clock OPEL CALIBRA 1988 Service Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 94 of 525

9Alternator-removal and

refitting

3

Note: Refer to Section 3 before proceeding

Except ‘compact’ series

alternators

Removal

1Disconnect the battery leads.

2Disconnect the air trunking from the air

cleaner, and the air box or throttle body, as

applicable, and remove it for improved

access.

3Disconnect the wiring plug, or disconnect

the wires from their terminals on the rear of

the alternator, noting their locations (see

illustration).

4Remove the drivebelt, (Section 8).

5Unscrew the two mounting bolts and nuts

and recover any washers and insulating

bushes, noting their locations. Note the earth

strap attached to the top mounting bolt (see

illustration).

6Withdraw the alternator, taking care not to

knock or drop it, as this can cause irreparable

damage.

Refitting

7Refitting is a reversal of removal,

remembering the following points.

8Ensure that the earth lead is in place on the

top mounting bolt.

9Refit and tension the drivebelt, (Section 8).

‘Compact’ series alternators

Removal

10Disconnect the battery negative lead.

11Remove the air inlet trunking and, if

necessary for improved access, the air

cleaner assembly.

12Mark the rotational direction on the

alternator drivebelt with chalk.

13Using a spanner or socket on the

automatic tensioning roller hexagon turn the

tensioning roller clockwise (as viewed from

the right-hand side of the car) and hold it in

this position. With the drivebelt tension

released, slip the drivebelt off the alternator

pulley, then allow the tensioner to return to its

original position.14Disconnect the electrical cable

connections at the rear of the alternator.

15Undo and remove the alternator lower

mounting bolt, and slacken both upper bolts

that secure the alternator mounting brackets

to the engine.

16Undo and remove both bolts that secure

the alternator to its mounting brackets, noting

the location of the different length bolts.

Swing the brackets clear and remove the

alternator from the engine.

Refitting

17Refitting is a reversal of removal. Tighten

the mounting bolts to the specified torque,

and refit the drivebelt as described in

Section 8.

10Alternator -testing

5

Due to the specialist knowledge and

equipment required to test or service an

alternator, it is recommended that if a fault is

suspected, the vehicle is taken to a dealer or a

specialist. Information is limited to the

inspection and renewal of the brushes.

Should the alternator not charge, or the

system be suspect, the following points may

be checked before seeking further assistance:

a)Check the drivebelt tension, as described

in Section 8

b)Check the condition of the battery and its

connections -see Section 5c)Inspect all electrical cables and

connections for condition and security

Note that if the alternator is found to be

faulty, it may prove more economical to buy a

factory-reconditioned unit, rather than having

the existing unit overhauled.

11Alternator brushes -removal,

inspection and refitting

3

Removal

Delco-Remy type (except ‘compact’

series)

1Remove the alternator, as described in

Section 9

2Scribe a line across the drive end housing

and the slip ring end housing, to ensure

correct alignment when reassembling.

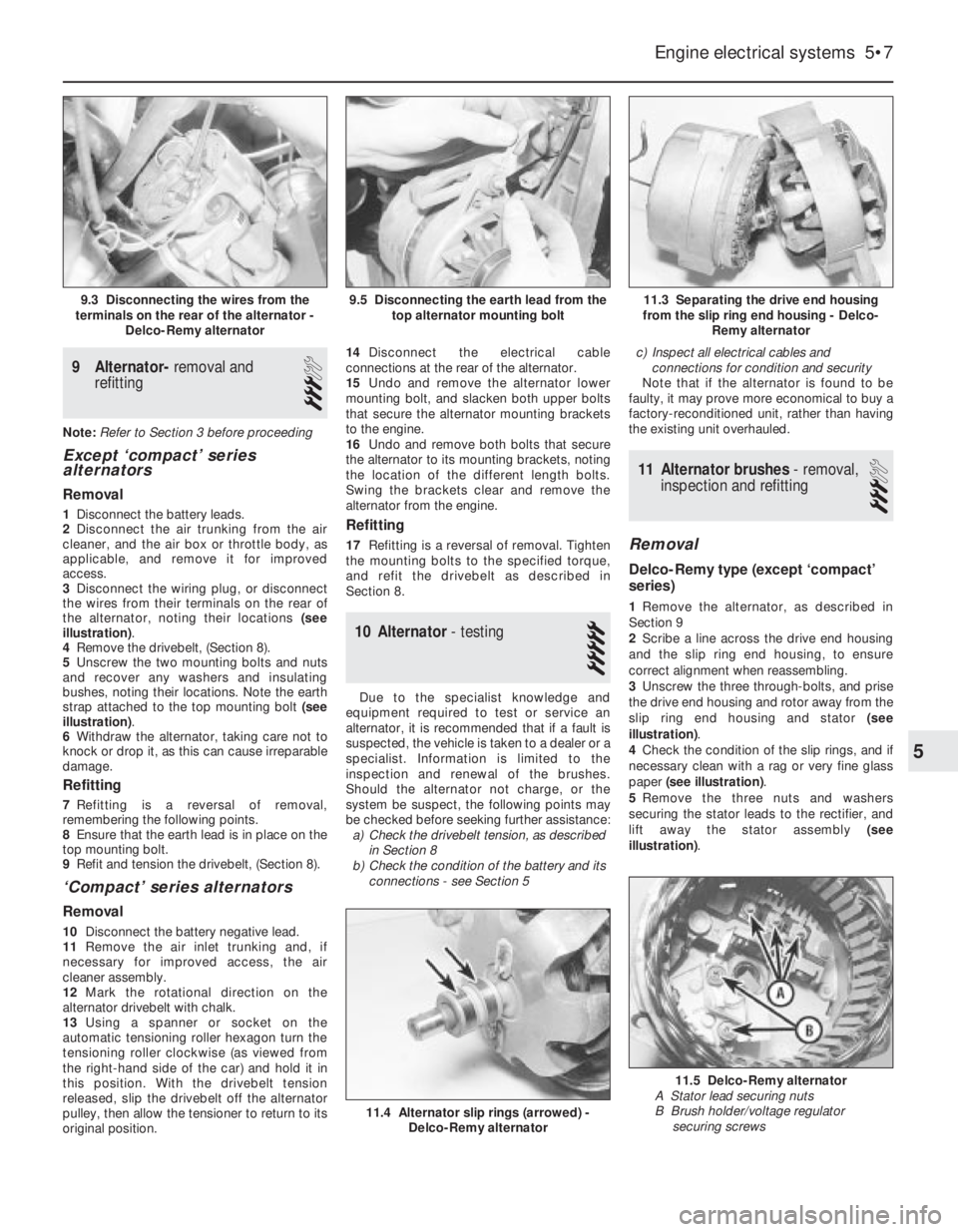

3Unscrew the three through-bolts, and prise

the drive end housing and rotor away from the

slip ring end housing and stator (see

illustration).

4Check the condition of the slip rings, and if

necessary clean with a rag or very fine glass

paper (see illustration).

5Remove the three nuts and washers

securing the stator leads to the rectifier, and

lift away the stator assembly (see

illustration).

Engine electrical systems 5•7

11.3 Separating the drive end housing

from the slip ring end housing - Delco-

Remy alternator

11.4 Alternator slip rings (arrowed) -

Delco-Remy alternator

11.5 Delco-Remy alternator

A Stator lead securing nuts

B Brush holder/voltage regulator

securing screws

9.5 Disconnecting the earth lead from the

top alternator mounting bolt9.3 Disconnecting the wires from the

terminals on the rear of the alternator -

Delco-Remy alternator

5

Page 100 of 525

Inspection

17Examine the distributor cap and rotor arm,

as described in paragraphs 6 and 7. Examine

the O-rings at the rear of the distributor body,

and on the rear of the shaft, and renew if

necessary.

Reassembly

18Reassembly is a reversal of dismantling,

ensuring that the thrustwashers are correctly

located. Note that the drive collar should be

refitted so that the drive peg on the collar is

aligned with the groove in the top of the

distributor shaft (it is possible to fit the drive

collar 180°out of position).

19Refit the distributor as described in

Section 18, and then check and if necessary

adjust the ignition timing, as described in

Section 21.

DOHC models (where

applicable)

20The distributor cap and rotor arm can be

examined as described in paragraphs 6 and 7.

21Ignition timing -checking and

adjustment

4

Note: Refer to Section 3 before proceeding. A

tachometer and a timing light will be required

during this procedure. For details of ignition

timing adjustment required to operate vehicles

on unleaded petrol, refer to Section 22.

14 NV and 16 SV models

Checking

1Start the engine and run it until it reaches

normal operating temperature, then switch

off.

2On 14 NV models, disconnect the vacuum

pipe from the distributor vacuum diaphragm

unit.

3On all models use a spanner applied to the

crankshaft pulley bolt to rotate the crankshaft

clockwise until the notch in the pulley’s

inboard rim aligns with the pointer protruding

from the oil pump housing. On 14 NV models,

where two notches (indicating 10°and 5°

BTDC respectively) are found, rotate the

crankshaft until the second notch (in thedirection of rotation -i.e. 5°BTDC) aligns. Use

white paint or similar to emphasise the pointer

and notch, to make them easier to see.

4Connect a timing light to No 1 cylinder

(nearest the timing belt end of the engine) HT

lead, also a tachometer; follow the equipment

manufacturer’s instructions for connection.

5Start the engine and allow it to idle -the

speed should be between 700 and 1000 rpm.

6On 14 NV models, aim the timing light at the

pointer and check that it is aligned with the

crankshaft pulley notch.

7On early 16 SV models, disconnect the

ignition timing basic adjustment coding plug.

This can be identified by a length of Black

wire joining Brown/Red and Brown/Yellow

wires in a connector plug clipped to the wiring

or heater/cooling system hoses beneath the

battery/ignition coil (see illustration, 16.1). This

causes the MSTS-i module to adopt its basic

adjustment mode, sending a constant firing

signal corresponding to 10°BTDC and

eliminating any advance below 2000 rpm. Aim

the timing light at the pointer and check that it

is aligned with the crankshaft pulley notch.

8On later 16 SV, C 16 NZ and C 16 NZ2

models, the coding plugs are no longer fitted.

For accurate checking, special Vauxhall test

equipment must be used which causes the

MSTS module to adopt its basic adjustment

mode.

9Without access to such equipment, it is

possible to check and adjust the ignition

timing, accurate results cannot be

guaranteed. Owners are therefore advised to

have this work carried out by a suitably

equipped Vauxhall dealer; at the very least,

make the initial setting yourself and then have

it checked as soon as possible.

10If you do attempt to check the ignition

timing yourself, note that the fixed reference

mark is now an extended line embossed on

the timing belt lower outer cover.

Adjustment

11If the notch and pointer are not aligned,

loosen the distributor clamp nut and turn the

distributor body slightly in the required

direction to align.

12Tighten the distributor clamp nut, and

check that the notch and pointer are still

aligned. 13Stop the engine, and disconnect the

timing light and tachometer.

14On 16 SV models, reconnect the basic

adjustment coding plug. On 14 NV models,

reconnect the vacuum pipe to the distributor

vacuum diaphragm unit.

Other models

15No adjustment of the ignition timing is

possible on 1.8 and 2.0 litre models, as the

adjustment is carried out automatically by the

electronic control module.

16The ignition timing can be checked by a

Vauxhall dealer using specialist dedicated test

equipment, if a fault is suspected.

22Ignition timing -adjustment

for use with unleaded petrol

3

14 NV models

1All models with the 14 NV engine have the

ignition timing adjusted for use with 95 RON

unleaded petrol before they leave the factory,

and no further adjustment is required.

2Leaded petrol (98 RON) can be used if

desired, with no adverse effects.

1.6, 1.8 and 2.0 SOHC models

Note: Models equipped with a catalytic

converter must be operated on 95 R0N

unleaded petrol at all times, and although an

octane coding plug may be fitted, it should

not be tampered with

3Models, other than 14 NV, are equipped

with an octane coding plug, which is located

Engine electrical systems 5•13

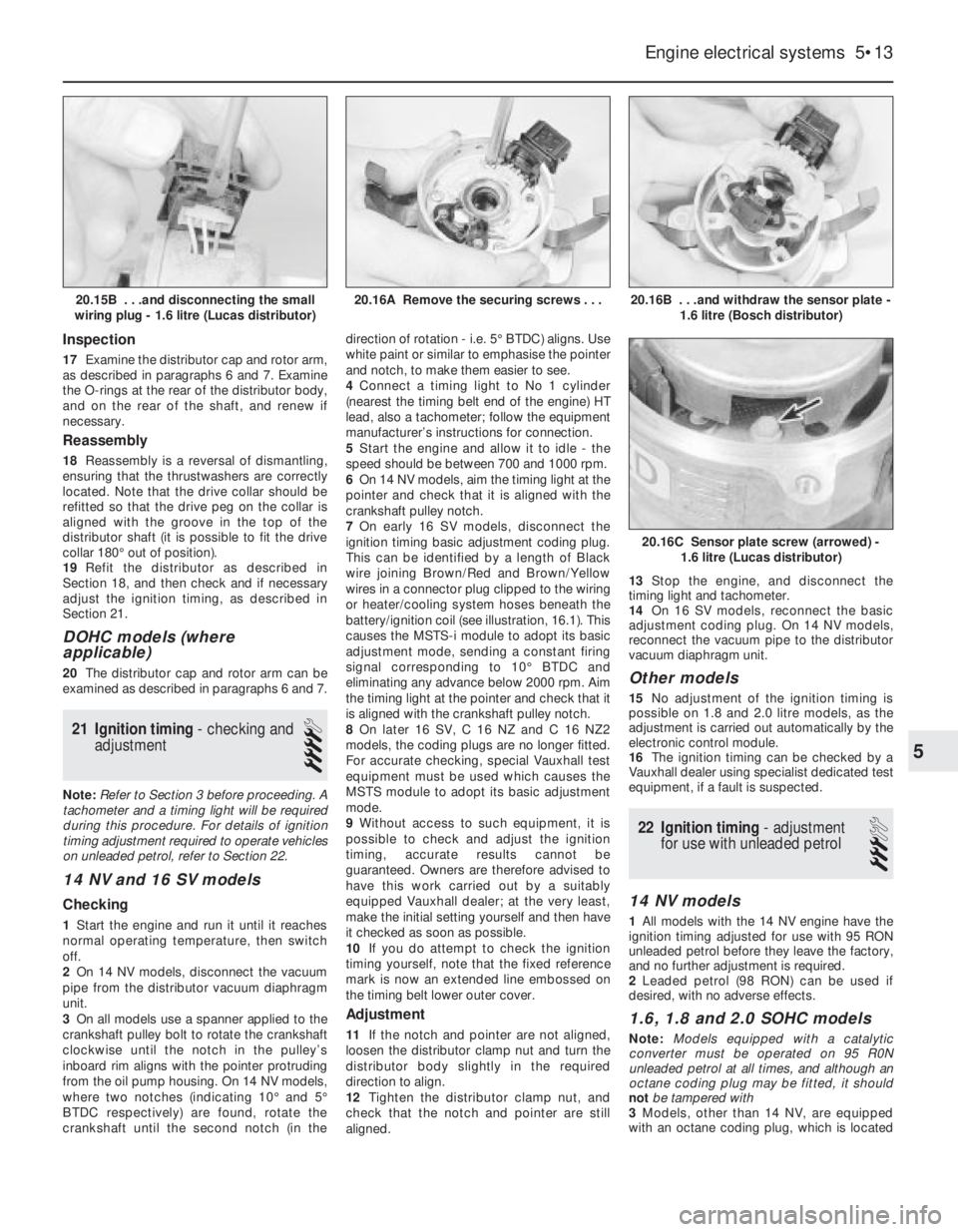

20.16B . . .and withdraw the sensor plate -

1.6 litre (Bosch distributor)

20.16C Sensor plate screw (arrowed) -

1.6 litre (Lucas distributor)

20.16A Remove the securing screws . . .20.15B . . .and disconnecting the small

wiring plug - 1.6 litre (Lucas distributor)

5

Page 117 of 525

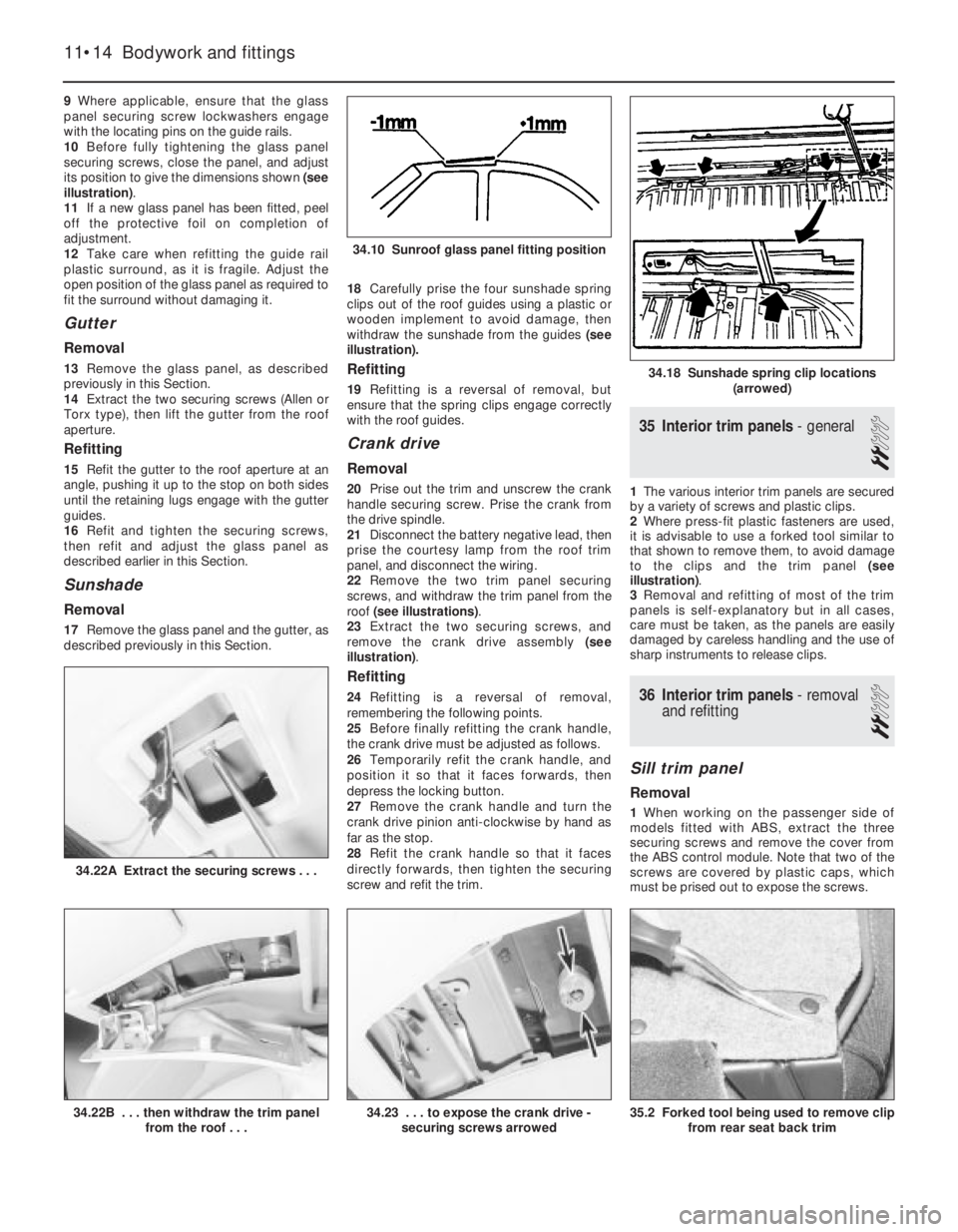

9Where applicable, ensure that the glass

panel securing screw lockwashers engage

with the locating pins on the guide rails.

10Before fully tightening the glass panel

securing screws, close the panel, and adjust

its position to give the dimensions shown (see

illustration).

11If a new glass panel has been fitted, peel

off the protective foil on completion of

adjustment.

12Take care when refitting the guide rail

plastic surround, as it is fragile. Adjust the

open position of the glass panel as required to

fit the surround without damaging it.

Gutter

Removal

13Remove the glass panel, as described

previously in this Section.

14Extract the two securing screws (Allen or

Torx type), then lift the gutter from the roof

aperture.

Refitting

15Refit the gutter to the roof aperture at an

angle, pushing it up to the stop on both sides

until the retaining lugs engage with the gutter

guides.

16Refit and tighten the securing screws,

then refit and adjust the glass panel as

described earlier in this Section.

Sunshade

Removal

17Remove the glass panel and the gutter, as

described previously in this Section. 18Carefully prise the four sunshade spring

clips out of the roof guides using a plastic or

wooden implement to avoid damage, then

withdraw the sunshade from the guides (see

illustration).

Refitting

19Refitting is a reversal of removal, but

ensure that the spring clips engage correctly

with the roof guides.

Crank drive

Removal

20Prise out the trim and unscrew the crank

handle securing screw. Prise the crank from

the drive spindle.

21Disconnect the battery negative lead, then

prise the courtesy lamp from the roof trim

panel, and disconnect the wiring.

22Remove the two trim panel securing

screws, and withdraw the trim panel from the

roof (see illustrations).

23Extract the two securing screws, and

remove the crank drive assembly (see

illustration).

Refitting

24Refitting is a reversal of removal,

remembering the following points.

25Before finally refitting the crank handle,

the crank drive must be adjusted as follows.

26Temporarily refit the crank handle, and

position it so that it faces forwards, then

depress the locking button.

27Remove the crank handle and turn the

crank drive pinion anti-clockwise by hand as

far as the stop.

28Refit the crank handle so that it faces

directly forwards, then tighten the securing

screw and refit the trim.

35Interior trim panels -general

2

1The various interior trim panels are secured

by a variety of screws and plastic clips.

2Where press-fit plastic fasteners are used,

it is advisable to use a forked tool similar to

that shown to remove them, to avoid damage

to the clips and the trim panel (see

illustration).

3Removal and refitting of most of the trim

panels is self-explanatory but in all cases,

care must be taken, as the panels are easily

damaged by careless handling and the use of

sharp instruments to release clips.

36Interior trim panels -removal

and refitting

2

Sill trim panel

Removal

1When working on the passenger side of

models fitted with ABS, extract the three

securing screws and remove the cover from

the ABS control module. Note that two of the

screws are covered by plastic caps, which

must be prised out to expose the screws.

11•14Bodywork and fittings

34.22A Extract the securing screws . . .

35.2 Forked tool being used to remove clip

from rear seat back trim34.23 . . . to expose the crank drive -

securing screws arrowed34.22B . . . then withdraw the trim panel

from the roof . . .

34.18 Sunshade spring clip locations

(arrowed)

34.10 Sunroof glass panel fitting position

Page 120 of 525

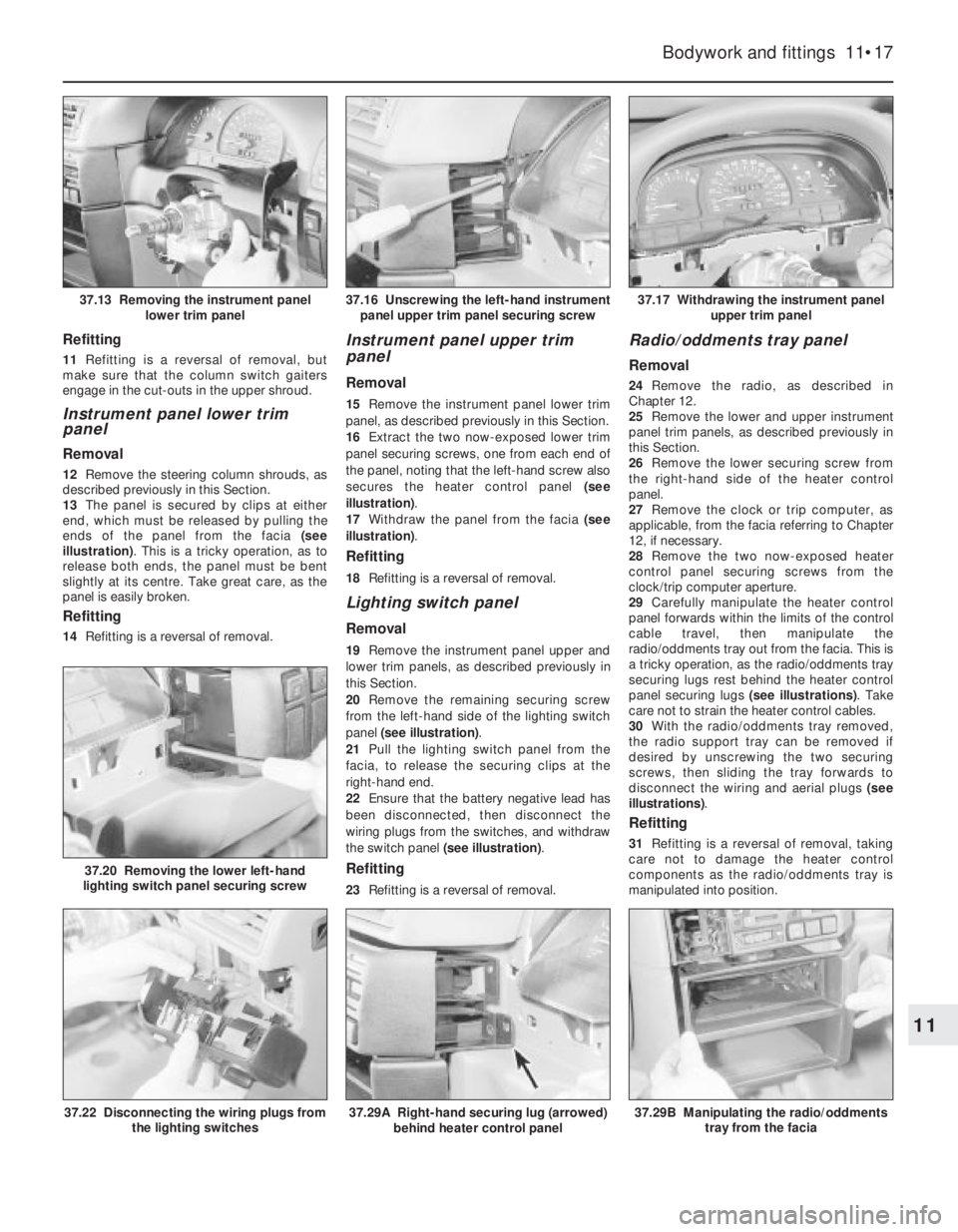

Refitting

11Refitting is a reversal of removal, but

make sure that the column switch gaiters

engage in the cut-outs in the upper shroud.

Instrument panel lower trim

panel

Removal

12Remove the steering column shrouds, as

described previously in this Section.

13The panel is secured by clips at either

end, which must be released by pulling the

ends of the panel from the facia (see

illustration). This is a tricky operation, as to

release both ends, the panel must be bent

slightly at its centre. Take great care, as the

panel is easily broken.

Refitting

14Refitting is a reversal of removal.

Instrument panel upper trim

panel

Removal

15Remove the instrument panel lower trim

panel, as described previously in this Section.

16Extract the two now-exposed lower trim

panel securing screws, one from each end of

the panel, noting that the left-hand screw also

secures the heater control panel (see

illustration).

17Withdraw the panel from the facia (see

illustration).

Refitting

18Refitting is a reversal of removal.

Lighting switch panel

Removal

19Remove the instrument panel upper and

lower trim panels, as described previously in

this Section.

20Remove the remaining securing screw

from the left-hand side of the lighting switch

panel (see illustration).

21Pull the lighting switch panel from the

facia, to release the securing clips at the

right-hand end.

22Ensure that the battery negative lead has

been disconnected, then disconnect the

wiring plugs from the switches, and withdraw

the switch panel (see illustration).

Refitting

23Refitting is a reversal of removal.

Radio/oddments tray panel

Removal

24Remove the radio, as described in

Chapter 12.

25Remove the lower and upper instrument

panel trim panels, as described previously in

this Section.

26Remove the lower securing screw from

the right-hand side of the heater control

panel.

27Remove the clock or trip computer, as

applicable, from the facia referring to Chapter

12, if necessary.

28Remove the two now-exposed heater

control panel securing screws from the

clock/trip computer aperture.

29Carefully manipulate the heater control

panel forwards within the limits of the control

cable travel, then manipulate the

radio/oddments tray out from the facia. This is

a tricky operation, as the radio/oddments tray

securing lugs rest behind the heater control

panel securing lugs (see illustrations). Take

care not to strain the heater control cables.

30With the radio/oddments tray removed,

the radio support tray can be removed if

desired by unscrewing the two securing

screws, then sliding the tray forwards to

disconnect the wiring and aerial plugs (see

illustrations).

Refitting

31Refitting is a reversal of removal, taking

care not to damage the heater control

components as the radio/oddments tray is

manipulated into position.

Bodywork and fittings 11•17

37.17 Withdrawing the instrument panel

upper trim panel

37.29B Manipulating the radio/oddments

tray from the facia37.29A Right-hand securing lug (arrowed)

behind heater control panel37.22 Disconnecting the wiring plugs from

the lighting switches

37.20 Removing the lower left-hand

lighting switch panel securing screw

37.16 Unscrewing the left-hand instrument

panel upper trim panel securing screw37.13 Removing the instrument panel

lower trim panel

11

Page 146 of 525

42Where applicable, screw the pressure-

proportioning valves into the base of the

cylinder.

43Refit the master cylinder, as described in

Section 15.

17Master cylinder (ABS) -

general

The master cylinder fitted to models with

ABS cannot be dismantled, and no attempt

should be made at overhaul.

If faulty, the complete unit must be

renewed, as described in Section 15.

18Vacuum servo - description

and testing

Description

1The vacuum servo is fitted between the

brake pedal and the master cylinder, and

provides assistance to the driver when the

pedal is depressed, reducing the effort required

to operate the brakes. The unit is operated by

vacuum from the inlet manifold. With the brake

pedal released, vacuum is channelled to both

sides of the internal diaphragm. However,

when the pedal is depressed, one side of the

diaphragm is opened to atmosphere, resulting

in assistance to the pedal effort. Should the

vacuum servo develop a fault, the hydraulic

system is not affected, but greater effort will be

required at the pedal.

Testing

2The operation of the servo can be checked

as follows.

3With the engine stopped, destroy the

vacuum in the servo by depressing the brake

pedal several times.

4Hold the brake pedal depressed and start

the engine. The pedal should sink slightly as

the engine is started.

5If the pedal does not sink, check the servo

vacuum hose for leaks.

6If no defects are found in the vacuum hose,

the fault must lie in the servo itself.7No overhaul of the servo is possible, and if

faulty, the complete unit must be renewed.

19Vacuum servo - removal and

refitting

4

Note: During the 1989 model year, some

vehicles were produced with the brake pedal

height incorrectly set, resulting in the brake

pedal resting approximately 15.0 mm (0.6 in)

above the clutch pedal instead of 4.0 mm

(0.16 in below). The correct pedal height can

be set by adjusting the vacuum servo

operating fork dimension, as described in

paragraphs 15 and 16

Removal

1Disconnect the battery negative lead.

2Working inside the vehicle, remove the

lower trim panel from the driver’s footwell.

3Disconnect the wiring plug from the brake

lamp switch, then twist the switch anti-

clockwise and remove it from its bracket.

4Pull the spring clip from the right-hand end

of the servo fork-to-pedal pivot pin.

5Using a pair of pliers, pull back the end of

the pedal return spring from the pedal, to

enable the servo fork-to-pedal pivot pin to be

removed. Withdraw the pivot pin.

6Remove the windscreen cowl panel, as

described in Chapter 11, then remove the

windscreen wiper motor and linkage as

described in Chapter 12.7Remove the coolant expansion tank as

described in Chapter 3.

8Pull the vacuum pipe from the brake servo.

9Unscrew the two securing nuts, and

carefully withdraw the brake master cylinder

from the studs on the servo. Move the master

cylinder forwards slightly, taking care not to

strain the brake pipes.

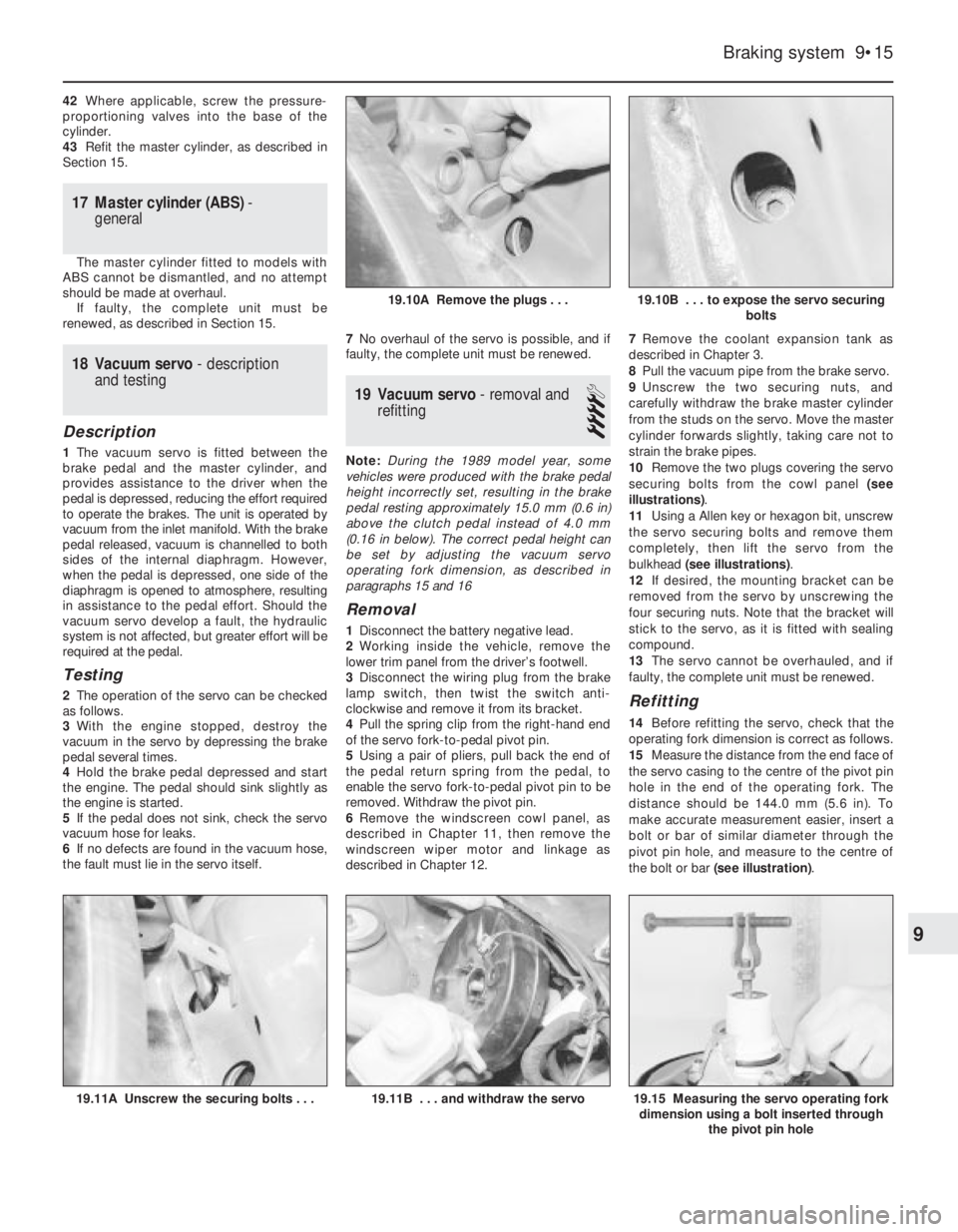

10Remove the two plugs covering the servo

securing bolts from the cowl panel (see

illustrations).

11Using a Allen key or hexagon bit, unscrew

the servo securing bolts and remove them

completely, then lift the servo from the

bulkhead (see illustrations).

12If desired, the mounting bracket can be

removed from the servo by unscrewing the

four securing nuts. Note that the bracket will

stick to the servo, as it is fitted with sealing

compound.

13The servo cannot be overhauled, and if

faulty, the complete unit must be renewed.

Refitting

14Before refitting the servo, check that the

operating fork dimension is correct as follows.

15Measure the distance from the end face of

the servo casing to the centre of the pivot pin

hole in the end of the operating fork. The

distance should be 144.0 mm (5.6 in). To

make accurate measurement easier, insert a

bolt or bar of similar diameter through the

pivot pin hole, and measure to the centre of

the bolt or bar (see illustration).

Braking system 9•15

19.11A Unscrew the securing bolts . . .19.15 Measuring the servo operating fork

dimension using a bolt inserted through

the pivot pin hole19.11B . . . and withdraw the servo

19.10B . . . to expose the servo securing

bolts19.10A Remove the plugs . . .

9

Page 152 of 525

19On DOHC models, use a new self-locking

nut to secure the equaliser yoke to the

handbrake lever operating rod, and screw the

nut onto the rod to the position noted before

removal.

20On SOHC models, tighten the cable

adjuster to expose the length of thread noted

before removal.

21Before lowering the vehicle to the ground,

adjust the handbrake, (Section 26).

29Brake pedal - removal and

refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the lower trim panel from the

driver’s footwell.3Disconnect the wiring plug from the brake

lamp switch, then twist the switch anti-

clockwise and remove it from its bracket.

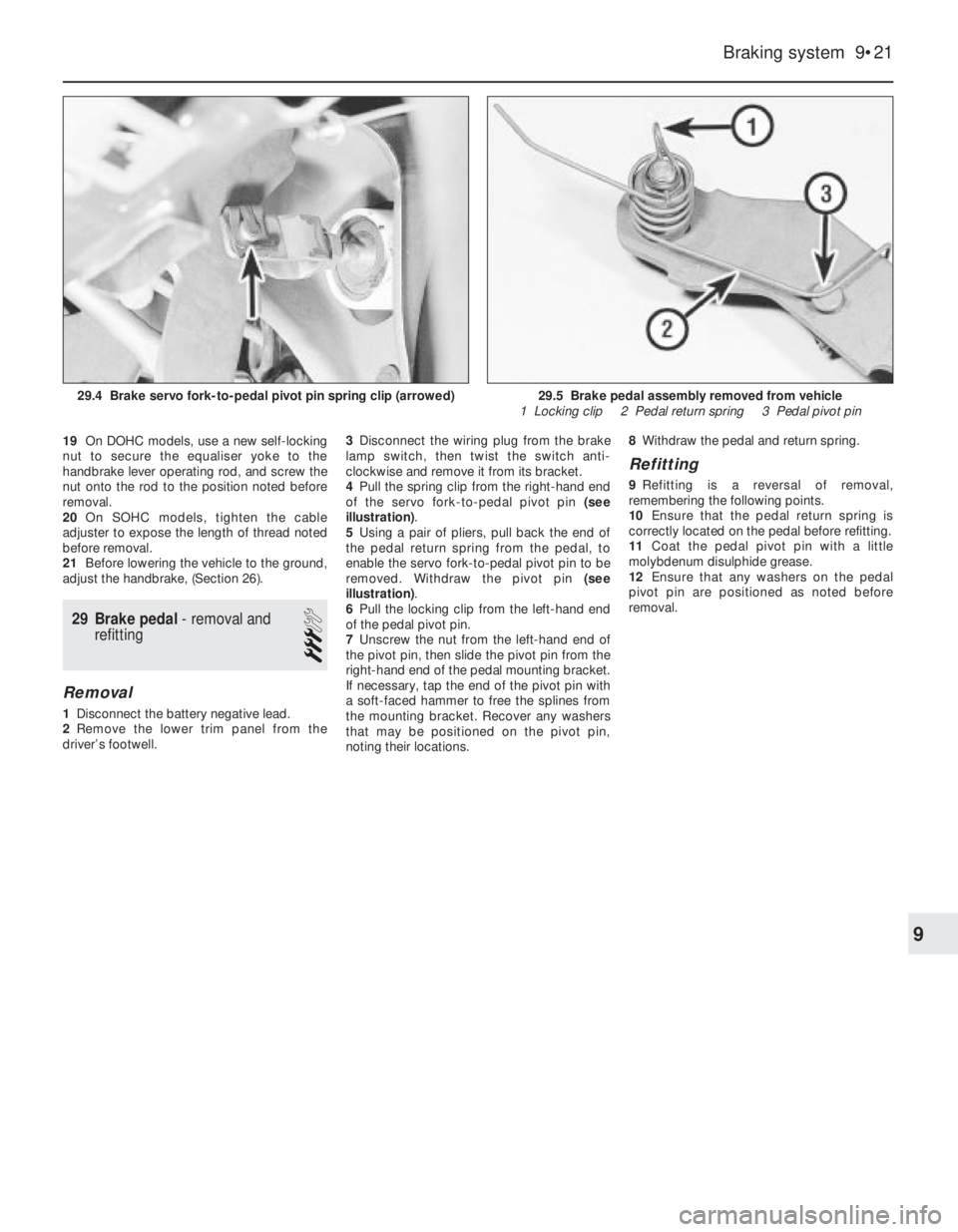

4Pull the spring clip from the right-hand end

of the servo fork-to-pedal pivot pin (see

illustration).

5Using a pair of pliers, pull back the end of

the pedal return spring from the pedal, to

enable the servo fork-to-pedal pivot pin to be

removed. Withdraw the pivot pin (see

illustration).

6Pull the locking clip from the left-hand end

of the pedal pivot pin.

7Unscrew the nut from the left-hand end of

the pivot pin, then slide the pivot pin from the

right-hand end of the pedal mounting bracket.

If necessary, tap the end of the pivot pin with

a soft-faced hammer to free the splines from

the mounting bracket. Recover any washers

that may be positioned on the pivot pin,

noting their locations.8Withdraw the pedal and return spring.

Refitting

9Refitting is a reversal of removal,

remembering the following points.

10Ensure that the pedal return spring is

correctly located on the pedal before refitting.

11Coat the pedal pivot pin with a little

molybdenum disulphide grease.

12Ensure that any washers on the pedal

pivot pin are positioned as noted before

removal.

Braking system 9•21

29.5 Brake pedal assembly removed from vehicle

1 Locking clip 2 Pedal return spring 3 Pedal pivot pin29.4 Brake servo fork-to-pedal pivot pin spring clip (arrowed)

9

Page 165 of 525

9Remove the two securing screws and

withdraw the sensor from the throttle body.

Refitting

10Refitting is a reversal of removal.

11On Motronic M4.1 system models, before

tightening the securing screws, adjust the

position of the sensor as follows:

a)Turn the sensor body anti-clockwise until

resistance is felt, then tighten the securing

screws.

b)When the throttle valve is opened, an

audible click should be noticeable from

the sensor, and similarly, this should be

repeated as the throttle valve is closed.

c)If necessary, adjust the position of the

sensor until a click is heard just as the

throttle valve begins to open.

12On M 1.5 systems, no adjustment is

required when refitting, as the sensor can only

be fitted in one position.

24Throttle valve potentiometer

- removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect the wiring plugs at the inlet air

temperature sensor and at the hot film mass

airflow meter.

3Undo and remove the bolts securing the air

box to the throttle body. Remove the air box

complete with air trunking.4Disconnect the wiring plug at the throttle

valve potentiometer, then undo the two

screws and withdraw the potentiometer from

the throttle body.

Refitting

5Refitting is a reversal of removal.

25Airflow meter (if fitted) -

removal and refitting

3

Note: If the air funnel is removed, a new

gasket must be used on refitting. The airflow

meter securing bolts must be coated with

thread-locking compound on refitting

Removal

1Remove the air cleaner assembly, as

described in Section 4.

2Unscrew the single bolt securing the airflow

meter to the front of the air cleaner cover (see

illustration).

3Unscrew the four securing bolts from inside

the air cleaner cover, recover the two

reinforcing plates, and withdraw the airflow

meter (see illustration).

4If desired, the air funnel can be unclipped

from inside the air cleaner cover.

Refitting

5Refitting is a reversal of removal,

remembering the following points.

6If the air funnel has been removed, refit it

using a new gasket.7Coat the threads of the four airflow meter

securing bolts that fit inside the air cleaner

cover with thread-locking compound.

26Air mass meter (if fitted) -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect the wiring plug from the air

mass meter. Recover the sealing ring (see

illustration).

3Loosen the clamp screws from the air

trunking on either side of the air mass meter,

then disconnect the air trunking and withdraw

the meter.

Refitting

4Refitting is a reversal of removal, but

inspect the air mass meter wiring plug sealing

ring and renew if necessary.

27Hot film mass airflow meter -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect the wiring plug at the hot film

mass airflow meter and at the inlet air

temperature sensor.

3Remove the upper part of the air cleaner

together with the inlet air trunking and air flow

meter.

4Release the hose clamps and separate the

airflow meter from the inlet air trunking, noting

the position of the trunking with the air flow

meter. If there is any external damage replace

the unit.

Refitting

5Refitting is a reversal of removal but ensure

that the air trunking is connected to the

airflow meter as shown (see illustration). Also

ensure that the marks on the air trunking and

air box are aligned as shown (see

illustration).

4B•12Fuel and exhaust systems - fuel injection models

25.2 Airflow meter securing bolt (arrowed)

- SOHC model

26.2 Recover the sealing ring from the air

mass meter wiring plug - DOHC model

27.5B Correct attachment of air trunking to

hot film mass airflow meter - Motronic M2.8

Arrows indicate air trunking to airflow meter

alignment notches

27.5A Hot film mass airflow meter

attachments - Motronic M2.8

1 Hot film mass airflow meter wiring plug

2 Inlet air temperature sensor wiring plug

25.3 Airflow meter securing bolts and

reinforcing plates, and air funnel

Page 181 of 525

2Also check the security and condition of all

the engine related pipes and hoses. Ensure

that all cable-ties or securing clips are in

place, and in good condition. Clips that are

broken or missing can lead to chafing of the

hoses, pipes or wiring, which could cause

more serious problems in the future.

3Carefully check the radiator hoses and

heater hoses along their entire length. Renew

any hose that is cracked, swollen or

deteriorated. Cracks will show up better if the

hose is squeezed. Pay close attention to the

hose clips that secure the hoses to the

cooling system components. Hose clips can

pinch and puncture hoses, resulting in cooling

system leaks. It is always beneficial to renew

hose clips whenever possible.

4Inspect all the cooling system components

(hoses, joint faces, etc.) for leaks.

5Where any problems are found on system

components, renew the component or gasket

with reference to Chapter 3.

6Where applicable, inspect the automatic

transmission fluid cooler hoses for leaks or

deterioration.

7With the vehicle raised, inspect the petrol

tank and filler neck for punctures, cracks and

other damage. The connection between the

filler neck and tank is especially critical.

Sometimes a rubber filler neck or connecting

hose will leak due to loose retaining clamps or

deteriorated rubber.

8Carefully check all rubber hoses and metal

fuel lines leading away from the petrol tank.

Check for loose connections, deteriorated

hoses, crimped lines, and other damage. Pay

particular attention to the vent pipes and

hoses, which often loop up around the filler

neck and can become blocked or crimped.

Follow the lines to the front of the vehicle,

carefully inspecting them all the way. Renew

damaged sections as necessary.

9From within the engine compartment,

check the security of all fuel hose attachments

and pipe unions, and inspect the fuel hoses

and vacuum hoses for kinks, chafing and

deterioration.

10Where applicable, check the condition of

the power steering fluid hoses and pipes.5Steering and suspension

check

2

Front suspension and steering

check

1Raise the front of the car, and support on

axle stands (“Jacking and Vehicle Support”).

2Visually inspect the balljoint dust covers

and the steering rack-and-pinion gaiters for

splits, chafing or deterioration. Any wear of

these components will cause loss of lubricant,

together with dirt and water entry, resulting in

rapid wear of the balljoints or steering gear.

3On vehicles with power steering, check the

fluid hoses for chafing or deterioration, and

the pipe and hose unions for fluid leaks. Also

check for signs of fluid leakage under

pressure from the steering gear rubber

gaiters, which would indicate failed fluid seals

within the steering gear.

4Grasp the roadwheel at the 12 o’clock and

6 o’clock positions, and try to rock it (see

illustration). Very slight free play may be felt,

but if the movement is appreciable, further

investigation is necessary to determine the

source. Continue rocking the wheel while an

assistant depresses the footbrake. If the

movement is now eliminated or significantly

reduced, it is likely that the hub bearings are

at fault. If the free play is still evident with the

footbrake depressed, then there is wear in the

suspension joints or mountings.

5Now grasp the wheel at the 9 o’clock and 3

o’clock positions, and try to rock it as before.

Any movement felt now may again be caused

by wear in the hub bearings or the steering

track-rod balljoints. If the inner or outer balljoint

is worn, the visual movement will be obvious.

6Using a large screwdriver or flat bar, check

for wear in the suspension mounting bushes

by levering between the relevant suspension

component and its attachment point. Some

movement is to be expected as the mountings

are made of rubber, but excessive wear

should be obvious. Also check the condition

of any visible rubber bushes, looking for splits,

cracks or contamination of the rubber.

7Inspect the front suspension lower arms for

distortion or damage (Chapter 10, Section 5).

8With the car standing on its wheels, have an

assistant turn the steering wheel back and

forth about an eighth of a turn each way.

There should be very little, if any, lost

movement between the steering wheel and

roadwheels. If this is not the case, closely

observe the joints and mountings previously

described, but in addition, check the steering

column universal joints for wear, and the rack-

and-pinion steering gear itself.

Suspension strut/shock

absorber check

Note:Suspension struts/shock absorbers

should always be renewed in pairs on the

same axle.9Check for any signs of fluid leakage around

the suspension strut/shock absorber body, or

from the rubber gaiter around the piston rod.

Should any fluid be noticed, the suspension

strut/shock absorber is defective internally,

and should be renewed.

10The efficiency of the suspension

strut/shock absorber may be checked by

bouncing the vehicle at each corner. The body

will return to its normal position and stop after

being depressed. If it rises and returns on a

rebound, the suspension strut/shock

absorber is probably suspect. Examine also

the suspension strut/shock absorber upper

and lower mountings for any signs of wear.

6Driveshaft gaiter check

2

With the vehicle raised and securely

supported on stands, turn the steering onto

full lock, then slowly rotate the roadwheel.

Inspect the condition of the outer constant

velocity (CV) joint rubber gaiters, squeezing

the gaiters to open out the folds (see

illustration). Check for signs of cracking,

splits or deterioration of the rubber, which

may allow the grease to escape, and lead to

water and grit entry into the joint. Also check

the security and condition of the retaining

clips. Repeat these checks on the inner CV

joints. If any damage or deterioration is found,

the gaiters should be renewed as described in

Chapter 8.

1•10Every 9000 miles or 12 months

6.1 Check the condition of the driveshaft

gaiters (A) and clips (B)

5.4 Check for wear in the hub bearings by

grasping the wheel and trying to rock it

A leak in the cooling system will usually

show up as white or rust coloured

deposits on the area adjoining the leak

Page 192 of 525

Apply a little grease to the threads of the

securing bolt, and tighten it to the specified

torque in the two stages given in the Specifi-

cations. Ensure that the thrustwasher is in

place under the bolt head, and prevent the

crankshaft from turning as during removal.

23Refit the camshaft sprockets. Ensure that

the locating pins on the ends of the camshafts

engage with the holes in the sprockets and

with the sprocket timing marks facing

forwards. Then tighten the securing bolts to

the specified torque in the two stages given in

the Specifications. Prevent the camshafts

from turning as during removal.

24Check the condition of the camshaft

cover rubber gasket and renew if necessary,

then refit the camshaft cover and tighten the

securing bolts (see illustration).

25Refit the HT leads to the spark plugs

(ensuring that they are refitted to their correct

cylinders), then clip the leads to the end of the

camshaft cover. Refit the spark plug cover

and tighten the securing bolts.

26Reconnect the breather hose to the

camshaft cover.

27Temporarily refit the crankshaft pulley,

and ensure that the crankshaft pulley and

camshaft sprocket timing marks are still

aligned as described in paragraph 6. Then fit a

new timing belt around the sprockets and

pulleys, starting at the crankshaft sprocket.

28Refit the crankshaft pulley, and tighten the

securing bolts to the specified torque. If

necessary, prevent the crankshaft from

turning as during removal. 29Adjust the timing belt tension, as

described from paragraph 35 onwards.

30Refit the outer timing belt cover, ensuring

that the rubber grommets are in place in the

screw holes, and tighten the securing screws.

31Refit the alternator drivebelt and adjust

the drivebelt tension, as described in Chapter

5.

32Refit the power steering pump drivebelt

and adjust the drivebelt tension, as described

in Chapter 10.

33Refit the air cleaner components as

applicable, referring to Chapter 4B, if

necessary.

34Reconnect the battery negative lead.

Adjustment

Note: The manufacturers specify the use of

special adjustment wrench Vauxhall tool No

KM-666 for adjusting the timing belt tension. If

access to this tool cannot be obtained an

approximate adjustment can be achieved

using the method described in this Section.

However it is emphasised that the vehicle

should be taken to a dealer at the earliest

possible opportunity to have the tension

adjusted using the special tool. Do not drive

the vehicle over any long distance until the

belt tension has been adjusted by a dealer

Approximate adjustment

35No checking of timing belt adjustment is

specified, and the following adjustment

procedure applies to a newly fitted belt. The

adjustment must be carried out with the

engine cold.36With the timing belt cover removed and

the tensioner pulley bolt slackened, ensure

that the TDC marks on the camshaft

sprockets and the crankshaft pulley are

aligned as described in paragraph 6. If

necessary, turn the crankshaft to achieve

alignment.

37Have an assistant press the tensioner

pulley against the belt until the belt can just be

twisted through 45°, using moderate pressure

with the thumb and forefinger, on the longest

belt run between the exhaust camshaft

sprocket and the belt idler pulley.

38Have the assistant hold the tensioner

pulley in position, and tighten the tensioner

pulley bolt to the specified torque in the two

stages given in the Specifications.

39Turn the crankshaft clockwise through

two complete revolutions, and check that,

with the crankshaft pulley TDC mark aligned

with the pointer on the rear timing belt cover,

the TDC marks on the camshaft sprockets are

still aligned with the notches in the camshaft

cover.

40Proceed as described in paragraphs 30 to

34, inclusive.

41Have the belt tension adjusted by a

Vauxhall dealer using the manufacturer’s

special tool at the earliest opportunity.Adjustment using Vauxhall special

tool (KM-666)

42Proceed as described in paragraphs 35

and 36.

43Fit the special tool KM-666 to the belt

tensioner pulley mounting plate, in

accordance with the tool manufacturer’s

instructions.

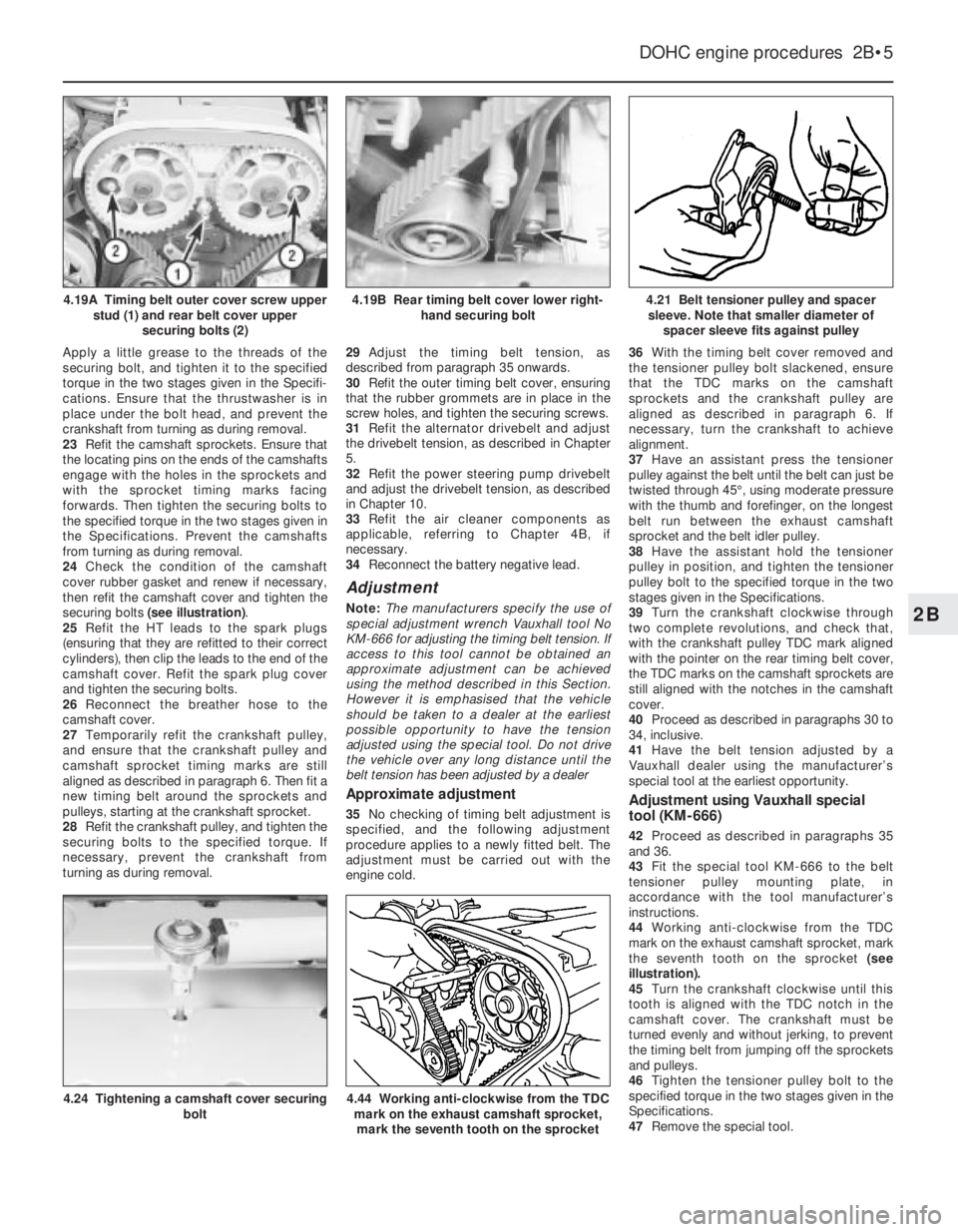

44Working anti-clockwise from the TDC

mark on the exhaust camshaft sprocket, mark

the seventh tooth on the sprocket (see

illustration).

45Turn the crankshaft clockwise until this

tooth is aligned with the TDC notch in the

camshaft cover. The crankshaft must be

turned evenly and without jerking, to prevent

the timing belt from jumping off the sprockets

and pulleys.

46Tighten the tensioner pulley bolt to the

specified torque in the two stages given in the

Specifications.

47Remove the special tool.

DOHC engine procedures 2B•5

4.21 Belt tensioner pulley and spacer

sleeve. Note that smaller diameter of

spacer sleeve fits against pulley

4.44 Working anti-clockwise from the TDC

mark on the exhaust camshaft sprocket,

mark the seventh tooth on the sprocket4.24 Tightening a camshaft cover securing

bolt

4.19B Rear timing belt cover lower right-

hand securing bolt4.19A Timing belt outer cover screw upper

stud (1) and rear belt cover upper

securing bolts (2)

2B

Page 193 of 525

48Turn the crankshaft clockwise until the

TDC marks on the camshaft sprockets are

aligned with the notches in the camshaft

cover, and check that the crankshaft pulley

TDC mark is aligned with the pointer on the

rear timing belt cover.

49Proceed as described in paragraphs 30 to

34 inclusive.

5Timing belt, with automatic

adjuster- removal, refitting

and adjustment

3

Removal

1The operations are essentially the same as

described in Section 4, except that the

tensioner pulley incorporates an automatic

adjuster that simplifies the procedure as

follows.

2To release the belt tension before removal,

unscrew the timing belt tensioner pulley

securing bolt slightly then, with a large

screwdriver (or similar tool) inserted in the slot

on the tensioner arm, turn the tensioner arm

until the timing belt is slack. Tighten the

securing bolt slightly to hold the tensioner in

this position.

Refitting

3To refit the timing belt, first ensure that the

coolant pump is correctly positioned by

checking that the lug on the coolant pump

flange is aligned with the corresponding lug

on the cylinder block. If this is not the case,

slacken the coolant pump mounting bolts

slightly and move the pump accordingly.

Tighten the bolts to the specified torque on

completion (see Chapter 3).

4Refit the timing belt as described in Section 4,

then tension it as follows.

Adjustment

5Slacken the tensioner pulley securing bolt

and move the tensioner arm anti-clockwise,

until the tensioner pointer lies at its stop.

Tighten the tensioner pulley securing bolt to

hold the tensioner in this position.

6Turn the crankshaft through two complete

revolutions in the normal direction of rotation

and check that with the crankshaft pulley TDC

mark aligned with the pointer on the rear

timing belt cover, the TDC marks on the

camshaft sprockets are still aligned with the

notches in the camshaft cover.

7Slacken the tensioner pulley securing bolt

once again and move the tensioner arm

clockwise, until the tensioner pointer is

aligned with the notch in the tensioner. In the

first few hours of operation a new belt will be

subjected to ‘settling-in’, (known as the

running-in procedure). If you are refitting a

used belt (one that has been ‘run-in’), align the

pointer to approximately 4 mm to the left of

the notch, refer to Section 14 in Chapter 2A.

Tighten the tensioner pulley securing bolt

securely. Turn the crankshaft through onecomplete revolution in the normal direction of

rotation and check that the crankshaft and

camshaft timing marks still align, then refit the

remainder of the components as described in

Section 4.

8With the timing belt adjustment set in this

way, correct tension will always be maintained

by the automatic tensioner and no further

checking or adjustment will be necessary.

6Camshaft front oil seal-

removal and refitting

3

Note: A new timing belt should be used on

refitting

Removal

1The camshaft front oil seals may be

renewed with the engine in the vehicle without

removing the camshafts as follows.

2Remove the timing belt and the relevant

camshaft sprocket(s), as described in Section 4.

3Punch or drill a small hole in the centre of

the now-exposed oil seal. Screw in a

self-tapping screw, and pull on the screw with

pliers to extract the seal.

4Clean the oil seal seat with a wooden or

plastic scraper.

5Turn the camshaft until the locating peg for

the camshaft sprocket is uppermost, then

lubricate the lips of a new camshaft front oil

seal with a little grease, and fit the oil seal,

using a tube or socket of similar diameter with

a washer and the camshaft sprocket bolt.Screw the camshaft sprocket bolt into the end

of the camshaft to draw the oil seal into

position on its shoulder (see illustration).

6Where applicable, repeat the procedure on

the remaining camshaft oil seal.

Refitting

7Refit the camshaft sprockets, the timing

belt and tension the timing belt as described

in Sections 4 and 5.

7Camshafts- removal,

inspection and refitting

4

Note: A new timing belt should be used on

refitting

Removal

1Remove the timing belt and the relevant

camshaft sprockets, as described in Section 4.

2If the exhaust camshaft is to be removed,

unscrew the two securing bolts and remove

the distributor from the end of the cylinder

head, referring to Chapter 5, if necessary.

3Check the camshaft bearing caps for identi-

fication marks, and if none are present, make

corresponding marks on the bearing caps and

the top surface of the cylinder head using a

centre punch. Note the orientation of the

bearing caps before removal, as they must be

refitted in exactly the same positions from

which they are removed (see illustration).

4Loosen the relevant camshaft bearing cap

nuts by half a turn, then loosen all the nuts by

a further half turn and so on (this is necessary

to slowly relieve the tension in the valve

springs). Note that the exhaust camshaft rear

bearing cap that also supports the distributor

is secured by four nuts (see illustration).

5Remove the bearing cap nuts and the

bearing caps, then carefully lift the relevant

camshaft from the cylinder head without

jerking.

6Repeat the procedure for the remaining

camshaft if desired.

Inspection

7With the camshaft(s) removed, examine the

bearing surfaces in the cylinder head and

bearing caps for signs of obvious wear or

2B•6DOHC engine procedures

6.5 Using the camshaft sprocket bolt,

washer, and a tube to fit a new camshaft

front oil seal

7.4 Exhaust camshaft rear bearing cap

securing nuts (arrowed)7.3 Camshaft bearing cap. Note position

of identification mark (arrowed)