tow OPEL COMBO 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: COMBO, Model: OPEL COMBO 2017Pages: 195, PDF Size: 4.71 MB

Page 122 of 195

120Driving and operatingSelector lever

Always move the selector lever in the

appropriate direction as far as it will

go.

Note

Do not hold the selector lever in an

intermediate position. Not fully

engaging a gear may lead to

malfunction and a warning message may be displayed in the Driver

Information Centre.

Return the selector lever to the

centre position. After a short while,

N will be displayed in the Driver

Information Centre and the system

will operate normally again.

Driver Information Centre 3 89.

After selecting A/M, + or - and

releasing the selector lever, the lever automatically returns to the centre

position.N:neutralo:drive positionA/M:switch between automatic and

manual mode

The transmission display

shows AUTO when in

automatic mode.R:reverse gear

Engage only when vehicle is

stationary. The transmission

display shows "R" when

reverse gear is engaged.+:shift to a higher gear-:shift to a lower gearCaution

It is not advisable to drive with the hand resting on the selector lever.

Starting-off

When the engine is started, depress

the brake pedal and move the

selector lever towards + to engage

first gear. Shift to a higher or lower

gear by moving selector lever to + or -.

Gears can be skipped by moving the selector lever repeatedly at short

intervals.

The driver will be alerted to an

incorrect gear selection by an audible warning chime in conjunction with a

message in the Driver Information

Centre 3 89. The system will

downshift, selecting the most

appropriate gear automatically.

If R is selected, reverse gear is

engaged. The vehicle starts to move

when the brake pedal is released. To

start off quickly, release the brake

pedal and accelerate immediately

after engaging a gear.

Page 123 of 195

Driving and operating121Move the selector lever towards A/M

to engage automatic mode; the

transmission shifts to other gears

automatically, dependent on driving conditions.

To engage manual mode, move the selector lever towards A/M. The

current gear will appear in the

transmission display.

Stopping the vehicle

In automatic or manual mode,

first gear is engaged and the clutch is

released when the vehicle is stopped. In R, reverse gear remains engaged.

When the vehicle is at a standstill, if

the engine is running and a forward or

reverse gear is engaged, a warning

chime will sound and the

transmission automatically shifts to

N in certain situations.

When stopping on gradients, engage

parking brake or depress the brake

pedal. To prevent overheating of the

clutch, an intermittent audible

warning chime may sound as a signal

to depress the brake pedal or apply

the parking brake.Switch off engine if stopping for a

lengthy period, e.g. in traffic jams.

Engine braking

Automatic mode

When driving downhill, the manual

transmission automated does not

shift into higher gears until a fairly

high engine speed has been reached. It shifts down in good time when

braking.

Manual mode

To utilise the engine braking effect,

select a lower gear in good time when

driving downhill.

Rocking the vehicle

Rocking the vehicle is only

permissible if the vehicle is stuck in

sand, mud, snow or a hole. Move the

selector lever between R and A/M (or

between + and -) in a repeat pattern,

while applying light pressure to the

accelerator pedal. Do not race the

engine and avoid sudden

acceleration.Parking

Apply the parking brake. The most

recently engaged gear (see

transmission display) remains

engaged.Caution

Do not leave the vehicle with the

transmission in position N.

When the ignition is switched on, a

warning chime will sound when the

vehicle is parked if the transmission is still in N.

When the ignition is switched off, the transmission no longer responds to

movement of the selector lever.

Manual mode If engine speed is too low, the

transmission automatically shifts to a

lower gear.

In manual mode, no automatic

shifting to a higher gear takes place

at high engine revolutions. If engine

Page 125 of 195

Driving and operating123message may appear in the Driver

Information Centre in conjunction with

a warning chime 3 94.

Note

The volume of the warning chime

can also be adjusted via the Driver

Information Centre 3 89.

Have the cause of the fault remedied

by a workshop.Brakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 83.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency

to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting off the system performs a self-test which may be audible.

Fault

In the event of a fault, control indicator

u illuminates in the instrument

cluster. Depending on version, a

corresponding warning message,

e.g. ABS unavailable , may also be

displayed in the Driver Information

Centre 3 89.

Page 132 of 195

130Driving and operating● The bumper is damaged. Takethe vehicle to a workshop to

repair the system.

● Other conditions, such as vibrations from a jackhammer,

are affecting system

performance.

In the event the system still does not

work properly, seek the assistance of

a workshop.

A warning chime is also sounded

briefly if a fault is present when

reverse gear is engaged 3 94.

Note

The volume of the warning chime

can also be adjusted via the Driver

Information Centre 3 89.

Important hints for using the

parking assist systems9 Warning

Under certain circumstances,

various reflective surfaces on

objects or clothing as well as

external noise sources may cause the system to fail to detect

obstacles.

Special attention has to be paid to

low obstacles which can damage

the lower part of the bumper. If

such obstacles leave the detection area of the sensors during

approach of the vehicle, a

continuous warning tone will

sound.Caution

Performance of the sensor can be reduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

systems can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles involved (e.g.

off-road vehicles, mini vans,

vans). Object identification in the upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross section, like objects of

narrow size or soft materials, may

not be detected by the system.

Parking assist will not avoid a

collision with objects which are out

of the detection range of the

sensors.

Note

The parking assist system

automatically detects factory-fitted

towing equipment. It is deactivated

when the connector is plugged in.

The sensor may detect a non-

existent object (echo disturbance)

caused by external acoustic or

mechanical disturbances.

Page 137 of 195

Driving and operating135Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Vehicles with natural gas engine may

require special towing equipment.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball bar for towing. Always keep the

coupling ball bar in the vehicle.

Driving characteristics and towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do so if a stabiliser, which acts on the

coupling ball, is being used to reduce

snaking movements.For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

1300 kg the use of a stabiliser is

strongly recommended when driving

above 80 km/h.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 185.

Trailer towing

Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12%.

The permitted trailer load applies up

to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than 8%, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 175.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

Page 138 of 195

136Driving and operatingThe maximum permissible vertical

coupling load (60 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

Rear axle load The permissible axle loads (see

identification plate or vehicle

documents) must not be exceeded.

Page 139 of 195

Vehicle care137Vehicle careGeneral Information...................137

Accessories and vehicle modifications .......................... 137

Vehicle storage ........................138

End-of-life vehicle recovery .....138

Vehicle checks ........................... 139

Performing work ......................139

Bonnet ..................................... 139

Engine oil ................................. 140

Engine coolant ......................... 141

Power steering fluid .................141

Washer fluid ............................ 142

Brakes ..................................... 142

Brake fluid ............................... 142

Vehicle battery ......................... 143

Wiper blade replacement ........144

Bulb replacement .......................145

Halogen headlights ..................145

Fog lights ................................. 147

Tail lights ................................. 147

Side turn signal lights ..............148

Centre high-mounted brake light ......................................... 148

Number plate light ...................148Interior lights ............................ 149

Instrument panel illumination ...150

Electrical system ........................151

Fuses ....................................... 151

Engine compartment fuse box . 152

Instrument panel fuse box .......153

Vehicle tools .............................. 154

Tools ........................................ 154

Wheels and tyres .......................155

Winter tyres ............................. 155

Tyre designations ....................155

Tyre pressure .......................... 156

Tyre pressure monitoring

system .................................... 157

Tread depth ............................. 158

Changing tyre and wheel size . 159 Wheel covers ........................... 159

Tyre chains .............................. 159

Tyre repair kit .......................... 159

Wheel changing .......................162

Spare wheel ............................ 163

Jump starting ............................. 166

Towing ....................................... 167

Towing the vehicle ...................167

Towing another vehicle ...........168

Appearance care .......................169

Exterior care ............................ 169

Interior care ............................. 171General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

change made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warrantyoffered by Opel. Furthermore, such

changes may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the type approval,

impacting the validity of your vehicle

registration.

Page 151 of 195

Vehicle care149

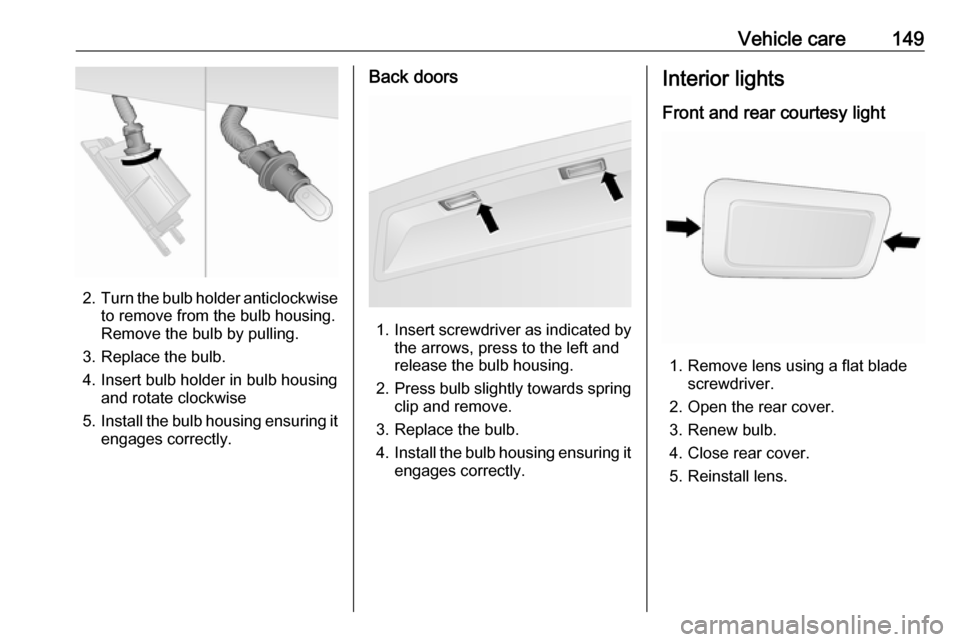

2.Turn the bulb holder anticlockwise

to remove from the bulb housing.

Remove the bulb by pulling.

3. Replace the bulb.

4. Insert bulb holder in bulb housing and rotate clockwise

5. Install the bulb housing ensuring it

engages correctly.

Back doors

1. Insert screwdriver as indicated by

the arrows, press to the left and

release the bulb housing.

2. Press bulb slightly towards spring

clip and remove.

3. Replace the bulb.

4. Install the bulb housing ensuring it

engages correctly.

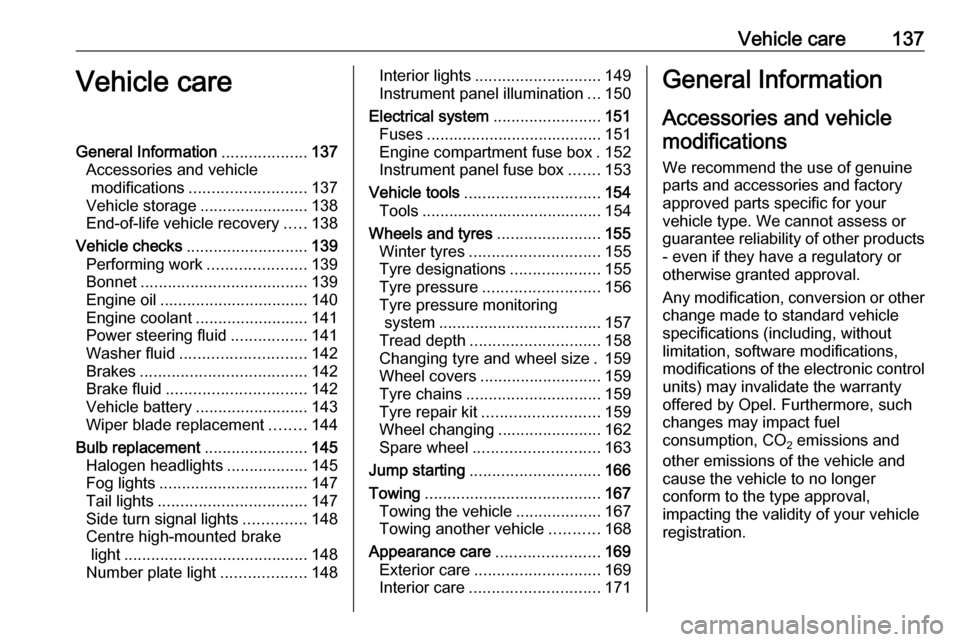

Interior lights

Front and rear courtesy light

1. Remove lens using a flat blade screwdriver.

2. Open the rear cover. 3. Renew bulb.

4. Close rear cover.

5. Reinstall lens.

Page 163 of 195

Vehicle care161damaged. Seek the assistance of

a workshop.

Do not run the compressor longer than 20 minutes.

11. Detach the tyre repair kit.

12. Remove any excess sealant using a cloth.

13. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

14. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

10 km (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than

1.8 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.8 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

15. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off and allow to cool.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -20 °C.

Replacing the sealant canister

To replace the sealant canister: 1. Disconnect the compressor air hose.

Page 165 of 195

Vehicle care163

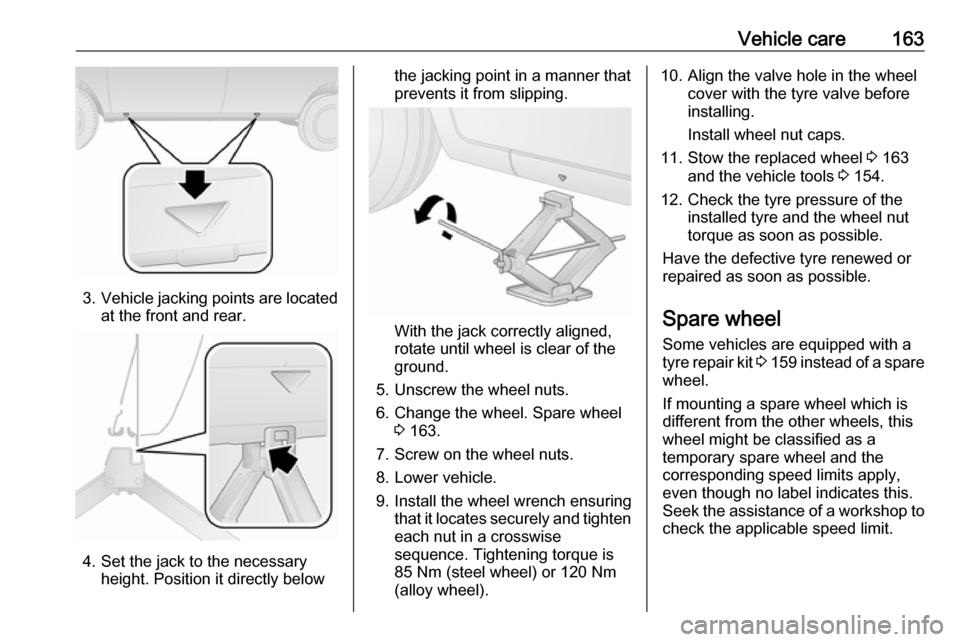

3.Vehicle jacking points are located

at the front and rear.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

With the jack correctly aligned,

rotate until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 163.

7. Screw on the wheel nuts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each nut in a crosswise

sequence. Tightening torque is

85 Nm (steel wheel) or 120 Nm

(alloy wheel).

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow the replaced wheel 3 163

and the vehicle tools 3 154.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Spare wheel Some vehicles are equipped with atyre repair kit 3 159 instead of a spare

wheel.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.