light OPEL COMBO 2010 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2010, Model line: COMBO, Model: OPEL COMBO 2010Pages: 212, PDF Size: 2.49 MB

Page 164 of 212

158 Self-help, vehicle care

Picture no: 15135s.tif

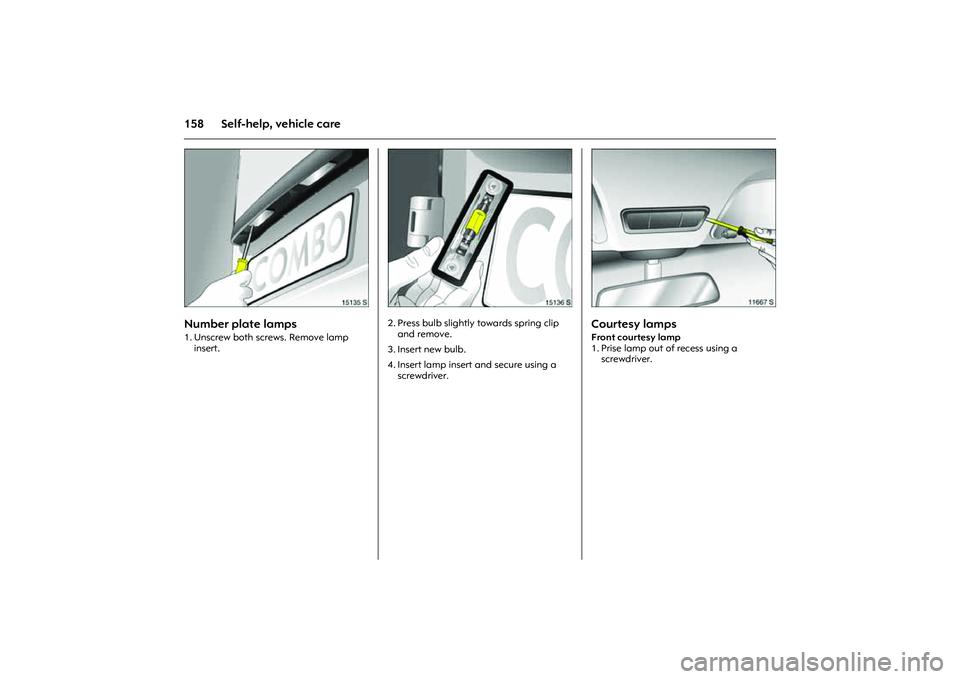

Number plate lamps 1. Unscrew both screws. Remove lamp

insert.

Picture no: 15136s.tif

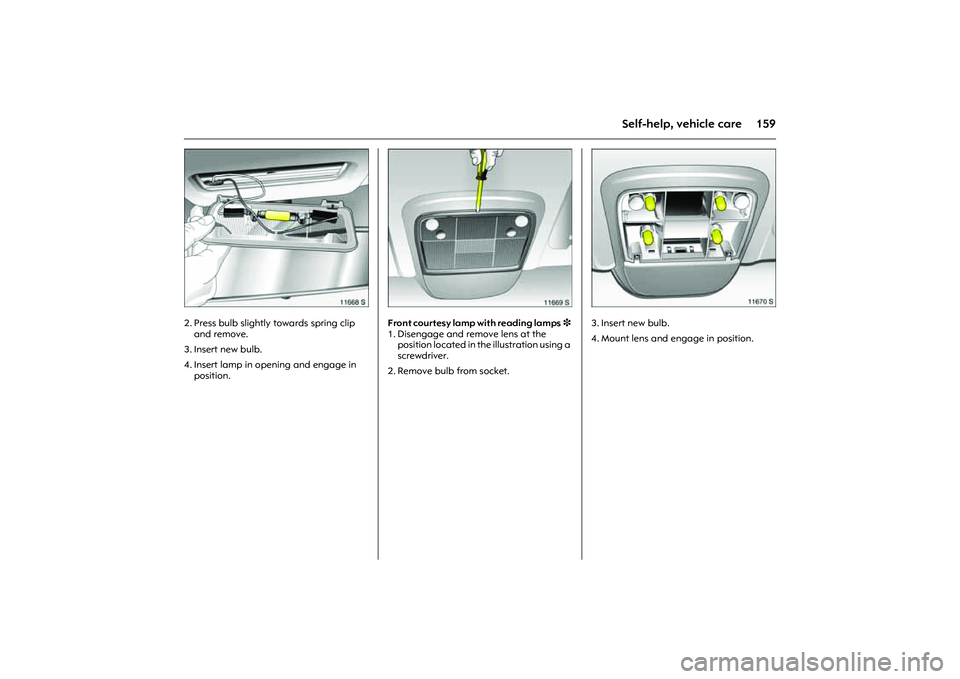

2. Press bulb slightly towards spring clip

and remove.

3. Insert new bulb.

4. Insert lamp insert and secure using a

screwdriver.

Picture no: 11667s.tif

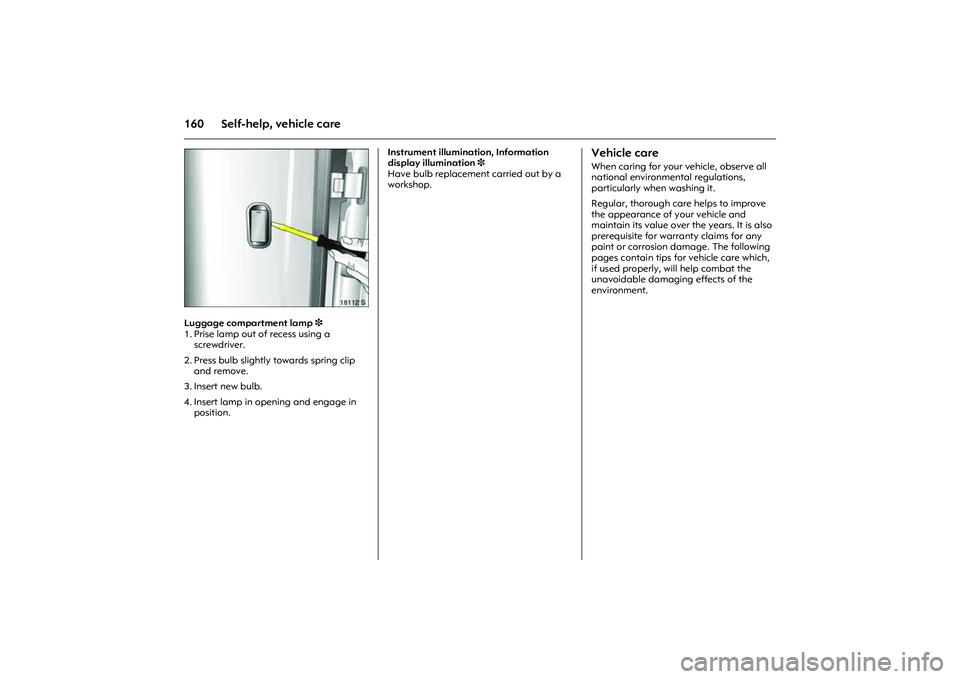

Courtesy lamps Front courtesy lamp

1. Prise lamp out of recess using a

screwdriver.

Page 165 of 212

159

Self-help, vehicle care

Picture no: 11668s.tif

2. Press bulb slightly towards spring clip

and remove.

3. Insert new bulb.

4. Insert lamp in opening and engage in

position.

Picture no: 11669s.tif

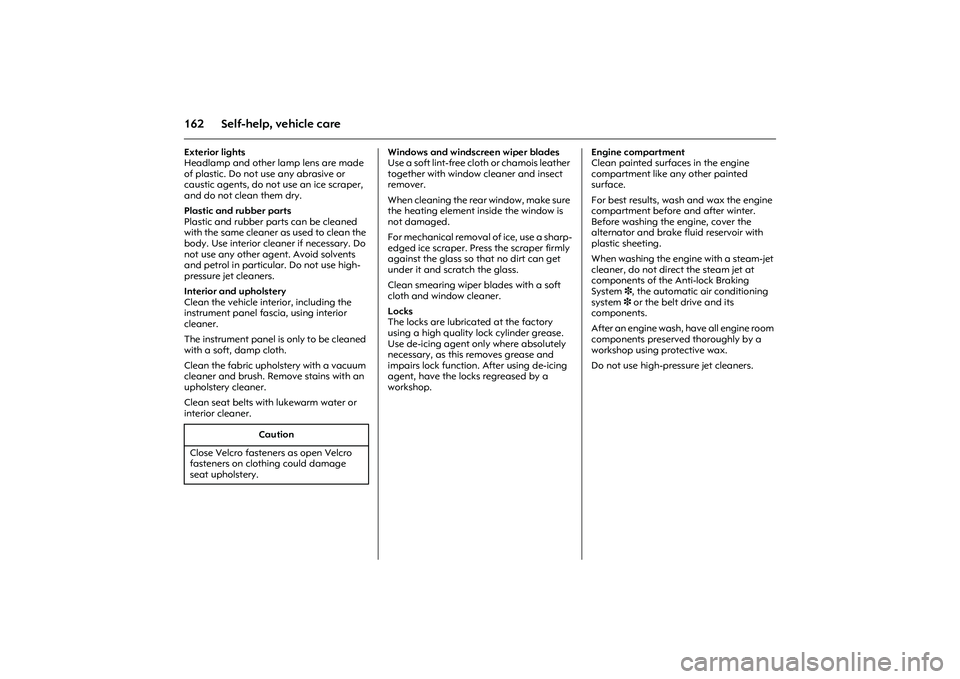

Front courtesy lamp with reading lamps3

1. Disengage and remove lens at the

position located in the illustration using a

screwdriver.

2. Remove bulb from socket.

Picture no: 11670s.tif

3. Insert new bulb.

4. Mount lens and engage in position.

Page 166 of 212

160 Self-help, vehicle care

Picture no: 18112s.tif

Luggage compartment lamp3

1. Prise lamp out of recess using a

screwdriver.

2. Press bulb slightly towards spring clip

and remove.

3. Insert new bulb.

4. Insert lamp in opening and engage in

position. Instrument illumination, Information

display illumination3

Have bulb replacement carried out by a

workshop.

Vehicle careWhen caring for your vehicle, observe all

national environmental regulations,

particularly when washing it.

Regular, thorough care helps to improve

the appearance of your vehicle and

maintain its value over the years. It is also

prerequisite for warranty claims for any

paint or corrosion damage. The following

pages contain tips for vehicle care which,

if used properly, will help combat the

unavoidable damaging effects of the

environment.

Page 168 of 212

162 Self-help, vehicle careExterior lights

Headlamp and other lamp lens are made

of plastic. Do not use any abrasive or

caustic agents, do not use an ice scraper,

and do not clean them dry.

Plastic and rubber parts

Plastic and rubber parts can be cleaned

with the same cleaner as used to clean the

body. Use interior cleaner if necessary. Do

not use any other agent. Avoid solvents

and petrol in particular. Do not use high-

pressure jet cleaners.

Interior and upholstery

Clean the vehicle interior, including the

instrument panel fascia, using interior

cleaner.

The instrument panel is only to be cleaned

with a soft, damp cloth.

Clean the fabric upholstery with a vacuum

cleaner and brush. Remove stains with an

upholstery cleaner.

Clean seat belts with lukewarm water or

interior cleaner. Windows and windscreen wiper blades

Use a soft lint-free cloth or chamois leather

together with window cleaner and insect

remover.

When cleaning the rear window, make sure

the heating element inside the window is

not damaged.

For mechanical removal of ice, use a sharp-

edged ice scraper. Press the scraper firmly

against the glass so that no dirt can get

under it and scratch the glass.

Clean smearing wiper blades with a soft

cloth and window cleaner.

Locks

The locks are lubricated at the factory

using a high quality lock cylinder grease.

Use de-icing agent only where absolutely

necessary, as this removes grease and

impairs lock function. After using de-icing

agent, have the locks regreased by a

workshop. Engine compartment

Clean painted surfaces in the engine

compartment like any other painted

surface.

For best results, wash and wax the engine

compartment before and after winter.

Before washing the engine, cover the

alternator and brake fluid reservoir with

plastic sheeting.

When washing the engine with a steam-jet

cleaner, do not direct the steam jet at

components of the Anti-lock Braking

System 3, the automatic air conditioning

system 3 or the belt drive and its

components.

After an engine wash, have all engine room

components preserved thoroughly by a

workshop using protective wax.

Do not use high-pressure jet cleaners.

Caution

Close Velcro fasteners as open Velcro

fasteners on clothing could damage

seat upholstery.

Page 171 of 212

165 Opel Service, maintenance

European service plan⊕Additional work.

o Intervals are shorter under extreme operating conditions and when such is necessary due to conditions specific to the country.

Service work after year

1)

km (x 1000)

1)

1)Whichever occurs first.

1

302

603

904

1205

150

Visually inspect control, lighting and signal devices as well as airbags;

check steering column lock and ignition switchxxxxx

Remote control: replace batteries (don’t forget the spare key) every 2 years

Check and correct windscreen wipers, windscreen washer system and headlamp

washer systemxxxxx

Check and correct coolant level and frost protection (pale orange)

2)

Note freeze protection temperature in the Service and Warranty Booklet

(confirmation box)

2)If loss is great/leaks are present, carry out follow-up work with customer consent.

xxxxx

Check water hoses for leaks and check to make sure they are firmly seated x x x x x

Check and correct brake fluid level

2) xxx

Check battery clamps to make sure they are firmly seated and check the battery eye x x x x x

Vehicle System Check with TECH 2 x x x x x

Replace pollen filter or active charcoal filter x x

⊕o

if the air is heavily polluted or there are high levels of airborne dust, sand or pollen,

the air-conditioning system will produce an odourVerbal arrangement between the

customer and Opel Partner

Replace the air filter element every 4 years/60,000 km

⊕

Replace spark plugsevery 4 years/60,000 km

Z 16 YNGevery 2 years/30,000 km

Visually inspect the ribbed V-belt every 2 years/60,000 km

⊕

Replace ribbed V-belt

Y 13 DTJ, Z 13 DTJ, Y 13 DT, Z 13 DT, Z 17 DTH every 10 years/150,000 km

⊕

Check valve play and adjust

Z16 XEP, Z 17 DTHevery 10 years/150,000 km

Page 173 of 212

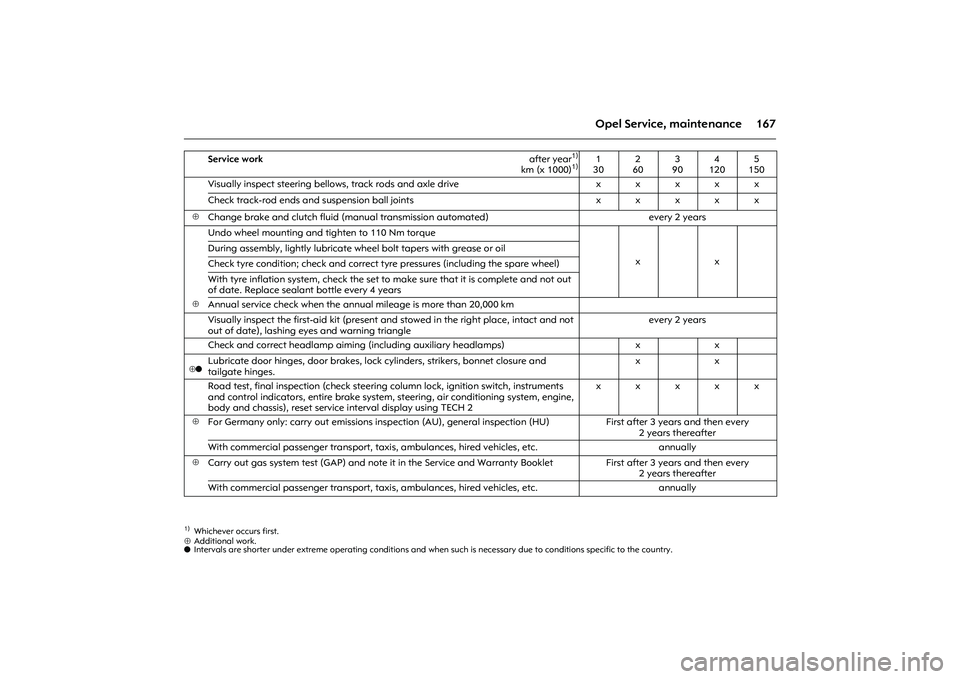

167 Opel Service, maintenance

⊕Additional work.

o Intervals are shorter under extreme operating conditions and when such is necessary due to conditions specific to the country.

Service work after year

1)

km (x 1000)

1)

1)Whichever occurs first.

1

302

603

904

1205

150

Visually inspect steering bellows, track rods and axle drive xxxxx

Check track-rod ends and suspension ball joints xxxxx

⊕

Change brake and clutch fluid (manual transmission automated) every 2 years

Undo wheel mounting and tighten to 110 Nm torque

xx During assembly, lightly lubricate wheel bolt tapers with grease or oil

Check tyre condition; check and correct tyre pressures (including the spare wheel)

With tyre inflation system, check the set to make sure that it is complete and not out

of date. Replace sealant bottle every 4 years

⊕

Annual service check when the annual mileage is more than 20,000 km

Visually inspect the first-aid kit (present and stowed in the right place, intact and not

out of date), lashing eyes and warning triangleevery 2 years

Check and correct headlamp aiming (including auxiliary headlamps) x x

⊕o

Lubricate door hinges, door brakes, lock cylinders, strikers, bonnet closure and

tailgate hinges.xx

Road test, final inspection (check steering column lock, ignition switch, instruments

and control indicators, entire brake system, steering, air conditioning system, engine,

body and chassis), reset service interval display using TECH 2xxxxx

⊕

For Germany only: carry out emissions inspection (AU), general inspection (HU) First after 3 years and then every

2 years thereafter

With commercial passenger transport, taxis, ambulances, hired vehicles, etc. annually

⊕

Carry out gas system test (GAP) and note it in the Service and Warranty Booklet First after 3 years and then every

2 years thereafter

With commercial passenger transport, taxis, ambulances, hired vehicles, etc. annually

Page 174 of 212

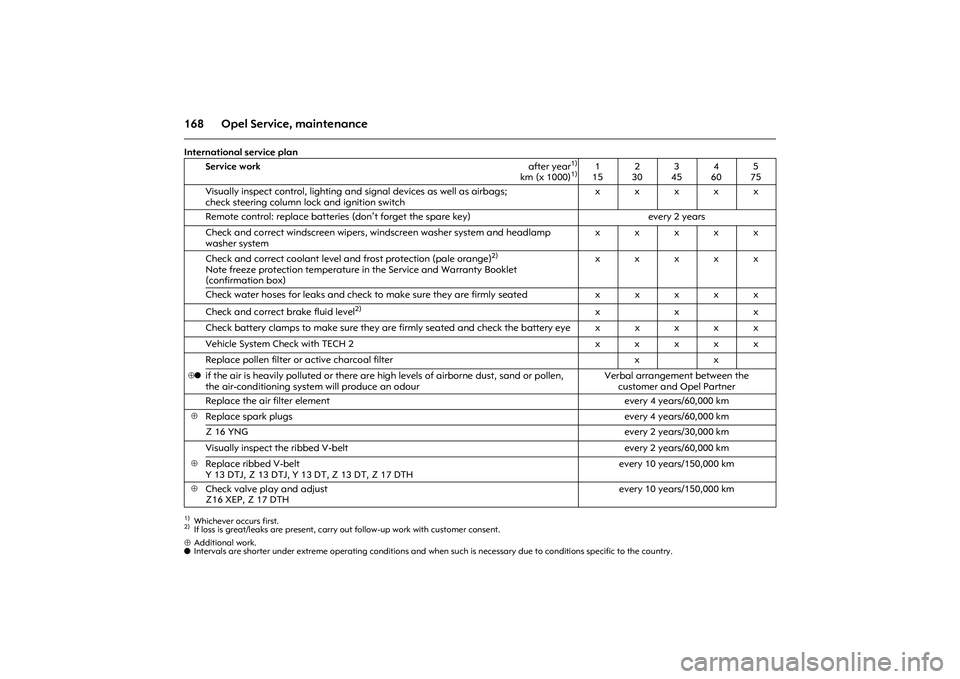

168 Opel Service, maintenanceInternational service plan⊕Additional work.

o Intervals are shorter under extreme operating conditions and when such is necessary due to conditions specific to the country.

Service work after year

1)

km (x 1000)

1)

1)Whichever occurs first.

1

152

303

454

605

75

Visually inspect control, lighting and signal devices as well as airbags;

check steering column lock and ignition switchxxxxx

Remote control: replace batteries (don’t forget the spare key) every 2 years

Check and correct windscreen wipers, windscreen washer system and headlamp

washer systemxxxxx

Check and correct coolant level and frost protection (pale orange)

2)

Note freeze protection temperature in the Service and Warranty Booklet

(confirmation box)

2)If loss is great/leaks are present, carry out follow-up work with customer consent.

xxxxx

Check water hoses for leaks and check to make sure they are firmly seated x x x x x

Check and correct brake fluid level

2) xxx

Check battery clamps to make sure they are firmly seated and check the battery eye x x x x x

Vehicle System Check with TECH 2 x x x x x

Replace pollen filter or active charcoal filter x x

⊕o

if the air is heavily polluted or there are high levels of airborne dust, sand or pollen,

the air-conditioning system will produce an odourVerbal arrangement between the

customer and Opel Partner

Replace the air filter element every 4 years/60,000 km

⊕

Replace spark plugsevery 4 years/60,000 km

Z 16 YNGevery 2 years/30,000 km

Visually inspect the ribbed V-belt every 2 years/60,000 km

⊕

Replace ribbed V-belt

Y 13 DTJ, Z 13 DTJ, Y 13 DT, Z 13 DT, Z 17 DTH every 10 years/150,000 km

⊕

Check valve play and adjust

Z16 XEP, Z 17 DTHevery 10 years/150,000 km

Page 176 of 212

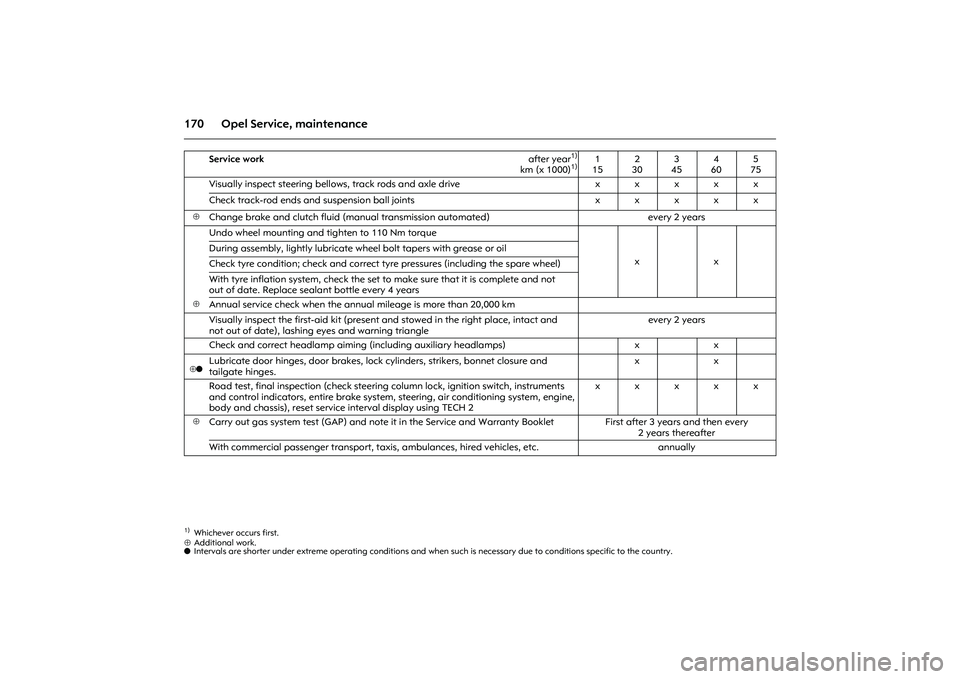

170 Opel Service, maintenance⊕Additional work.

o Intervals are shorter under extreme operating conditions and when such is necessary due to conditions specific to the country.

Service work after year

1)

km (x 1000)

1)

1)Whichever occurs first.

1

152

303

454

605

75

Visually inspect steering bellows, track rods and axle drive x x x x x

Check track-rod ends and suspension ball joints x x x x x

⊕

Change brake and clutch fluid (manual transmission automated) every 2 years

Undo wheel mounting and tighten to 110 Nm torque

xx During assembly, lightly lubricate wheel bolt tapers with grease or oil

Check tyre condition; check and correct tyre pressures (including the spare wheel)

With tyre inflation system, check the set to make sure that it is complete and not

out of date. Replace sealant bottle every 4 years

⊕

Annual service check when the annual mileage is more than 20,000 km

Visually inspect the first-aid kit (present and stowed in the right place, intact and

not out of date), lashing eyes and warning triangleevery 2 years

Check and correct headlamp aiming (including auxiliary headlamps) x x

⊕o

Lubricate door hinges, door brakes, lock cylinders, strikers, bonnet closure and

tailgate hinges.xx

Road test, final inspection (check steering column lock, ignition switch, instruments

and control indicators, entire brake system, steering, air conditioning system, engine,

body and chassis), reset service interval display using TECH 2xxxxx

⊕

Carry out gas system test (GAP) and note it in the Service and Warranty Booklet First after 3 years and then every

2 years thereafter

With commercial passenger transport, taxis, ambulances, hired vehicles, etc. annually

Page 190 of 212

![OPEL COMBO 2010 Workshop Manual 184 Technical dataEngine data Sales designation

Engine identifier code1.4 TWINPORT

Z 14 XEPCNG

Z 16 YNG1.3 CDTI

Z 13 DTJ1.7 CDTI

Z 17 DTH

Number of cylinders 4 4 4 4

Piston displacement [cm

3 ] 1364 1 OPEL COMBO 2010 Workshop Manual 184 Technical dataEngine data Sales designation

Engine identifier code1.4 TWINPORT

Z 14 XEPCNG

Z 16 YNG1.3 CDTI

Z 13 DTJ1.7 CDTI

Z 17 DTH

Number of cylinders 4 4 4 4

Piston displacement [cm

3 ] 1364 1](/img/37/58222/w960_58222-189.png)

184 Technical dataEngine data Sales designation

Engine identifier code1.4 TWINPORT

Z 14 XEPCNG

Z 16 YNG1.3 CDTI

Z 13 DTJ1.7 CDTI

Z 17 DTH

Number of cylinders 4 4 4 4

Piston displacement [cm

3 ] 1364 1598 1248 1686

Brake horse power [kW/bhp]

at rpm 66

560069

620055

400074

4400

Torque [Nm]

at rpm 125

4000133

4200170

1750 to 2500240

2300

Fuel type

1)

1)Standard high-quality fuels, unleaded DIN EN 228, diesel DIN EN 590. Any commercially available natural gas containing methane can be used for

natural gas operation.

Petrol Natural gas/petrol Diesel Diesel

Octane requirement [RON]

2)

recommended

possible

possible

Cetane requirement [CN]

2)

2)Standard high-quality fuels: R = Regular, P = Premium, PP = Premium Plus, D = Diesel. Value printed in bold: recommended fuel.

95 (P)

3)

98 (PP)

3)

91 (R)

3)4)

–

3)Knock control system automatically adjusts ignition timing according to type of fuel used (octane number). 4)Slight reduction in engine output and torque if 91 RON is used.

95 (P)

3)

98 (PP)

3)

–

––

–

–

49 (D)

5)

5)A lower value is possible with winter diesel fuels.

–

–

–

49 (D)

5)

Max. permissible engine speed,

continuous operation approx. [rpm ]. 6200 6400 5020 to 5180 5000 to 5200

Oil consumption [l/1000 km] 0.6 0.6 0.6 0.6

Page 192 of 212

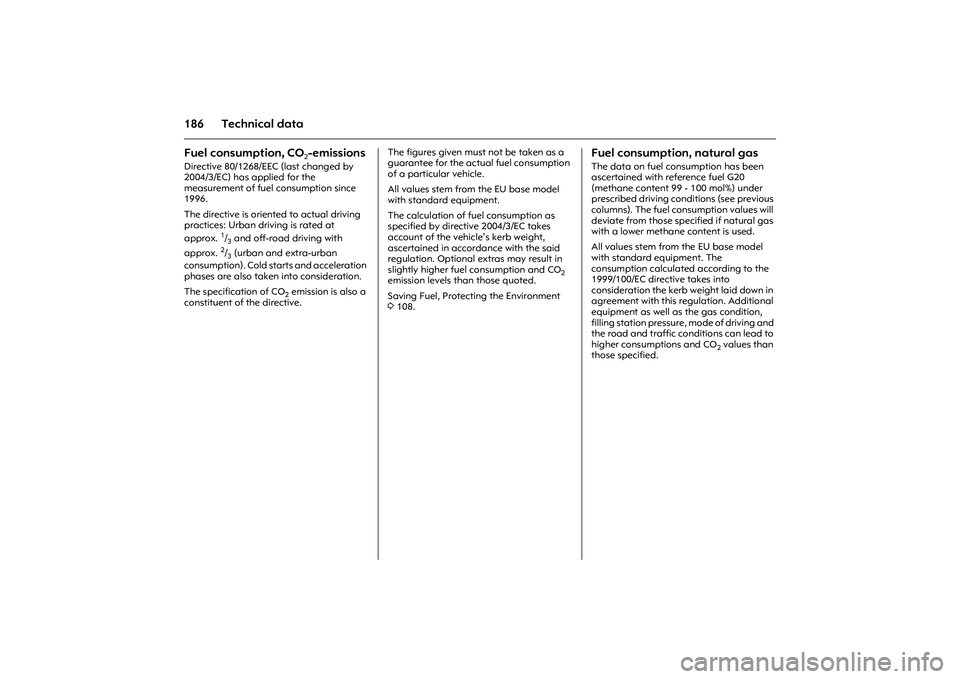

186 Technical dataFuel consumption, CO

2-emissions

Directive 80/1268/EEC (last changed by

2004/3/EC) has applied for the

measurement of fuel consumption since

1996.

The directive is oriented to actual driving

practices: Urban driving is rated at

approx.

1/3 and off-road driving with

approx. 2/3 (urban and extra-urban

consumption). Cold starts and acceleration

phases are also taken into consideration.

The specification of CO

2 emission is also a

constituent of the directive.The figures given must not be taken as a

guarantee for the actual fuel consumption

of a particular vehicle.

All values stem from the EU base model

with standard equipment.

The calculation of fuel consumption as

specified by directive 2004/3/EC takes

account of the vehicle’s kerb weight,

ascertained in accordance with the said

regulation. Optional extras may result in

slightly higher fuel consumption and CO

2

emission levels than those quoted.

Saving Fuel, Protecting the Environment

3108.

Fuel consumption, natural gasThe data on fuel consumption has been

ascertained with reference fuel G20

(methane content 99 - 100 mol%) under

prescribed driving conditions (see previous

columns). The fuel consumption values will

deviate from those specified if natural gas

with a lower methane content is used.

All values stem from the EU base model

with standard equipment. The

consumption calculated according to the

1999/100/EC directive takes into

consideration the kerb weight laid down in

agreement with this regulation. Additional

equipment as well as the gas condition,

filling station pressure, mode of driving and

the road and traffic conditions can lead to

higher consumptions and CO

2 values than

those specified.