.

It is connected to the transmission by a pair of

flexible hoses, with a metal pipe at each end.

2When removing the radiator, either clamp

the transmission fluid cooler flexible hoses, or

slacken their clamps, work them off their

unions and swiftly plug or cap each hose end

and union to minimise the loss of fluid and to

prevent the entry of dirt.

Refitting

3On refitting, reverse the removal procedure

and do not forget to check the transmission

fluid level, topping-up as necessary to replace

the lost fluid, as described in Chapter 7B.

Cooling, heating and ventilation systems 3•3

6.7B Withdrawing the radiator -

2.0 litre SOHC model6.7A Radiator freed from top right-hand mounting -

1.6 litre model

6.6 Compressing a radiator securing clip -

2.0 litre SOHC model

3