boot OPEL CALIBRA 1988 Service User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 138 of 525

18If both brake assemblies are dismantled

at the same time, take care not to mix up the

components. Note that the left-hand and

right-hand adjuster components are marked.

The threaded rod is marked “L” or “R”, and

the other “handed” components are colour-

coded black for the left-hand side, and silver

for the right-hand side.

19Dismantle and clean the adjuster strut.

Apply a smear of silicone-based grease to the

adjuster threads.

20Examine the return springs. If they are

distorted, or if they have seen extensiveservice, renewal is advisable. Weak springs

may cause the brakes to bind.

21If a new handbrake operating lever was

not supplied with the new shoes (where

applicable), transfer the lever from the old

shoes. The lever may be secured with a pin

and circlip, or by a rivet, which will have to be

drilled out.

22If the components are to be refitted as an

assembly, assemble the new shoes, springs

and adjuster components. Expand the

adjuster strut to ease fitting (see

illustrations).

23Offer the shoes to the brake backplate. Be

careful not to damage the wheel cylinder

boots, or to displace the pistons. Remember

to remove the rubber band or spring clip from

the wheel cylinder, where applicable.

24When the shoes are in position, insert the

hold-down pins and secure them with the

springs and cups (see illustration).

25Reconnect the handbrake cable, then refit

the hub, and adjust the bearing if the hub was

removed.

26Fitting the shoes and springs together as

an assembly may be too difficult. It is possible

to fit the shoes and secure them with the

hold-down pins and then fit the adjuster strut,

the return springs and adjuster.27Back off the adjuster wheel to reduce the

length of the strut, until the brake drum will

pass over the shoes.

28Make sure that the handbrake operating

lever is correctly positioned, with the pin on

the edge of the shoe web, not riding on top of

it, then refit and secure the brake drum.

29Repeat the operations on the remaining

side of the vehicle.

30Adjust the brakes by operating the

footbrake at least fifteen times. A clicking

noise will be heard at the drums, as the

automatic adjusters operate. When the

clicking stops, adjustment is complete.

31Check the handbrake adjustment, as

described in Section 26.

32Refit the roadwheels, and lower the

vehicle to the ground. Do not fully tighten the

roadwheel bolts until the vehicle is resting on

its wheels.

33New brake linings should be carefully

bedded-in and, where possible, heavy braking

should be avoided during the first 100 miles

(160 km) or so after fitting new linings.

7Handbrake shoes (rear disc

brakes) - inspection, removal

and refitting

3

Note: When working on the brake

components, take care not to disperse brake

dust into the air, or to inhale it, since it may

contain asbestos, which can damage your

health.

Inspection

1Although 2.0 litre models are fitted with rear

disc brakes, the handbrake operates

independently of the footbrake, using brake

shoes on the inside of the disc in a similar way

to rear drum brake models.

2To inspect the handbrake shoes on all

SOHC models, it is necessary to remove the

hub/disc, as described in Chapter 10.

3To inspect the handbrake shoes on DOHC

models it will be necessary to remove the

brake disc, as described in Section 10.

4With the hub/disc or the disc (as applicable)

removed, check that the friction material has

not worn down to less than the specified

minimum.

Braking system 9•7

6.22A Right-hand adjuster strut correctly

fitted to shoes

6.24 Rear brake components correctly

assembled (hub removed for clarity)6.22C Adjuster lever spring fitted to

leading shoe6.22B Fitting the upper return spring to

the shoes

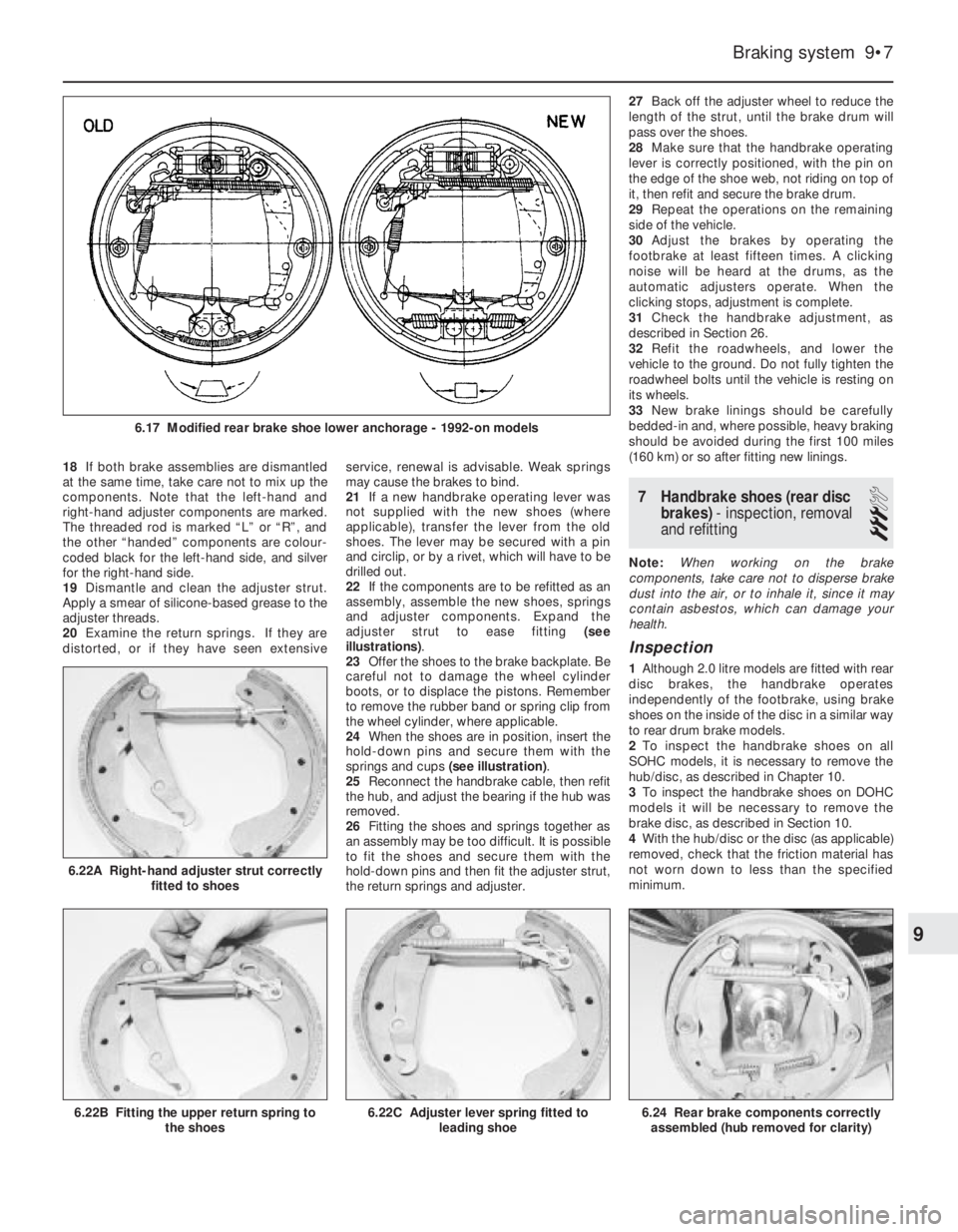

6.17 Modified rear brake shoe lower anchorage - 1992-on models

9

Page 183 of 525

14Brake fluid renewal

3

Renew the brake and bleed the system.

Refer to Chapter 9 for full details.

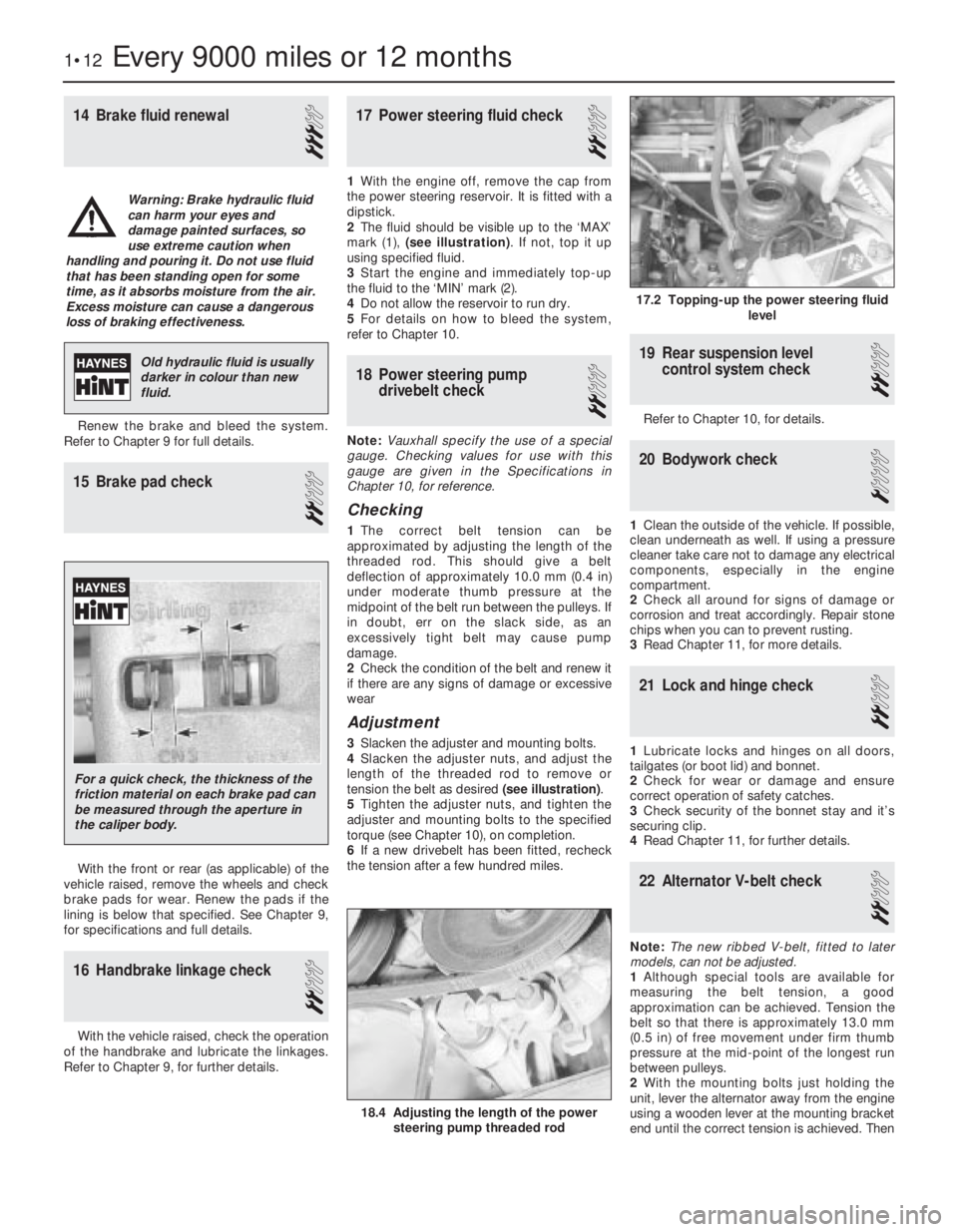

15Brake pad check

2

With the front or rear (as applicable) of the

vehicle raised, remove the wheels and check

brake pads for wear. Renew the pads if the

lining is below that specified. See Chapter 9,

for specifications and full details.

16Handbrake linkage check

2

With the vehicle raised, check the operation

of the handbrake and lubricate the linkages.

Refer to Chapter 9, for further details.

17Power steering fluid check

2

1With the engine off, remove the cap from

the power steering reservoir. It is fitted with a

dipstick.

2The fluid should be visible up to the ‘MAX’

mark (1), (see illustration). If not, top it up

using specified fluid.

3Start the engine and immediately top-up

the fluid to the ‘MIN’ mark (2).

4Do not allow the reservoir to run dry.

5For details on how to bleed the system,

refer to Chapter 10.

18Power steering pump

drivebelt check

2

Note:Vauxhall specify the use of a special

gauge. Checking values for use with this

gauge are given in the Specifications in

Chapter 10, for reference.

Checking

1The correct belt tension can be

approximated by adjusting the length of the

threaded rod. This should give a belt

deflection of approximately 10.0 mm (0.4 in)

under moderate thumb pressure at the

midpoint of the belt run between the pulleys. If

in doubt, err on the slack side, as an

excessively tight belt may cause pump

damage.

2Check the condition of the belt and renew it

if there are any signs of damage or excessive

wear

Adjustment

3Slacken the adjuster and mounting bolts.

4Slacken the adjuster nuts, and adjust the

length of the threaded rod to remove or

tension the belt as desired (see illustration).

5Tighten the adjuster nuts, and tighten the

adjuster and mounting bolts to the specified

torque (see Chapter 10), on completion.

6If a new drivebelt has been fitted, recheck

the tension after a few hundred miles.

19Rear suspension level

control system check

2

Refer to Chapter 10, for details.

20Bodywork check

1

1Clean the outside of the vehicle. If possible,

clean underneath as well. If using a pressure

cleaner take care not to damage any electrical

components, especially in the engine

compartment.

2Check all around for signs of damage or

corrosion and treat accordingly. Repair stone

chips when you can to prevent rusting.

3Read Chapter 11, for more details.

21Lock and hinge check

2

1Lubricate locks and hinges on all doors,

tailgates (or boot lid) and bonnet.

2Check for wear or damage and ensure

correct operation of safety catches.

3Check security of the bonnet stay and it’s

securing clip.

4Read Chapter 11, for further details.

22Alternator V-belt check

2

Note:The new ribbed V-belt, fitted to later

models, can not be adjusted.

1Although special tools are available for

measuring the belt tension, a good

approximation can be achieved. Tension the

belt so that there is approximately 13.0 mm

(0.5 in) of free movement under firm thumb

pressure at the mid-point of the longest run

between pulleys.

2With the mounting bolts just holding the

unit, lever the alternator away from the engine

using a wooden lever at the mounting bracket

end until the correct tension is achieved. Then

1•12Every 9000 miles or 12 months

17.2 Topping-up the power steering fluid

level

18.4 Adjusting the length of the power

steering pump threaded rod

Warning: Brake hydraulic fluid

can harm your eyes and

damage painted surfaces, so

use extreme caution when

handling and pouring it. Do not use fluid

that has been standing open for some

time, as it absorbs moisture from the air.

Excess moisture can cause a dangerous

loss of braking effectiveness.

Old hydraulic fluid is usually

darker in colour than new

fluid.

For a quick check, the thickness of the

friction material on each brake pad can

be measured through the aperture in

the caliper body.

Page 246 of 525

Tools and Working Facilities REF•7

REF

Special tools

The tools in this list are those which are not

used regularly, are expensive to buy, or which

need to be used in accordance with their

manufacturers’ instructions. Unless relatively

difficult mechanical jobs are undertaken

frequently, it will not be economic to buy

many of these tools. Where this is the case,

you could consider clubbing together with

friends (or joining a motorists’ club) to make a

joint purchase, or borrowing the tools against

a deposit from a local garage or tool hire

specialist. It is worth noting that many of the

larger DIY superstores now carry a large

range of special tools for hire at modest rates.

The following list contains only those tools

and instruments freely available to the public,

and not those special tools produced by the

vehicle manufacturer specifically for its dealer

network. You will find occasional references

to these manufacturers’ special tools in the

text of this manual. Generally, an alternative

method of doing the job without the vehicle

manufacturers’ special tool is given. However,

sometimes there is no alternative to using

them. Where this is the case and the relevant

tool cannot be bought or borrowed, you will

have to entrust the work to a dealer.

MValve spring compressor

MValve grinding tool

MPiston ring compressor

MPiston ring removal/installation tool

MCylinder bore hone

MBalljoint separator

MCoil spring compressors (where applicable)

MTwo/three-legged hub and bearing puller

MImpact screwdriver

MMicrometer and/or vernier calipers

MDial gauge

MStroboscopic timing light

MDwell angle meter/tachometer

MUniversal electrical multi-meter

MCylinder compression gauge

MHand-operated vacuum pump and gauge

MClutch plate alignment set

MBrake shoe steady spring cup removal tool

MBush and bearing removal/installation set

MStud extractors

MTap and die set

MLifting tackle

MTrolley jack

Buying tools

Reputable motor accessory shops and

superstores often offer excellent quality tools

at discount prices, so it pays to shop around.

Remember, you don’t have to buy the most

expensive items on the shelf, but it is always

advisable to steer clear of the very cheap

tools. Beware of ‘bargains’ offered on market

stalls or at car boot sales. There are plenty of

good tools around at reasonable prices, but

always aim to purchase items which meet the

relevant national safety standards. If in doubt,

ask the proprietor or manager of the shop for

advice before making a purchase.

Care and maintenance of tools

Having purchased a reasonable tool kit, it is

necessary to keep the tools in a clean and

serviceable condition. After use, always wipe

off any dirt, grease and metal particles using a

clean, dry cloth, before putting the tools away.

Never leave them lying around after they have

been used. A simple tool rack on the garage

or workshop wall for items such as

screwdrivers and pliers is a good idea. Store

all normal spanners and sockets in a metal

box. Any measuring instruments, gauges,

meters, etc, must be carefully stored where

they cannot be damaged or become rusty.

Take a little care when tools are used.

Hammer heads inevitably become marked,

and screwdrivers lose the keen edge on their

blades from time to time. A little timely

attention with emery cloth or a file will soon

restore items like this to a good finish.

Working facilities

Not to be forgotten when discussing tools

is the workshop itself. If anything more than

routine maintenance is to be carried out, a

suitable working area becomes essential.

It is appreciated that many an owner-

mechanic is forced by circumstances to

remove an engine or similar item without the

benefit of a garage or workshop. Having done

this, any repairs should always be done under

the cover of a roof.

Wherever possible, any dismantling should

be done on a clean, flat workbench or table at

a suitable working height.

Any workbench needs a vice; one with a jaw

opening of 100 mm is suitable for most jobs.

As mentioned previously, some clean dry

storage space is also required for tools, as well

as for any lubricants, cleaning fluids, touch-up

paints etc, which become necessary.

Another item which may be required, and

which has a much more general usage, is an

electric drill with a chuck capacity of at least 8

mm. This, together with a good range of twist

drills, is virtually essential for fitting

accessories.

Last, but not least, always keep a supply of

old newspapers and clean, lint-free rags

available, and try to keep any working area as

clean as possible.

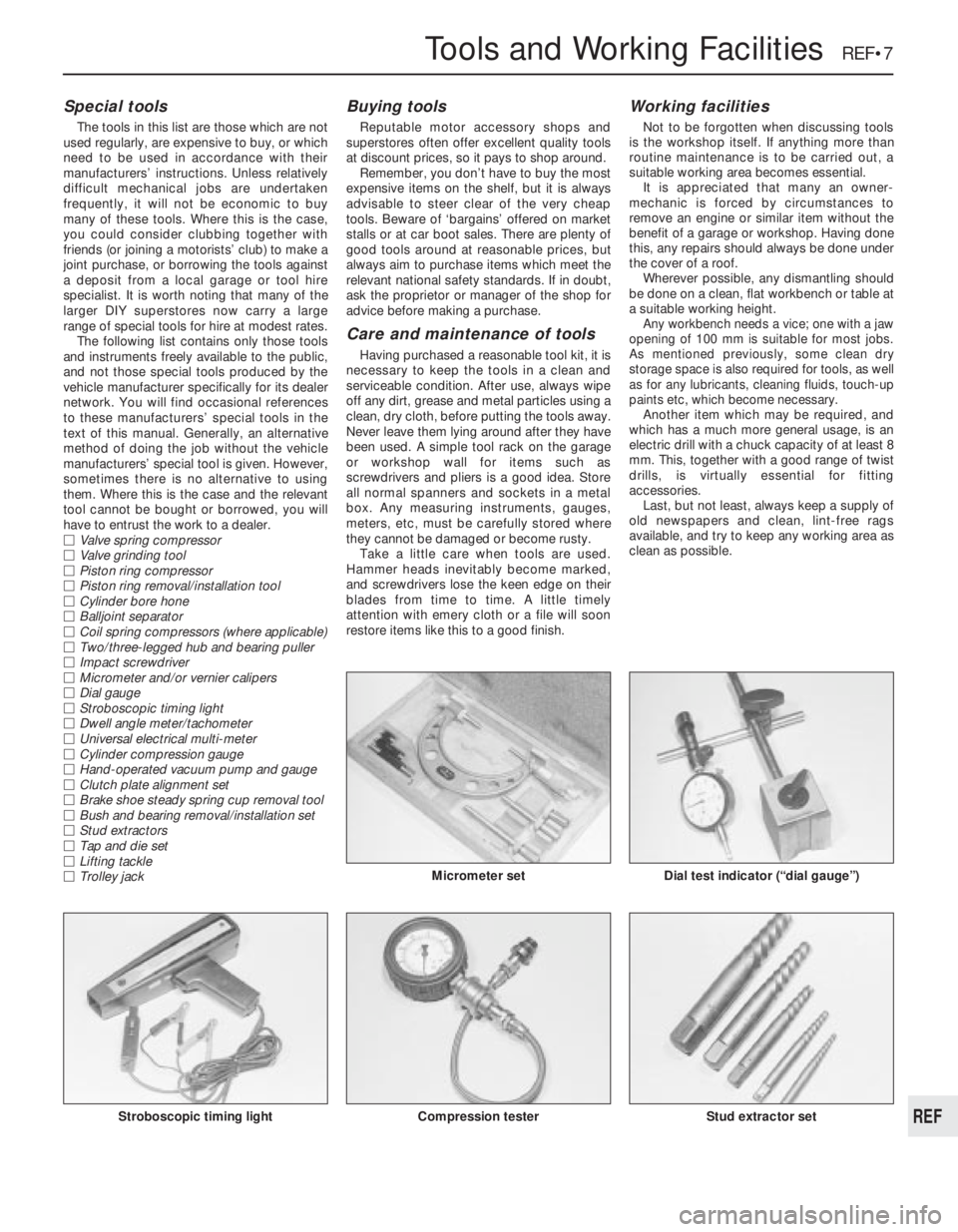

Stroboscopic timing light Stud extractor setCompression tester

Dial test indicator (“dial gauge”)Micrometer set

Page 252 of 525

The pages that follow provide an easy-reference guide to the more

common problems that may occur during the operation of the vehicle.

These problems and their possible causes are grouped under headings

denoting various components or systems, such as Engine, Cooling

system, etc. The Chapter and/or Section that deals with the problem is

also shown in brackets. Whatever the fault, certain basic principles

apply. These are as follows:

Verify the fault. This is simply a matter of being sure that you know

what the symptoms are before starting work. This is particularly

important if you are investigating a fault for someone else, who may

not have described it very accurately.

Do not overlook the obvious. For example, if the vehicle will not start,

is there petrol in the tank? (Do not take anyone else’s word on this

particular point, and do not trust the fuel gauge either!) If an electrical

fault is indicated, look for loose or broken wires before digging out the

test gear.Cure the disease, not the symptom. Substituting a flat battery with a

fully charged one will get you off the hard shoulder, but if the

underlying cause is not attended to, the new battery will go the same

way. Similarly, changing oil-fouled spark plugs for a new set will get

you moving again, but remember that the reason for the fouling (if it

was not simply an incorrect grade of plug) will have to be established

and corrected.

Do not take anything for granted. Particularly, do not forget that a

“new” component may itself be defective (especially if it’s been rattling

around in the boot for months). Also do not leave components out of a

fault diagnosis sequence just because they are new or recently fitted.

When you do finally diagnose a difficult fault, you will probably realise

that all the evidence was there from the start.

Engine fails to rotate when attempting to start

MBattery terminal connections loose or corroded (Chapter 1).

MBattery discharged or faulty (Chapter 5).

MBroken, loose or disconnected wiring in the starting circuit

(Chapter 5).

MDefective starter solenoid or switch (Chapter 5).

MDefective starter motor (Chapter 5).

MStarter pinion or flywheel ring gear teeth loose or broken

(Chapters 2A and 5).

MEngine earth strap broken or disconnected (Chapter 5).

Engine rotates, but will not start

MFuel tank empty.

MBattery discharged (engine rotates slowly), (Chapter 5).

MBattery terminal connections loose or corroded (Chapter 1).

MIgnition components damp or damaged (Chapters 1 and 5).

MBroken, loose or disconnected wiring in the ignition circuit

(Chapters 1 and 5).

MWorn, faulty or incorrectly gapped spark plugs (Chapter 1).

MChoke mechanism incorrectly adjusted, worn or sticking -

carburettor models (Chapter 4A).

MFaulty fuel cut-off solenoid - carburettor models (Chapter 4A).

MFuel injection system fault - fuel-injected models (Chapter 4B).

MMajor mechanical failure (e.g. camshaft drive), (Chapter 2A or 2B).

Engine difficult to start when cold

MBattery discharged (Chapter 5).

MBattery terminal connections loose or corroded (Chapter 1).

MWorn, faulty or incorrectly gapped spark plugs (Chapter 1).

MChoke mechanism incorrectly adjusted, worn or sticking -

carburettor models (Chapter 4A).

MFuel injection system fault - fuel-injected models (Chapter 4B).

MOther ignition system fault (Chapters 1 and 5).

MLow cylinder compressions (Chapter 2A).

Engine difficult to start when hot

MAir filter element dirty or clogged (Chapter 1).

MChoke mechanism incorrectly adjusted, worn or sticking -

carburettor models (Chapter 4A).

MFuel injection system fault - fuel-injected models (Chapter 4B).

MLow cylinder compressions (Chapter 2A).

Starter motor noisy or excessively rough in

engagement

MStarter pinion or flywheel ring gear teeth loose or broken

(Chapters 2A and 5).

MStarter motor mounting bolts loose or missing (Chapter 5).

MStarter motor internal components worn or damaged (Chapter 5).

Engine starts, but stops immediately

MLoose or faulty electrical connections in the ignition circuit

(Chapters 1 and 5B).

MVacuum leak at the carburettor/throttle body or inlet manifold

(Chapter 4A or 4B).

MBlocked carburettor jet(s) or internal passages - carburettor

models (Chapter 4A).

MBlocked injector/fuel injection system fault - fuel-injected models

(Chapter 4B).

Engine idles erratically

MAir filter element clogged (Chapter 1).

MVacuum leak at the carburettor/throttle body, inlet manifold or

associated hoses (Chapter 4A or 4B).

MWorn, faulty or incorrectly gapped spark plugs (Chapter 1).

MUneven or low cylinder compressions (Chapter 2A).

MCamshaft lobes worn (Chapter 2A or 2B).

MTiming belt incorrectly tensioned (Chapter 2A or 2B).

MBlocked carburettor jet(s) or internal passages - carburettor

models (Chapter 4A).

MBlocked injector/fuel injection system fault - fuel-injected models

(Chapter 4B).

Engine misfires at idle speed

MWorn, faulty or incorrectly gapped spark plugs (Chapter 1).

MFaulty spark plug HT leads (Chapter 1).

MVacuum leak at the carburettor/throttle body, inlet manifold or

associated hoses (Chapter 4A or 4B).

MBlocked carburettor jet(s) or internal passages - carburettor

models (Chapter 4A).

MBlocked injector/fuel injection system fault - fuel-injected models

(Chapter 4B).

MDistributor cap cracked or tracking internally (where applicable),

(Chapter 1).

MUneven or low cylinder compressions (Chapter 2A).

MDisconnected, leaking, or perished crankcase ventilation hoses

(Chapter 4C).

Engine misfires throughout the driving speed

range

MFuel filter choked (Chapter 1).

MFuel pump faulty, or delivery pressure low (Chapter 4A or 4B).

MFuel tank vent blocked, or fuel pipes restricted (Chapter 4A or 4B).

MVacuum leak at the carburettor/throttle body, inlet manifold or

associated hoses (Chapter 4A or 4B).

MWorn, faulty or incorrectly gapped spark plugs (Chapter 1).

MFaulty spark plug HT leads (Chapter 1).

MDistributor cap cracked or tracking internally (where applicable),

(Chapter 1).

Fault Finding REF•13

REF

Engine

Page 264 of 525

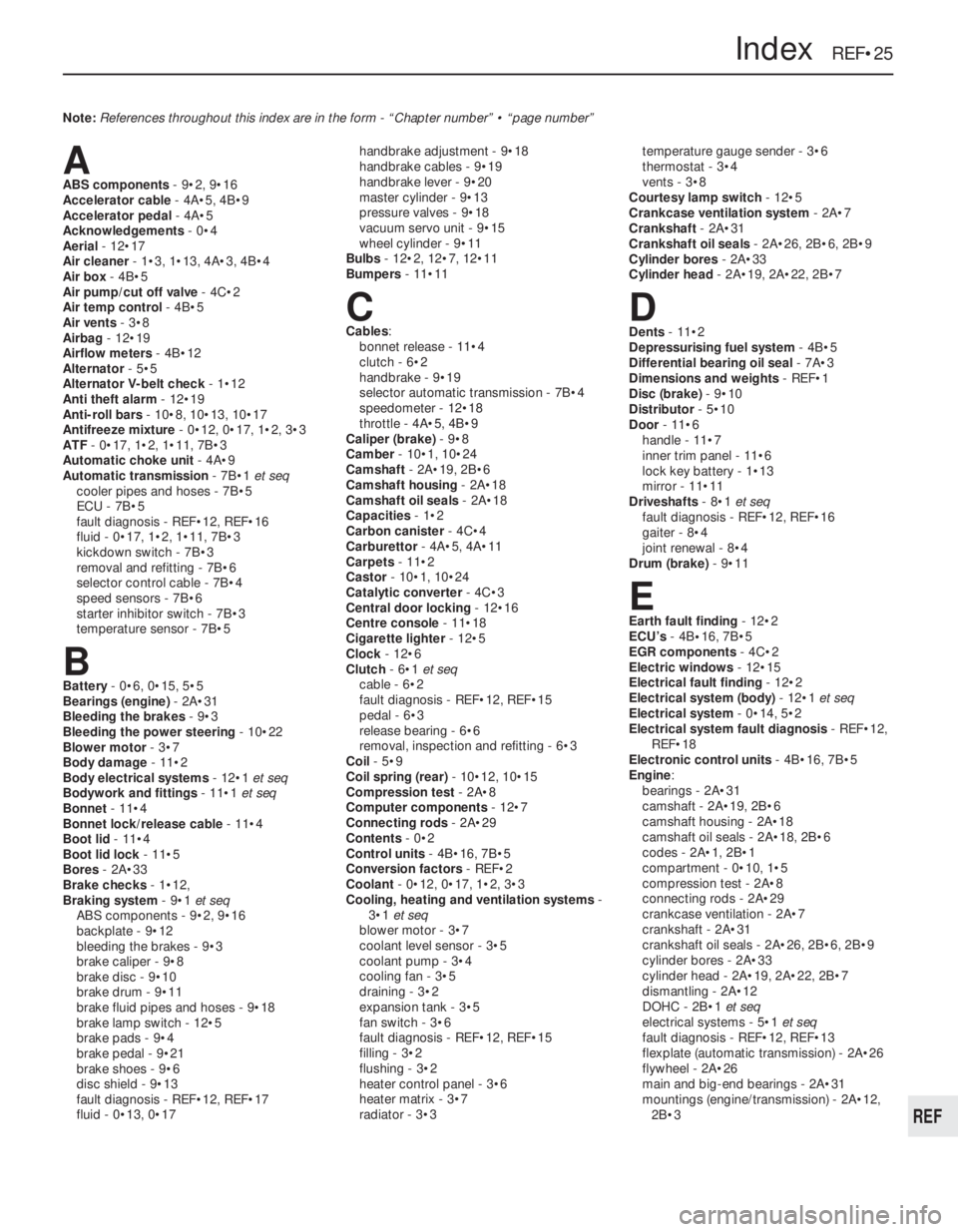

AABS components- 9•2, 9•16

Accelerator cable- 4A•5, 4B•9

Accelerator pedal- 4A•5

Acknowledgements- 0•4

Aerial- 12•17

Air cleaner- 1•3, 1•13, 4A•3, 4B•4

Air box- 4B•5

Air pump/cut off valve- 4C•2

Air temp control- 4B•5

Air vents- 3•8

Airbag- 12•19

Airflow meters- 4B•12

Alternator- 5•5

Alternator V-belt check- 1•12

Anti theft alarm- 12•19

Anti-roll bars- 10•8, 10•13, 10•17

Antifreeze mixture- 0•12, 0•17, 1•2, 3•3

ATF- 0•17, 1•2, 1•11, 7B•3

Automatic choke unit- 4A•9

Automatic transmission- 7B•1 et seq

cooler pipes and hoses - 7B•5

ECU - 7B•5

fault diagnosis - REF•12, REF•16

fluid - 0•17, 1•2, 1•11, 7B•3

kickdown switch - 7B•3

removal and refitting - 7B•6

selector control cable - 7B•4

speed sensors - 7B•6

starter inhibitor switch - 7B•3

temperature sensor - 7B•5

BBattery- 0•6, 0•15, 5•5

Bearings (engine)- 2A•31

Bleeding the brakes- 9•3

Bleeding the power steering- 10•22

Blower motor- 3•7

Body damage- 11•2

Body electrical systems - 12•1 et seq

Bodywork and fittings- 11•1 et seq

Bonnet- 11•4

Bonnet lock/release cable- 11•4

Boot lid- 11•4

Boot lid lock- 11•5

Bores- 2A•33

Brake checks- 1•12,

Braking system- 9•1 et seq

ABS components - 9•2, 9•16

backplate - 9•12

bleeding the brakes - 9•3

brake caliper - 9•8

brake disc - 9•10

brake drum - 9•11

brake fluid pipes and hoses - 9•18

brake lamp switch - 12•5

brake pads - 9•4

brake pedal - 9•21

brake shoes - 9•6

disc shield - 9•13

fault diagnosis - REF•12, REF•17

fluid - 0•13, 0•17handbrake adjustment - 9•18

handbrake cables - 9•19

handbrake lever - 9•20

master cylinder - 9•13

pressure valves - 9•18

vacuum servo unit - 9•15

wheel cylinder - 9•11

Bulbs- 12•2, 12•7, 12•11

Bumpers- 11•11

CCables:

bonnet release - 11•4

clutch - 6•2

handbrake - 9•19

selector automatic transmission - 7B•4

speedometer - 12•18

throttle - 4A•5, 4B•9

Caliper (brake)- 9•8

Camber- 10•1, 10•24

Camshaft- 2A•19, 2B•6

Camshaft housing- 2A•18

Camshaft oil seals- 2A•18

Capacities- 1•2

Carbon canister- 4C•4

Carburettor- 4A•5, 4A•11

Carpets- 11•2

Castor- 10•1, 10•24

Catalytic converter- 4C•3

Central door locking- 12•16

Centre console- 11•18

Cigarette lighter- 12•5

Clock- 12•6

Clutch- 6•1 et seq

cable - 6•2

fault diagnosis - REF•12, REF•15

pedal - 6•3

release bearing - 6•6

removal, inspection and refitting - 6•3

Coil- 5•9

Coil spring (rear)- 10•12, 10•15

Compression test- 2A•8

Computer components- 12•7

Connecting rods- 2A•29

Contents- 0•2

Control units- 4B•16, 7B•5

Conversion factors- REF•2

Coolant- 0•12, 0•17, 1•2, 3•3

Cooling, heating and ventilation systems-

3•1 et seq

blower motor - 3•7

coolant level sensor - 3•5

coolant pump - 3•4

cooling fan - 3•5

draining - 3•2

expansion tank - 3•5

fan switch - 3•6

fault diagnosis - REF•12, REF•15

filling - 3•2

flushing - 3•2

heater control panel - 3•6

heater matrix - 3•7

radiator - 3•3temperature gauge sender - 3•6

thermostat - 3•4

vents - 3•8

Courtesy lamp switch- 12•5

Crankcase ventilation system- 2A•7

Crankshaft- 2A•31

Crankshaft oil seals- 2A•26, 2B•6, 2B•9

Cylinder bores- 2A•33

Cylinder head- 2A•19, 2A•22, 2B•7DDents- 11•2

Depressurising fuel system- 4B•5

Differential bearing oil seal- 7A•3

Dimensions and weights- REF•1

Disc (brake)- 9•10

Distributor- 5•10

Door- 11•6

handle - 11•7

inner trim panel - 11•6

lock key battery - 1•13

mirror - 11•11

Driveshafts- 8•1 et seq

fault diagnosis - REF•12, REF•16

gaiter - 8•4

joint renewal - 8•4

Drum (brake)- 9•11

EEarth fault finding- 12•2

ECU’s - 4B•16, 7B•5

EGR components- 4C•2

Electric windows- 12•15

Electrical fault finding- 12•2

Electrical system (body)- 12•1 et seq

Electrical system- 0•14, 5•2

Electrical system fault diagnosis- REF•12,

REF•18

Electronic control units- 4B•16, 7B•5

Engine:

bearings - 2A•31

camshaft - 2A•19, 2B•6

camshaft housing - 2A•18

camshaft oil seals - 2A•18, 2B•6

codes - 2A•1, 2B•1

compartment - 0•10, 1•5

compression test - 2A•8

connecting rods - 2A•29

crankcase ventilation - 2A•7

crankshaft - 2A•31

crankshaft oil seals - 2A•26, 2B•6, 2B•9

cylinder bores - 2A•33

cylinder head - 2A•19, 2A•22, 2B•7

dismantling - 2A•12

DOHC - 2B•1 et seq

electrical systems - 5•1 et seq

fault diagnosis - REF•12, REF•13

flexplate (automatic transmission) - 2A•26

flywheel - 2A•26

main and big-end bearings - 2A•31

mountings (engine/transmission) - 2A•12,

2B•3

Index REF•25

REF

Note:References throughout this index are in the form - “Chapter number” • “page number”