sensor OPEL CALIBRA 1988 Service Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 210 of 525

a)Inlet and exhaust manifolds (where

applicable)

b)Starter motor

c)Rear coolant gallery and hoses

d)Oil pressure switch

e)Oil temperature switch (where applicable)

f)Oil level sensor (where applicable)

g)Knock sensor (where applicable)

h)TDC sensor (where applicable)

i)Distributor components

j)Fuel pump (where applicable)

k)Thermostat/housing (N 16 NZ2, 1.8 and

2.0 litre models)

l)Power steering pump and mounting

bracket (where applicable)

m)Alternator mounting bracket

n)Engine lifting brackets

o)Dipstick/crankcase breather tube

p)Inlet manifold mounting bracket (where

applicable)

13To ensure maximum life, with minimum

trouble, from a rebuilt engine, not only must

everything be correctly assembled, but it must

also be spotlessly clean. All oilways and

coolant passages must be clear, and all

washers must be fitted in their original

positions. Oil all bearings and other moving

surfaces thoroughly with clean engine oil

during assembly.

14Before assembly begins, renew any bolts

or studs with damaged threads.

15Obtain a torque wrench, an angle-torque

gauge, sockets and bits, an oil can, clean

lint-free rag, and a set of engine gaskets and

oil seals, together with a new oil filter.16If they have been removed, new cylinder

head bolts, flywheel bolts, big-end bearing

cap bolts and main bearing cap bolts will also

be required.

17On completion of reassembly, refit the

applicable ancillary components listed in

paragraph 12.

18Follow procedure shown in Section 37.

11Timing belt and sprockets

(without automatic tensioner) -

removal, refitting and adjustment

3

Note: A two-legged puller may be required to

remove the crankshaft sprocket on N 16 NZ2,

1.8 and 2.0 litre models.Some of the later 1.4

and 1.6 litre engines, identifiable by the

squared-off top surfaces of the timing belt

covers, are fitted with spring-loaded auto-matic timing belt tensioners to ensure correct

belt tensioning on assembly.

Removal

1Disconnect the battery negative lead.

2On models with power steering, remove the

pump drivebelt, see Chapters 1 and 10.

3Remove the alternator drivebelt, as

described in Chapter 5.

4On C 16 NZ2, 1.8 and 2.0 litre models,

disconnect the wiring from the temperature

gauge sender.

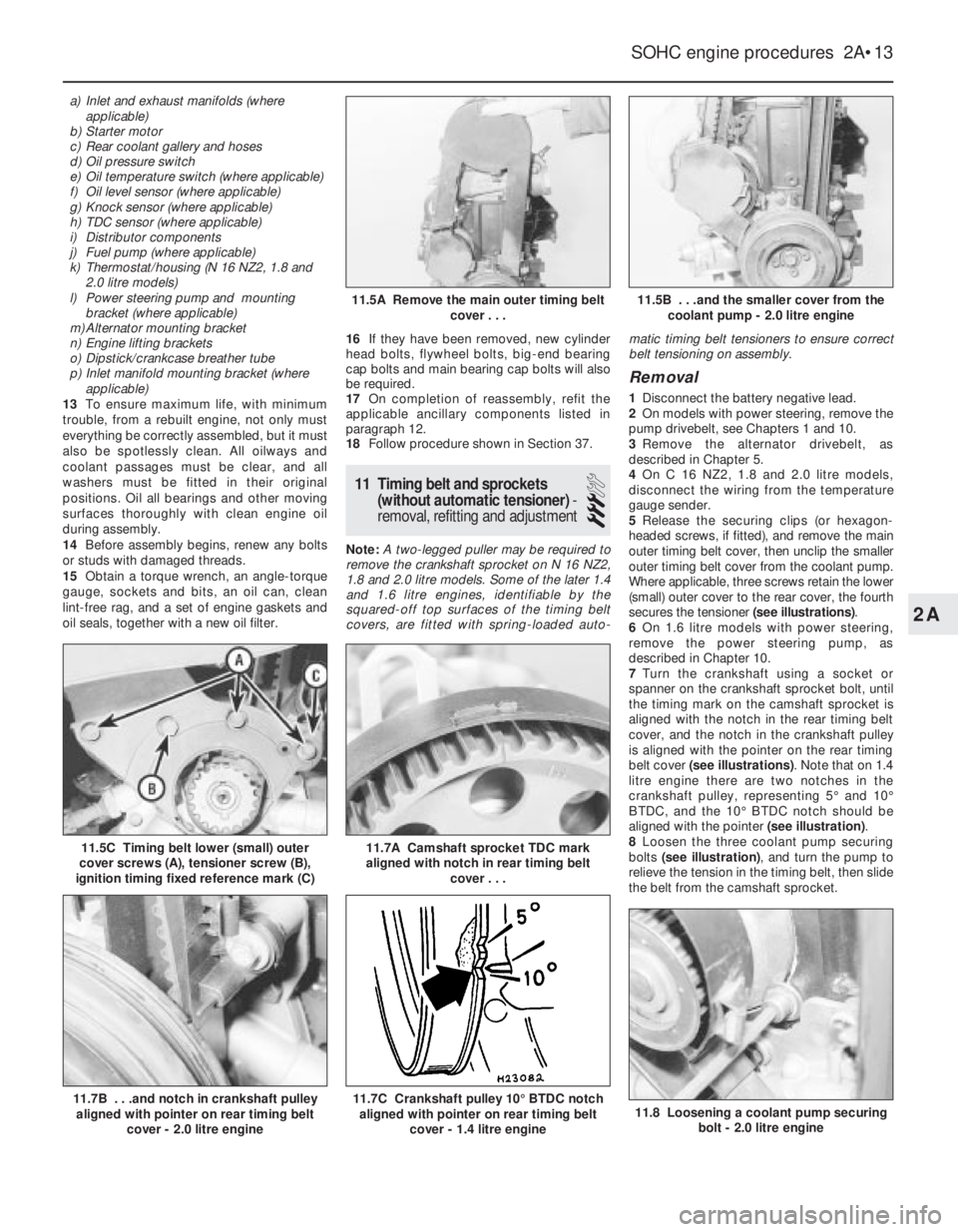

5Release the securing clips (or hexagon-

headed screws, if fitted), and remove the main

outer timing belt cover, then unclip the smaller

outer timing belt cover from the coolant pump.

Where applicable, three screws retain the lower

(small) outer cover to the rear cover, the fourth

secures the tensioner (see illustrations).

6On 1.6 litre models with power steering,

remove the power steering pump, as

described in Chapter 10.

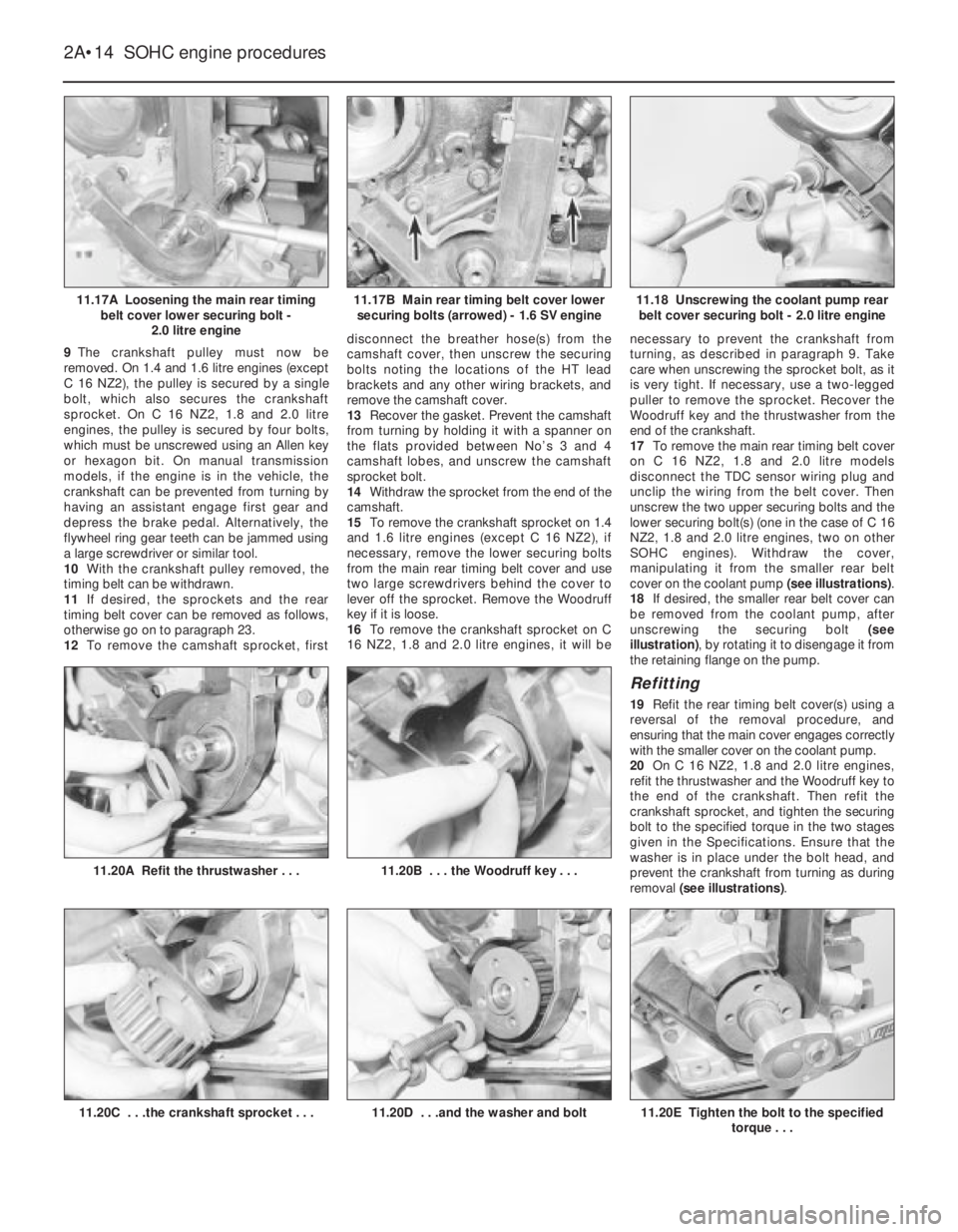

7Turn the crankshaft using a socket or

spanner on the crankshaft sprocket bolt, until

the timing mark on the camshaft sprocket is

aligned with the notch in the rear timing belt

cover, and the notch in the crankshaft pulley

is aligned with the pointer on the rear timing

belt cover (see illustrations). Note that on 1.4

litre engine there are two notches in the

crankshaft pulley, representing 5°and 10°

BTDC, and the 10°BTDC notch should be

aligned with the pointer (see illustration).

8Loosen the three coolant pump securing

bolts (see illustration), and turn the pump to

relieve the tension in the timing belt, then slide

the belt from the camshaft sprocket.

SOHC engine procedures 2A•13

11.5C Timing belt lower (small) outer

cover screws (A), tensioner screw (B),

ignition timing fixed reference mark (C)

11.8 Loosening a coolant pump securing

bolt - 2.0 litre engine11.7C Crankshaft pulley 10°BTDC notch

aligned with pointer on rear timing belt

cover - 1.4 litre engine11.7B . . .and notch in crankshaft pulley

aligned with pointer on rear timing belt

cover - 2.0 litre engine

11.7A Camshaft sprocket TDC mark

aligned with notch in rear timing belt

cover . . .

11.5B . . .and the smaller cover from the

coolant pump - 2.0 litre engine11.5A Remove the main outer timing belt

cover . . .

2A

Page 211 of 525

9The crankshaft pulley must now be

removed. On 1.4 and 1.6 litre engines (except

C 16 NZ2), the pulley is secured by a single

bolt, which also secures the crankshaft

sprocket. On C 16 NZ2, 1.8 and 2.0 litre

engines, the pulley is secured by four bolts,

which must be unscrewed using an Allen key

or hexagon bit. On manual transmission

models, if the engine is in the vehicle, the

crankshaft can be prevented from turning by

having an assistant engage first gear and

depress the brake pedal. Alternatively, the

flywheel ring gear teeth can be jammed using

a large screwdriver or similar tool.

10With the crankshaft pulley removed, the

timing belt can be withdrawn.

11If desired, the sprockets and the rear

timing belt cover can be removed as follows,

otherwise go on to paragraph 23.

12To remove the camshaft sprocket, firstdisconnect the breather hose(s) from the

camshaft cover, then unscrew the securing

bolts noting the locations of the HT lead

brackets and any other wiring brackets, and

remove the camshaft cover.

13Recover the gasket. Prevent the camshaft

from turning by holding it with a spanner on

the flats provided between No’s 3 and 4

camshaft lobes, and unscrew the camshaft

sprocket bolt.

14Withdraw the sprocket from the end of the

camshaft.

15To remove the crankshaft sprocket on 1.4

and 1.6 litre engines (except C 16 NZ2), if

necessary, remove the lower securing bolts

from the main rear timing belt cover and use

two large screwdrivers behind the cover to

lever off the sprocket. Remove the Woodruff

key if it is loose.

16To remove the crankshaft sprocket on C

16 NZ2, 1.8 and 2.0 litre engines, it will benecessary to prevent the crankshaft from

turning, as described in paragraph 9. Take

care when unscrewing the sprocket bolt, as it

is very tight. If necessary, use a two-legged

puller to remove the sprocket. Recover the

Woodruff key and the thrustwasher from the

end of the crankshaft.

17To remove the main rear timing belt cover

on C 16 NZ2, 1.8 and 2.0 litre models

disconnect the TDC sensor wiring plug and

unclip the wiring from the belt cover. Then

unscrew the two upper securing bolts and the

lower securing bolt(s) (one in the case of C 16

NZ2, 1.8 and 2.0 litre engines, two on other

SOHC engines). Withdraw the cover,

manipulating it from the smaller rear belt

cover on the coolant pump (see illustrations).

18If desired, the smaller rear belt cover can

be removed from the coolant pump, after

unscrewing the securing bolt (see

illustration), by rotating it to disengage it from

the retaining flange on the pump.

Refitting

19Refit the rear timing belt cover(s) using a

reversal of the removal procedure, and

ensuring that the main cover engages correctly

with the smaller cover on the coolant pump.

20On C 16 NZ2, 1.8 and 2.0 litre engines,

refit the thrustwasher and the Woodruff key to

the end of the crankshaft. Then refit the

crankshaft sprocket, and tighten the securing

bolt to the specified torque in the two stages

given in the Specifications. Ensure that the

washer is in place under the bolt head, and

prevent the crankshaft from turning as during

removal (see illustrations).

2A•14SOHC engine procedures

11.17A Loosening the main rear timing

belt cover lower securing bolt -

2.0 litre engine11.18 Unscrewing the coolant pump rear

belt cover securing bolt - 2.0 litre engine

11.20E Tighten the bolt to the specified

torque . . .11.20D . . .and the washer and bolt11.20C . . .the crankshaft sprocket . . .

11.20B . . . the Woodruff key . . .11.20A Refit the thrustwasher . . .

11.17B Main rear timing belt cover lower

securing bolts (arrowed) - 1.6 SV engine

Page 224 of 525

28Crankshaft rear oil seal -

renewal

4

Renewal

1With the engine removed from the vehicle,

remove the flywheel, or flexplate (as

applicable) as described in Sections 25 and

26.

2Punch or drill a small hole in the centre of

the now-exposed oil seal. Screw in a

self-tapping screw, and pull on the screw with

pliers to extract the seal. Several attempts

may be necessary. Be careful not to damage

the sealing face of the crankshaft.

3Clean the oil seal seat with a wooden or

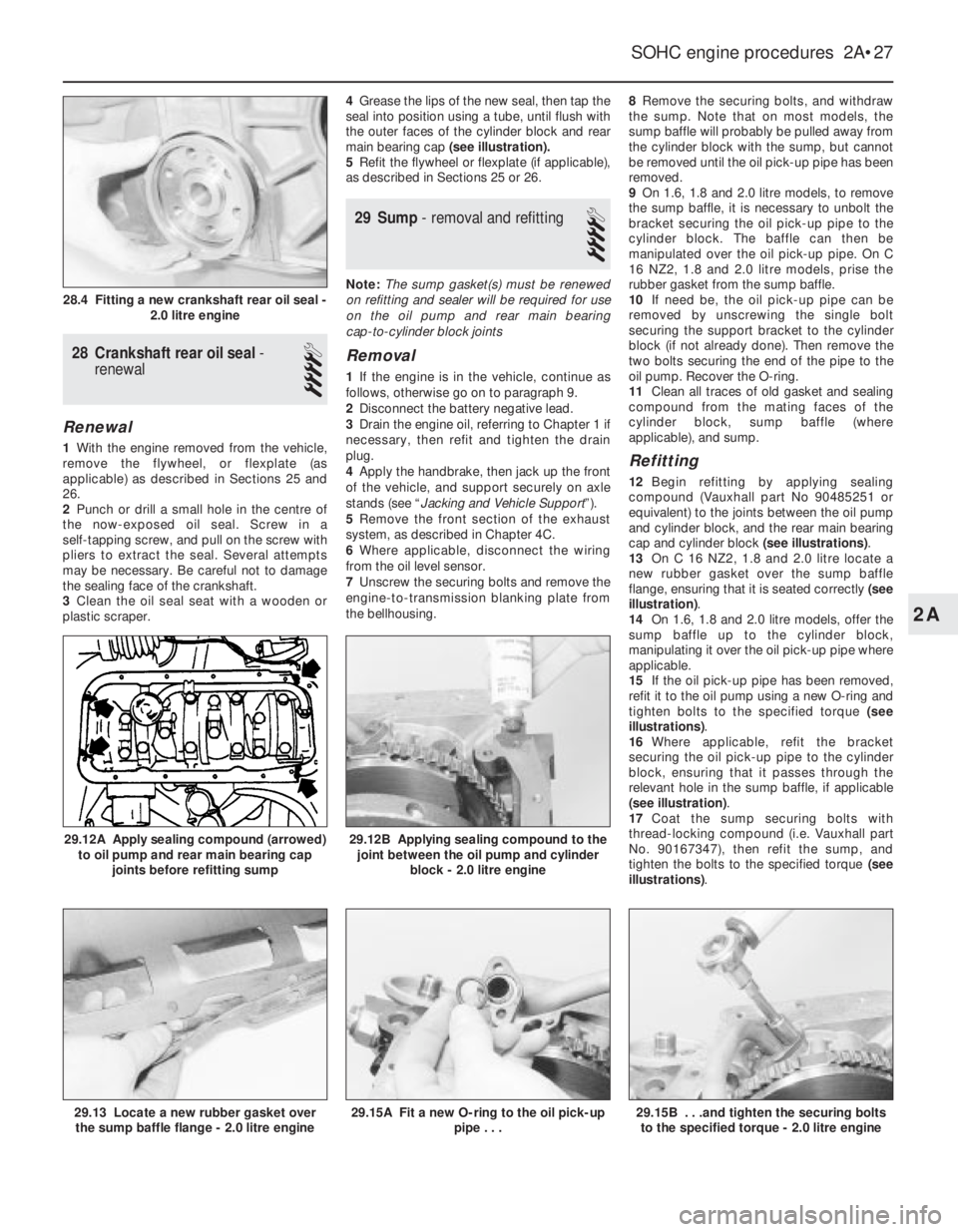

plastic scraper.4Grease the lips of the new seal, then tap the

seal into position using a tube, until flush with

the outer faces of the cylinder block and rear

main bearing cap (see illustration).

5Refit the flywheel or flexplate (if applicable),

as described in Sections 25 or 26.

29Sump - removal and refitting

4

Note: The sump gasket(s) must be renewed

on refitting and sealer will be required for use

on the oil pump and rear main bearing

cap-to-cylinder block joints

Removal

1If the engine is in the vehicle, continue as

follows, otherwise go on to paragraph 9.

2Disconnect the battery negative lead.

3Drain the engine oil, referring to Chapter 1 if

necessary, then refit and tighten the drain

plug.

4Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”).

5Remove the front section of the exhaust

system, as described in Chapter 4C.

6Where applicable, disconnect the wiring

from the oil level sensor.

7Unscrew the securing bolts and remove the

engine-to-transmission blanking plate from

the bellhousing.8Remove the securing bolts, and withdraw

the sump. Note that on most models, the

sump baffle will probably be pulled away from

the cylinder block with the sump, but cannot

be removed until the oil pick-up pipe has been

removed.

9On 1.6, 1.8 and 2.0 litre models, to remove

the sump baffle, it is necessary to unbolt the

bracket securing the oil pick-up pipe to the

cylinder block. The baffle can then be

manipulated over the oil pick-up pipe. On C

16 NZ2, 1.8 and 2.0 litre models, prise the

rubber gasket from the sump baffle.

10If need be, the oil pick-up pipe can be

removed by unscrewing the single bolt

securing the support bracket to the cylinder

block (if not already done). Then remove the

two bolts securing the end of the pipe to the

oil pump. Recover the O-ring.

11Clean all traces of old gasket and sealing

compound from the mating faces of the

cylinder block, sump baffle (where

applicable), and sump.

Refitting

12Begin refitting by applying sealing

compound (Vauxhall part No 90485251 or

equivalent) to the joints between the oil pump

and cylinder block, and the rear main bearing

cap and cylinder block (see illustrations).

13On C 16 NZ2, 1.8 and 2.0 litre locate a

new rubber gasket over the sump baffle

flange, ensuring that it is seated correctly (see

illustration).

14On 1.6, 1.8 and 2.0 litre models, offer the

sump baffle up to the cylinder block,

manipulating it over the oil pick-up pipe where

applicable.

15If the oil pick-up pipe has been removed,

refit it to the oil pump using a new O-ring and

tighten bolts to the specified torque (see

illustrations).

16Where applicable, refit the bracket

securing the oil pick-up pipe to the cylinder

block, ensuring that it passes through the

relevant hole in the sump baffle, if applicable

(see illustration).

17Coat the sump securing bolts with

thread-locking compound (i.e. Vauxhall part

No. 90167347), then refit the sump, and

tighten the bolts to the specified torque (see

illustrations).

SOHC engine procedures 2A•27

29.12B Applying sealing compound to the

joint between the oil pump and cylinder

block - 2.0 litre engine

29.15B . . .and tighten the securing bolts

to the specified torque - 2.0 litre engine29.15A Fit a new O-ring to the oil pick-up

pipe . . .29.13 Locate a new rubber gasket over

the sump baffle flange - 2.0 litre engine

29.12A Apply sealing compound (arrowed)

to oil pump and rear main bearing cap

joints before refitting sump

28.4 Fitting a new crankshaft rear oil seal -

2.0 litre engine

2A

Page 228 of 525

7If any of the ring end gaps exceed the

specified tolerance, the relevant rings will have

to be renewed, and if the ring grooves in the

pistons are worn, new pistons may be required.

8Clean out the piston ring grooves using a

piece of old piston ring as a scraper. Take

care not to scratch the surface of the pistons.

Protect your fingers, piston ring edges are

sharp. Also probe the groove oil return holes,

to ensure that they are not blocked.

9Check the cylinder bores for signs of wear

ridges towards the top of the bores. If wear

ridges are evident, and new piston rings are

being fitted, the top ring must be stepped to

clear the wear ridge, or the bore must be

de-ridged using a scraper.

10Fit the oil control ring sections with the

lower steel ring gap offset 25 to 50 mm to the

right of the spreader ring gap, and the upper

steel ring gap offset by the same distance to

the left of the spreader ring gap.

11Fit the lower compression ring, noting that

the ring is tapered or stepped. The ring should

be fitted with the word “TOP” uppermost.

12Fit the upper compression ring, and offset

the ring gap by 180°to the lower compression

ring gap. If a stepped ring is being fitted, fit

the ring with the smaller diameter of the step

uppermost.

13If new pistons are to be fitted, they must

be selected from the grades available, after

measuring the cylinder bores as described in

Section 36.

14Normally the appropriate oversize pistons

are supplied by the dealer when the block is

rebored.15Whenever new piston rings are being

installed, the glaze on the original cylinder

bores should be “broken”, using either

abrasive paper or a glaze-removing tool in an

electric drill. If abrasive paper is used, use

strokes at 60°to the bore centre line, to create

a cross-hatching effect.

34Crankshaft and bearings -

removal and refitting

4

Note: New main bearing cap bolts must be

used on refitting

Removal

1With the engine removed from the vehicle,

continue as follows.

2Remove the cylinder head, as described

previously in Section 20.

3Remove the sump, oil pick-up pipe and

sump baffle (where applicable), as described

in Section 29.

4Remove the oil pump, as described in

Section 30.

5Remove the flywheel or flexplate (if

applicable), as described in Sections 25 and

26.

6Remove the pistons and connecting rods,

as described in Section 32.

7Invert the engine so that it is standing on

the top face of the cylinder block.

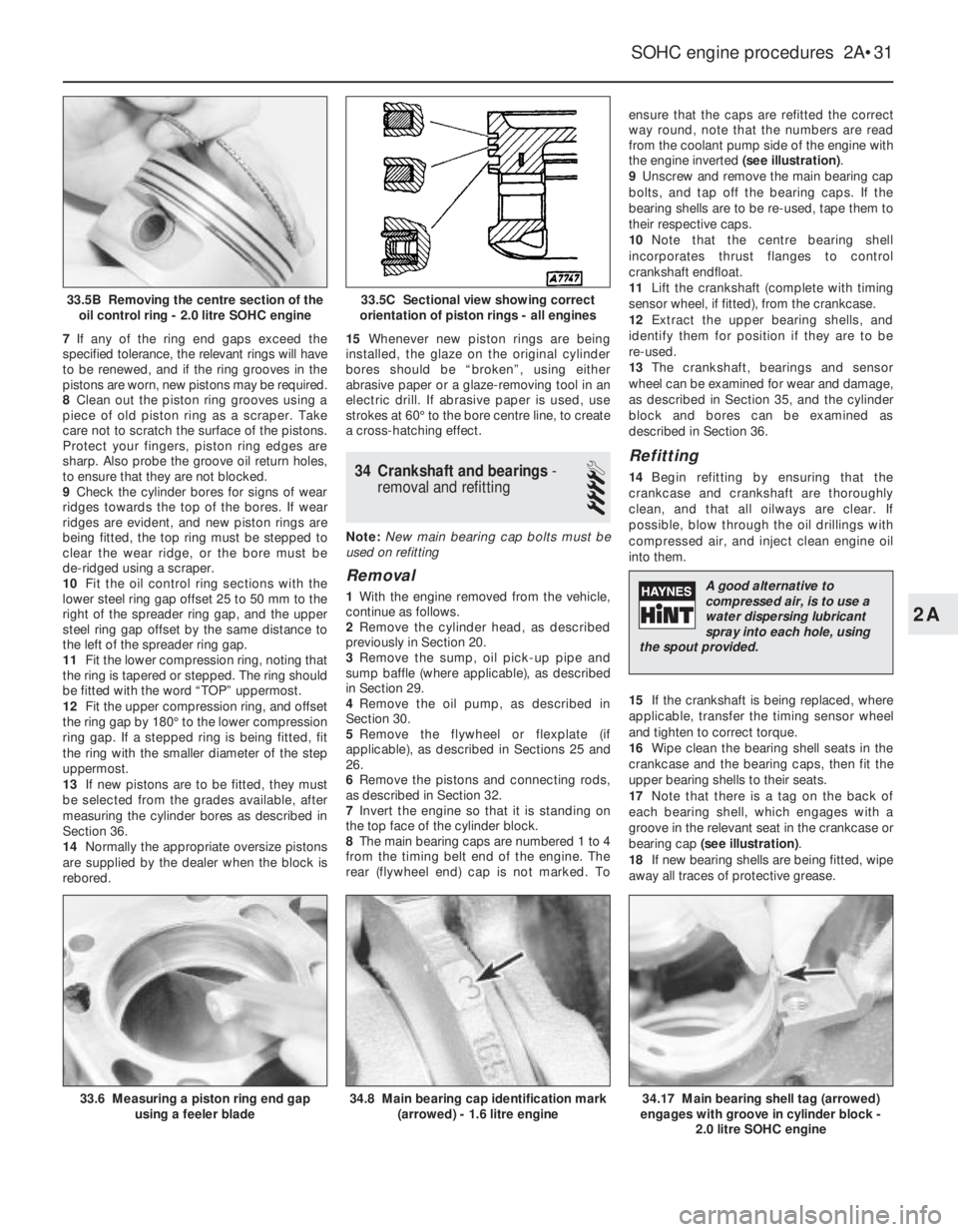

8The main bearing caps are numbered 1 to 4

from the timing belt end of the engine. The

rear (flywheel end) cap is not marked. Toensure that the caps are refitted the correct

way round, note that the numbers are read

from the coolant pump side of the engine with

the engine inverted (see illustration).

9Unscrew and remove the main bearing cap

bolts, and tap off the bearing caps. If the

bearing shells are to be re-used, tape them to

their respective caps.

10Note that the centre bearing shell

incorporates thrust flanges to control

crankshaft endfloat.

11Lift the crankshaft (complete with timing

sensor wheel, if fitted), from the crankcase.

12Extract the upper bearing shells, and

identify them for position if they are to be

re-used.

13The crankshaft, bearings and sensor

wheel can be examined for wear and damage,

as described in Section 35, and the cylinder

block and bores can be examined as

described in Section 36.

Refitting

14Begin refitting by ensuring that the

crankcase and crankshaft are thoroughly

clean, and that all oilways are clear. If

possible, blow through the oil drillings with

compressed air, and inject clean engine oil

into them.

15If the crankshaft is being replaced, where

applicable, transfer the timing sensor wheel

and tighten to correct torque.

16Wipe clean the bearing shell seats in the

crankcase and the bearing caps, then fit the

upper bearing shells to their seats.

17Note that there is a tag on the back of

each bearing shell, which engages with a

groove in the relevant seat in the crankcase or

bearing cap (see illustration).

18If new bearing shells are being fitted, wipe

away all traces of protective grease.

SOHC engine procedures 2A•31

33.6 Measuring a piston ring end gap

using a feeler blade34.8 Main bearing cap identification mark

(arrowed) - 1.6 litre engine34.17 Main bearing shell tag (arrowed)

engages with groove in cylinder block -

2.0 litre SOHC engine

33.5C Sectional view showing correct

orientation of piston rings - all engines33.5B Removing the centre section of the

oil control ring - 2.0 litre SOHC engine

2A

A good alternative to

compressed air, is to use a

water dispersing lubricant

spray into each hole, using

the spout provided.

Page 230 of 525

31Refit the previously removed

components, referring to the relevant

Sections of this Chapter.

35Crankshaft and bearings -

examination

4

Examination

1Examine the crankpin and main journal

surfaces for signs of scoring or scratches, and

check the ovality and taper of the crankpins

and main journals. If the bearing surface

dimensions do not fall within the tolerance

ranges given in the Specifications at the

beginning of this Chapter, the crankpins

and/or main journals will have to be reground.

2Big-end and crankpin wear is accompanied

by distinct metallic knocking, particularly

noticeable when the engine is pulling from low

revs, and some loss of oil pressure.

3Main bearing and main journal wear is

accompanied by severe engine vibration rumble

- getting progressively worse as engine rev’s

increase - and again by loss of oil pressure.

4If the crankshaft requires regrinding, take it

to an engine reconditioning specialist, who

will machine it for you and supply the correct

undersize bearing shells.

5Inspect the big-end and main bearing shells

for signs of general wear, scoring, pitting and

scratches. The bearings should be matt grey

in colour. With leadindium bearings, should a

trace of copper colour be noticed, the

bearings are badly worn, as the lead bearing

material has worn away to expose the indium

underlay. Renew the bearings if they are in

this condition, or if there are any signs of

scoring or pitting. You are strongly advised

to renew the bearings - regardless of their

condition at time of major overhaul.

Refitting used bearings is a false economy.

6The undersizes available are designed to

correspond with crankshaft regrind sizes. Thebearings are in fact, slightly more than the

stated undersize, as running clearances have

been allowed for during their manufacture.

7Main and big-end bearing shells can be

identified as to size by the marking on the

back of the shell. Standard size shell bearings

are marked STD or .00, undersize shells are

marked with the undersize such as 0.020 u/s.

This marking method applies only to

replacement bearing shells, and not to those

used during production.

8An accurate method of determining bearing

wear is by using a Plastigage. The crankshaft

is located in the main bearings (and, if

necessary, the big-end bearings), and the

Plastigage filament is located across the

journal. Vauxhall recommend that the

crankshaft journal and bearing shells are

lightly lubricated, to prevent the Plastigage

from tearing as the bearing cap is removed.

The bearing cap should be fitted, and the

bolts tightened to the specified torque. The

cap is then removed, and the width of the

filament is checked against a scale that shows

the bearing running clearance. The clearance

should be compared with that given in the

Specifications.

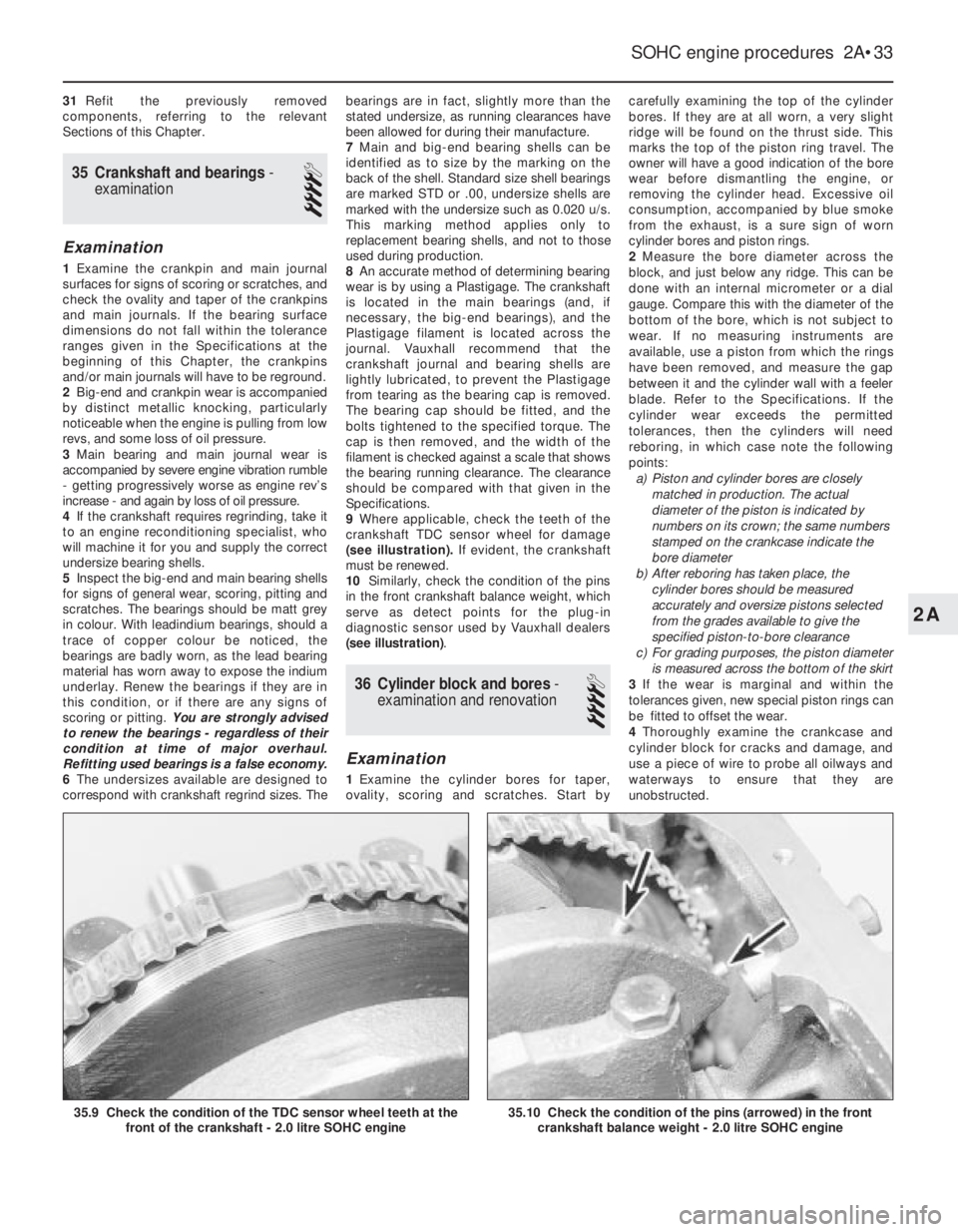

9Where applicable, check the teeth of the

crankshaft TDC sensor wheel for damage

(see illustration). If evident, the crankshaft

must be renewed.

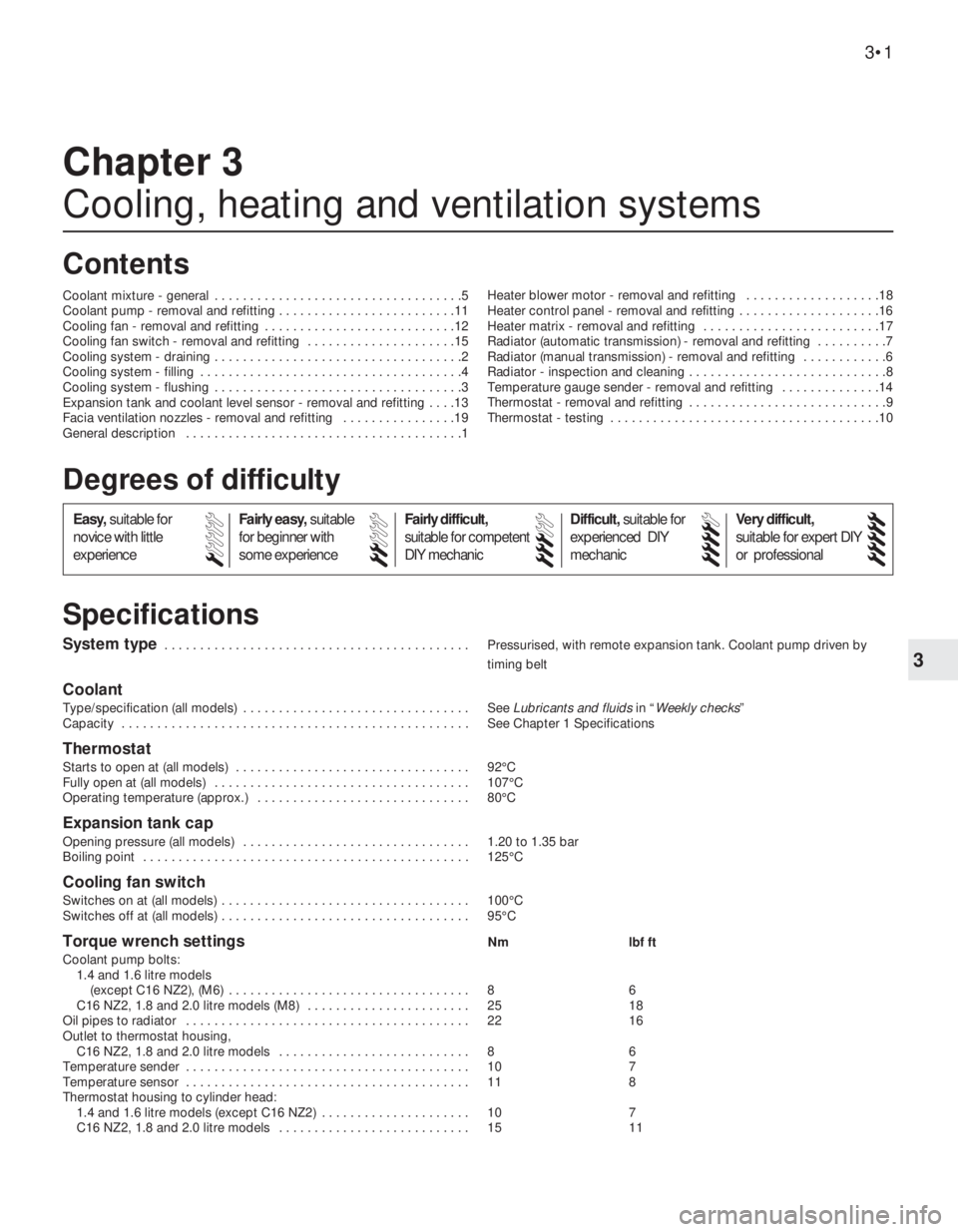

10Similarly, check the condition of the pins

in the front crankshaft balance weight, which

serve as detect points for the plug-in

diagnostic sensor used by Vauxhall dealers

(see illustration).

36Cylinder block and bores -

examination and renovation

4

Examination

1Examine the cylinder bores for taper,

ovality, scoring and scratches. Start bycarefully examining the top of the cylinder

bores. If they are at all worn, a very slight

ridge will be found on the thrust side. This

marks the top of the piston ring travel. The

owner will have a good indication of the bore

wear before dismantling the engine, or

removing the cylinder head. Excessive oil

consumption, accompanied by blue smoke

from the exhaust, is a sure sign of worn

cylinder bores and piston rings.

2Measure the bore diameter across the

block, and just below any ridge. This can be

done with an internal micrometer or a dial

gauge. Compare this with the diameter of the

bottom of the bore, which is not subject to

wear. If no measuring instruments are

available, use a piston from which the rings

have been removed, and measure the gap

between it and the cylinder wall with a feeler

blade. Refer to the Specifications. If the

cylinder wear exceeds the permitted

tolerances, then the cylinders will need

reboring, in which case note the following

points:

a)Piston and cylinder bores are closely

matched in production. The actual

diameter of the piston is indicated by

numbers on its crown; the same numbers

stamped on the crankcase indicate the

bore diameter

b)After reboring has taken place, the

cylinder bores should be measured

accurately and oversize pistons selected

from the grades available to give the

specified piston-to-bore clearance

c)For grading purposes, the piston diameter

is measured across the bottom of the skirt

3If the wear is marginal and within the

tolerances given, new special piston rings can

be fitted to offset the wear.

4Thoroughly examine the crankcase and

cylinder block for cracks and damage, and

use a piece of wire to probe all oilways and

waterways to ensure that they are

unobstructed.

SOHC engine procedures 2A•33

35.10 Check the condition of the pins (arrowed) in the front

crankshaft balance weight - 2.0 litre SOHC engine35.9 Check the condition of the TDC sensor wheel teeth at the

front of the crankshaft - 2.0 litre SOHC engine

2A

Page 231 of 525

5Note that the rubber plug located next to

the bellhousing flange on the cylinder block

covers the aperture for the installation of a

diagnostic TDC sensor. The sensor, when

connected to a monitoring unit, indicates TDC

from the position of the pins set into the

crankshaft balance weight.

37Examination and renovation

-general

4

General

1With the engine completely stripped, clean all

components and examine them for wear. Each

component should be checked, and where

necessary renewed or renovated, as described

in the relevant Sections of this Chapter.

2Renew main and big-end bearing shells as

a matter of course, unless it is known that

they have had little wear, and are in perfect

condition.

3If in doubt whether to renew a component

that is still just serviceable, consider the time

and effort that will be incurred should the

component fail at an early date after rebuild.

Obviously, the age and expected life of the

vehicle must influence the standards applied.4Gaskets, oil seals and O-rings must all be

renewed as a matter of routine. Flywheel,

cylinder head, and main and big-end bearing

cap bolts must be renewed, because of the

high stress to which they are subjected.

5Renew the engine core plugs while they are

easily accessible, if they show signs of

leakage. Knock out the old plugs with a

hammer and chisel or punch. Clean the plug

seats, smear the new plugs with sealing

compound, and tap them squarely into

position.

38Initial start-up after major

overhaul or repair

2

1Make a final check to ensure that

everything has been reconnected to the

engine, and that no rags or tools have been

left in the engine compartment.

2Check that oil and coolant levels are

correct.

3Start the engine. This may take a little longer

than usual, as fuel is pumped to the engine.

4Check that the oil pressure warning lamp

goes out when the engine starts. This may

take a few seconds as the new oil filter fills

with oil.5Run the engine at a fast tickover, and check

for leaks of oil, fuel and coolant. If a new

camshaft has been fitted, pay careful

attention to the running-in procedure given in

Section 18, paragraphs 17 and 18. Where

applicable, check the power steering and/or

automatic transmission fluid cooler unions for

leakage. Some smoke and odd smells may be

experienced, as assembly lubricants and

sealers burn off the various components.

6Bring the engine to normal operating

temperature. Check the ignition timing, idle

speed and the mixture (where applicable), as

described in Chapter 4A or 4B.

7Allow the engine to cool, then recheck the

oil and coolant levels. Top-up if necessary

8If new bearings, pistons, etc., have been

fitted, the engine should be run-in at reduced

speeds and loads for the first 500 miles (800

km) or so. It is beneficial to change the engine

oil and filter after this mileage.

2A•34SOHC engine procedures

Page 232 of 525

3

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressurised, with remote expansion tank. Coolant pump driven by

timing belt

Coolant

Type/specification (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Lubricants and fluidsin “Weekly checks”

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1 Specifications

Thermostat

Starts to open at (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92°C

Fully open at (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107°C

Operating temperature (approx.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80°C

Expansion tank cap

Opening pressure (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.20 to 1.35 bar

Boiling point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125°C

Cooling fan switch

Switches on at (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100°C

Switches off at (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95°C

Torque wrench settingsNm lbf ft

Coolant pump bolts:

1.4 and 1.6 litre models

(except C16 NZ2), (M6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

C16 NZ2, 1.8 and 2.0 litre models (M8) . . . . . . . . . . . . . . . . . . . . . . . 25 18

Oil pipes to radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 16

Outlet to thermostat housing,

C16 NZ2, 1.8 and 2.0 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Temperature sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 8

Thermostat housing to cylinder head:

1.4 and 1.6 litre models (except C16 NZ2) . . . . . . . . . . . . . . . . . . . . . 10 7

C16 NZ2, 1.8 and 2.0 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 11

Chapter 3

Cooling, heating and ventilation systems

Coolant mixture - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Coolant pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .11

Cooling fan - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cooling fan switch - removal and refitting . . . . . . . . . . . . . . . . . . . . .15

Cooling system - draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Cooling system - filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cooling system - flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Expansion tank and coolant level sensor - removal and refitting . . . .13

Facia ventilation nozzles - removal and refitting . . . . . . . . . . . . . . . .19

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1Heater blower motor - removal and refitting . . . . . . . . . . . . . . . . . . .18

Heater control panel - removal and refitting . . . . . . . . . . . . . . . . . . . .16

Heater matrix - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .17

Radiator (automatic transmission) - removal and refitting . . . . . . . . . .7

Radiator (manual transmission) - removal and refitting . . . . . . . . . . . .6

Radiator - inspection and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Temperature gauge sender - removal and refitting . . . . . . . . . . . . . .14

Thermostat - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Thermostat - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 236 of 525

C16 NZ2, 1.8 and 2.0 litre models, remove the

timing belt. Details are as described in

Chapter 2A.

3Remove timing belt tension roller from oil

pump, where applicable.

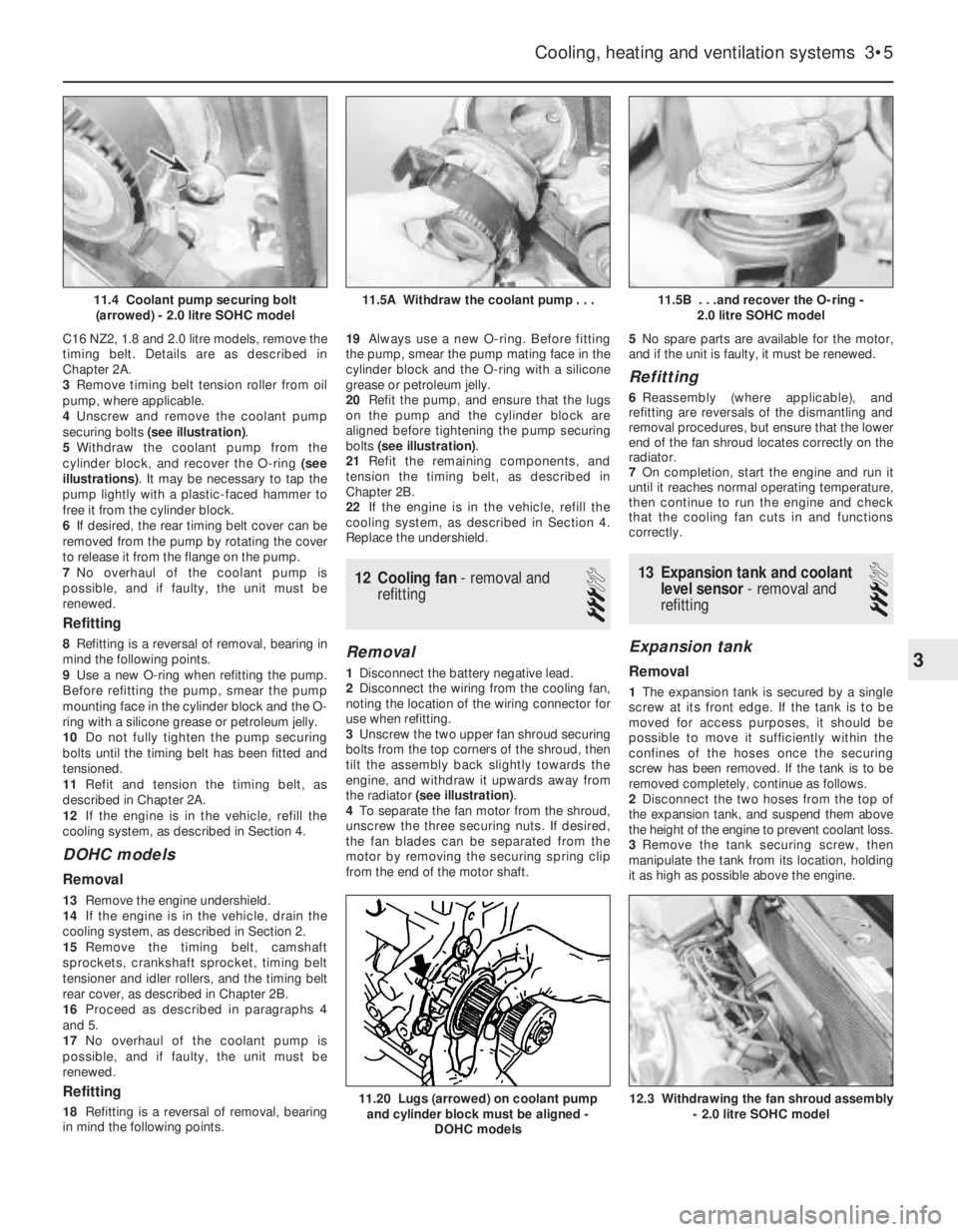

4Unscrew and remove the coolant pump

securing bolts (see illustration).

5Withdraw the coolant pump from the

cylinder block, and recover the O-ring (see

illustrations). It may be necessary to tap the

pump lightly with a plastic-faced hammer to

free it from the cylinder block.

6If desired, the rear timing belt cover can be

removed from the pump by rotating the cover

to release it from the flange on the pump.

7No overhaul of the coolant pump is

possible, and if faulty, the unit must be

renewed.

Refitting

8Refitting is a reversal of removal, bearing in

mind the following points.

9Use a new O-ring when refitting the pump.

Before refitting the pump, smear the pump

mounting face in the cylinder block and the O-

ring with a silicone grease or petroleum jelly.

10Do not fully tighten the pump securing

bolts until the timing belt has been fitted and

tensioned.

11Refit and tension the timing belt, as

described in Chapter 2A.

12If the engine is in the vehicle, refill the

cooling system, as described in Section 4.

DOHC models

Removal

13Remove the engine undershield.

14If the engine is in the vehicle, drain the

cooling system, as described in Section 2.

15Remove the timing belt, camshaft

sprockets, crankshaft sprocket, timing belt

tensioner and idler rollers, and the timing belt

rear cover, as described in Chapter 2B.

16Proceed as described in paragraphs 4

and 5.

17No overhaul of the coolant pump is

possible, and if faulty, the unit must be

renewed.

Refitting

18Refitting is a reversal of removal, bearing

in mind the following points.19Always use a new O-ring. Before fitting

the pump, smear the pump mating face in the

cylinder block and the O-ring with a silicone

grease or petroleum jelly.

20Refit the pump, and ensure that the lugs

on the pump and the cylinder block are

aligned before tightening the pump securing

bolts (see illustration).

21Refit the remaining components, and

tension the timing belt, as described in

Chapter 2B.

22If the engine is in the vehicle, refill the

cooling system, as described in Section 4.

Replace the undershield.

12Cooling fan - removal and

refitting

3

Removal

1Disconnect the battery negative lead.

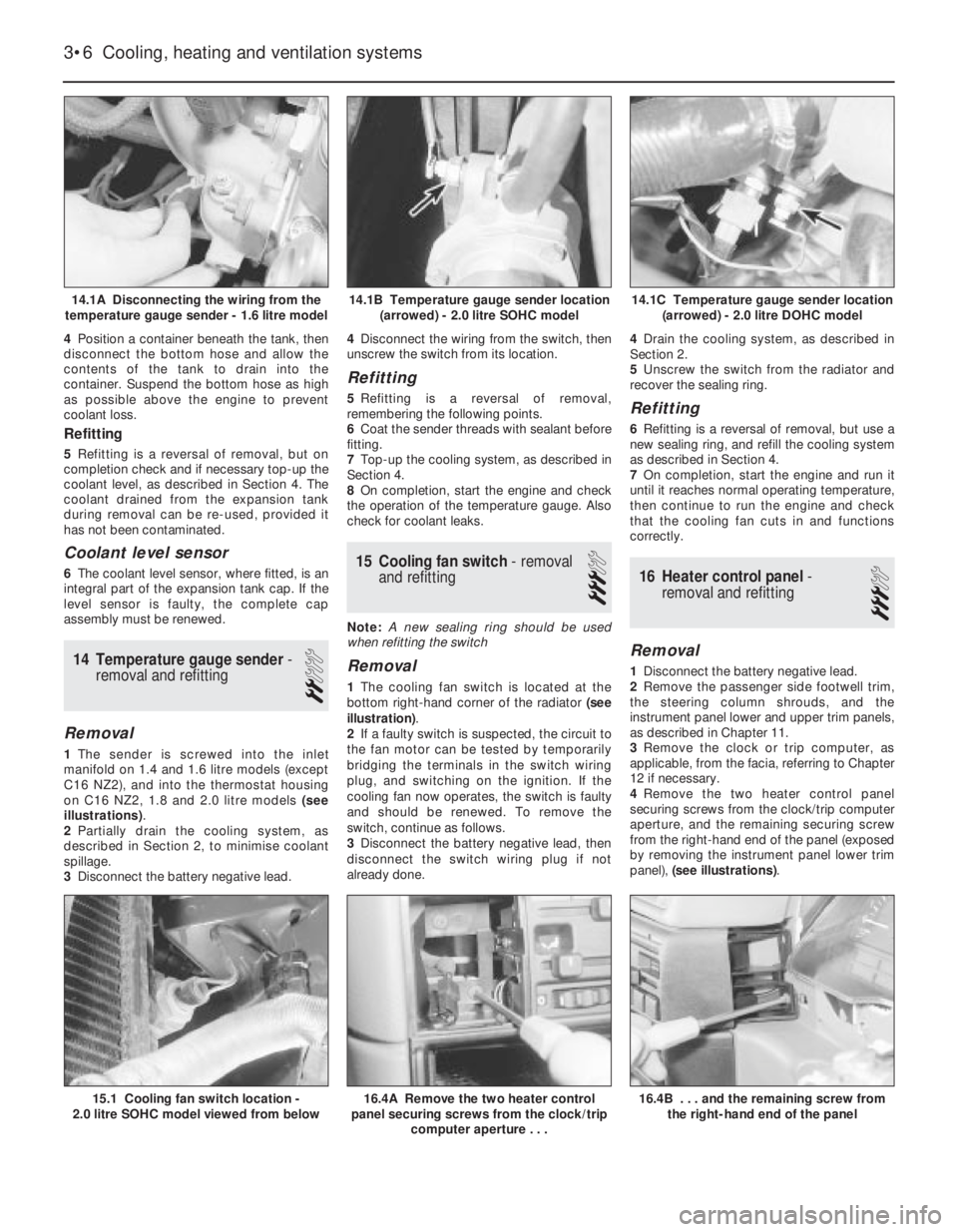

2Disconnect the wiring from the cooling fan,

noting the location of the wiring connector for

use when refitting.

3Unscrew the two upper fan shroud securing

bolts from the top corners of the shroud, then

tilt the assembly back slightly towards the

engine, and withdraw it upwards away from

the radiator (see illustration).

4To separate the fan motor from the shroud,

unscrew the three securing nuts. If desired,

the fan blades can be separated from the

motor by removing the securing spring clip

from the end of the motor shaft.5No spare parts are available for the motor,

and if the unit is faulty, it must be renewed.

Refitting

6Reassembly (where applicable), and

refitting are reversals of the dismantling and

removal procedures, but ensure that the lower

end of the fan shroud locates correctly on the

radiator.

7On completion, start the engine and run it

until it reaches normal operating temperature,

then continue to run the engine and check

that the cooling fan cuts in and functions

correctly.

13Expansion tank and coolant

level sensor -removal and

refitting

3

Expansion tank

Removal

1The expansion tank is secured by a single

screw at its front edge. If the tank is to be

moved for access purposes, it should be

possible to move it sufficiently within the

confines of the hoses once the securing

screw has been removed. If the tank is to be

removed completely, continue as follows.

2Disconnect the two hoses from the top of

the expansion tank, and suspend them above

the height of the engine to prevent coolant loss.

3Remove the tank securing screw, then

manipulate the tank from its location, holding

it as high as possible above the engine.

Cooling, heating and ventilation systems 3•5

11.5B . . .and recover the O-ring -

2.0 litre SOHC model

12.3 Withdrawing the fan shroud assembly

- 2.0 litre SOHC model11.20 Lugs (arrowed) on coolant pump

and cylinder block must be aligned -

DOHC models

11.5A Withdraw the coolant pump . . .11.4 Coolant pump securing bolt

(arrowed) - 2.0 litre SOHC model

3

Page 237 of 525

4Position a container beneath the tank, then

disconnect the bottom hose and allow the

contents of the tank to drain into the

container. Suspend the bottom hose as high

as possible above the engine to prevent

coolant loss.

Refitting

5Refitting is a reversal of removal, but on

completion check and if necessary top-up the

coolant level, as described in Section 4. The

coolant drained from the expansion tank

during removal can be re-used, provided it

has not been contaminated.

Coolant level sensor

6The coolant level sensor, where fitted, is an

integral part of the expansion tank cap. If the

level sensor is faulty, the complete cap

assembly must be renewed.

14Temperature gauge sender -

removal and refitting

2

Removal

1The sender is screwed into the inlet

manifold on 1.4 and 1.6 litre models (except

C16 NZ2), and into the thermostat housing

on C16 NZ2, 1.8 and 2.0 litre models (see

illustrations).

2Partially drain the cooling system, as

described in Section 2, to minimise coolant

spillage.

3Disconnect the battery negative lead.4Disconnect the wiring from the switch, then

unscrew the switch from its location.

Refitting

5Refitting is a reversal of removal,

remembering the following points.

6Coat the sender threads with sealant before

fitting.

7Top-up the cooling system, as described in

Section 4.

8On completion, start the engine and check

the operation of the temperature gauge. Also

check for coolant leaks.

15Cooling fan switch -removal

and refitting

3

Note: A new sealing ring should be used

when refitting the switch

Removal

1The cooling fan switch is located at the

bottom right-hand corner of the radiator (see

illustration).

2If a faulty switch is suspected, the circuit to

the fan motor can be tested by temporarily

bridging the terminals in the switch wiring

plug, and switching on the ignition. If the

cooling fan now operates, the switch is faulty

and should be renewed. To remove the

switch, continue as follows.

3Disconnect the battery negative lead, then

disconnect the switch wiring plug if not

already done.4Drain the cooling system, as described in

Section 2.

5Unscrew the switch from the radiator and

recover the sealing ring.

Refitting

6Refitting is a reversal of removal, but use a

new sealing ring, and refill the cooling system

as described in Section 4.

7On completion, start the engine and run it

until it reaches normal operating temperature,

then continue to run the engine and check

that the cooling fan cuts in and functions

correctly.

16Heater control panel -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the passenger side footwell trim,

the steering column shrouds, and the

instrument panel lower and upper trim panels,

as described in Chapter 11.

3Remove the clock or trip computer, as

applicable, from the facia, referring to Chapter

12 if necessary.

4Remove the two heater control panel

securing screws from the clock/trip computer

aperture, and the remaining securing screw

from the right-hand end of the panel (exposed

by removing the instrument panel lower trim

panel), (see illustrations).

3•6Cooling, heating and ventilation systems

14.1A Disconnecting the wiring from the

temperature gauge sender - 1.6 litre model14.1C Temperature gauge sender location

(arrowed) - 2.0 litre DOHC model

16.4B . . . and the remaining screw from

the right-hand end of the panel16.4A Remove the two heater control

panel securing screws from the clock/trip

computer aperture . . .15.1 Cooling fan switch location -

2.0 litre SOHC model viewed from below

14.1B Temperature gauge sender location

(arrowed) - 2.0 litre SOHC model

Page 262 of 525

Glossary of Technical Terms REF•23

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).

Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful tothe ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

RotorIn a distributor, the rotating device

inside the cap that connects the centre

electrode and the outer terminals as it turns,

distributing the high voltage from the coil

secondary winding to the proper spark plug.

Also, that part of an alternator which rotates

inside the stator. Also, the rotating assembly

of a turbocharger, including the compressor

wheel, shaft and turbine wheel.

RunoutThe amount of wobble (in-and-out

movement) of a gear or wheel as it’s rotated.

The amount a shaft rotates “out-of-true.” The

out-of-round condition of a rotating part.

SSealantA liquid or paste used to prevent

leakage at a joint. Sometimes used in

conjunction with a gasket.

Sealed beam lampAn older headlight design

which integrates the reflector, lens and

filaments into a hermetically-sealed one-piece

unit. When a filament burns out or the lens

cracks, the entire unit is simply replaced.

Serpentine drivebeltA single, long, wide

accessory drivebelt that’s used on some

newer vehicles to drive all the accessories,

instead of a series of smaller, shorter belts.

Serpentine drivebelts are usually tensioned by

an automatic tensioner.

ShimThin spacer, commonly used to adjust

the clearance or relative positions between

two parts. For example, shims inserted into or

under bucket tappets control valve

clearances. Clearance is adjusted by

changing the thickness of the shim.

Slide hammerA special puller that screws

into or hooks onto a component such as a

shaft or bearing; a heavy sliding handle on the

shaft bottoms against the end of the shaft to

knock the component free.

SprocketA tooth or projection on the

periphery of a wheel, shaped to engage with a

chain or drivebelt. Commonly used to refer to

the sprocket wheel itself.

Starter inhibitor switchOn vehicles with an

O-ring

Serpentine drivebelt

Plastigage

REF