lock OPEL CORSA E 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: CORSA E, Model: OPEL CORSA E 2019Pages: 231, PDF Size: 6.87 MB

Page 167 of 231

Vehicle care165Low beam

1. Rotate the cap (2) anticlockwiseand remove it.

2. Press the clip to disengage bulbholder. Withdraw the bulb holder

from the reflector.

3. Detach the bulb from the bulb holder and replace the bulb.

4. Insert the bulb holder with the clip

downwards and engage into the

reflector until it clicks.

5. Install cap.

High beam

1. Rotate the cap (3) anticlockwise and remove it.

Page 168 of 231

166Vehicle care2. Press the clip to disengage bulbholder. Withdraw the bulb holder

from the reflector.

3. Detach the bulb from the bulb holder and replace the bulb.

4. Insert the bulb holder with the clip

downwards and engage into the

reflector until it clicks.

5. Install cap.

Sidelight / daytime running light

with bulbs

1. Rotate bulb socket (1) anticlockwise to disengage.

2. Press both clips together andwithdraw the bulb socket from theheadlamp housing.

3. Remove the bulb from the socket by pulling.

4. Replace and insert new bulb into socket.

5. Insert the bulb socket into the headlamp housing and turn

clockwise.

Page 169 of 231

Vehicle care167Sidelight / daytime running light

with LEDs

Sidelights and daytime running lights

are designed as LEDs and cannot be

changed. Consult a workshop in case of a defective LED.

Xenon headlights9 Danger

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Sidelight / daytime running lights are

designed as LEDs and cannot be

changed.

Bulbs for corner lighting can be

changed.

Front turn lights 3 168.

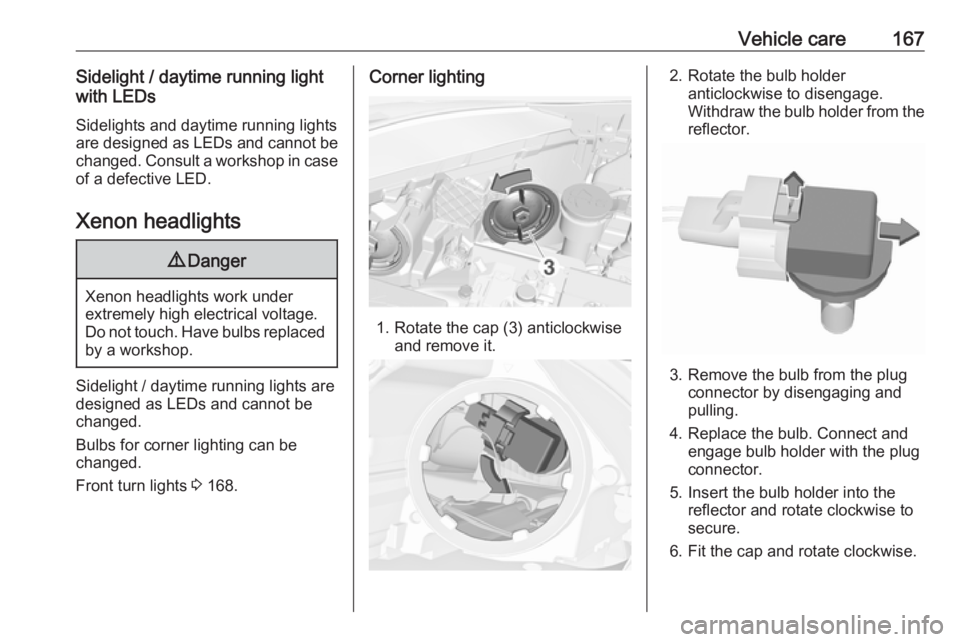

Corner lighting

1. Rotate the cap (3) anticlockwise

and remove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Remove the bulb from the plug connector by disengaging and

pulling.

4. Replace the bulb. Connect and engage bulb holder with the plug

connector.

5. Insert the bulb holder into the reflector and rotate clockwise to

secure.

6. Fit the cap and rotate clockwise.

Page 170 of 231

168Vehicle careFront fog lightsThe bulbs are accessible from the

underside of the vehicle.

1. Turn the bulb holder anti- clockwise and remove it from the

reflector.

2. Disengage the bulb socket from the plug connector by pressing

the retaining lug.

3. Remove and replace the bulb socket with bulb and attach the

plug connector.

4. Insert the bulb socket into the reflector by turning clockwise and

engage.

Front turn lights Front turn lights consist of long-life

bulbs which cannot be changed.

Consult a workshop in case of a

defective long-life bulb.

Tail lights

1. Release the cover in the load compartment on the respective

side and remove.

On the right side, remove all

components, such as tyre repair

kit or tools, from the rear insert.

Compress this insert at the upper side and remove from the

sidewall.

Page 171 of 231

Vehicle care169

2. Unscrew both plastic securingnuts from the inside by hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Press the retaining lugs and remove the bulb carrier from the

light assembly.

5. Remove the bulb by pushing the bulb slightly into the socket and

rotating anticlockwise:

Tail light / brake light ( 1)

Turn light ( 2)

6. Insert bulb into bulb carrier and turn clockwise. Engage bulbcarrier into the light assembly. Fit

light assembly with the retaining

pins into the recesses of the

vehicle body and tighten the

plastic securing nuts from inside

the load compartment.

Close cover and engage.

Reversing light / rear fog light Left-hand drive models

Reversing light is located on the right

light assembly in the tailgate, and the rear fog light is located on the left light

assembly in the tailgate.

Right-hand drive models

Reversing light is located on the left

light assembly in the tailgate, and the rear fog light is located on the right

light assembly in the tailgate.

Page 172 of 231

170Vehicle careThe description of bulb replacement

is the same for both lights.

1. Remove screw from the tailgate.

2. Move light assembly slightly to the

outside, then withdraw from the

tailgate.

3. Remove the bulb holder by turning.

4. Remove the bulb by pushingslightly into the socket and

rotating anticlockwise. Replace

the bulb.

5. Insert the bulb socket into the assembly and turn to secure.

6. Attach light assembly into the tailgate and secure with the

screw.

Side turn lights

To replace bulb, remove lamp

housing:

1. Slide lamp to its left side and remove with its right end.

Page 173 of 231

Vehicle care171

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder andreplace it.

4. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Centre high-mounted brake light

Have LEDs replaced by a workshop.

Number plate light

1. Insert screwdriver in recess of the

cover, press to the side and

release spring.

2. Remove lamp downwards, taking care not to pull on the cable.

3. Remove bulb holder from lamp housing by turning anticlockwise.

Page 174 of 231

172Vehicle care4. Pull bulb from bulb holder andreplace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and let engage.

Interior lights Have the following bulbs replaced by

a workshop:

● courtesy light, reading lights

● load compartment light

● dome light

● instrument panel illuminationElectrical system

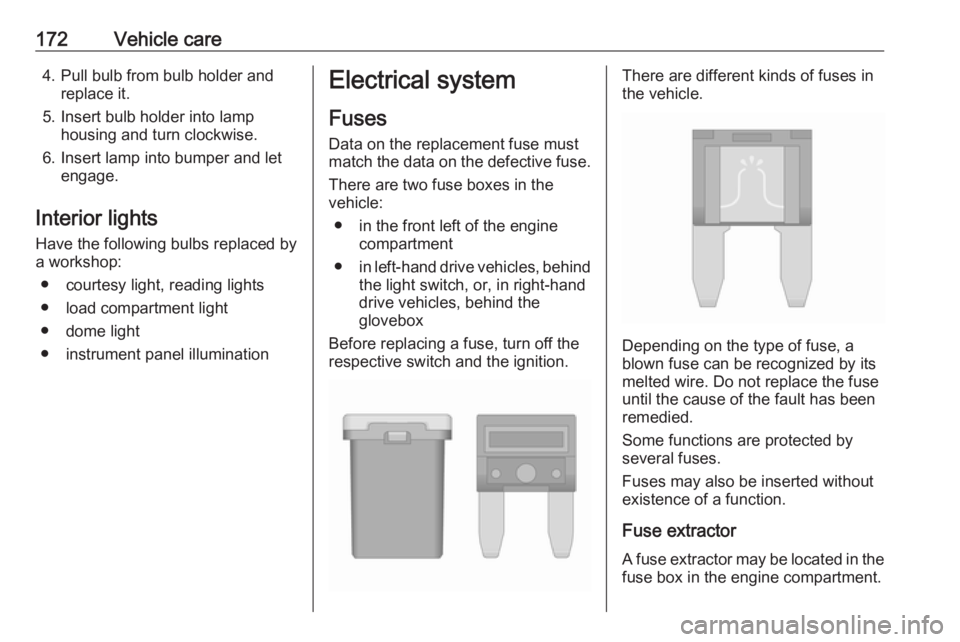

Fuses

Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● in the front left of the engine compartment

● in left-hand drive vehicles, behind

the light switch, or, in right-hand

drive vehicles, behind the

glovebox

Before replacing a fuse, turn off the

respective switch and the ignition.There are different kinds of fuses in

the vehicle.

Depending on the type of fuse, a

blown fuse can be recognized by its

melted wire. Do not replace the fuse until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without existence of a function.

Fuse extractorA fuse extractor may be located in the

fuse box in the engine compartment.

Page 187 of 231

Vehicle care1859Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Steel wheels: When using locking

wheel nuts, do not attach wheel

covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 175/70 R14, 185/70 R14,

185/65 R15, 205/45 R17.

Tyre chains are permitted on tyres of

size 195/55 R16 with rims of size

16 x 6 and 16 x 6.5, the latter only in combination with limited steering

angle. Seek the assistance of a

workshop.

Tyre chains are not permitted on tyres of size 215/45 R17 and 215/40 R18.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at the tyre's side wall near the rim

cannot be repaired with the tyre repair kit.

Page 195 of 231

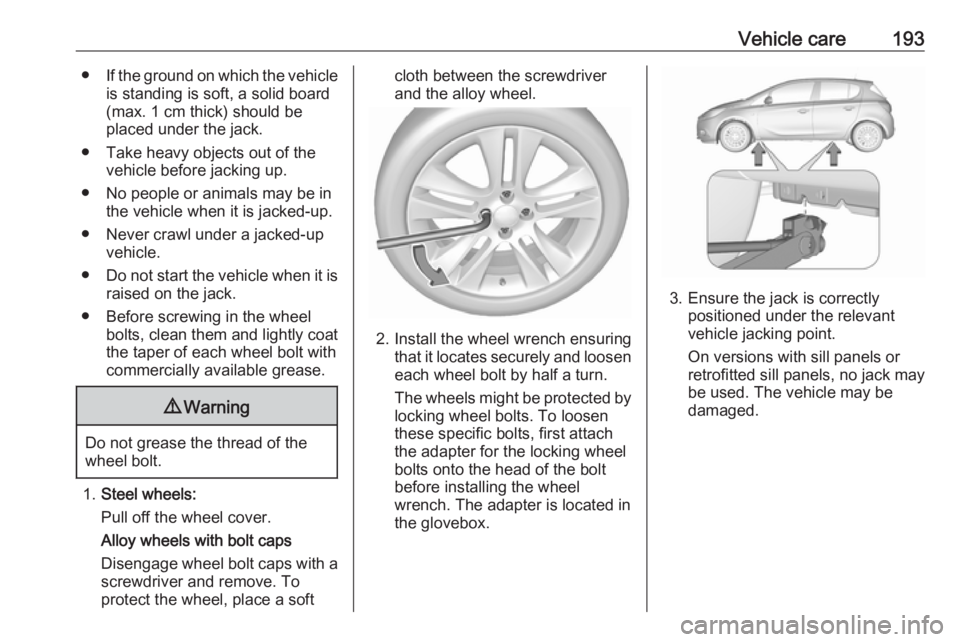

Vehicle care193●If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them and lightly coat

the taper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

1. Steel wheels:

Pull off the wheel cover.

Alloy wheels with bolt caps Disengage wheel bolt caps with a

screwdriver and remove. To

protect the wheel, place a soft

cloth between the screwdriver

and the alloy wheel.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

On versions with sill panels or

retrofitted sill panels, no jack may

be used. The vehicle may be

damaged.