sensor OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5690 of 6000

7A–1 AUTOMATIC TRANSMISSION (4L30–E)

TRANSMISSION

AUTOMATIC TRANSMISSION (4L30–E)

CONTENTS

Service Precaution 7A–3. . . . . . . . . . . . . . . . . . . . . .

Construction 7A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Range Reference Chart 7A–4. . . . . . . . . . . . . . . . . .

Normal Operation Of 2000 4L30–E

Transmission 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Information 7A–5. . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis Procedure 7A–8. . . . . . . . . . . . .

Preliminary Inspection Chart 7A–9. . . . . . . . . . . . . .

Checking Transmission Fluid Level and

Condition 7A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Driving 7A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis Check Trans

Indicator Chart 7A–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis

Symptoms Index 7A–13. . . . . . . . . . . . . . . . . . . . . . . .

Stall Test 7A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Pressure Test 7A–23. . . . . . . . . . . . . . . . . . . . . .

Shift Speed Chart (V6 3.2L 6VD1 Model) 7A–24. . .

Shift Speed Chart (V6 3.5L 6VE1 Model) 7A–26. .

Lockup Speed Chart (V6 3.2L 6VD1 Model) 7A–28

Lockup Speed Chart (V6 3.5L 6VE1 Model) 7A–28

Changing Transmission Fluid 7A–29. . . . . . . . . . . . .

Selector Lever 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (With Transfer Case) 7A–33. . . . . . . .

Transmission And Associated Parts 7A–33. . . . . .

Removal 7A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Main Case Valve Body) 7A–39. . . . . . . . .

Removal 7A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Adapter Case Valve Body) 7A–40. . . . . . .

Removal 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Main Case) 7A–41. . . . . . . .

Removal 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Adapter Case) 7A–43. . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powertrain Control Module (PCM) 7A–43. . . . . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensor (Extension Housing) 7A–44. . . . . . . .

Removal 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Oil Temperature Sensor

(Adapter Case) 7A–44. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Oil Seal (Converter Housing) 7A–45. . . . . . . .

Removal 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal (Extension Housing) 7A–46. . . . . . . . .

Removal 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (4L30–E) 7A–46. . . . . . . . . . . . . . . . . .

Disassembly 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 7A–50. . . . . . . . . . . . . . . . . . . . . . . . . .

Converter Housing And Oil Pump Assembly 7A–60

Disassembled View 7A–60. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–60. . . . . . . . . . . . . . . . . .

Reassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–61. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–61. . . . . . . . . . . . . . . . . .

Reassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Case Valve Body 7A–62. . . . . . . . . . . . . . . . . . .

Disassembled View 7A–62. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–62. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–63. . . . . . . . . . . . . . . . . .

Reassembly 7A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Adapter Case Valve Body 7A–64. . . . . . . . . . . . . . . .

Disassembled View 7A–64. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–64. . . . . . . . . . . . . . . . . .

Reassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch And Sprag Unit 7A–65. . . . . . . . . . . . . .

Disassembled View 7A–65. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–65. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–66. . . . . . . . . . . . . . . . . .

Page 5707 of 6000

7A–18

AUTOMATIC TRANSMISSION (4L30–E)

Chart 9c: Coastdown Harsh Shift Or Clunk At 3–2 Downshift

StepActionYe sNo

1Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes

of High Line

Pressure in this

section

2Does DTC P1850 set?

Diagnose P1850

first

Replace band

apply solenoid

(PWM) (323)

Chart 10: Intermittent 4TH TO 2ND Gear Downshift At Steady Speed

StepActionYe sNo

1Check for consistent speed sensor reading with scan tool.

Was the reading correct?Replace mode

switch for

intermittent

contact.

Go to Step 2

21. Check for wiring harness damage or short to ground. If OK, go

to (2).

2. Check transmission speed sensor connections. If OK, go to

(3).

3. Replace transmission speed sensor.

Was the replacement complete?

—

Replace speed

sensor.

Chart 11: Engine Flare At Shifting During Turning Only (Usually With Warm Engine)

StepActionYe sNo

1Check for oil leaks at transmission.

Was the problem found?Replace

transmission oil

filter and gasket

—

Chart 12: Engine Flare During 1–2 Or 2–3 Shift

StepActionYe sNo

1Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes

of Low Line

Pressure in this

section

21. Check for a stuck 1–2 accumulator valve (320).

2. Check for servo piston (106) leaks.

3. Check for a stuck band apply solenoid (323).

Was line pressure normal?

Repair or replace—

Page 5709 of 6000

7A–20

AUTOMATIC TRANSMISSION (4L30–E)

Chart 15a: Possible Causes of Low Line Pressure

StepActionYe sNo

1Check oil level.

Was the problem found?

Fill with ATFGo to Step 2

2Check for defective throttle position sensor.

Was the problem found?Replace throttle

position sensor

Go to Step 3

3Check for plugged, loose, or damaged oil filter (79).

Was the problem found?Inspect oil filter,

tighten bolts or

replace oil filter

(79)

Go to Step 4

4Check for a stuck force motor plunger (404). (Adapter case valve

body)

Was the problem found?Replace force

motor plunger

(404)

Go to Step 5

5Check for a stuck feed limit valve (412). (Adapter case valve body)

Was the problem found?Replace feed limit

valve (412)

Go to Step 6

6Check for loose converter bolts (4 & 5).

Was the problem found?Tighten converter

bolts (4 & 5)

Go to Step 7

7Check for a stuck pressure regulator valve (208). (Oil pump)

Was the problem found?Replace pressure

regulator valve

(208)

Go to Step 8

8Check for a stuck boost valve (205).(Oil pump)

Was the problem found?Replace boost

valve (205)

Go to Step 9

9Check for blocked intermediate oil passages to pressure

regulator valve. (Oil pump)

Was the problem found?

Replace oil pumpGo to Step 10

10Check for defective oil pump (9, 201, 202 & 209).

Was the problem found?

Replace oil pumpGo to Step 11

11Check for internal leaks.

– Check balls missing or out of location in valve bodies

– Seals cut or damaged

– Gaskets defective, etc.

Was the problem found?Install balls, or

correct ball

location

Replace seals

Replace gaskets

—

Page 5710 of 6000

7A–21 AUTOMATIC TRANSMISSION (4L30–E)

Chart 15b: Possible Causes Of High Line Pressure

NOTE: If transmission is operating in backup mode, high

line pressure will be present.

Step

ActionYe sNo

1Check for defective throttle position sensor.

Was the problem found?Replace throttle

position sensor.

Go to Step 2.

2Check for a stuck force motor plunger (404). (Open

circuit/intermittent) (Adapter case valve body)

Was the problem found?Replace force

motor plunger

(404)

Go to Step 3

3Check for a stuck feed limit valve (412). (Adapter case valve body)

Was the problem found?Replace force

motor plunger

(412)

Go to Step 4

4Check converter bolts (4 & 5).

Was the problem found?Tighten converter

bolts (4 & 5)

Go to Step 5

5Check for a stuck pressure regulator valve (208). (Oil pump)

Was the problem found?Replace pressure

regulator valve

(208)

Go to Step 6

6Check for a stuck boost valve (205). (Oil pump)

Was the problem found?Replace boost

valve (205)

Go to Step 7

7Check for internal leaks.

– Check balls missing or out of location in valve bodies

– Seals cut or missing

– Gaskets defective, etc.

Was the problem found?Install balls, or

correct ball

location

Replace seals

Replace gaskets

—

Page 5711 of 6000

7A–22

AUTOMATIC TRANSMISSION (4L30–E)

Chart 16: Possible Causes Of

Transmission Fluid Leaks

Before attempting to correct an oil leak, the actual source

of the leak must be determined. In many cases, the

source of the leak may be difficult to determine due to

“wind flow” around the engine and transmission.

The suspected area should be wiped clean before in-

specting for the source of the leak.Oil leaks around the engine and transmission are gener-

ally carried toward the rear of the vehicle by the air

stream. In determining the source of an leak, the following

two checks should be made:

1. With the engine running, check for external line

pressure leaks.

2. With the engine off, check for oil leaks due to the

raised oil level caused by drainback of converter oil

into the transmission.

Possible Causes Of Fluid Leaks Due To Sealing Malfunction

240RX008

Legend

(1) Electrical Connector (Main Case) Seal

(2) Transmission Vent (Breather)

(3) Speed Sensor O–Ring

(4) Extension (Adapter) Lip Seal

(5) Extension (Adapter) to Main Case Gasket

(6) Overfill and Oil Drain Screws Gasket

(7) Oil Pan Gasket (Main Case)

(8) Selector Shaft Seal(9) Oil Cooler Connectors (2)

(10) Oil Pan Gasket (Adapter Case)

(11) Converter housing attaching bolts not correctly

torqued

(12) Converter Housing Lip Seal

(13) Line Pressure Tap Plug

(14) Electrical Connector (Adapter Case) Seal

(15) Adapter Case Seal Rings (2)

Page 5723 of 6000

7A–34

AUTOMATIC TRANSMISSION (4L30–E)

4. Disconnect shift lock cable from the selector lever

assembly side.

256RW012

5. Disconnect wiring harness connectors.

6. Disconnect shift control rod from the selector lever

assembly side.

256RW013

7. Remove selector lever assembly (3).

8. Remove transfer control lever (4).

9. Remove transfer and exhaust protector (5).

10. Remove rear propeller shaft (6).

11. Remove front propeller shaft (7).

12. Remove harness protector (8).

13. Support transfer case with a jack and remove two rear

mount nuts (9) from the 3rd crossmember side.

14. Remove eight third crossmember bolts and third

crossmember (10).15. Disconnect one oxygen sensor connector from the

transmission harness.

150RW002

16. Remove exhaust pipe (11).

17. Disconnect transmission oil cooler pipe (12) from A/T

side.

18. Remove oil pipe clamp from torque converter

housing bracket.

253RY001

19. Loosen oil pipe clamp bolt at the engine mount side.

20. Remove starter (13).

21. Disconnect fuel pipe clamp bracket from

transmission side.

22. Disconnect transmission harness connectors (14)

from transmission, and transfer.

23. Remove under covers (3 pieces) (15) from

transmission case.

24. Lower the front of the transmission a little, then

remove flex plate torque converter fixing bolts (6

pieces) (16) by turning crankshaft.

25. Support the transmission with a transmission jack,

and hoist engine with a chain block.

26. Remove engine transmission fixing bolts (17).

Page 5726 of 6000

7A–37 AUTOMATIC TRANSMISSION (4L30–E)

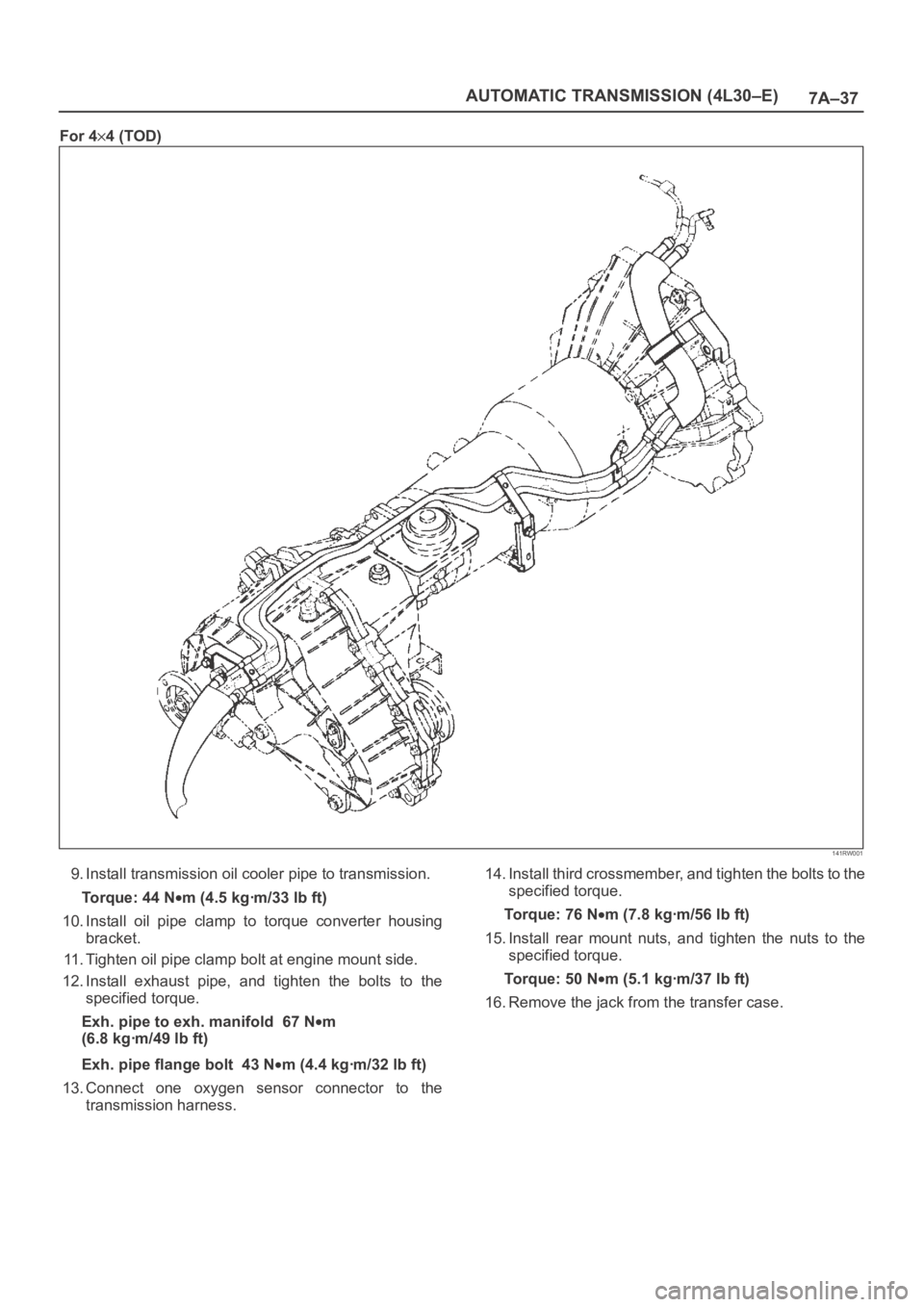

For 44 (TOD)

141RW001

9. Install transmission oil cooler pipe to transmission.

Torque: 44 N

m (4.5 kgꞏm/33 lb ft)

10. Install oil pipe clamp to torque converter housing

bracket.

11. Tighten oil pipe clamp bolt at engine mount side.

12. Install exhaust pipe, and tighten the bolts to the

specified torque.

Exh. pipe to exh. manifold 67 N

m

(6.8 kgꞏm/49 lb ft)

Exh. pipe flange bolt 43 N

m (4.4 kgꞏm/32 lb ft)

13. Connect one oxygen sensor connector to the

transmission harness.14. Install third crossmember, and tighten the bolts to the

specified torque.

To r q u e : 7 6 N

m (7.8 kgꞏm/56 lb ft)

15. Install rear mount nuts, and tighten the nuts to the

specified torque.

To r q u e : 5 0 N

m (5.1 kgꞏm/37 lb ft)

16. Remove the jack from the transfer case.

Page 5728 of 6000

7A–39 AUTOMATIC TRANSMISSION (4L30–E)

Solenoid (Main Case Valve Body)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Remove transfer and exhaust protectors.

4. Drain fluid.

5. Remove exhaust pipe and disconnect oxygen sensor

connector.

6. Support transfer case with a jack and remove third

crossmember.

7. Remove sixteen 10 mm screws, main case oil pan,

magnet, and gasket.

8. Remove three 13 mm screws, oil filter.

9. Disconnect wiring harness from band control

solenoid and shift solenoids. Pull only on connectors,

not on wiring harness.

10. Remove spring pin for shift solenoid A, shift solenoid

B, and band control solenoid respectively, using

suitable pliers taking care not to damage solenoids.

210RW010

244RW003

11. Remove shift solenoid A, shift solenoid B, band

control solenoid, and gaskets from main case valve

body. Do not pull on wiring harness. Remove

solenoids by grasping the metal tip.

Installation

1. Install shift solenoid A, shift solenoid B, band control

solenoid with new gaskets to main case valve body

respectively.

2. Carefully install spring pin with hammer to avoid

damage to valve body, etc.

243RW004

3. Connect wiring harness to solenoids.

4. Install oil filter with a new gasket and the three 13 mm

screws. Tighten the screws to the specified torque.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

5. Install magnet, main case oil pan with new gasket,

sixteen 10 mm screws. Tighten the screws to the

specified torque.

To r q u e : 11 N

m (1.1 kgꞏm/96 lb in)

6. Install third crossmember and rear mount nuts.

Tighten the nuts and bolts to the specified torque.

Third crossmember bolt: 76 N

m

(7.8 kgꞏm/56 lb ft)

Rear mount nut: 50 N

m (5.1 kgꞏm/37 lb ft)

7. Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque:

43 N

m(4.4kgꞏm/32lbft)

8. Install the transfer and exhaust protectors. Tighten

the bolts to the specified torque.

Torque: 37 N

m (3.8 kgꞏm/27 lb ft)

9. Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON

–III. Refer to Changing

Transmission Fluid in this section.

10. Connect the battery ground cable.

Page 5729 of 6000

7A–40

AUTOMATIC TRANSMISSION (4L30–E)

Solenoid (Adapter Case Valve Body)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Drain fluid.

4. Remove transfer and exhaust protectors.

5. Remove exhaust pipe and disconnect oxygen sesnor

connector.

6. Remove adapter case oil pan twelve fixing 10 mm

screws, adapter case oil pan, and gasket.

NOTE: Oil pan still contains transmission fluid. Place a

large drain container under the oil pan and drain the fluid

carefully.

7. Disconnect wiring harness from force motor solenoid

and converter clutch solenoid. Pull only on

connectors, not on wiring harness.

8. Remove 11 mm bolt and converter clutch solenoid

with two O–rings.

210RW011

9. Remove 11 mm bolt, retainer, and force motor

solenoid.

210RW009

Installation

1. Install force motor solenoid, retainer, and 11 mm bolt

to adapter case valve body. Tighten the bolt to the

specified torque.

To r q u e : 1 0 N

m (1.0 kgꞏm/87 lb in)

2. Install converter clutch solenoid with two O– rings,

and 11 mm bolt to adapter case valve body. Tighten

the bolt to the specified torque.

Torque : 10 N

m (1.0 kgꞏm/87 lb in)

3. Connect wiring harness assembly to solenoids.

4. Install adapter case oil pan, new gasket, and twelve

10 mm screws. Tighten the screws to the specified

torque.

Torque : 11 N

m (1.1 kgꞏm/96 lb in)

5. Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolt to the specified torque.

Exhaust pipe flange bolt torque :

43 N

m(4.4kgꞏm/32lbft)

6. Install transfer and exhaust protectors. Tighten the

bolt to the specified torque.

Torque : 37 N

m(3.8kgꞏm/27lbft)

7. Fill transmission through overfill screw hole oil pan,

using ATF DEXRON

–III. Refer to Changing

Transmission Fluid in this section.

8. Connect battery ground cable.

Page 5730 of 6000

7A–41 AUTOMATIC TRANSMISSION (4L30–E)

Valve Body Assembly (Main Case)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Remove transfer and exhaust protectors.

4. Drain fluid.

5. Remove exhaust pipe and disconnect oxygen sensor

connector.

6. Support transfer case with a jack and remove third

crossmember.

7. Remove sixteen 10 mm screws, main case oil pan,

magnet and gasket.

8. Remove three 13 mm oil filter fixing screws, then

remove oil filter.

9. Remove two 13 mm manual detent fixing screws,

then remove roller and spring assembly.

10. Disconnect wiring harness from band control

solenoid and shift solenoids. Pull only on connectors,

not on wiring harness.

11. Remove four 13 mm servo cover fixing screws, then

remove servo cover and gasket.

12. Remove seven 13 mm valve body fixing screws.

Disconnect the ground wire from the main case

valve body.

13. Remove main case valve body with manual valve link

and transfer plate. Note the position of the link (long

end into valve, short end into range selector lever).

14. Remove transfer plate gasket from main case.

15. Remove two check balls from main case.

Installation

1. Install two check balls to main case.

244RW002

2. Inspect electrical 4 pin connector and seal of main

case. Replace if necessary.3. Use two 5–8840–0022–0 (J–25025–B) guide pin to

install main case.

Install valve body assembly and manual valve link.

NOTE: Valve must be extended as the short end of

manual valve link is connected to the range selector lever.

Long end of link goes into valve.

4. Install seven 13 mm screws, and tighten them to the

specified torque.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

243RS008

5. Install 8.5 mm connector of ground wire the head of

this valve body bolt and reinstall it. Tighten the bolt to

the specified torque.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

244RW001

6. Remove two guide pins from main case.

7. Install servo cover gasket, cover, and four 13 mm

screws. Tighten the screws to the specified torque.

To r q u e : 2 5 N

m (2.6 kgꞏm/18 lb ft)