jacking OPEL COMBO E 2019.1 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019.1, Model line: COMBO E, Model: OPEL COMBO E 2019.1Pages: 283, PDF Size: 10.57 MB

Page 241 of 283

Vehicle care239Replace the used sealant bottle.

Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

Wheel changing Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.● Never crawl under a jacked-upvehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

Tightening torques

Caution

If the vehicle is equipped with alloy

wheels, tighten the wheel bolts

manually at least for the first five

turns.

There are two different types of

wheels with two different bolts and tightening torques.

Tightening torque for alloy wheels is

100 Nm.

Tightening torque for steel wheels is

115 Nm.

Use the correct wheel bolts for the respective wheels.

Jacking positions The jacking positions shown refer to

the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

Page 242 of 283

240Vehicle care

The rear arm position of the lifting

platform is centrically under the

relevant vehicle jacking point.

The front arm position of the lifting

platform is centrically under the

relevant vehicle jacking point.

Spare wheel The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in a holder

beneath the vehicle floor.

1. Depending on the version, open the tailgate or the rear doors 3 31,

3 32.

2. Fit the wheel wrench on one

hexagon bolt. Turn it

anticlockwise until the spare wheel holder is low enough allow

the catch to be unhooked.

Page 243 of 283

Vehicle care241

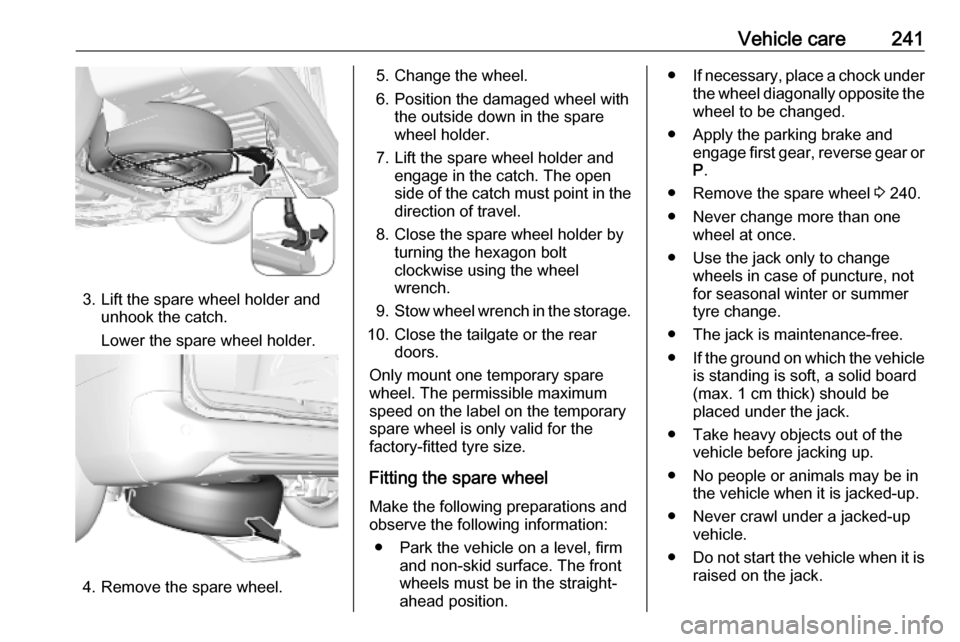

3. Lift the spare wheel holder andunhook the catch.

Lower the spare wheel holder.

4. Remove the spare wheel.

5. Change the wheel.

6. Position the damaged wheel with the outside down in the spare

wheel holder.

7. Lift the spare wheel holder and engage in the catch. The open

side of the catch must point in the

direction of travel.

8. Close the spare wheel holder by turning the hexagon bolt

clockwise using the wheel

wrench.

9. Stow wheel wrench in the storage.

10. Close the tailgate or the rear doors.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 240.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

Page 244 of 283

242Vehicle care● Before screwing in the wheelbolts, clean them.9Warning

Do not grease wheel bolts.

9Warning

Ensure to use always the correct

wheel bolts if changing the

wheels. When installing the spare

wheel, the bolts for alloy wheels can also be used.

● Note that the spare wheel is secured by the conical contact ofeach bolt if the wheel bolts for the

alloy wheels are used. In this

case, the washers do not come

into contact with the spare wheel.

1. Disengage wheel bolt caps with the wheel bolt cover remover.

3 230

Steel wheels with cover: Pull off

the wheel cover.

Alloy wheels: Disengage wheel

bolt caps with the wheel bolt cover remover.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

The wheels might be protected by

locking wheel nuts. To loosen

these specific nuts first attach the

adapter onto the head of the nut

before installing the wheel

wrench. The adapter is located in

the tool box. 3 230

3. Ensure the jack is correctly

positioned under the relevant

vehicle jacking point.

Page 245 of 283

Vehicle care243

4. Set the jack to the necessaryheight. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Ensure that the edge of the body

fits into the notch of the jack.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 240.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each bolt in a crosswise

sequence. Tightening torque is

115 Nm.

If the vehicle is equipped with

alloy wheels, note that the wheel

bolts can also be used for the steel spare wheel. In this case, the

spare wheel is secured by the

conical contact of each bolt.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow the replaced wheel 3 240,

the vehicle tools 3 230 and the

adapter for the locking wheel nuts.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Page 273 of 283

Customer information271Translation of the original declaration

of conformity

Declaration of conformity according

to EC Directive 2006/42/EC

We declare that the product:

Product designation: Jack

Type/GM part number: 3637376

Type/PSA part number: 9649243380

is in compliance with the provisions of

Directive 2006/42/EC.

Applied technical standards:GMN9737:jackingGM 14337:standard equipment

jack – hardware

testsGMW15005:standard equipment jack and spare tyre,

vehicle testISO TS 16949:quality

management

systemsThe signatory is authorised to

compile the technical documentation.

Rüsselsheim, 13th December 2016

signed by

André-Alexander Konter

Engineering Group Manager Tyre

and Wheel Systems

Adam Opel AG

D-65423 Rüsselsheim

ICASA type approval numbers

List of all Independent

Communications Authority of South Africa (ICASA) type approval

numbers:

TA-2016/121, TA-2016/3261,

TA-2017/2387,TA-2017/2745,

TA-2013/430, TA-2017/1106,

TA-2016/929, TA-2017/3180REACH

Registration, Evaluation,

Authorisation and Restriction of

Chemicals (REACH) is a European

Union regulation adopted to improve

the protection of human health and

the environment from the risks that

can be posed by chemicals. Visit

www.opel.com for further information

and for access to the Article 33

communication.

Registered trademarksApple Inc.

Apple CarPlay™ is a trademark of Apple Inc.

App Store ®

and iTunes Store ®

are

registered trademarks of Apple Inc.

iPhone ®

, iPod ®

, iPod touch ®

, iPod

nano ®

, iPad ®

and Siri ®

are registered

trademarks of Apple Inc.Bluetooth SIG, Inc.

Bluetooth ®

is a registered trademark

of Bluetooth SIG, Inc.DivX, LLC

DivX ®

and DivX Certified ®

are

registered trademarks of DivX, LLC.