wheel bolts OPEL CORSA 2009 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2009, Model line: CORSA, Model: OPEL CORSA 2009Pages: 284, PDF Size: 4.96 MB

Page 190 of 284

184 Driving and operationTowing equipment

3

Only use towing equipment that has been

approved for your vehicle. Ask a workshop

to retrofit towing equipment. It may be

necessary to make changes that affect the

cooling system, heat shields or other

equipment.

Mounting dimensions of towing equipment

3269.

Stowage of coupling ball bar

The coupling ball bar is stowed in a bag in

the spare wheel well and secured to the

lashing eyes in the luggage compartment

3 187.

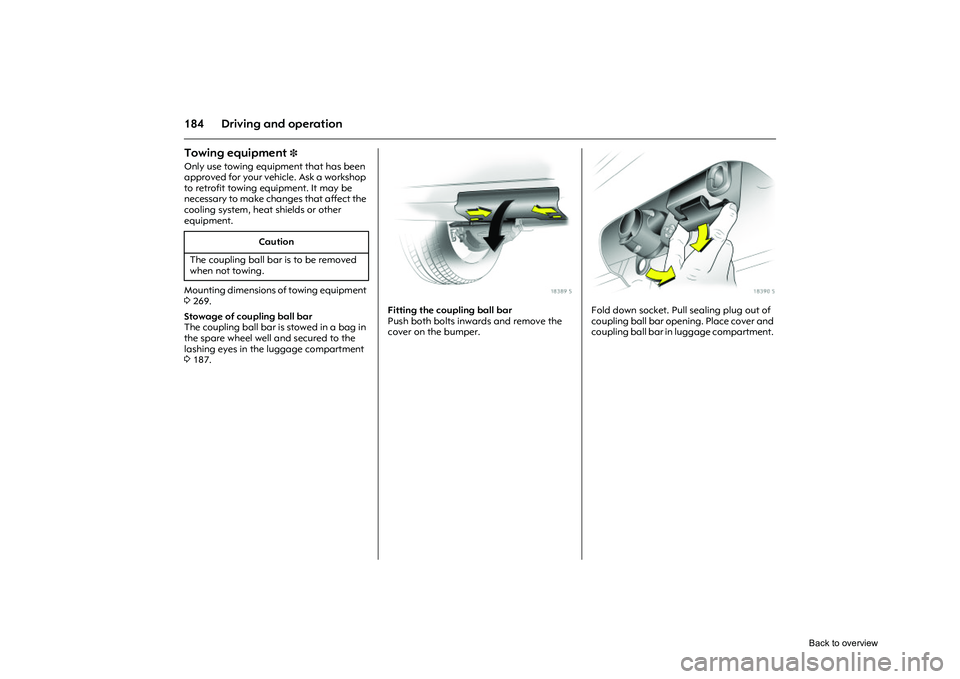

Picture no: 18389s.tif

Fitting the coupling ball bar

Push both bolts inwards and remove the

cover on the bumper.

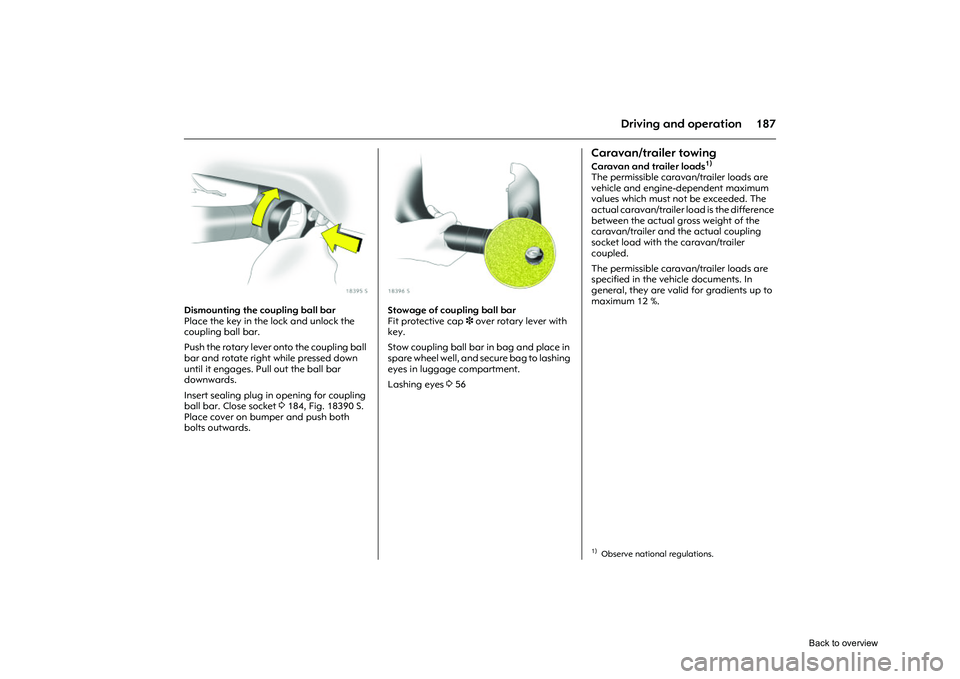

Picture no: 18390s.tif

Fold down socket. Pull sealing plug out of

coupling ball bar opening. Place cover and

coupling ball bar in luggage compartment.

Caution

The coupling ball bar is to be removed

when not towing.

Back to overview

Page 193 of 284

187

Driving and operation

Picture no: 18395s.tif

Dismounting the coupling ball bar

Place the key in the lock and unlock the

coupling ball bar.

Push the rotary lever onto the coupling ball

bar and rotate right while pressed down

until it engages. Pull out the ball bar

downwards.

Insert sealing plug in opening for coupling

ball bar. Close socket 3184, Fig. 18390 S.

Place cover on bumper and push both

bolts outwards.

Picture no: 18396s.tif

Stowage of coupling ball bar

Fit protective cap 3 over rotary lever with

key.

Stow coupling ball bar in bag and place in

spare wheel well, and se cure bag to lashing

eyes in luggage compartment.

Lashing eyes 356

Caravan/trailer towingCaravan and trailer loads

1)

The permissible caravan/trailer loads are

vehicle and engine-dependent maximum

values which must not be exceeded. The

actual caravan/trailer load is the difference

between the actual gross weight of the

caravan/trailer and the actual coupling

socket load with the caravan/trailer

coupled.

The permissible caravan/trailer loads are

specified in the vehicle documents. In

general, they are valid for gradients up to

maximum 12 %. 1)Observe national regulations.

Back to overview

Page 206 of 284

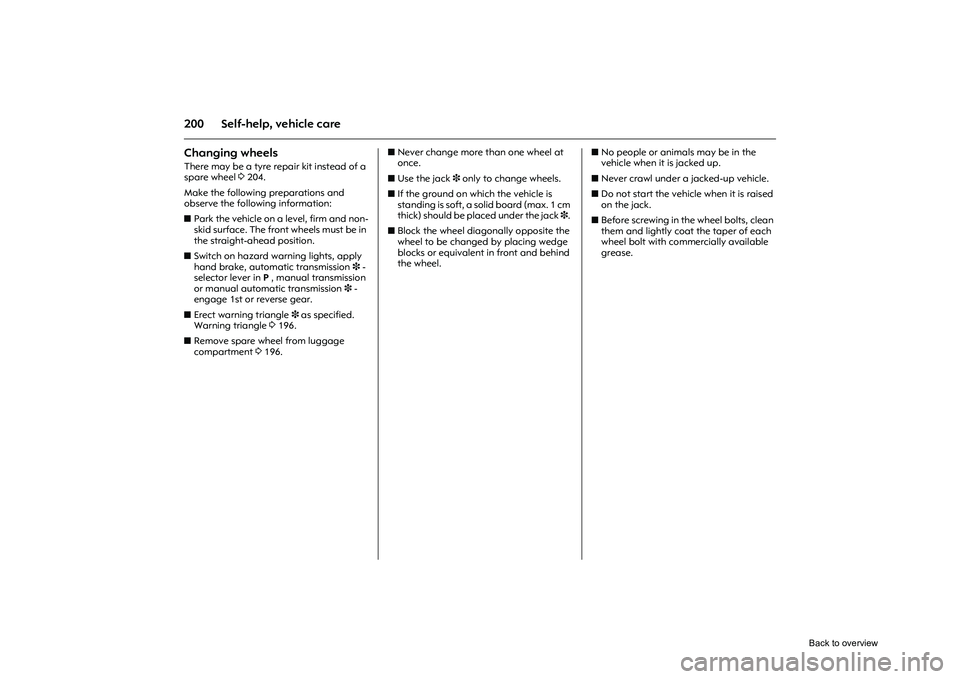

200 Self-help, vehicle careChanging wheels There may be a tyre repair kit instead of a

spare wheel 3204.

Make the following preparations and

observe the following information:

z Park the vehicle on a level, firm and non-

skid surface. The front wheels must be in

the straight-ahead position.

z Switch on hazard warning lights, apply

hand brake, automa tic transmission 3 -

selector lever in P , manual transmission

or manual automatic transmission 3 -

engage 1st or reverse gear.

z Erect warning triangle 3 as specified.

Warning triangle 3196.

z Remove spare wheel from luggage

compartment 3196. z

Never change more than one wheel at

once.

z Use the jack 3 only to change wheels.

z If the ground on which the vehicle is

standing is soft, a solid board (max. 1 cm

thick) should be placed under the jack 3.

z Block the wheel diagonally opposite the

wheel to be changed by placing wedge

blocks or equivalent in front and behind

the wheel. z

No people or animals may be in the

vehicle when it is jacked up.

z Never crawl under a jacked-up vehicle.

z Do not start the vehicle when it is raised

on the jack.

z Before screwing in the wheel bolts, clean

them and lightly coat the taper of each

wheel bolt with comm ercially available

grease.

Back to overview

Page 207 of 284

201

Self-help, vehicle care

Picture no: 17243t.tif

1. Pull off the wheel trim with the hook 3.

Vehicle tools 3 198.

For wheel trims with visible wheel bolts 3:

The trim can remain on the wheel. Do not

remove the retaining washers 3 on the

wheel bolts.

Picture no: 17244t.tif

Alloy wheels 3: Disengage the wheel bolt

caps with a screwdriver and remove.

Protect the wheel by inserting a soft cloth

between the screwdriver and ally wheel.

Picture no: 17245t.tif

2. Push the wheel bolt wrench 3 on as far

as possible and slacken the wheel bolts

half a turn.

Back to overview

Page 209 of 284

203

Self-help, vehicle care

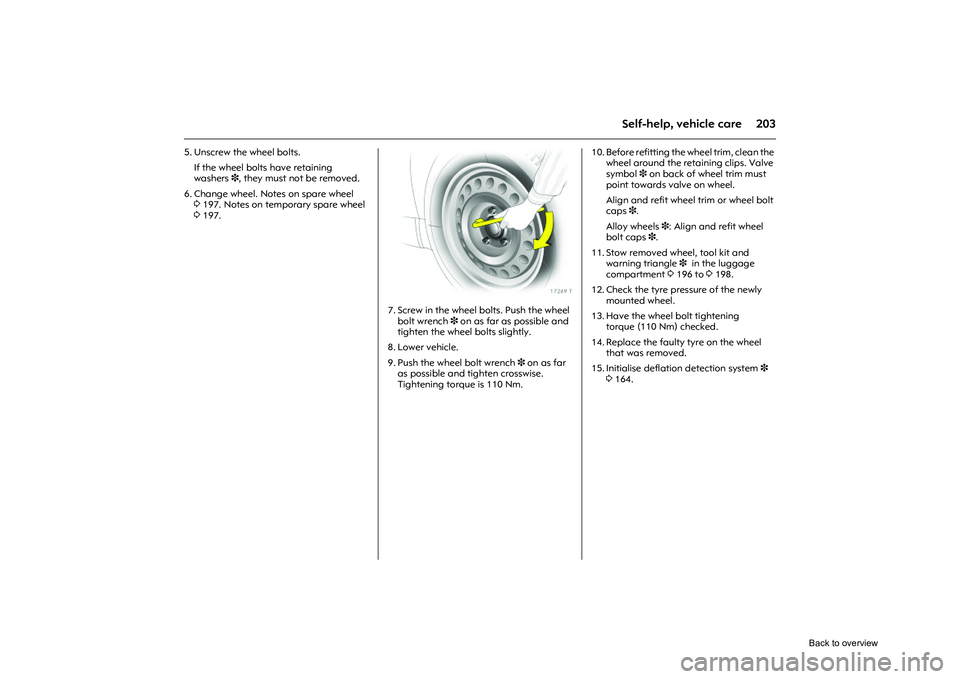

5. Unscrew the wheel bolts. If the wheel bolts have retaining

washers 3, they must not be removed.

6. Change wheel. Notes on spare wheel 3197. Notes on temporary spare wheel

3 197.

Picture no: 17249t.tif

7. Screw in the wheel bolts. Push the wheel

bolt wrench 3 on as far as possible and

tighten the wheel bolts slightly.

8. Lower vehicle.

9. Push the wheel bolt wrench 3 on as far

as possible and tighten crosswise.

Tightening torque is 110 Nm. 10. Before refitting the wheel trim, clean the

wheel around the retaining clips. Valve

symbol 3 on back of wheel trim must

point towards valve on wheel.

Align and refit wheel trim or wheel bolt

caps 3.

Alloy wheels 3: Align and refit wheel

bolt caps 3.

11. Stow removed wheel, tool kit and warning triangle 3 in the luggage

compartment 3196 to 3198.

12. Check the tyre pressure of the newly mounted wheel.

13. Have the wheel bolt tightening torque (110 Nm) checked.

14. Replace the faulty tyre on the wheel that was removed.

15. Initialise deflation detection system 3

3 164.

Back to overview