ignition OPEL COMBO 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: COMBO, Model: OPEL COMBO 2017Pages: 195, PDF Size: 4.71 MB

Page 134 of 195

132Driving and operatingFuel selector

Pressing Y in the centre console

switches between petrol and natural

gas operation. The LED 1 status

shows the current operating mode.

1 off:natural gas

operation1 illuminates:petrol operation

As soon as the natural gas tanks are

empty, petrol operation is

automatically engaged. Control

indicator Y illuminates in the Driver

Information Centre 3 89 until the

ignition is switched off.

When switching automatically

between petrol or gas operation, a

brief delay of engine tractive power

may be noticeable.

Every six months run the petrol tank

down until control indicator §

illuminates and then refuel. This is

necessary to maintain fuel quality as

well as system function necessary for

petrol operation.

Fill the tank completely at regular

intervals to prevent corrosion in the

tank.

Refuelling

Fuel filler flap is located at left rear

side of vehicle.9 Danger

Before refuelling, switch off engine

and any external heaters with

combustion chambers. Switch off

any mobile phones.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

Caution

In case of misfuelling, do not

switch on ignition.

Release the fuel filler flap by pulling

the flap by hand.

Insert ignition key into fuel filler cap

and turn anticlockwise to unlock.

To remove fuel filler cap, rotate

anticlockwise.

Caution

To avoid damage, do not attempt

to operate the sliding side door

when the fuel filler flap is open.

Page 135 of 195

Driving and operating133Note

Depending on model, the sliding

side door may be fitted with a safety

system that prevents the door from

being opened fully when the fuel

filler flap is open.

Sliding side door 3 26.

The fuel filler cap can be retained in

the bracket on the fuel filler flap.

To refuel, fully insert the pump nozzle

and switch it on.

After automatic cut-off, the tank can be topped up by operating the pump

nozzle a maximum of two more times.

Caution

Wipe off any overflowing fuel

immediately.

To close, replace fuel filler cap and

turn clockwise.

Insert ignition key into fuel filler cap

and turn clockwise to lock, then

remove key.

Close the fuel filler flap.

Natural gas refuelling

Open the fuel filler flap.

9 Warning

Refuel only with a maximum

output pressure of 250 bar. Use

only temperature compensated

filling stations.

The refuelling procedure must be

completed, i.e. the filler neck must be vented.

The capacity of the natural gas tank

depends on outside temperature,

filling pressure and type of refuelling

system.

Close the fuel filler flap after

refuelling.

Terms for " natural gas vehicles "

abroad:

GermanErdgasfahrzeugeEnglishNGVs = Natural Gas Vehi‐

clesFrenchVéhicules au gaz naturel –

or – Véhicules GNVItalianMetano auto

Page 141 of 195

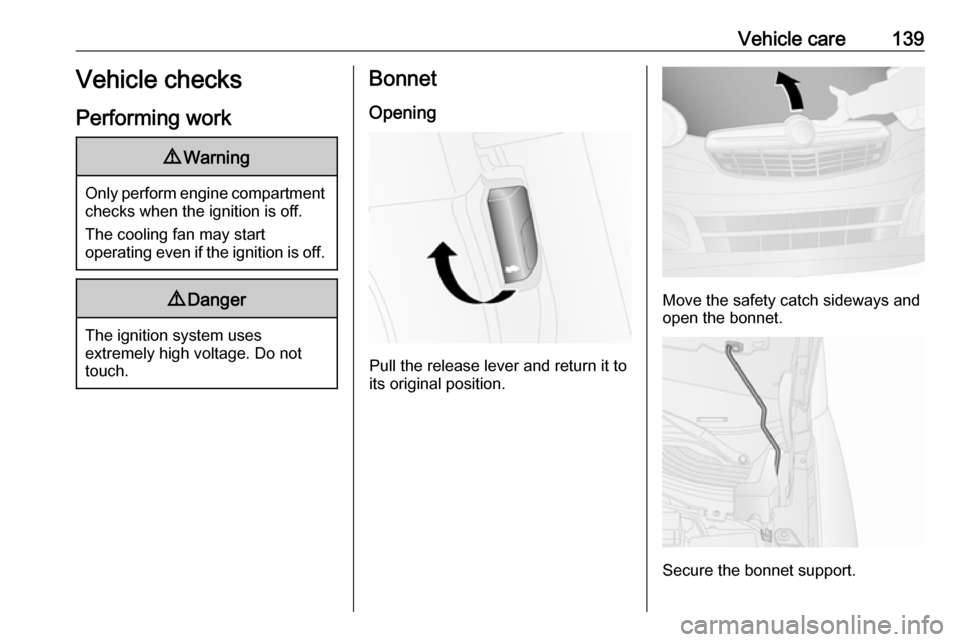

Vehicle care139Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system uses

extremely high voltage. Do not

touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Move the safety catch sideways and

open the bonnet.

Secure the bonnet support.

Page 145 of 195

Vehicle care143Only use high-performance brake

fluid approved for the vehicle.

Brake and clutch fluid 3 173.

Vehicle battery

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the vehicle battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to vehicle battery

discharge. Disconnect the clamp from

the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Battery discharge protection 3 104.

Replacing the vehicle battery Note

Any deviation from the instructions

given in this paragraph may lead to

a temporary deactivation of the stop-

start system.

In vehicles with stop-start system,

ensure the correct battery is used

when replacing the vehicle battery.

We recommend that you have the

vehicle battery replaced by a

workshop.

Stop-start system 3 114.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed 14.6

volts when using a battery

charger. Otherwise the vehicle

battery may be damaged.

Jump starting 3 166.

Warning label

Meaning of symbols: ● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of reach of children.

Page 147 of 195

Vehicle care145Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base! Do

not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement, switch on

the ignition, operate and check the

lights.Halogen headlights

Headlights have separate systems for low beam/sidelight 1 (outer bulb),

high beam/daytime running light 2

(inner bulb).

To access bulbs, pull off protective

covers.

Low beam 1. Remove protective cover.

2. Detach connector from bulb.

3. Disengage wire clip and remove bulb from reflector.

4.Insert new bulb in reflector so that

the locating tab of the bulb aligns

with the reflector recess.

5. Attach connector to bulb.

6. Engage wire clip.

7. Install protective cover.

High beam 1. Remove protective cover.

2. Detach connector from bulb.

3. Disengage wire clip and remove bulb from reflector.

Page 150 of 195

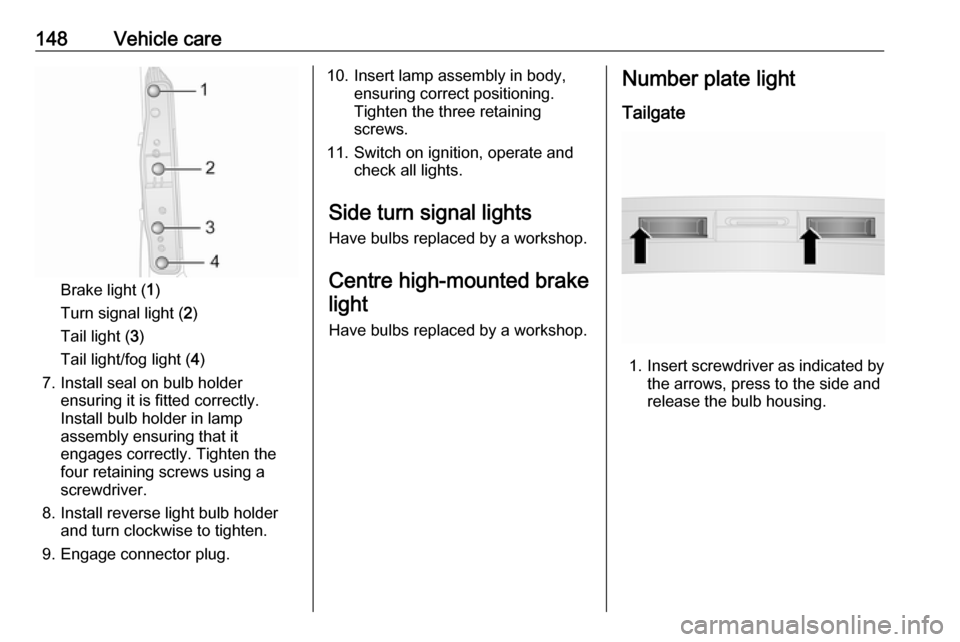

148Vehicle care

Brake light (1)

Turn signal light ( 2)

Tail light ( 3)

Tail light/fog light ( 4)

7. Install seal on bulb holder ensuring it is fitted correctly.

Install bulb holder in lamp

assembly ensuring that it

engages correctly. Tighten the

four retaining screws using a

screwdriver.

8. Install reverse light bulb holder and turn clockwise to tighten.

9. Engage connector plug.

10. Insert lamp assembly in body, ensuring correct positioning.

Tighten the three retaining

screws.

11. Switch on ignition, operate and check all lights.

Side turn signal lights

Have bulbs replaced by a workshop.

Centre high-mounted brake light

Have bulbs replaced by a workshop.Number plate light

Tailgate

1. Insert screwdriver as indicated by

the arrows, press to the side and

release the bulb housing.

Page 153 of 195

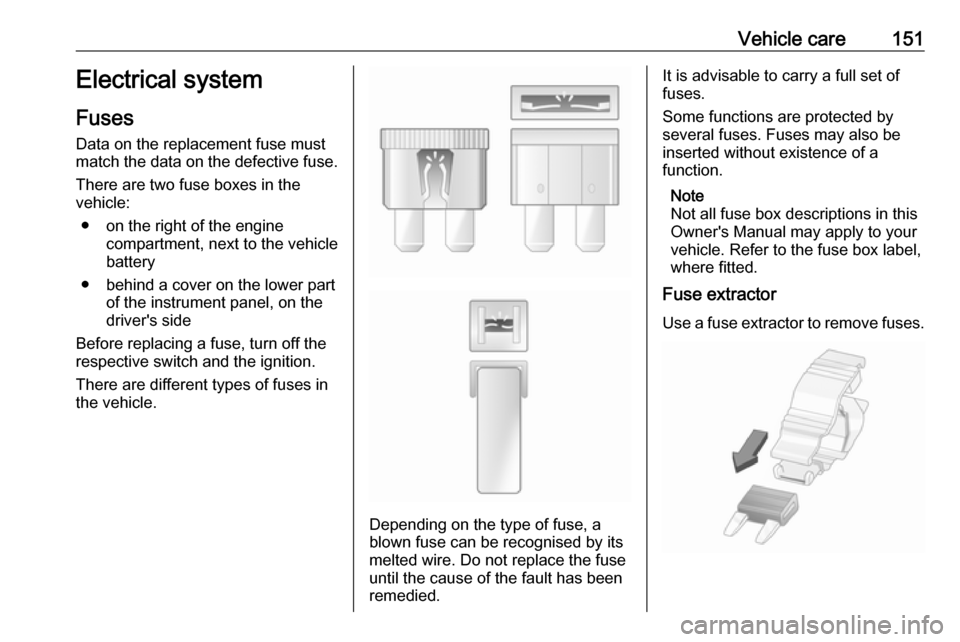

Vehicle care151Electrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● on the right of the engine compartment, next to the vehicle

battery

● behind a cover on the lower part of the instrument panel, on the

driver's side

Before replacing a fuse, turn off the

respective switch and the ignition.

There are different types of fuses in the vehicle.

Depending on the type of fuse, a

blown fuse can be recognised by its

melted wire. Do not replace the fuse until the cause of the fault has been

remedied.

It is advisable to carry a full set of

fuses.

Some functions are protected by

several fuses. Fuses may also be

inserted without existence of a

function.

Note

Not all fuse box descriptions in this

Owner's Manual may apply to your

vehicle. Refer to the fuse box label,

where fitted.

Fuse extractor

Use a fuse extractor to remove fuses.

Page 158 of 195

156Vehicle careDirectional tyres

Directional tyres must be mounted so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 185.

The tyre pressure information label

on the door frame (if fitted) indicates

the original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 178.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 185.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressures.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa (0.1 bar) for a 10 °C

temperature increase. This must be

considered when warm tyres are

checked.

Page 159 of 195

Vehicle care157Tyre pressure monitoringsystem

The Tyre Pressure Monitoring

System (TPMS) uses radio and

sensor technology to check tyre

pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

The TPMS sensors monitor the air pressure in the tyres and transmit tyre

pressure readings to a receiver

located in the vehicle.

All wheels must be equipped with

pressure sensors and the tyres must

have the prescribed pressure.

Tyre pressure chart 3 185.

Note

In countries where the tyre pressure monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

Low tyre pressure condition

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 86 together

with a warning chime. In vehicles with Multifunction version of the Driver

Information Centre, a corresponding message is also displayed.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 185.

After inflating, driving may be

required to update the tyre pressure

values in the system. During this time

w may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure of all

four tyres.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

value cannot be recognised by the

system and w flashes for several

seconds then illuminates

continuously. In vehicles with

Multifunction version of the Driver Information Centre, a corresponding

message is also displayed.

Page 160 of 195

158Vehicle careA spare wheel or temporary spare

wheel is not equipped with pressure

sensors. TPMS is not operational for

these wheels. For the further three

wheels, TPMS remains operational.

Spare wheel 3 163, Wheel changing

3 162.

Control indicator w and (depending

on version) a corresponding message appears at each ignition cycle untilthe tyres are inflated to the correct

tyre pressure.

Driver Information Centre 3 89.

Relearn function

After changing wheels, TPMS needs

to recalculate. The relearn process

takes up to 20 minutes of driving with

a minimum speed of 20 km/h.

If problems occur during the relearn

process, control indicator w flashes

for several seconds then illuminates

continuously and (depending on

version) a warning message is

displayed in the Driver Information

Centre.

Driver Information Centre 3 89.General information

The use of tyre chains or

commercially available liquid tyre

repair kits can impair the function of

the system. Factory-approved tyre

repair kits can be used.

Tyre repair kit 3 159, Tyre chains

3 159.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, TPMS sensors must be dismounted

and serviced by a workshop.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and

rear wheels periodically. Ensure that

the direction of rotation of the wheels

is the same as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.