ECU OPEL COMBO 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: COMBO, Model: OPEL COMBO 2017Pages: 195, PDF Size: 4.71 MB

Page 69 of 195

Storage67luggage (7 kg) and all fluids (fuel

tank 90% full).

Optional equipment and

accessories increase the kerb

weight.

● Driving with a roof load increases

the sensitivity of the vehicle to

cross-winds and has a

detrimental effect on vehicle

handling due to the vehicle's

higher centre of gravity.

Distribute the load evenly and secure it properly with retaining

straps. Adjust the tyre pressure

and vehicle speed according to

the load conditions. Check and

retighten the straps frequently.

Do not drive faster than

120 km/h.

The permissible roof load (which includes the weight of the roof

rack) is 100 kg. The roof load is

the combined weight of the roof

rack and the load.

Page 141 of 195

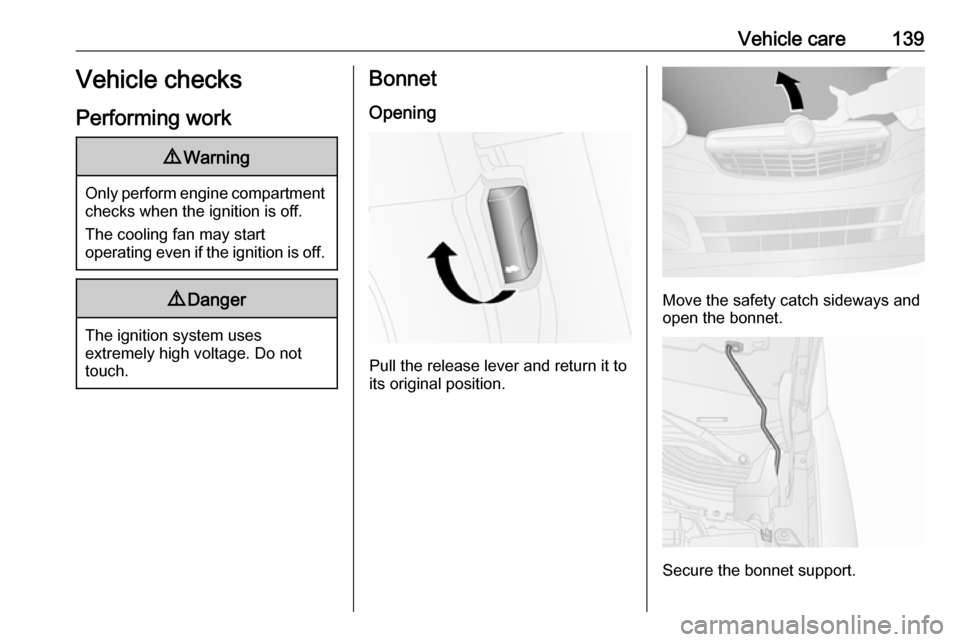

Vehicle care139Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system uses

extremely high voltage. Do not

touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Move the safety catch sideways and

open the bonnet.

Secure the bonnet support.

Page 164 of 195

162Vehicle care2. Turn the canister anticlockwise tolift it out.

3. Insert the new canister and turn it clockwise.

4. Connect the compressor air hose to the canister and fit the flexible

filler tube into its allocated space.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 159.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first or reverse gear.

● Remove the spare wheel 3 163.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

the wheel cover using a suitable

tool.

2. Attach wheel wrench securely and loosen each wheel nut by halfa turn.

Page 165 of 195

Vehicle care163

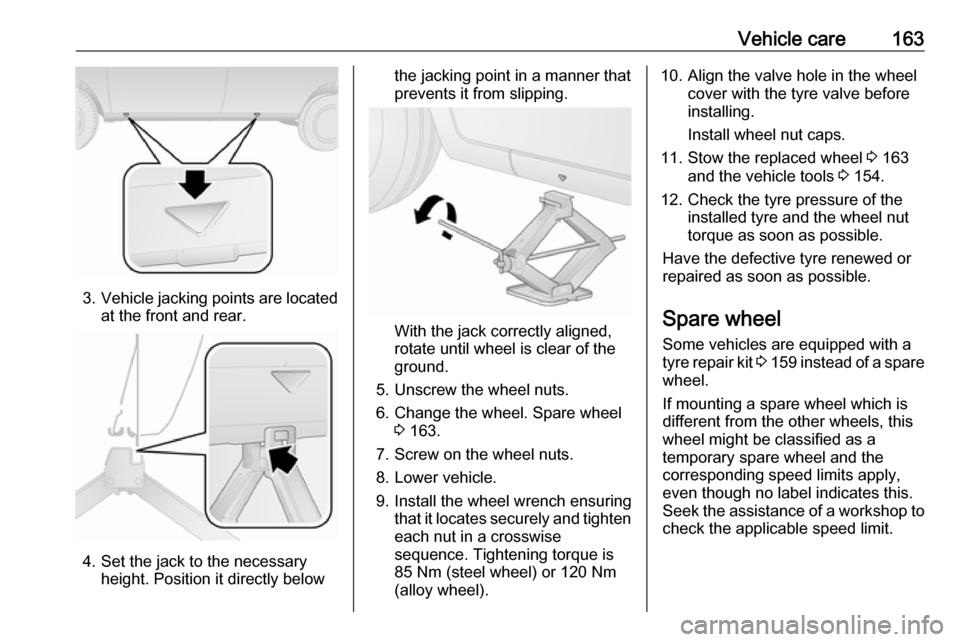

3.Vehicle jacking points are located

at the front and rear.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

With the jack correctly aligned,

rotate until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 163.

7. Screw on the wheel nuts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each nut in a crosswise

sequence. Tightening torque is

85 Nm (steel wheel) or 120 Nm

(alloy wheel).

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow the replaced wheel 3 163

and the vehicle tools 3 154.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Spare wheel Some vehicles are equipped with atyre repair kit 3 159 instead of a spare

wheel.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

Page 167 of 195

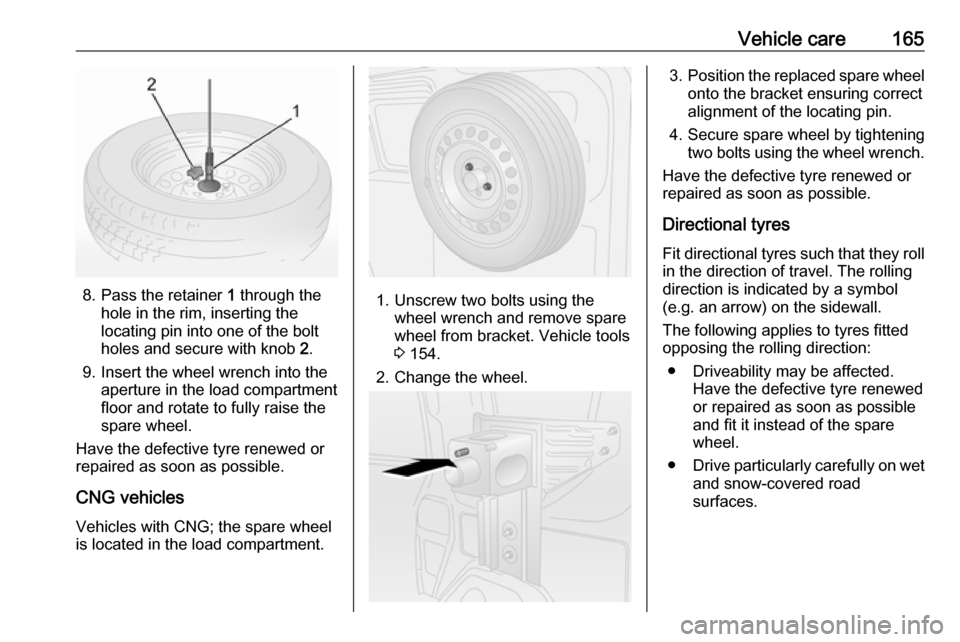

Vehicle care165

8. Pass the retainer 1 through the

hole in the rim, inserting the

locating pin into one of the bolt

holes and secure with knob 2.

9. Insert the wheel wrench into the aperture in the load compartment

floor and rotate to fully raise the

spare wheel.

Have the defective tyre renewed or repaired as soon as possible.

CNG vehicles

Vehicles with CNG; the spare wheel

is located in the load compartment.1. Unscrew two bolts using the wheel wrench and remove spare

wheel from bracket. Vehicle tools

3 154.

2. Change the wheel.

3. Position the replaced spare wheel

onto the bracket ensuring correct

alignment of the locating pin.

4. Secure spare wheel by tightening two bolts using the wheel wrench.

Have the defective tyre renewed or

repaired as soon as possible.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Drive particularly carefully on wet

and snow-covered road

surfaces.

Page 189 of 195

Customer information187● vehicle reactions in particulardriving situations (e.g. inflation ofan airbag, activation of the

stability regulation system)

● environmental conditions (e.g. temperature)

This data is exclusively technical and

helps identifying and correcting errors

as well as optimizing vehicle

functions.

Motion profiles indicating travelled

routes cannot be created with this

data.

If services are used (e.g. repair

works, service processes, warranty cases, quality assurance),

employees of the service network

(manufacturer included) are able to

read out this technical information

from the event and error data storage

modules applying special diagnostic

devices. If required, you will receive

further information at these

workshops. After an error has been

corrected, the data is deleted from the error storage module or it is

constantly overwritten.When using the vehicle, situations

may occur in which technical data

related to other information (accident

report, damages on the vehicle,

witness statements etc.) may be

associated with a specific person -

possibly, with the assistance of an

expert.

Additional functions contractually

agreed upon with the client (e.g.

vehicle location in emergency cases)

allow the transmission of particular vehicle data from the vehicle.

Radio Frequency

Identification (RFID)

RFID technology is used in some

vehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in-

vehicle transmitters for garage door

openers. RFID technology in Opel

vehicles does not use or record

personal information or link with any

other Opel system containing

personal information.

Page 194 of 195

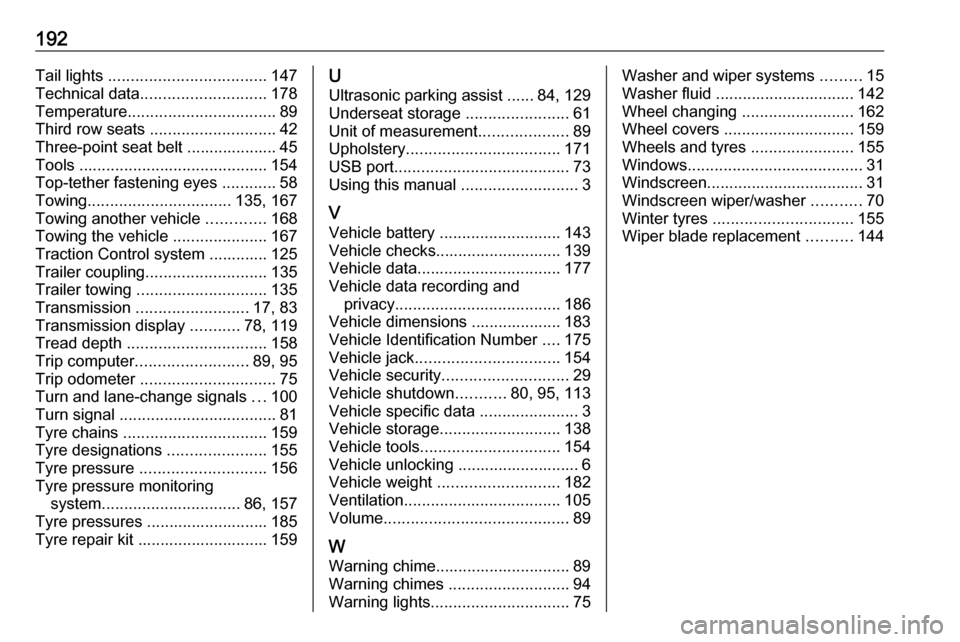

192Tail lights ................................... 147

Technical data ............................ 178

Temperature ................................. 89

Third row seats ............................ 42

Three-point seat belt .................... 45

Tools .......................................... 154

Top-tether fastening eyes ............58

Towing ................................ 135, 167

Towing another vehicle .............168

Towing the vehicle .....................167

Traction Control system ............. 125

Trailer coupling ........................... 135

Trailer towing ............................. 135

Transmission ......................... 17, 83

Transmission display ...........78, 119

Tread depth ............................... 158

Trip computer ......................... 89, 95

Trip odometer .............................. 75

Turn and lane-change signals ...100

Turn signal ................................... 81

Tyre chains ................................ 159

Tyre designations ......................155

Tyre pressure ............................ 156

Tyre pressure monitoring system ............................... 86, 157

Tyre pressures ........................... 185

Tyre repair kit ............................. 159U

Ultrasonic parking assist ...... 84, 129

Underseat storage .......................61

Unit of measurement ....................89

Upholstery .................................. 171

USB port ....................................... 73

Using this manual ..........................3

V Vehicle battery ........................... 143

Vehicle checks............................ 139

Vehicle data ................................ 177

Vehicle data recording and privacy ..................................... 186

Vehicle dimensions .................... 183

Vehicle Identification Number ....175

Vehicle jack ................................ 154

Vehicle security ............................ 29

Vehicle shutdown ...........80, 95, 113

Vehicle specific data ......................3

Vehicle storage ........................... 138

Vehicle tools ............................... 154

Vehicle unlocking ........................... 6

Vehicle weight ........................... 182

Ventilation ................................... 105

Volume ......................................... 89

W

Warning chime.............................. 89

Warning chimes ........................... 94

Warning lights ............................... 75Washer and wiper systems .........15

Washer fluid ............................... 142

Wheel changing .........................162

Wheel covers ............................. 159

Wheels and tyres .......................155

Windows ....................................... 31

Windscreen................................... 31 Windscreen wiper/washer ...........70

Winter tyres ............................... 155

Wiper blade replacement ..........144