engine OPEL CORSA E 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: CORSA E, Model: OPEL CORSA E 2019Pages: 231, PDF Size: 6.87 MB

Page 163 of 231

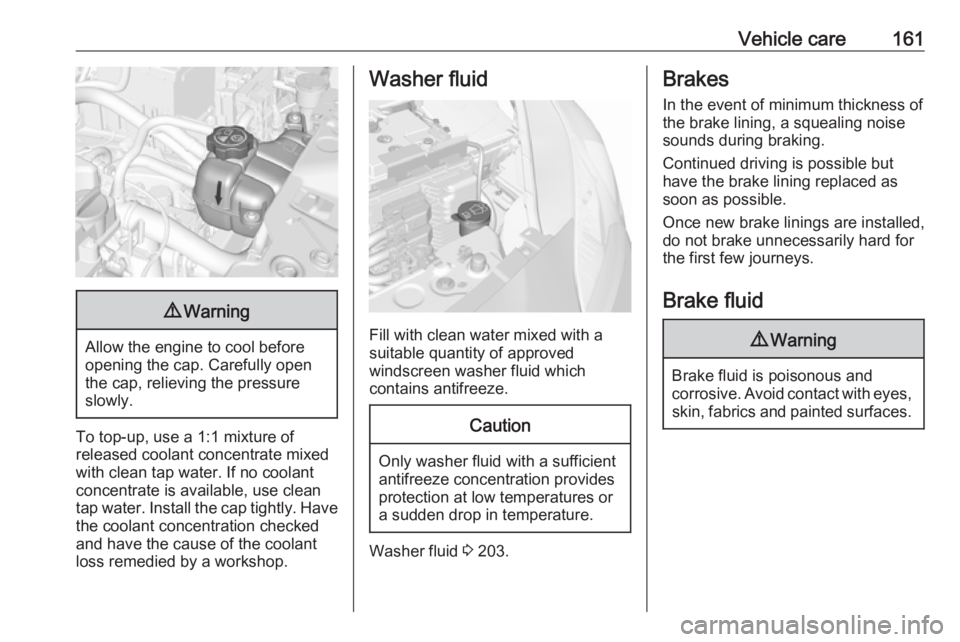

Vehicle care1619Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

To top-up, use a 1:1 mixture of released coolant concentrate mixed

with clean tap water. If no coolant

concentrate is available, use clean

tap water. Install the cap tightly. Have the coolant concentration checked

and have the cause of the coolant

loss remedied by a workshop.

Washer fluid

Fill with clean water mixed with a

suitable quantity of approved

windscreen washer fluid which

contains antifreeze.

Caution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

Washer fluid 3 203.

Brakes

In the event of minimum thickness of

the brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

Page 164 of 231

162Vehicle care

The brake fluid level must be betweenthe MIN and MAX marks.

If fluid level is below the MIN mark,

seek the assistance of a workshop.

Brake and clutch fluid 3 203.

Vehicle battery

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the vehicle battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to vehicle battery

discharge. Disconnect the clamp from

the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Battery discharge protection 3 108.

Disconnecting the battery

If the vehicle's battery is to be

disconnected (e.g. for maintenance

work), the alarm siren must be

deactivated as follows: Switch the

ignition on then off, then disconnect

the vehicle's battery within

15 seconds.

Replacing the vehicle battery

Note

Any deviation from the instructions

given in this section may lead to

temporary deactivation or

disturbance of the stop-start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap,

and the ventilation in the vicinity of the negative terminal must be opened.

Ensure that the battery is always

replaced by the same type of battery.

We recommend the use of an original

Opel battery.

Note

Using an AGM vehicle battery

different from the original Opel

vehicle battery may result in a lower performance.

We recommend that you have the

vehicle battery replaced by a

workshop.

Page 166 of 231

164Vehicle careRear window

Lift wiper arm. Disengage wiper bladeas shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base! Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check

After a bulb replacement switch on

the ignition, operate and check the

lights.

Halogen headlights Halogen headlights with separate

bulbs for sidelight, low beam and high

beam.

Sidelight / daytime running light (1)

Low beam (2)

High beam (3)

Front turn lights 3 168.

Page 174 of 231

172Vehicle care4. Pull bulb from bulb holder andreplace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and let engage.

Interior lights Have the following bulbs replaced by

a workshop:

● courtesy light, reading lights

● load compartment light

● dome light

● instrument panel illuminationElectrical system

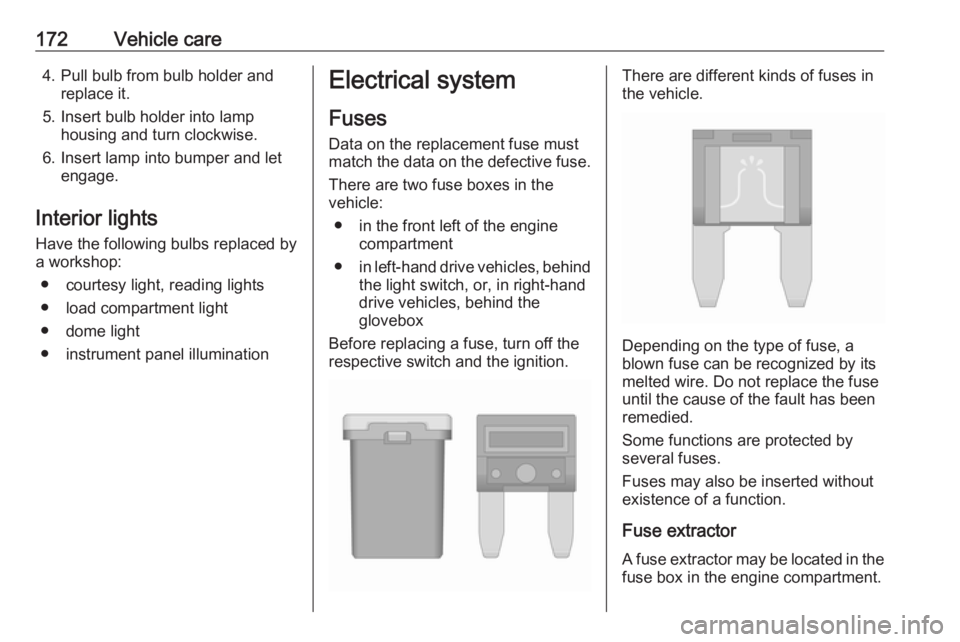

Fuses

Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● in the front left of the engine compartment

● in left-hand drive vehicles, behind

the light switch, or, in right-hand

drive vehicles, behind the

glovebox

Before replacing a fuse, turn off the

respective switch and the ignition.There are different kinds of fuses in

the vehicle.

Depending on the type of fuse, a

blown fuse can be recognized by its

melted wire. Do not replace the fuse until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without existence of a function.

Fuse extractorA fuse extractor may be located in the

fuse box in the engine compartment.

Page 175 of 231

Vehicle care173

Place the fuse extractor on the

various types of fuse from the top, and

withdraw fuse.

Engine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover and fold it

upwards until it stops. Remove the

cover vertically upwards.

Page 176 of 231

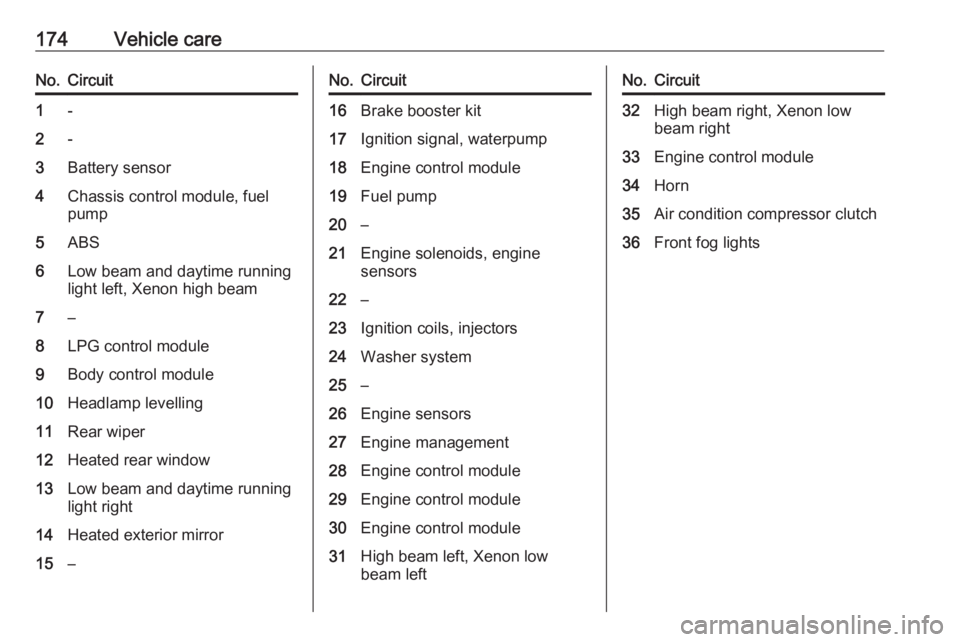

174Vehicle careNo.Circuit1-2-3Battery sensor4Chassis control module, fuel

pump5ABS6Low beam and daytime running

light left, Xenon high beam7–8LPG control module9Body control module10Headlamp levelling11Rear wiper12Heated rear window13Low beam and daytime running

light right14Heated exterior mirror15–No.Circuit16Brake booster kit17Ignition signal, waterpump18Engine control module19Fuel pump20–21Engine solenoids, engine

sensors22–23Ignition coils, injectors24Washer system25–26Engine sensors27Engine management28Engine control module29Engine control module30Engine control module31High beam left, Xenon low

beam leftNo.Circuit32High beam right, Xenon low

beam right33Engine control module34Horn35Air condition compressor clutch36Front fog lights

Page 181 of 231

Vehicle care179Choose a tyre appropriate for the

maximum speed of your vehicle.

Refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents. Optional equipment

could reduce the maximum speed of

the vehicle.

Directional tyres

Directional tyres must be mounted so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey.

Do not forget the spare wheel.

Tyre pressure 3 214.

The tyre pressure information label

on the right door frame indicates the original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter

tyres.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code. Engine data 3 210.

● Identify the respective tyre.

The tyre pressure table indicates the

required pressure for a specific tyre size only 3 214.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

Page 189 of 231

Vehicle care1874.Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within 10 min.

Tyre pressure 3 214.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 min,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 min. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Page 191 of 231

Vehicle care189

1. Take the sealant bottle andbracket with air hose from the

insert.

2. Detach air hose from bracket and screw onto sealant bottle

connection.

3. Position the sealant bottle on the bracket. Make sure that the bottle

does not fall.

4. Unscrew valve cap from defective

tyre.

5. Screw tyre inflation hose to valve.

6. Screw air hose onto compressor connection.

7. Switch on ignition. To avoid discharging the battery,

we recommend running the

engine.

Page 198 of 231

196Vehicle care3. Connect the black lead to thenegative terminal of the booster

vehicle battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of 1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

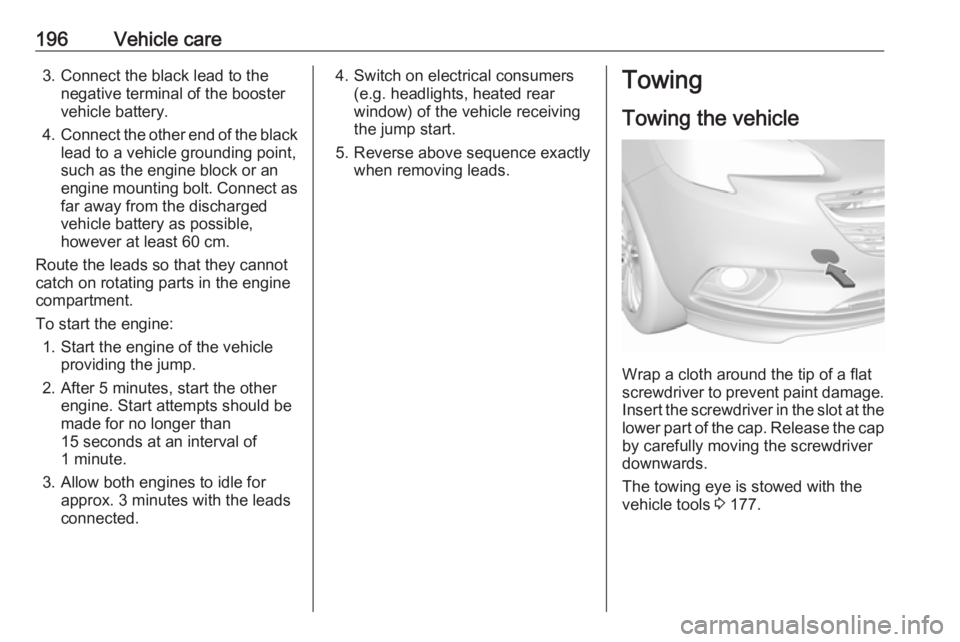

Towing the vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage.

Insert the screwdriver in the slot at the

lower part of the cap. Release the cap by carefully moving the screwdriver

downwards.

The towing eye is stowed with the

vehicle tools 3 177.