parking brake OPEL CORSA E 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: CORSA E, Model: OPEL CORSA E 2019Pages: 231, PDF Size: 6.87 MB

Page 185 of 231

Vehicle care183tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure

sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle. The sensors are matched to the

wheel positions, using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn light at the current

active position is illuminated until

sensor is matched.

Consult a workshop for service. There

are 2 minutes to match the first wheel position, and 5 minutes overall to

match all four wheel positions. If it

takes longer, the matching process

stops and must be restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Use MENU on the stalk to select

the Vehicle Information

Menu ? in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Midlevel display:

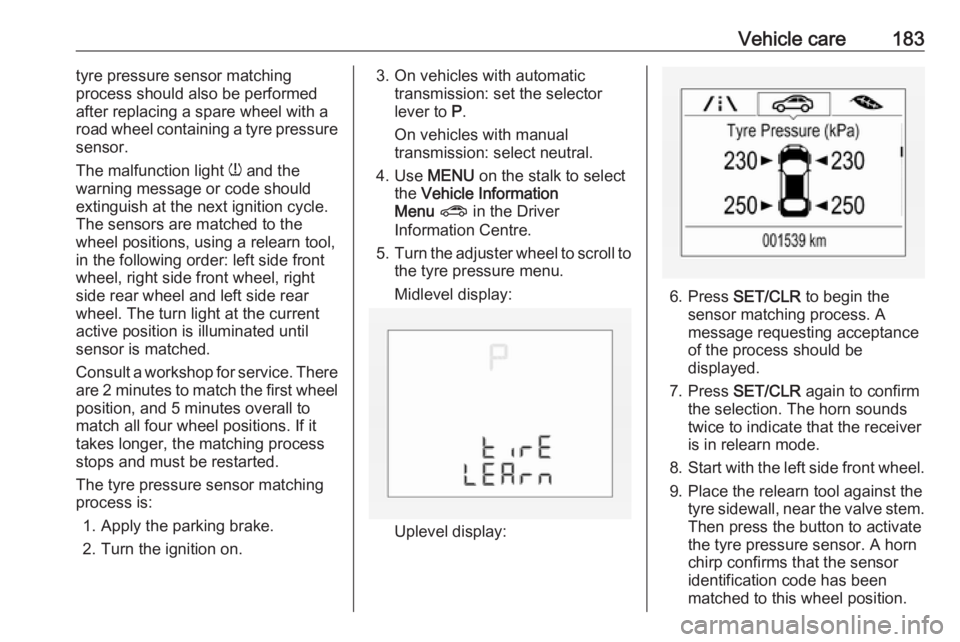

Uplevel display:

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

Page 188 of 231

186Vehicle care9Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is stowed in the load

compartment.

Depending on the equipment, the tyre repair kit is in a compartment in the

right sidewall or in a compartment

under the floor cover.

Vehicles with tyre repair kit under

the floor cover

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

Page 193 of 231

Vehicle care191General informationNote

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30 min.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

The adapters possibly supplied can

be used to pump up other items e.g. footballs, air mattresses, inflatable

dinghies etc. They can be located on the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them and lightly coat

the taper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

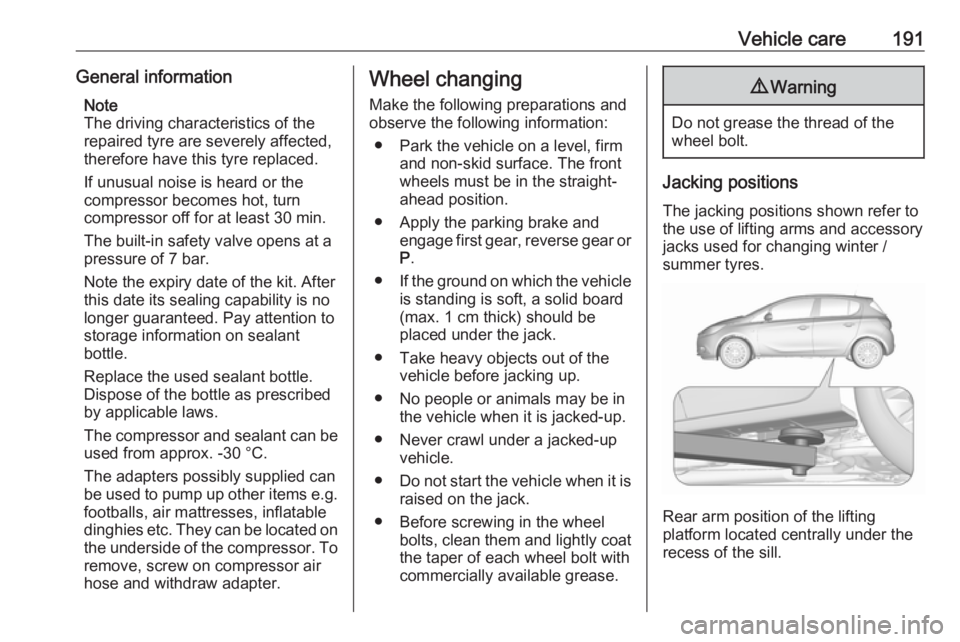

Jacking positions

The jacking positions shown refer to the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

Rear arm position of the lifting

platform located centrally under the

recess of the sill.

Page 194 of 231

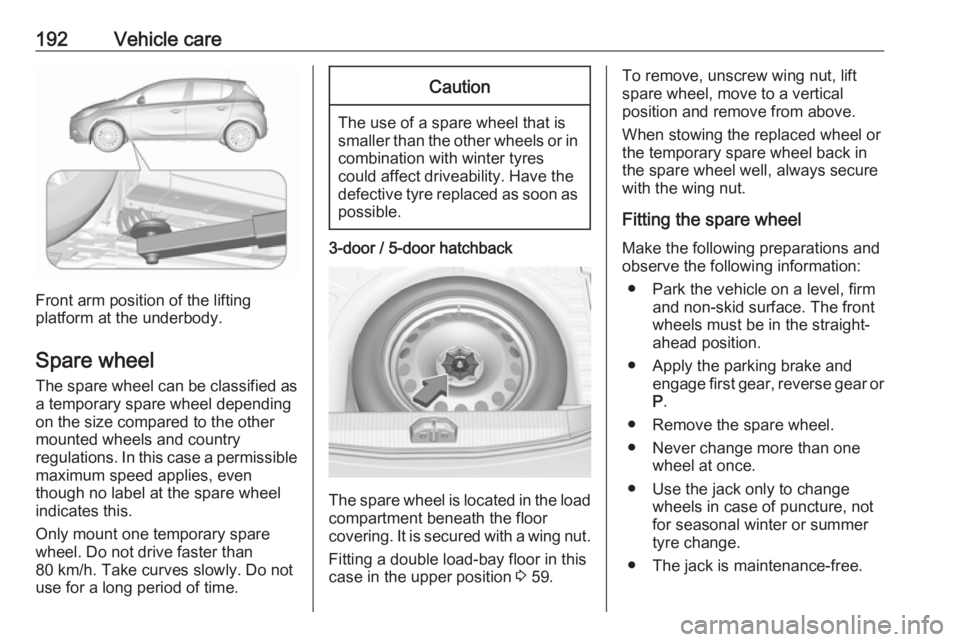

192Vehicle care

Front arm position of the lifting

platform at the underbody.

Spare wheel The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

3-door / 5-door hatchback

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

Fitting a double load-bay floor in this

case in the upper position 3 59.

To remove, unscrew wing nut, lift

spare wheel, move to a vertical

position and remove from above.

When stowing the replaced wheel or

the temporary spare wheel back in

the spare wheel well, always secure

with the wing nut.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

Page 197 of 231

Vehicle care195Jump starting

Do not start with a quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 V). Its capacity

(Ah) must not be much less than

that of the discharged vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

.

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both vehicle

batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

vehicle battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged vehicle battery.

Page 199 of 231

Vehicle care197

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: the vehicle must be towed facing

forwards, not faster than 80 km/h nor further than 100 km. In all other cases

and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop.

After towing, unscrew the towing eye.

Insert cap at the top and engage

downwards.

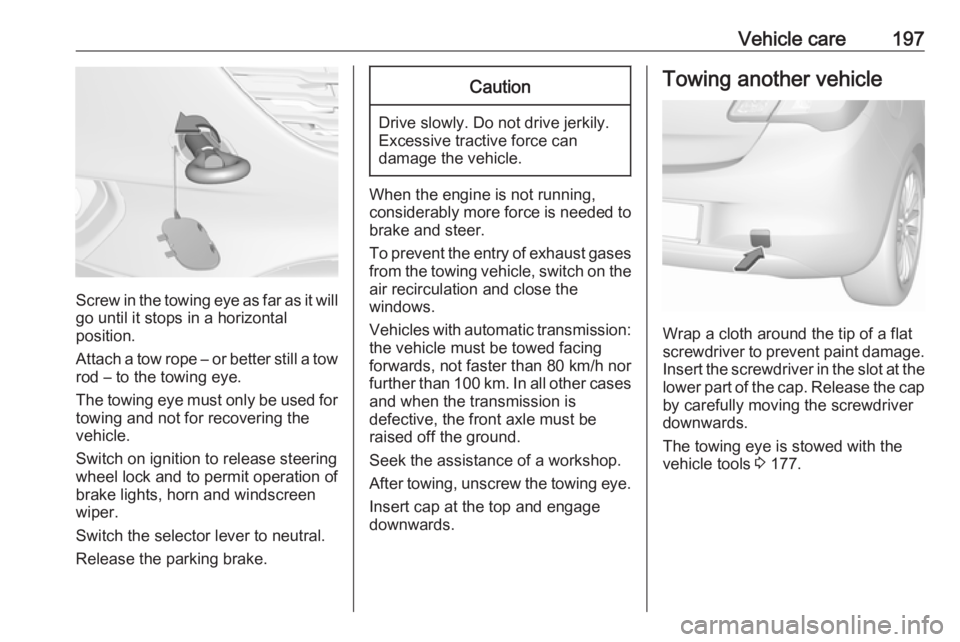

Towing another vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage. Insert the screwdriver in the slot at the

lower part of the cap. Release the cap by carefully moving the screwdriver

downwards.

The towing eye is stowed with the

vehicle tools 3 177.

Page 228 of 231

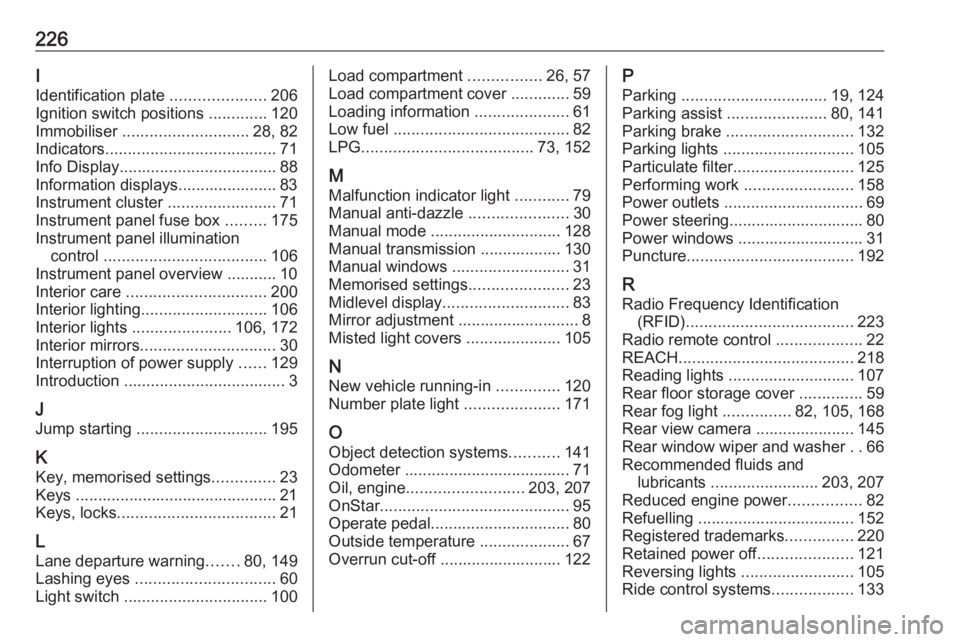

226I

Identification plate .....................206

Ignition switch positions .............120

Immobiliser ............................ 28, 82

Indicators ...................................... 71

Info Display ................................... 88

Information displays...................... 83

Instrument cluster ........................71

Instrument panel fuse box .........175

Instrument panel illumination control .................................... 106

Instrument panel overview ........... 10

Interior care ............................... 200

Interior lighting ............................ 106

Interior lights ...................... 106, 172

Interior mirrors .............................. 30

Interruption of power supply ......129

Introduction .................................... 3

J

Jump starting ............................. 195

K

Key, memorised settings ..............23

Keys ............................................. 21

Keys, locks ................................... 21

L

Lane departure warning .......80, 149

Lashing eyes ............................... 60

Light switch ................................ 100Load compartment ................26, 57

Load compartment cover .............59

Loading information .....................61

Low fuel ....................................... 82

LPG ...................................... 73, 152

M

Malfunction indicator light ............79

Manual anti-dazzle ......................30

Manual mode ............................. 128

Manual transmission .................. 130

Manual windows ..........................31

Memorised settings ......................23

Midlevel display ............................ 83

Mirror adjustment ........................... 8

Misted light covers .....................105

N New vehicle running-in ..............120

Number plate light .....................171

O Object detection systems ...........141

Odometer ..................................... 71

Oil, engine .......................... 203, 207

OnStar .......................................... 95

Operate pedal ............................... 80

Outside temperature ....................67

Overrun cut-off ........................... 122P

Parking ................................ 19, 124

Parking assist ......................80, 141

Parking brake ............................ 132

Parking lights ............................. 105

Particulate filter ........................... 125

Performing work ........................158

Power outlets ............................... 69

Power steering.............................. 80

Power windows ............................ 31

Puncture ..................................... 192

R Radio Frequency Identification (RFID) ..................................... 223

Radio remote control ...................22

REACH ....................................... 218

Reading lights ............................ 107

Rear floor storage cover ..............59

Rear fog light ...............82, 105, 168

Rear view camera ...................... 145

Rear window wiper and washer ..66

Recommended fluids and lubricants ........................ 203, 207

Reduced engine power ................82

Refuelling ................................... 152 Registered trademarks ...............220

Retained power off .....................121

Reversing lights .........................105

Ride control systems ..................133