sensor OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5640 of 6000

6E–211 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

5. Connect the negative battery cable.

Air Cleaner/Air Filter

Removal Procedure

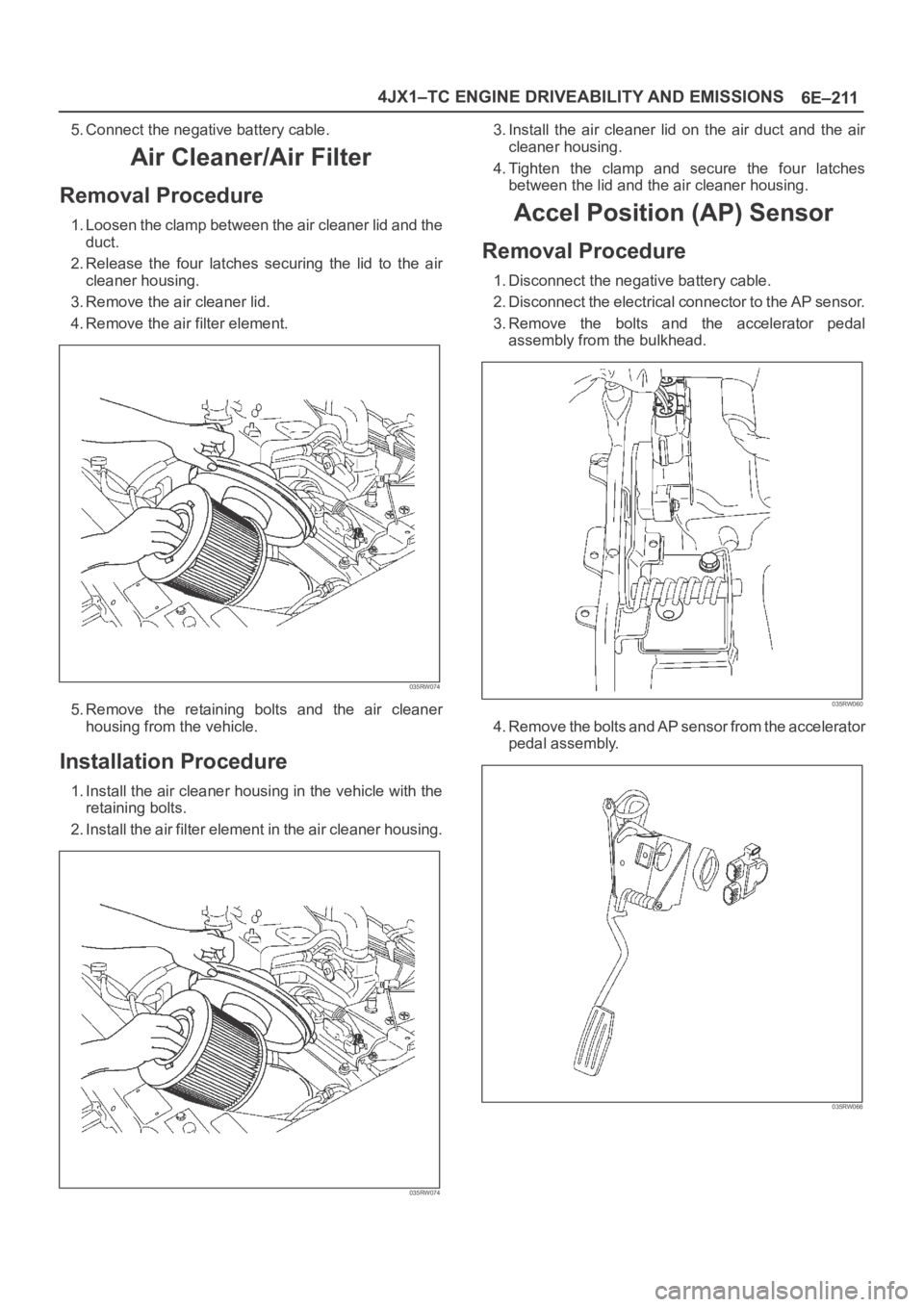

1. Loosen the clamp between the air cleaner lid and the

duct.

2. Release the four latches securing the lid to the air

cleaner housing.

3. Remove the air cleaner lid.

4. Remove the air filter element.

035RW074

5. Remove the retaining bolts and the air cleaner

housing from the vehicle.

Installation Procedure

1. Install the air cleaner housing in the vehicle with the

retaining bolts.

2. Install the air filter element in the air cleaner housing.

035RW074

3. Install the air cleaner lid on the air duct and the air

cleaner housing.

4. Tighten the clamp and secure the four latches

between the lid and the air cleaner housing.

Accel Position (AP) Sensor

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector to the AP sensor.

3.Remove the bolts and the accelerator pedal

assembly from the bulkhead.

035RW060

4. Remove the bolts and AP sensor from the accelerator

pedal assembly.

035RW066

Page 5641 of 6000

6E–212

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Install the AP sensor to the accelerator pedal

assembly.

035RW066

2. Install the accelerator pedal assembly to the

bulkhead.

3. Connect the electrical connector to the AP sensor.

035RW060

4. Connect the negative battery cable.

Accelerator Pedal Replacement

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector to the AP sensor.3.Remove the bolts and the accelerator pedal

assembly from the bulkhead.

035RW060

4. Remove the bolts and AP sensor from the accelerator

pedal assembly.

035RW066

Installation Procedure

1. Install the AP sensor to the accelerator pedal

assembly.

2. Install the accelerator pedal assembly to the

bulkhead.

Page 5642 of 6000

6E–213 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

3. Connect the electrical connector to the AP sensor.

035RW060

4. Connect the negative battery cable.

Fuel Filter Cap

General Description

The fuel filler cap includes a vacuum valve and a pressure

valve.

If high vacuum or high pressure occurs in the fuel tank,

each valve works to adjust the pressure in order to

prevent damage to the tank at the EGR valve.

TS23767

Inspection Procedure

NOTE: Replace the fuel filler cap with the same type of

filler cap that was originally installed on the vehicle.

Check the seal ring in the filler cap for any abnormality

and for seal condition.

Replace the filler cap if any abnormality is found.

Fuel Filter

Removal and Installation Procedure

Refer to the Engine fuel in the 4JX1 Engine section.

Fuel Gauge Unit

Removal Procedure

1. Disconnect the negative battery cable.

2. Loosen the fuel filler cap.

3. Drain the fuel from the tank.

Tighten

Tighten the drain plug to 20 Nꞏm (14 lb ft.).

TS22907

4. Disconnect the wiring connector from the fuel gauge

unit.

TS23771

5. Remove the fuel gauge unit retaining screws.

Page 5643 of 6000

6E–214

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

6. Remove the fuel gauge unit.

Cover or plug the fuel tank to prevent dust, dirt, or

debris from entering the tank.

TS22911

Installation Procedure

1. Install the fuel gauge unit.

2. Install the fuel gauge unit retaining screws.

TS22911

3. Connect the wiring connector to the fuel gauge unit.

TS23771

4. Fill the fuel tank with fuel.

Tighten the fuel filler cap.

Check for leaks at the fuel gauge unit gasket.

5. Connect the negative battery cable.

Fuel Injectors

Removal and Installation Procedure

Refer to Engine Fuel in 4JX1 Engine Section.

Fuel Temperature Sensor

Removal Procedure

CAUTION: To reduce the risk of fire and personal

injury, it is necessary to relieve the fuel system

pressure before servicing the fuel system

components.

CAUTION: After relieving the system pressure, a

small amount of fuel may be released when servicing

fuel lines or connections. Reduce the chance of

personal injury by covering the fuel line fittings with

a shop towel before disconnecting the fittings. The

towels will absorb any fuel that may leak out. When

the disconnect is completed, place the towel in an

approved container.

1. Disconnect the negative battery cable.

2. Remove the intercooler assembly.

3. Remove the cylinder head. Refer to engine

mechanical section.

Page 5644 of 6000

6E–215 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

4. Remove the rear side engine hanger.

035RW070

5. Remove the fuel return adapter.

035RW069

6. Remove the fuel pressure sensor from the fuel return

adapter.

035RW068

Installation Procedure

1. Install the fuel pressure sensor in the fuel return

adapter.

035RW068

Page 5645 of 6000

6E–216

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

2. Install the fuel return adapter.

035RW069

3. Install the rear side engine hanger. Tighten the rear

side engine hanger fixing bolts to specified torque.

Torque: 19 Nꞏm (14 lb ft)

035RW070

4. Install the cylinder head. Refer to engine mechanical

section.

5. Install the intercooler assembly.

6. Connect the negative battery cable.

Rail Pressure (RP) Sensor

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the air cleaner cover and air duct.

3. Remove the intercooler assembly.

4. Remove the injector oil pipe.

5. Remove the intake throttle valve.

6. Remove the cylinder head cover noise inselation.

7. Remove the cylinder head cover.

8. Remove the RP sensor.

Installation Procedure

Refer to the RP Sensor Programming.

1. Install the RP sensor.

2. Install the cylinder head cover.

3. Install the cylinder head cover noise inselation.

4. Install the intake throttle valve.

5. Install the injector oil pipe.

6. Install the intercooler assembly and tighten

intercooler assembly fixing bolts to specified torque.

Torque: 20 Nꞏm (14 lb ft)

7. Install the air cleaner cover and air duct.

8. Connect the negative battery cable.

Fuel Tank

Removal Procedure

Refer toEngine Fuel in 4JX1 Engine section.

060RW068

Page 5646 of 6000

6E–217 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

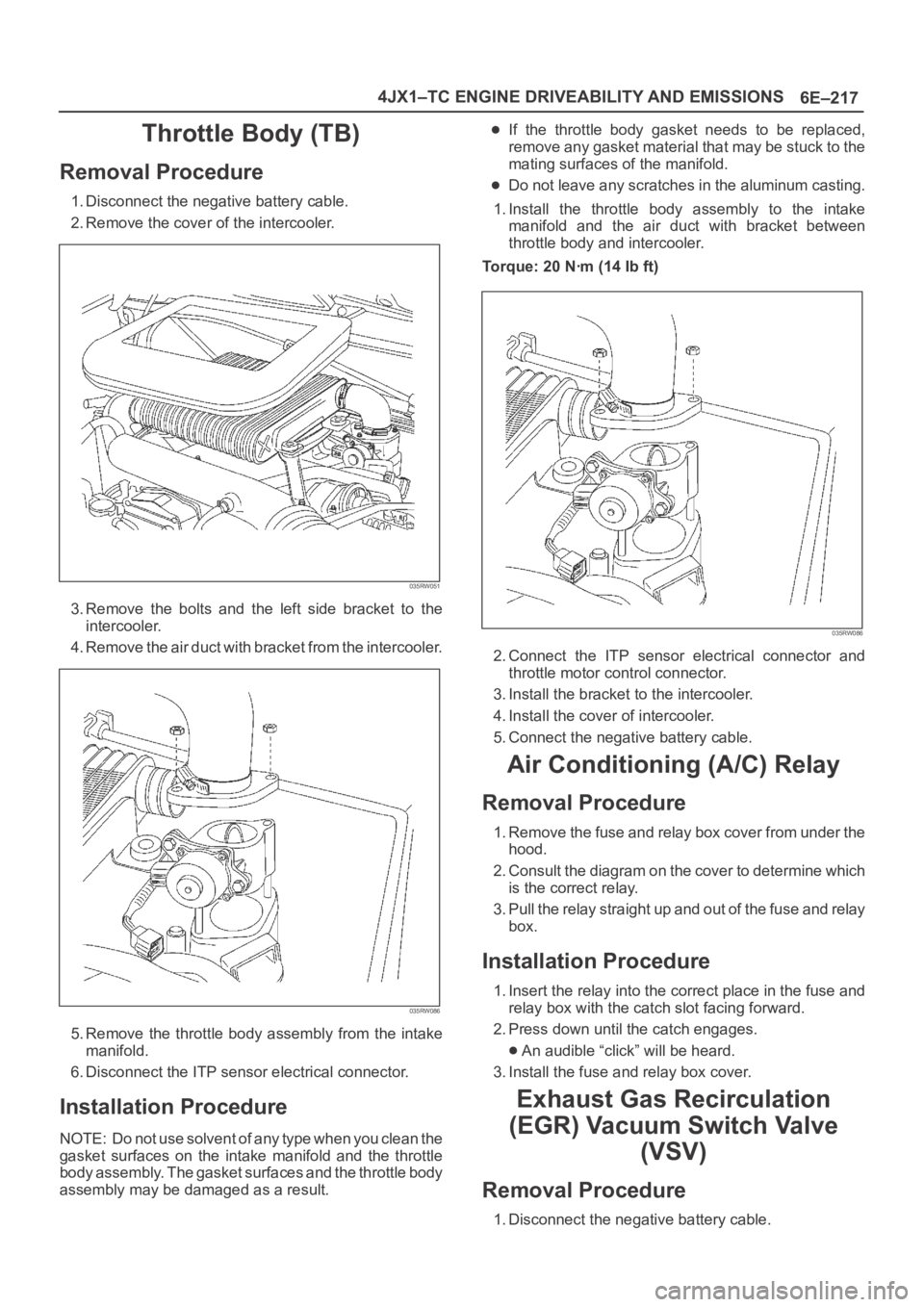

Throttle Body (TB)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the cover of the intercooler.

035RW051

3. Remove the bolts and the left side bracket to the

intercooler.

4 . R e m o v e t h e a i r d u c t w i t h b r a c k e t f r o m t h e i n t e r c o o l e r.

035RW086

5. Remove the throttle body assembly from the intake

manifold.

6. Disconnect the ITP sensor electrical connector.

Installation Procedure

NOTE: Do not use solvent of any type when you clean the

gasket surfaces on the intake manifold and the throttle

body assembly. The gasket surfaces and the throttle body

assembly may be damaged as a result.

If the throttle body gasket needs to be replaced,

remove any gasket material that may be stuck to the

mating surfaces of the manifold.

Do not leave any scratches in the aluminum casting.

1. Install the throttle body assembly to the intake

manifold and the air duct with bracket between

throttle body and intercooler.

Torque: 20 Nꞏm (14 Ib ft)

035RW086

2. Connect the ITP sensor electrical connector and

throttle motor control connector.

3. Install the bracket to the intercooler.

4. Install the cover of intercooler.

5. Connect the negative battery cable.

Air Conditioning (A/C) Relay

Removal Procedure

1. Remove the fuse and relay box cover from under the

hood.

2. Consult the diagram on the cover to determine which

is the correct relay.

3. Pull the relay straight up and out of the fuse and relay

box.

Installation Procedure

1. Insert the relay into the correct place in the fuse and

relay box with the catch slot facing forward.

2. Press down until the catch engages.

An audible “click” will be heard.

3. Install the fuse and relay box cover.

Exhaust Gas Recirculation

(EGR) Vacuum Switch Valve

(VSV)

Removal Procedure

1. Disconnect the negative battery cable.

Page 5647 of 6000

6E–218

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

2. Disconnect the EGR VSV connector and vacuum

hose from the EGR VSV.

035RW063

3. Remove the MAP sensor assembly and EGR VSV.

035RW067

4. Remove the EGR VSV from the MAP sensor bracket.

035RW062

Installation Procedure

1. Install the EGR VSV and tighten nut to specified

torque.

Torque: 8 Nꞏm (69 lb in)

035RW062

Page 5648 of 6000

6E–219 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

2. Install the MAP sensor assembly and EGR VSV and

tighten MAP sensor bracket fixing bolts specified

torque.

Torque: 9 Nꞏm (78 lb in)

035RW067

3. Connect the EGR VSV connector and vacuum hose

in the EGR VSV.

035RW063

4. Connect the negative battery cable.

Electronic Vacuum Regurating

Va l v e ( E V RV )

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the EVRV hose and the EVRV connector.

035RW065

3. Remove the EVRV.

035RW064

Page 5649 of 6000

6E–220

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Install the EVRV.

035RW064

2. Connect the EVRV hose and the EVRV connector.

035RW065

3. Connect the negative battery cable.

Wiring and Connectors

Wiring Harness Service

The ECM harness electrically connects the ECM to the

various solenoids, switches and sensors in the vehicle

engine compartment and passenger compartment.

Replace wire harnesses with the proper part number

replacement.

Because of the low amperage and voltage levels utilized

in powertrain control systems, it is essential that all wiring

in environmentally exposed areas be repaired with crimp

and seal splice sleeves.The following wire harness repair information is intended

as a general guideline only. Refer to

Chassis Electrical f o r

all wire harness repair procedures.

Connectors and Terminals

Use care when probing a connector and when replacing

terminals. It is possible to short between opposite

terminals. Damage to components could result. Always

use jumper wires between connectors for circuit

checking. NEVER probe through Weather-Pack seals.

Use an appropriate connector test adapter kit which

contains an assortment of flexible connectors used to

probe terminals during diagnosis. Use an appropriate

fuse remover and test tool for removing a fuse and to

adapt the fuse holder to a meter for diagnosis.

Open circuits are often difficult to locate by sight because

oxidation or terminal misalignment are hidden by the

connectors. Merely wiggling a connector on a sensor, or

in the wiring harness, may temporarily correct the open

circuit. Intermittent problems may also be caused by

oxidized or loose connections.

Be certain of the type of connector/terminal before

making any connector or terminal repair. Weather-Pack

and Com-Pack III terminals look similar, but are serviced

differently.

Wire Harness Repair: Twisted

Shielded Cable

Removal Procedure

1. Remove the outer jacket.

2. Unwrap the aluminum/mylar tape. Do not remove the

mylar.

047