direction OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5278 of 6000

ENGINE MECHANICAL 6A – 5

Charging System

Model (HITACHI) LR160-734B LR170 – 760 LR190 – 750B

Rated voltage V 12

Rated output A 60 70 90

Rotation direction

Clockwise

(As viewed from pulled)

Pulley effective diameter mm (in) 60 (2.36) 69 (2.72)

Weight N (kg/lb) 41 (4.2/9.3) 52 (5.3/11.7)

Page 5318 of 6000

ENGINE MECHANICAL 6A – 45

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

1. Camshaft Journal diameter

1) Use a micrometer to measure each camshaft

journal diameter in two directions (1) and (2). If

the measured value is less than the specified

limit, the camshaft must be replaced.

Standard: 29.939 – 29.96 mm (1.1787 – 1.1795 in)

Limit: 29.84 mm (1.17 in)

2. Cam Height

1) Measure the cam height (H) with a micrometer.

If the measured value is less than the specified

limit, the camshaft must be replaced.

Standard: IN 46.62 mm (1.8354 in)

EX 46.72 mm (1.8394 in)

Limit: IN 46.57 mm (1.8335 in)

EX 46.67 mm (1.8374 in)3. Cam Run-Out

1) Mount the camshaft on V-blocks.

2) Measure the cam height (H) with a micrometer.

If the measured value is less than the specified

limit, the camshaft must be replaced.

Standard: 0.02 mm (0.0008 in) or less

Limit: 0.10 mm (0.0039 in)

4. Camshaft oil clearance

1) Clean the camshaft, camshaft bracket and

camshaft carrier.

2) Put camshaft carrier on the cylinder head.

3) Put camshaft on the camshaft carrier.

4) Put plastigauge on the camshaft journal.

5) Install camshaft bracket to original position and

tighten bolts to specified torque in the numerical

order shown in the illustration.

Torque: A; 21.6 Nꞏm (2.2 kgꞏm/15.9 lb ft)

B; 38.0 Nꞏm (3.9 kgꞏm/28.2 lb ft)

C; 21.6 Nꞏm (2.2 kgꞏm/15.9 lb ft)

D; 38.0 Nꞏm (3.9 kgꞏm/28.2 lb ft)

(1)Ft Rr

(2)

014RW179

H

012RW059

014RW171

CC

D

B

CC

B

CC

D

CC

B

C

A AA A A A

AAAA

110RW035

Page 5336 of 6000

ENGINE MECHANICAL 6A – 63

VALVE CLEARANCE ADJUSTMENT

NOTE:

1. Valve clearance should be inspected and adjusted

while the engine is cool.

2. The tightening of the camshaft bearing cap and

camshaft carrier assembly should be checked

before inspecting and adjusting valve clearance.

INSPECTION

1. Remove cylinder head noise insulator cover and

cylinder head cover.

Refer to “Cylinder Head” in this manual.

2. Disconnect all harness connecters of the injector

and remove harness assembly.

3. Drain oil from oil rail assembly.

4. Remove injector clamp nuts and fixing bolts to take

out injector assembly.

5. Loosen oil rail bolts, remove oil rail assembly.

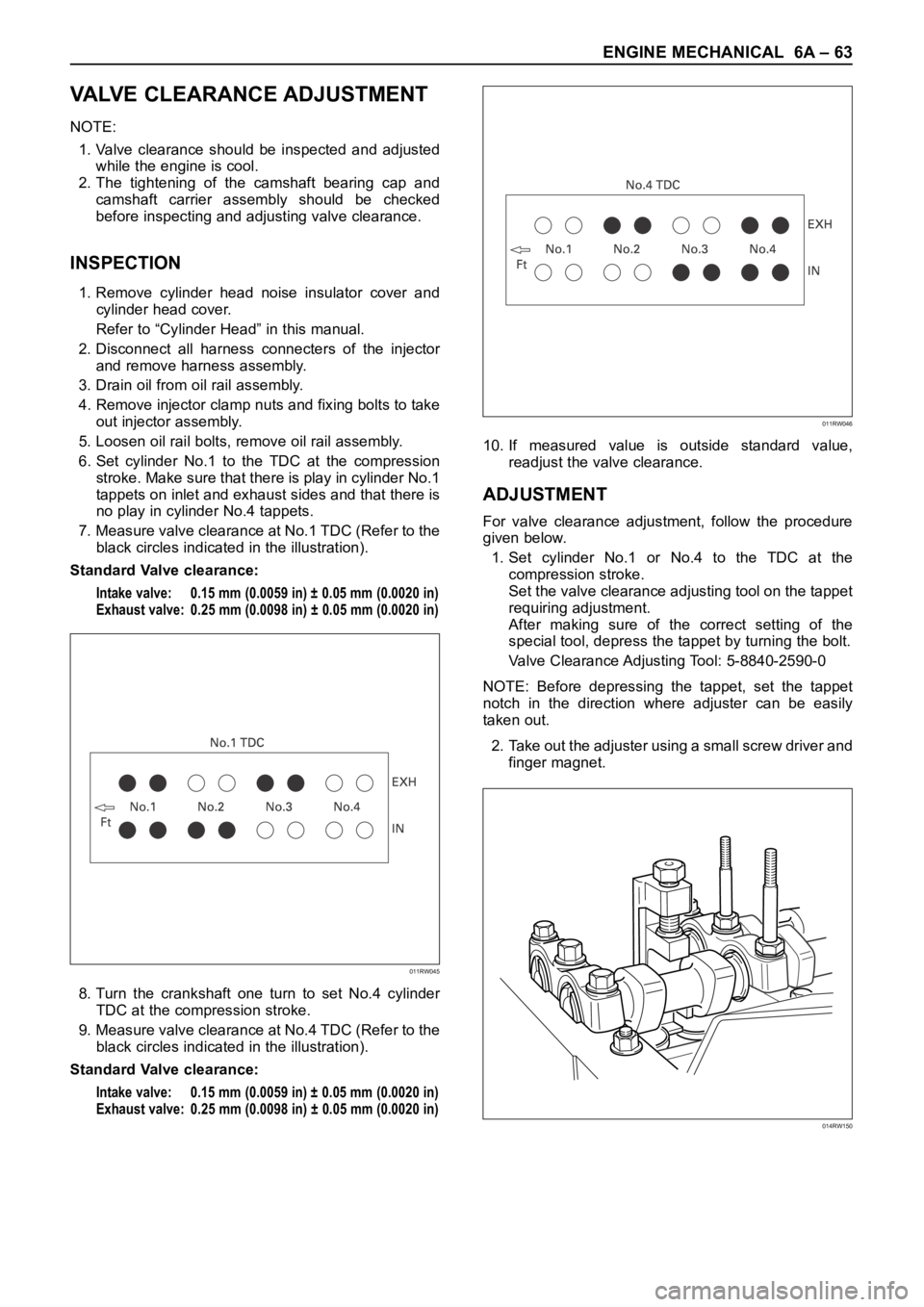

6. Set cylinder No.1 to the TDC at the compression

stroke. Make sure that there is play in cylinder No.1

tappets on inlet and exhaust sides and that there is

no play in cylinder No.4 tappets.

7. Measure valve clearance at No.1 TDC (Refer to the

black circles indicated in the illustration).

Standard Valve clearance:

Intake valve: 0.15 mm (0.0059 in) ± 0.05 mm (0.0020 in)

Exhaust valve: 0.25 mm (0.0098 in) ± 0.05 mm (0.0020 in)

8. Turn the crankshaft one turn to set No.4 cylinder

TDC at the compression stroke.

9. Measure valve clearance at No.4 TDC (Refer to the

black circles indicated in the illustration).

Standard Valve clearance:

Intake valve: 0.15 mm (0.0059 in) ± 0.05 mm (0.0020 in)

Exhaust valve: 0.25 mm (0.0098 in) ± 0.05 mm (0.0020 in)

10. If measured value is outside standard value,

readjust the valve clearance.

ADJUSTMENT

For valve clearance adjustment, follow the procedure

given below.

1. Set cylinder No.1 or No.4 to the TDC at the

compression stroke.

Set the valve clearance adjusting tool on the tappet

requiring adjustment.

After making sure of the correct setting of the

special tool, depress the tappet by turning the bolt.

Valve Clearance Adjusting Tool: 5-8840-2590-0

NOTE: Before depressing the tappet, set the tappet

notch in the direction where adjuster can be easily

taken out.

2. Take out the adjuster using a small screw driver and

finger magnet.

011RW045

011RW046

014RW150

Page 5356 of 6000

ENGINE MECHANICAL 6A – 83

Discerning Mark

Piston Ring Discerning Mark

1st compression ring 1N

2nd compression ring 2N

Ring End Gap mm(in)

Piston Ring Standard Gap Limit

1st 0.25 – 0.40

compression ring (0.0098 – 0.0157)

2nd 0.20 – 0.35 1.5

compression ring (0.0079 – 0.0138) (0.0590)

Oil ring0.10 – 0.30

(0.0039 – 0.0118)

2. Measure the clearance between the piston ring

groove and the piston ring with a feeler gauge. If the

piston ring groove/piston ring clearance exceeds

the specified limit, the piston and/or piston rings

must be replaced.

mm(in)

Standard Limit

1st0.05 – 0.09

Compression (0.0020 – 0.0035)

ring

2nd0.05 – 0.09 0.15

(0.0020 – 0.0035) (0.0059)

Oil ring0.03 – 0.07

(0.0012 – 0.0028)Piston pin

Visually inspect the piston pin for cracks, flaws, and

other damage and replace if necessary.

1. Use a micrometer to measure the piston pin outside

diameter in both directions at three different

positions. If the measurement exceeds the

specified limit, the piston pin must be replaced.

Standard: 30.995 – 31.000 mm (1.2212 – 1.2214 in)

Limit: 30.97 mm (1.2202 in)

N

012RW037015RW076

012RW082

Page 5363 of 6000

6A – 90 ENGINE MECHANICAL

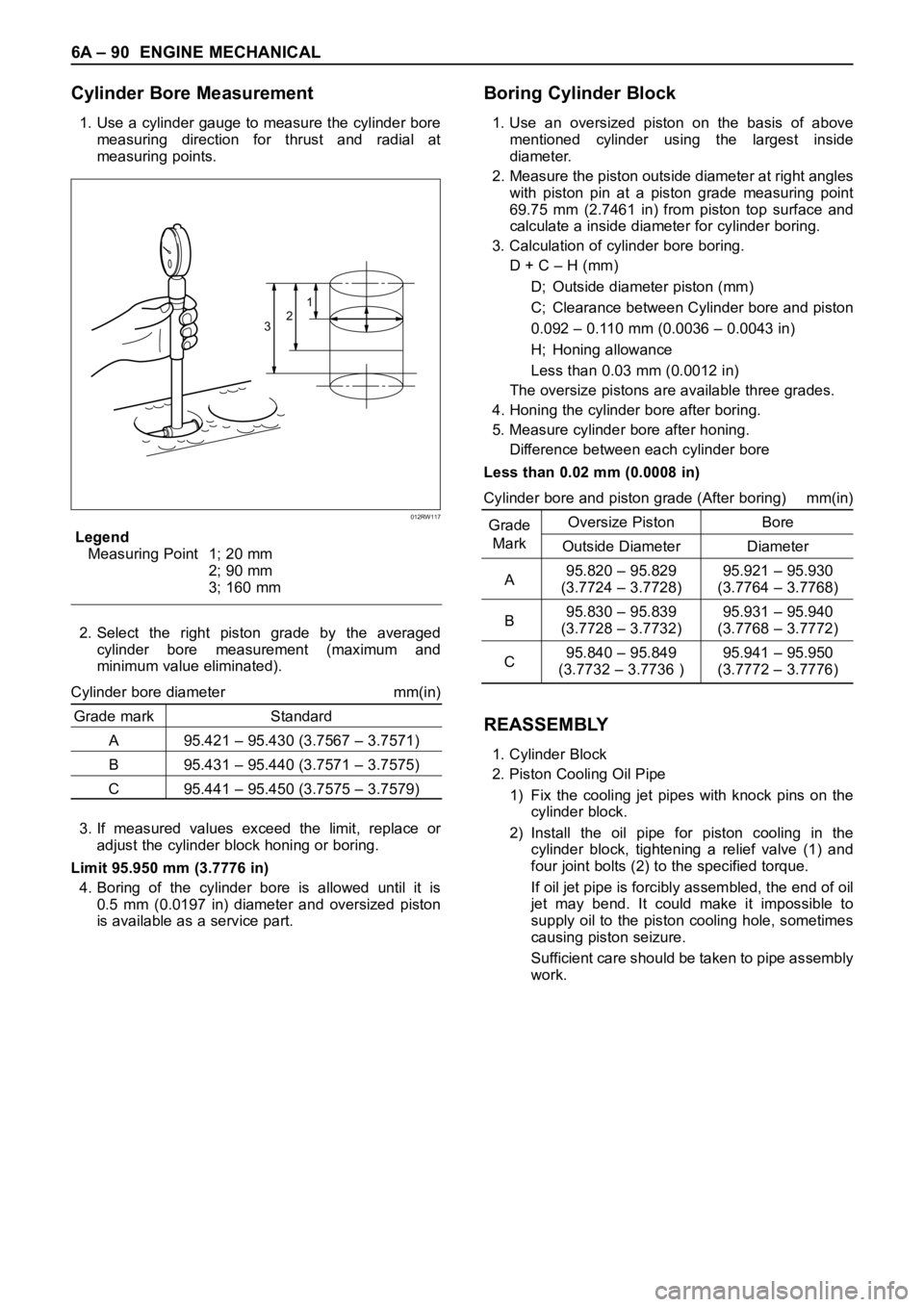

Cylinder Bore Measurement

1. Use a cylinder gauge to measure the cylinder bore

measuring direction for thrust and radial at

measuring points.

Legend

Measuring Point 1; 20 mm

2; 90 mm

3; 160 mm

2. Select the right piston grade by the averaged

cylinder bore measurement (maximum and

minimum value eliminated).

Cylinder bore diameter mm(in)

Grade mark Standard

A 95.421 – 95.430 (3.7567 – 3.7571)

B 95.431 – 95.440 (3.7571 – 3.7575)

C 95.441 – 95.450 (3.7575 – 3.7579)

3. If measured values exceed the limit, replace or

adjust the cylinder block honing or boring.

Limit 95.950 mm (3.7776 in)

4. Boring of the cylinder bore is allowed until it is

0.5 mm (0.0197 in) diameter and oversized piston

is available as a service part.

Boring Cylinder Block

1. Use an oversized piston on the basis of above

mentioned cylinder using the largest inside

diameter.

2. Measure the piston outside diameter at right angles

with piston pin at a piston grade measuring point

69.75 mm (2.7461 in) from piston top surface and

calculate a inside diameter for cylinder boring.

3. Calculation of cylinder bore boring.

D + C – H (mm)

D; Outside diameter piston (mm)

C; Clearance between Cylinder bore and piston

0.092 – 0.110 mm (0.0036 – 0.0043 in)

H; Honing allowance

Less than 0.03 mm (0.0012 in)

The oversize pistons are available three grades.

4. Honing the cylinder bore after boring.

5. Measure cylinder bore after honing.

Difference between each cylinder bore

Less than 0.02 mm (0.0008 in)

Cylinder bore and piston grade (After boring) mm(in)

GradeOversize Piston Bore

Mark

Outside Diameter Diameter

A95.820 – 95.829 95.921 – 95.930

(3.7724 – 3.7728) (3.7764 – 3.7768)

B95.830 – 95.839 95.931 – 95.940

(3.7728 – 3.7732) (3.7768 – 3.7772)

C95.840 – 95.849 95.941 – 95.950

(3.7732 – 3.7736 ) (3.7772 – 3.7776)

REASSEMBLY

1. Cylinder Block

2. Piston Cooling Oil Pipe

1) Fix the cooling jet pipes with knock pins on the

cylinder block.

2) Install the oil pipe for piston cooling in the

cylinder block, tightening a relief valve (1) and

four joint bolts (2) to the specified torque.

If oil jet pipe is forcibly assembled, the end of oil

jet may bend. It could make it impossible to

supply oil to the piston cooling hole, sometimes

causing piston seizure.

Sufficient care should be taken to pipe assembly

work.

321

012RW117

Page 5406 of 6000

ENGINE ELECTRICAL 6D – 3

ON-VEHICLE SERVICE

BATTERY CHARGING

Observe the following safety precautions when

charging the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during the

charging procedure.

Battery charging should be discontinued or the rate

of charge reduced if the battery feels hot to the

touch.

Battery charging should be discontinued or the rate

of charge reduced if the battery begins to gas or

spew electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue

dot or ring, it may be necessary to jiggle or tilt the

battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be

either quick-charged or slow-charged in the same

manner as other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

JUMP STARTING

JUMP STARTING WITH AN AUXILIARY

(BOOSTER) BATTERY

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.

Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: Failure to carefully follow the jump

starting procedure could result in the following:

1. Serious personal injury, particularly to your

eyes.

2. Property damage from a battery explosion,

battery acid, or an electrical fire.

3. Damage to the electronic components of one or

both vehicles.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode. Remove any rings, watches, or other jewelry

before working around the battery. Protect your eyes by

wearing an approved set of goggles.

Never allow battery fluid to come in contact with your

eyes or skin.

Never allow battery fluid to come in contact with fabrics

or painted surfaces.

Battery fluid is a highly corrosive acid.Should battery fluid come in contact with your eyes,

skin, fabric, or a painted surface, immediately and

thoroughly rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of the reach of young

children.

JUMP STARTING PROCEDURE

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector lever in the “PARK”

position.

If the vehicle is equipped with a manual

transmission place the shift lever in the “NEUTRAL”

position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the

positive terminal of the discharged battery.

Do not allow the vehicles to touch each other.

This will cause a ground connection, effectively

neutralizing the charging procedure.

Be sure that the booster battery has a 12 volt rating.

4. Attach one end of the remaining cable to the

negative terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the A/C compressor

bracket or the generator mounting bracket) of the

vehicle with the discharged battery.

This ground connection must be at least 450 mm

(18 in) from the battery of the vehicle whose battery

is being charged.

WARNING: Never attach the end of the jumper

cable directly to the negative terminal of the dead

battery.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical

accessories have been turned “OFF”.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in the reverse order.

Be sure to first disconnect the negative cable from

the vehicle with the discharged battery.

Page 5416 of 6000

ENGINE ELECTRICAL 6D – 13

Pinion

1) Check by hand to see if the pinion rotates smoothly

in the dirve direction, or if it is locked when it is

rotated reversely.

If not, replace the pinion.

Yoke assembly

1) Check the magnet inside the yoke.

Replace the yoke assembly if it is broken.

REASSEMBLY

To install, follow the removal steps in the reverse order,

noting the following points:

Grease application places

1) Gears in reduction gear

2) Shift lever operating portion

3) Sliding potion of pinion

4) Plunger sliding portion of magnetic switch

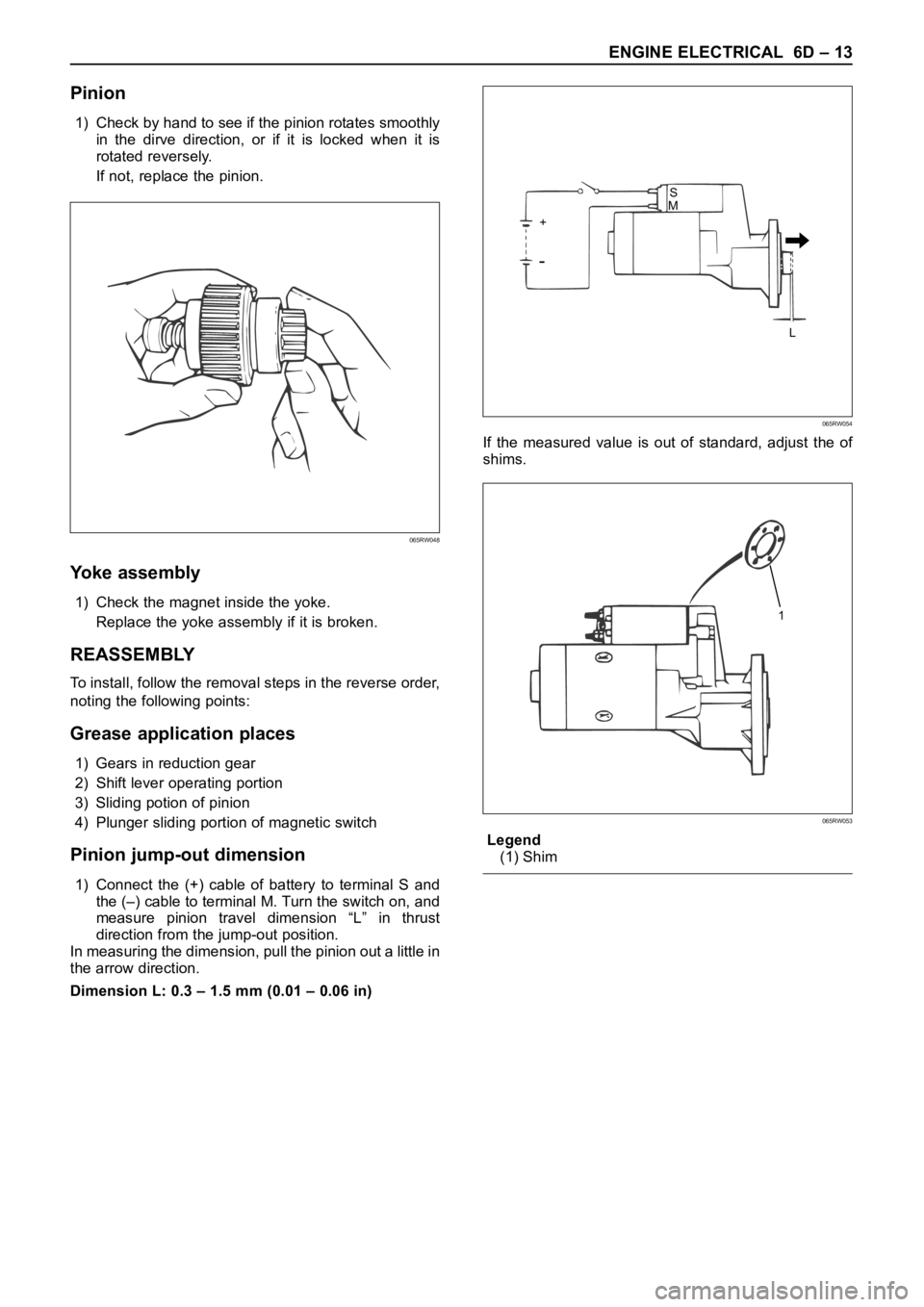

Pinion jump-out dimension

1) Connect the (+) cable of battery to terminal S and

the (–) cable to terminal M. Turn the switch on, and

measure pinion travel dimension “L” in thrust

direction from the jump-out position.

In measuring the dimension, pull the pinion out a little in

the arrow direction.

Dimension L: 0.3 – 1.5 mm (0.01 – 0.06 in)If the measured value is out of standard, adjust the of

shims.

Legend

(1) Shim

065RW048

S

+

L M

065RW054

1

065RW053

Page 5424 of 6000

ENGINE ELECTRICAL 6D – 21

Rectifier Assembly

1. Measure the resistance between each diode

terminal and aluminum diode fin in forward and

reverse directions with the connection of the tester

leads switched. The diodes are normal if resistance

is nearly zero ohms in one direction and is infinitely

high in the other direction.

2. If a diode has no resistance or equal resistance in

both directions, it is defective and should be

replaced together with the holder.

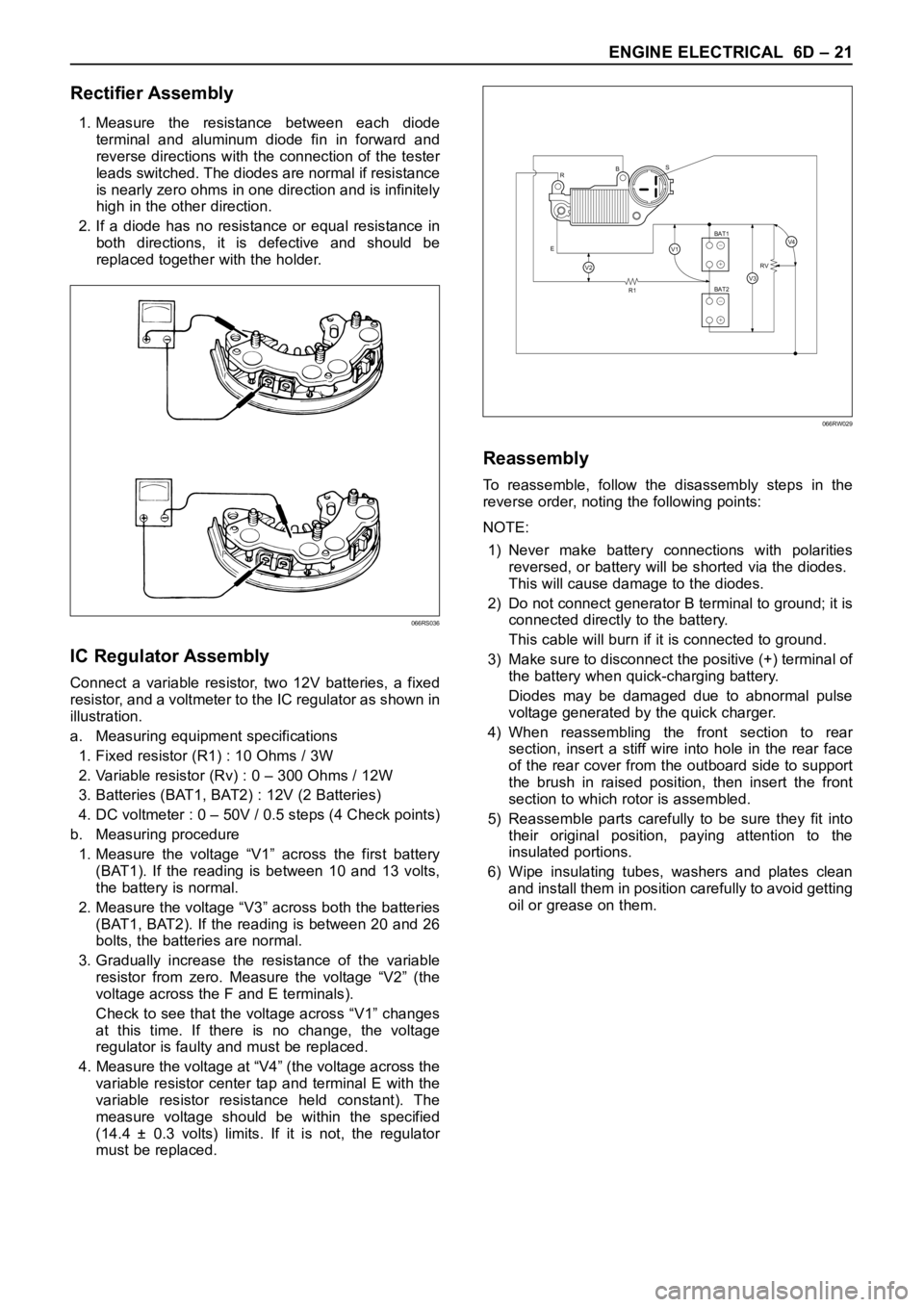

IC Regulator Assembly

Connect a variable resistor, two 12V batteries, a fixed

resistor, and a voltmeter to the IC regulator as shown in

illustration.

a. Measuring equipment specifications

1. Fixed resistor (R1) : 10 Ohms / 3W

2. Variable resistor (Rv) : 0 – 300 Ohms / 12W

3. Batteries (BAT1, BAT2) : 12V (2 Batteries)

4. DC voltmeter : 0 – 50V / 0.5 steps (4 Check points)

b. Measuring procedure

1. Measure the voltage “V1” across the first battery

(BAT1). If the reading is between 10 and 13 volts,

the battery is normal.

2. Measure the voltage “V3” across both the batteries

(BAT1, BAT2). If the reading is between 20 and 26

bolts, the batteries are normal.

3. Gradually increase the resistance of the variable

resistor from zero. Measure the voltage “V2” (the

voltage across the F and E terminals).

Check to see that the voltage across “V1” changes

at this time. If there is no change, the voltage

regulator is faulty and must be replaced.

4. Measure the voltage at “V4” (the voltage across the

variable resistor center tap and terminal E with the

variable resistor resistance held constant). The

measure voltage should be within the specified

(14.4 ± 0.3 volts) limits. If it is not, the regulator

must be replaced.

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

NOTE:

1) Never make battery connections with polarities

reversed, or battery will be shorted via the diodes.

This will cause damage to the diodes.

2) Do not connect generator B terminal to ground; it is

connected directly to the battery.

This cable will burn if it is connected to ground.

3) Make sure to disconnect the positive (+) terminal of

the battery when quick-charging battery.

Diodes may be damaged due to abnormal pulse

voltage generated by the quick charger.

4) When reassembling the front section to rear

section, insert a stiff wire into hole in the rear face

of the rear cover from the outboard side to support

the brush in raised position, then insert the front

section to which rotor is assembled.

5) Reassemble parts carefully to be sure they fit into

their original position, paying attention to the

insulated portions.

6) Wipe insulating tubes, washers and plates clean

and install them in position carefully to avoid getting

oil or grease on them.

066RS036

R

EBS

R1RV

BAT2 BAT1

V2V3

V4V1+

−

+

−

066RW029

Page 5425 of 6000

6D – 22 ENGINE ELECTRICAL

1. Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in

the front cover.2. Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified

torque.

Torque: 111 Nꞏm (82 lb ft)

066RS022

066RS010

MAIN DATA AND SPECIFICATIONS

General Specifications

Model LR160-734B LR-170-760

Battery voltage V 12

Rated output A 60 70

Direction of rotation Clockwise

(as viewed from pulley side)

Rated rotation speed rpm 5,000

Maximum speed rpm 18,000

Page 5719 of 6000

7A–30

AUTOMATIC TRANSMISSION (4L30–E)

Removal

1. Disconnect battery ground cable.

2. Remove transfer control lever knob.

3. Remove front console.

Disconnect wiring harness connectors from front

console.

4. Disconnect shift lock cable (1) from the selector lever

assembly side.

256RW012

5. Disconnect shift control rod (2) from the selector lever

assembly side.

256RW013

6. Disconnect wiring harness connectors from the

selector lever assembly.

7. Remove selector lever assembly.

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

Adjustment of select lever and control rod

1. Place the vehicle on a level surface.

NOTE: If the vehicle is not on level surface, the shift

select cable set positions will vary with the movement of

engine. To prevent possible misadjustment of the cable,

the vehicle must be placed on a level surface.

2. Install the shift control rod (1) to the transmission

select lever (2), and then place the lever in the “N”

position.

3. Set select lever in the “N” position.

4. Push select lever forward (“R” position side) and

s e c u r e i t ( u s i n g a r u b b e r b a n d ( 3 ) , e t c . ) s o t h a t t h e p i n

comes into contact with the wall of the detent plate.

5. Install the shift control rod (1) to the selector lever arm

(4).

To r q u e : 3 2 N

m (3.3 kgꞏm/24 lb ft)

NOTE: Do not apply oil to the threaded portions.

256RW014

6. After adjustment, make sure that the selector lever

operates normally, and that each selector position is

properly indicated. (The red mark shows through the

window.)

Adjustment of shift lock cable

1. Set ignition key in “LOCK” position and selector lever

in “P” position.

2. Adjust cable screw cap on selector lever side to

provide a gap (slack for cable) of 1 – 2 mm between

rod on steering lock side and stopper.

Adjust cap as follows:

a. Pull screw cap (1) in arrow direction to remove

inner cable slack.

b. With cable kept as (a), adjust gap between nut (2)

and bracket to 5 mm (0.2 in).

c. Lock inner cable by turning nut (3) while holding nut

(2) in place.

Torque : 3.7 N

m (38 kgꞏcm/33 lb in)