brake OPEL CASCADA 2015 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2015, Model line: CASCADA, Model: OPEL CASCADA 2015Pages: 253, PDF Size: 7.58 MB

Page 177 of 253

Driving and operating175

applicable version), taking into

consideration the vehicle weight in running order, as specified by the

regulation.

The figures are provided only for the

purpose of comparison between

different vehicle variants and must

not be taken as a guarantee for the

actual fuel consumption of a

particular vehicle. Additional

equipment may result in slightly

higher results than the stated

consumption and CO 2 figures.

Furthermore, fuel consumption is dependent on personal driving style

as well as road and traffic conditions.Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for

trailer brake light cannot detect a

partial bulb outage, e.g. in case of 4 x

5 Watt bulbs, the function only detects lamp outage when only a single

5 Watt lamp remains or none remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball

bar for towing. Always keep the

coupling ball bar in the vehicle.Driving characteristics and

towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the coupling ball, is being used to reduce snaking movements.

For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

1200 kg the use of a stabiliser is

strongly recommended when driving

above 80 km/h.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 239.

Page 183 of 253

Vehicle care181Vehicle careGeneral Information...................181

Vehicle checks ........................... 182

Bulb replacement .......................189

Electrical system ........................197

Vehicle tools .............................. 203

Wheels and tyres .......................204

Jump starting ............................. 219

Towing ....................................... 220

Appearance care .......................222General Information

Accessories and vehicle

modifications

We recommend the use of genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

■ Wash the vehicle. Wax painted parts of the vehicle. Exterior care

3 222.

■ Have the wax in the engine compartment and underbody

checked.

■ Clean and preserve the rubber seals.

■ Fill up fuel tank completely.

■ Change the engine oil.

■ Drain the washer fluid reservoir.

■ Check the coolant antifreeze and corrosion protection.

■ Adjust tyre pressure to the value specified for full load.

■ Park the vehicle in a dry, well ventilated place. Engage first orreverse gear or set selector lever to P . Prevent the vehicle from rolling.

■ Do not apply the parking brake.

Page 188 of 253

186Vehicle care

Power steering fluid level normally

does not have to be checked. If an

unusual noise sounds during steering or the power steering reacts

unusually, seek the assistance of a

workshop.

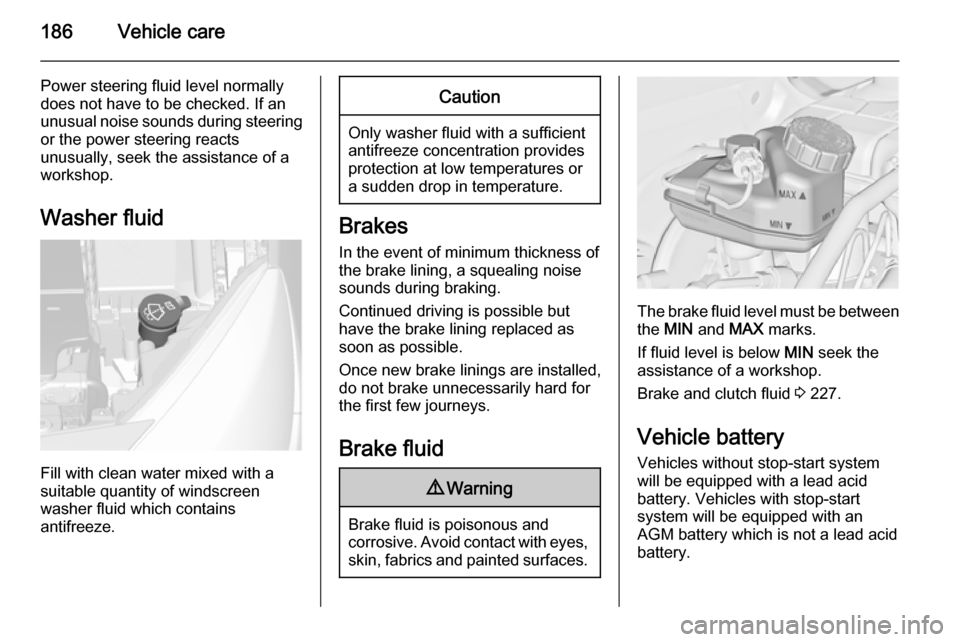

Washer fluid

Fill with clean water mixed with a

suitable quantity of windscreen

washer fluid which contains

antifreeze.

Caution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

Brakes

In the event of minimum thickness ofthe brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

Brake fluid

9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

The brake fluid level must be betweenthe MIN and MAX marks.

If fluid level is below MIN seek the

assistance of a workshop.

Brake and clutch fluid 3 227.

Vehicle battery Vehicles without stop-start system

will be equipped with a lead acid

battery. Vehicles with stop-start

system will be equipped with an

AGM battery which is not a lead acid

battery.

Page 196 of 253

194Vehicle careTail lights

1. Open and remove the cover onthe inside of the boot lid by loosen

the screw with a coin.

2. Brake lights, tail lights and fog light are designed as Light

Emitting Diodes (LEDs) and

cannot be changed.

Remove bulb holder by turning

anti-clockwise.

Turn signal lights ( 1)

Reversing lights ( 2)

3. Remove and replace bulb

4. Insert bulb holder into tail light assembly and turn clockwise.

5. Close the cover by inserting thefastener clips first. Lock the cover

by turning the screw clockwise

with a coin.

Additional lights in the boot lid

frame

1. Open the boot lid.

Page 201 of 253

Vehicle care199

No.Circuit1Engine control module2Lambda sensor3Fuel injection, ignition system4Fuel injection, ignition system5–6Mirror heating7Fan control8Lambda sensor, engine cooling9Rear window sensor10Vehicle battery sensor11Trunk release12Adaptive forward lighting, auto‐

matic light control13ABS Valves14–15Engine control module16StarterNo.Circuit17Transmission control module18Heated rear window19Front power windows20Rear power windows21Rear eletrical centre22Left high beam (Halogen)23Headlamp washer system24Right low beam (Xenon)25Left low beam (Xenon)26Front fog lights27Diesel fuel heating28Start stop system29Electric parking brake30ABS pump31–32AirbagNo.Circuit33Adaptive forward lighting, auto‐

matic light control34Exhaust gas recirculation35Power windows, rain sensor,

exterior mirror36Climate control37–38Vacuum pump39Fuel system control module40Windscreen washer system41Right high beam (Halogen)42Radiator fan43Windscreen wiper44–45Radiator fan46–47Horn

Page 203 of 253

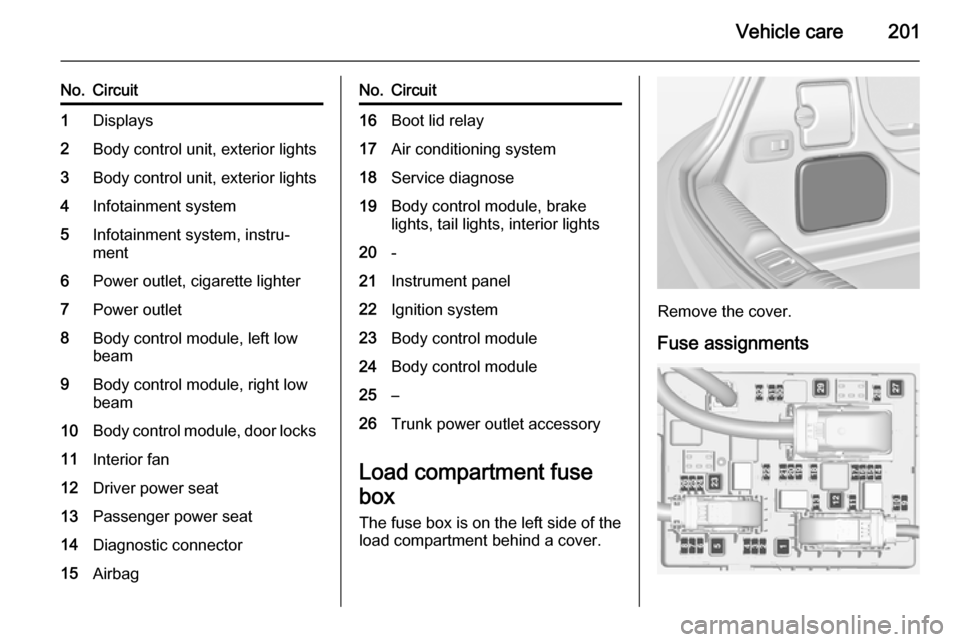

Vehicle care201

No.Circuit1Displays2Body control unit, exterior lights3Body control unit, exterior lights4Infotainment system5Infotainment system, instru‐

ment6Power outlet, cigarette lighter7Power outlet8Body control module, left low

beam9Body control module, right low

beam10Body control module, door locks11Interior fan12Driver power seat13Passenger power seat14Diagnostic connector15AirbagNo.Circuit16Boot lid relay17Air conditioning system18Service diagnose19Body control module, brake

lights, tail lights, interior lights20-21Instrument panel22Ignition system23Body control module24Body control module25–26Trunk power outlet accessory

Load compartment fuse

box

The fuse box is on the left side of the

load compartment behind a cover.

Remove the cover.

Fuse assignments

Page 210 of 253

208Vehicle care

and left side rear tyre. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are two minutes to match the first tyre/wheel position, and five minutes

overall to match all four tyre/wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The TPMS sensor matching process is:

1. Apply the parking brake; on vehicles with automatic

transmission set the selector lever

to P.

2. Turn the ignition on.

3. Use the MENU button on the turn

signal lever to select the Vehicle

Information Menu in the Driver

Information Centre (DIC).

4. Turn the adjuster wheel to scroll to

the tyre pressure menu.5. Press the SET/CLR button to

begin the sensor matching process. A message requesting

acceptance of the process should display.

6. Press the SET/CLR button again

to confirm the selection. The horn

sounds twice to signal the

receiver is in relearn mode.

7. Start with the left side front tyre.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirp

confirms that the sensor

identification code has been

matched to this tyre and wheel

position.

9. Proceed to the right side front tyre,

and repeat the procedure in

Step 8.

10. Proceed to the right side rear tyre,

and repeat the procedure in

Step 8.

11. Proceed to the left side rear tyre, and repeat the procedure in

Step 8. The horn sounds twice toindicate the sensor identification

code has been matched to the left side rear tyre, and the TPMS

sensor matching process is no

longer active.

12. Turn off the ignition.

13. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure label.

14. Ensure the tyre loading status is set according selected pressure

3 96.

Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the DIC shows the actual tyre

pressure. Therefore it is important to

check tyre pressure with cold tyres.

Tread depth

Check tread depth at regular

intervals.

Page 211 of 253

Vehicle care209

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

is the same as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle

modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, the wheel

covers might not be attached to the

steel wheels.

Page 212 of 253

210Vehicle careTyre chains

Use tyre chains only on front wheels.

Tyre chains are permitted on tyres of

size 225/55 R 17. Always use fine

mesh chains that add no more than

10 mm to the tyre tread and the

inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

The use of tyre chains is not permitted

on the temporary spare wheel.

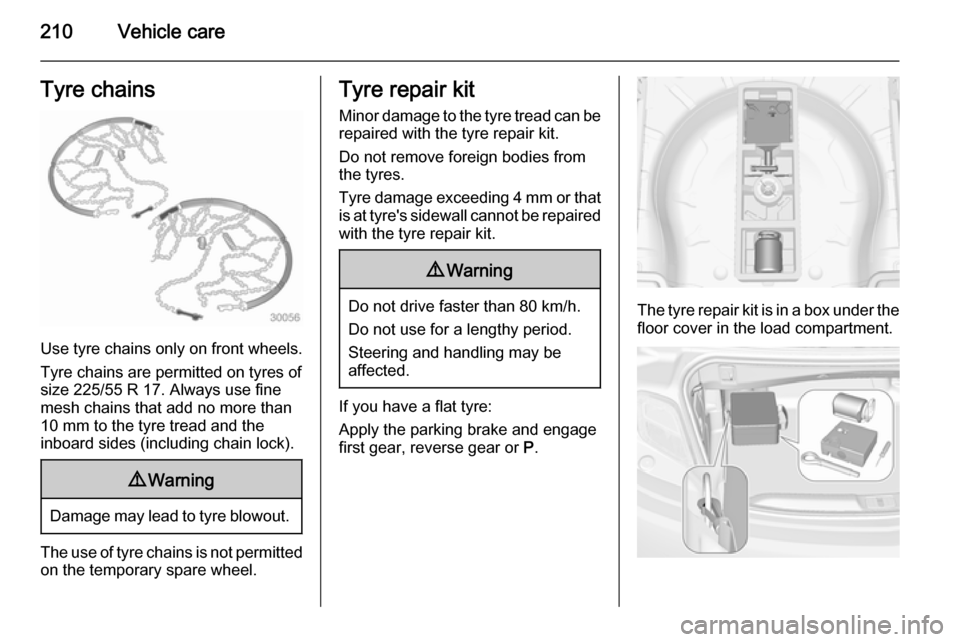

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is in a box under the

floor cover in the load compartment.

Page 215 of 253

Vehicle care213

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away the tyre repair kit in the

load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.

Wheel changing Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 210.Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-slippery surface. The front wheels must be in the straight-

ahead position.

■ Apply the parking brake and engage first gear, reverse gear or

P .

■ Remove the spare wheel 3 216.

■ Never change more than one wheel

at once.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.

■ The jack is maintenance-free.

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ Take heavy objects out of the vehicle before jacking up.

■ No people or animals may be in the

vehicle when it is jacked-up.