Seat OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 774 of 6000

4D2–7 TRANSFER CASE (TOD)

TOD ECU

Removal

1. Disconnect the ground cable.

2. Move the right-hand seat forward and remove the

second seat foot rest (1).

3. Disconnect the connector from the ECU (2).

4. Remove the bolts and detach the ECU (2) from the

bracket.

F07RW021

Installation

1. Perform the removal step in reverse order.

Page 815 of 6000

5A–5 BRAKE CONTROL SYSTEM

FR

Front Right

GEN

Generator

MV

Millivolts

RL

Rear Left

RR

Rear RightRPS

Revolution per Second

VDC

Vo l t s D C

VA C

Vo l t s A C

W/L

Warning Light

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS malfunction can be classified into two types, those

which can be detected by the ABS warning light and those

which can be detected as a vehicle abnormality by the

driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

Box Wrench

Brake Fluid

Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

J-39200 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

Computer System Service Precautions

The Anti-lock Brake System interfaces directly with the

Electronic Hydraulic Control Unit (EHCU) which is a

control computer that is similar in some regards to the

Powertrain Control Module. These modules are designed

to withstand normal current draws associated with

vehicle operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for opens

or shorts, do not ground or apply voltage to any of the

circuits unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested with a high impedance multimeter (J-39200) or

special tools as described in this section. Power should

never be removed or applied to any control module with

the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure toobserve these precautions may result in Anti-lock Brake

System damage.

If welding work is to be performed on the vehicle using

an electric arc welder, the EHCU and valve block

connectors should be disconnected before the

welding operation begins.

The EHCU and valve block connectors should never

be connected or disconnected with the ignition “ON” .

EHCU of the Anti-lock Brake System are not

separately serviceable and must be replaced as

assemblies. Do not disassemble any component

which is designated as non-serviceable in this

Section.

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS” warning light will

illuminate. But actually no trouble exists. After

inspection stop the engine once and re-start it, then

make sure that the “ABS” warning light does not

illuminate.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS)

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS to a

non-operative state by removing the fuse for the ABS

(40A). After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning light does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may be

helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be useful

in isolating the failure. Most intermittent problems are

caused by faulty electrical connections or wiring. When

an intermittent failure is encountered, check suspect

circuits for:

Suspected harness damage.

Poor mating of connector halves or terminals not fully

seated in the connector body (backed out).

Improperly formed or damaged terminals.

Page 961 of 6000

6A–5

ENGINE MECHANICAL

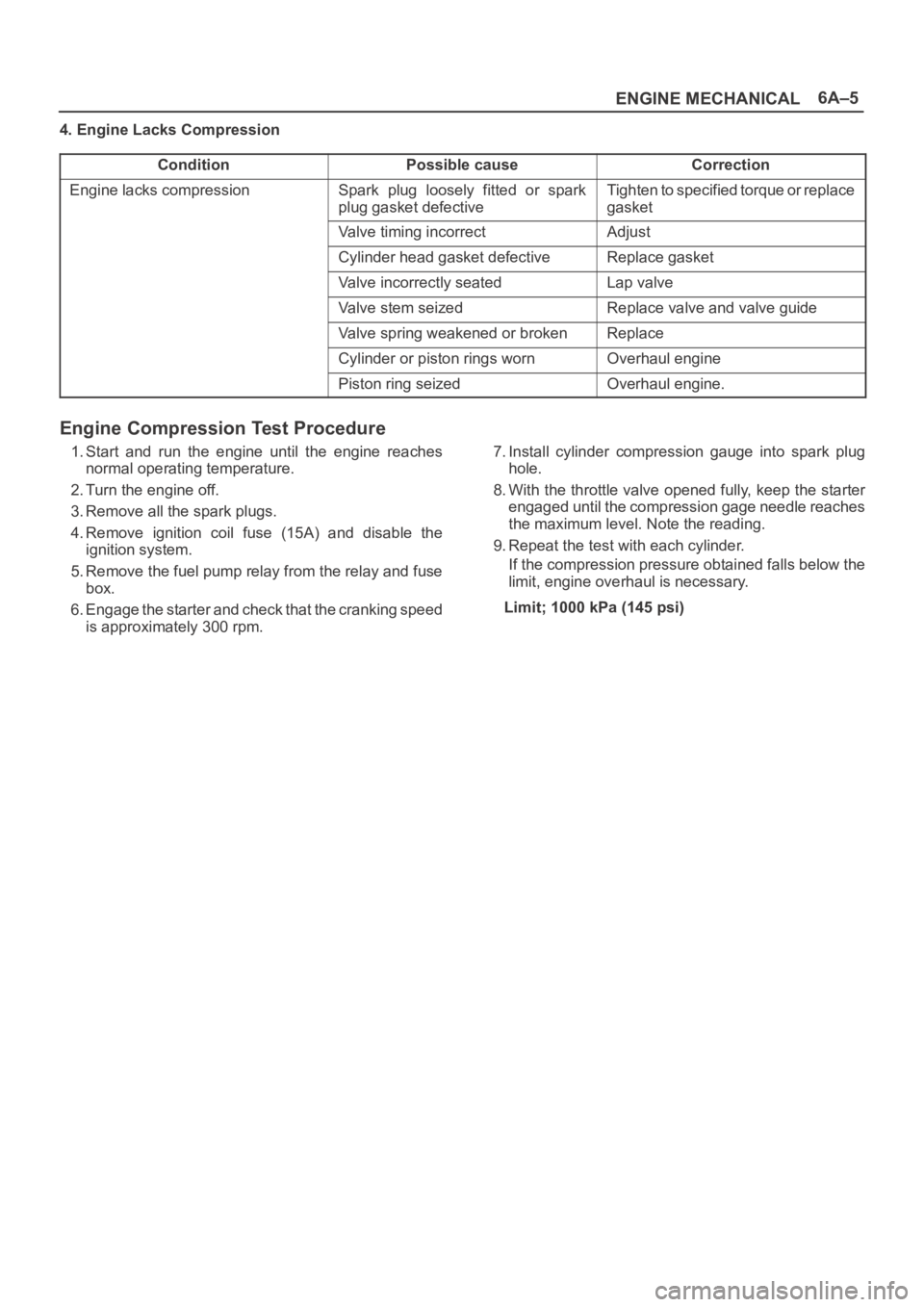

4. Engine Lacks Compression

Condition

Possible causeCorrection

Engine lacks compressionSpark plug loosely fitted or spark

plug gasket defectiveTighten to specified torque or replace

gasket

Valve timing incorrectAdjust

Cylinder head gasket defectiveReplace gasket

Valve incorrectly seatedLap valve

Valve stem seizedReplace valve and valve guide

Valve spring weakened or brokenReplace

Cylinder or piston rings wornOverhaul engine

Piston ring seizedOverhaul engine.

Engine Compression Test Procedure

1. Start and run the engine until the engine reaches

normal operating temperature.

2. Turn the engine off.

3. Remove all the spark plugs.

4. Remove ignition coil fuse (15A) and disable the

ignition system.

5. Remove the fuel pump relay from the relay and fuse

box.

6. Engage the starter and check that the cranking speed

is approximately 300 rpm.7. Install cylinder compression gauge into spark plug

hole.

8. With the throttle valve opened fully, keep the starter

engaged until the compression gage needle reaches

the maximum level. Note the reading.

9. Repeat the test with each cylinder.

If the compression pressure obtained falls below the

limit, engine overhaul is necessary.

Limit; 1000 kPa (145 psi)

Page 963 of 6000

6A–7

ENGINE MECHANICAL

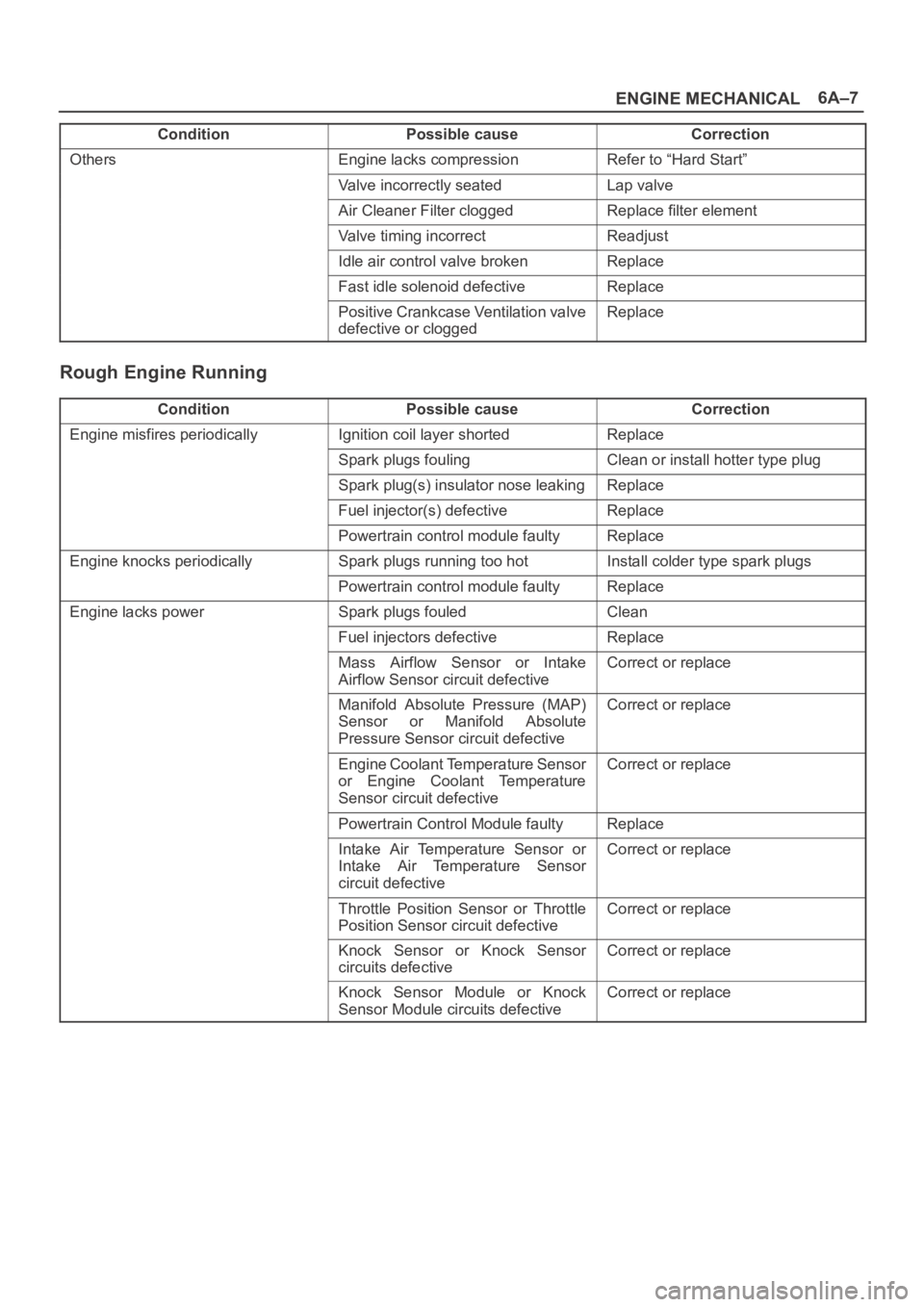

Condition CorrectionPossible cause

OthersEngine lacks compressionRefer to “Hard Start”

Valve incorrectly seatedLap valve

Air Cleaner Filter cloggedReplace filter element

Valve timing incorrectReadjust

Idle air control valve brokenReplace

Fast idle solenoid defectiveReplace

Positive Crankcase Ventilation valve

defective or cloggedReplace

Rough Engine Running

ConditionPossible causeCorrection

Engine misfires periodicallyIgnition coil layer shortedReplace

Spark plugs foulingClean or install hotter type plug

Spark plug(s) insulator nose leakingReplace

Fuel injector(s) defectiveReplace

Powertrain control module faultyReplace

Engine knocks periodicallySpark plugs running too hotInstall colder type spark plugs

Powertrain control module faultyReplace

Engine lacks powerSpark plugs fouledClean

Fuel injectors defectiveReplace

Mass Airflow Sensor or Intake

Airflow Sensor circuit defectiveCorrect or replace

Manifold Absolute Pressure (MAP)

Sensor or Manifold Absolute

Pressure Sensor circuit defectiveCorrect or replace

Engine Coolant Temperature Sensor

or Engine Coolant Temperature

Sensor circuit defectiveCorrect or replace

Powertrain Control Module faultyReplace

Intake Air Temperature Sensor or

Intake Air Temperature Sensor

circuit defectiveCorrect or replace

Throttle Position Sensor or Throttle

Position Sensor circuit defectiveCorrect or replace

Knock Sensor or Knock Sensor

circuits defectiveCorrect or replace

Knock Sensor Module or Knock

Sensor Module circuits defectiveCorrect or replace

Page 968 of 6000

6A–12

ENGINE MECHANICAL

ConditionPossible causeCorrection

Noise from connecting rods or from

connecting rod bearings

(Faulty connecting rods orBearing or crankshaft pin wornReplace connecting rod bearings

and crankshaft or regrind crankshaft

pin and install the undersize bearing

yg

connecting rod bearings usually

make an abnormal noise slightly

higher than the crank bearing noise,

which becomes more evident when

Crankpin out of roundReplace connecting rod bearings

and crankshaft or regrind crankshaft

pin and install the undersize bearing

which becomes more evident when

engine is accelerated)Connecting rod bentCorrect or replaceg)

Connecting rod bearing seizedReplace connecting rod bearings

and crankshaft or regrind crankshaft

pin and install the undersize bearing

Troubleshooting Procedure

Abnormal noise stops when the spark plug on the cylinder

with defective part is shorted out.

Condition

Possible causeCorrection

Piston and cylinder noise

(Faulty piston or cylinder usually

kbidhil

Piston clearance increased due to

cylinder wearReplace piston and cylinder body

makes a combined mechanical

thumping noise which increasesPiston seizedReplace piston and cylinder bodyg

when engine is suddenly accelerated

but diminishes

gradually as thePiston ring brokenReplace piston and cylinder bodybut diminishes gradually as the

engine warms up)Piston defectiveReplace pistons and others

Troubleshooting Procedure

Short out each spark plug and listen for change in engine

noise.

Condition

Possible causeCorrection

Piston pin noise

(Piston makes noise each time it

goes up and down)Piston pin or piston pin hole wornReplace piston, piston pin and

connecting rod assy

Troubleshooting Procedure

The slapping sound stops when spark plug on bad

cylinder is shorted out.

Condition

Possible causeCorrection

Timing belt noiseTiming belt tension is incorrectReplace pusher or adjust the tension

pulley or replace timing belt

Tensioner bearing defectiveReplace

Timing belt defectiveReplace

Timing pulley defectiveReplace

Timing belt comes in contact with

timing coverReplace timing belt and timing cover

Valve noiseValve clearance incorrectReplace adjusting shim

Valve and valve guide seizedReplace valve and valve guide

Valve spring broken or weakenedReplace

Valve seat off–positionedCorrect

Camshaft worn outReplace

Crankshaft noiseCrankshaft end play excessive

(noise occurs when clutch is

engaged)Replace thrust bearing

Page 970 of 6000

6A–14

ENGINE MECHANICAL

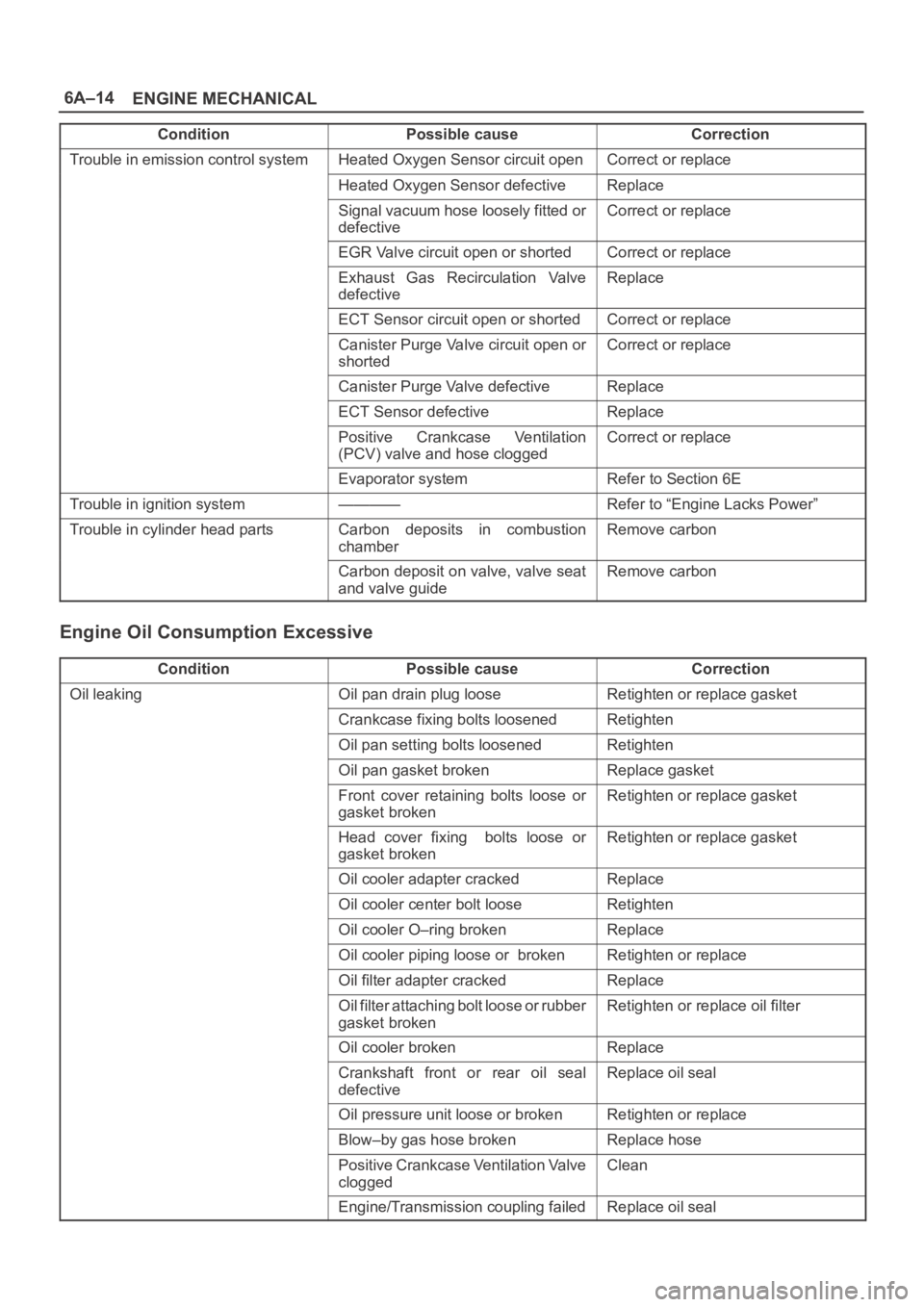

Condition CorrectionPossible cause

Trouble in emission control systemHeated Oxygen Sensor circuit openCorrect or replace

Heated Oxygen Sensor defectiveReplace

Signal vacuum hose loosely fitted or

defectiveCorrect or replace

EGR Valve circuit open or shortedCorrect or replace

Exhaust Gas Recirculation Valve

defectiveReplace

ECT Sensor circuit open or shortedCorrect or replace

Canister Purge Valve circuit open or

shortedCorrect or replace

Canister Purge Valve defectiveReplace

ECT Sensor defectiveReplace

Positive Crankcase Ventilation

(PCV) valve and hose cloggedCorrect or replace

Evaporator systemRefer to Section 6E

Trouble in ignition system————Refer to “Engine Lacks Power”

Trouble in cylinder head partsCarbon deposits in combustion

chamberRemove carbon

Carbon deposit on valve, valve seat

and valve guideRemove carbon

Engine Oil Consumption Excessive

ConditionPossible causeCorrection

Oil leakingOil pan drain plug looseRetighten or replace gasket

Crankcase fixing bolts loosenedRetighten

Oil pan setting bolts loosenedRetighten

Oil pan gasket brokenReplace gasket

Front cover retaining bolts loose or

gasket brokenRetighten or replace gasket

Head cover fixing bolts loose or

gasket brokenRetighten or replace gasket

Oil cooler adapter crackedReplace

Oil cooler center bolt looseRetighten

Oil cooler O–ring brokenReplace

Oil cooler piping loose or brokenRetighten or replace

Oil filter adapter crackedReplace

Oil filter attaching bolt loose or rubber

gasket brokenRetighten or replace oil filter

Oil cooler brokenReplace

Crankshaft front or rear oil seal

defectiveReplace oil seal

Oil pressure unit loose or brokenRetighten or replace

Blow–by gas hose brokenReplace hose

Positive Crankcase Ventilation Valve

cloggedClean

Engine/Transmission coupling failedReplace oil seal

Page 995 of 6000

6A–39

ENGINE MECHANICAL

Valve Stem Oil Controller , Valve Spring and Valve Guide

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

Drain engine coolant.

3. Remove cylinder head assembly.

Refer to removal procedure for Cylinder Head in

this manual.

4. Remove camshaft.

Refer to removal procedure for Camshaft in this

manual.

5. Remove tappets with shim.

NOTE: Do not damage shim surface.

6. Remove valve springs using 5–8840–2446–0 valve

spring compressor and 5–8840–2547–0 valve spring

compressor adapter then remove upper valve spring

seat and lower seat.

014RW042

7. Remove oil controller using 5–8840–0623–0 oil

controller remover, remove each valve stem oil

controller.

8. Remove valve guide using 5–8840–2549–0 valve

guide replacer.

Installation

1. Install valve guide using 5–8840–2442–0 valve guide

installer.

2. Install oil controller using 5–8840–0624–0 oil

controller installer.

3. Install lower valve spring seat, valve spring and upper

valve spring seat then put split collars on the upper

spring seat, using 5–8840–2446–0 valve spring

compressor and 5–8840–2547–0 valve spring

compressor adapter to install the split collars.

014RW042

4. Install tappet with shim.

5. Install camshaft assembly.

Refer to installation procedure for Camshaft in this

manual.

6. Install cylinder head assembly.

Refer to installation procedure for Cylinder Head in

this manual.

7. Fill engine oil until full level.

8. Fill engine coolant.

Page 997 of 6000

6A–41

ENGINE MECHANICAL

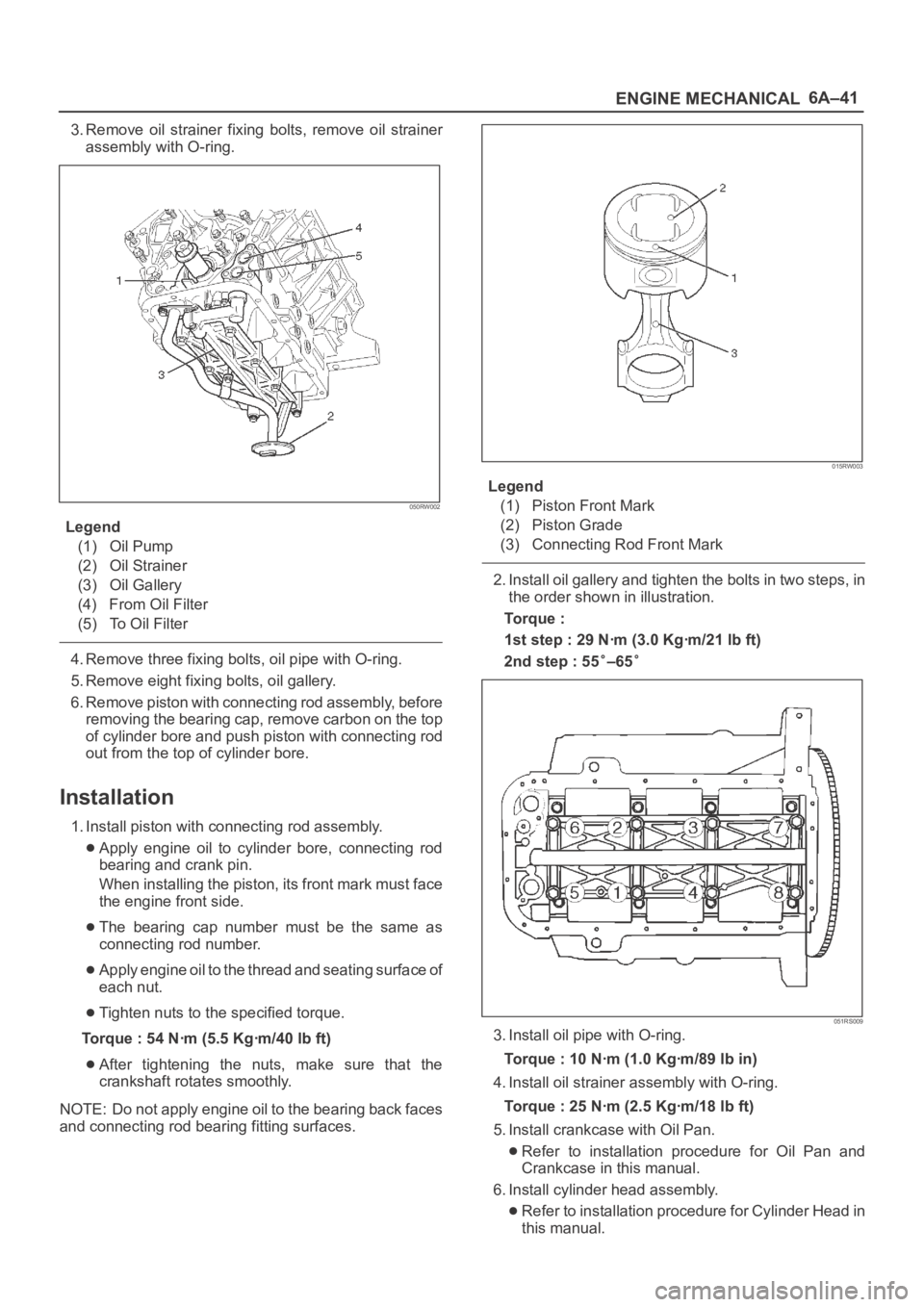

3. Remove oil strainer fixing bolts, remove oil strainer

assembly with O-ring.

050RW002

Legend

(1) Oil Pump

(2) Oil Strainer

(3) Oil Gallery

(4) From Oil Filter

(5) To Oil Filter

4. Remove three fixing bolts, oil pipe with O-ring.

5. Remove eight fixing bolts, oil gallery.

6. Remove piston with connecting rod assembly, before

removing the bearing cap, remove carbon on the top

of cylinder bore and push piston with connecting rod

out from the top of cylinder bore.

Installation

1. Install piston with connecting rod assembly.

Apply engine oil to cylinder bore, connecting rod

bearing and crank pin.

When installing the piston, its front mark must face

the engine front side.

The bearing cap number must be the same as

connecting rod number.

Apply engine oil to the thread and seating surface of

each nut.

Tighten nuts to the specified torque.

Torque : 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

After tightening the nuts, make sure that the

crankshaft rotates smoothly.

NOTE: Do not apply engine oil to the bearing back faces

and connecting rod bearing fitting surfaces.

015RW003

Legend

(1) Piston Front Mark

(2) Piston Grade

(3) Connecting Rod Front Mark

2. Install oil gallery and tighten the bolts in two steps, in

the order shown in illustration.

To r q u e :

1st step : 29 Nꞏm (3.0 Kgꞏm/21 lb ft)

2nd step : 55

–65

051RS009

3. Install oil pipe with O-ring.

Torque : 10 Nꞏm (1.0 Kgꞏm/89 lb in)

4. Install oil strainer assembly with O-ring.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

5. Install crankcase with Oil Pan.

Refer to installation procedure for Oil Pan and

Crankcase in this manual.

6. Install cylinder head assembly.

Refer to installation procedure for Cylinder Head in

this manual.

Page 999 of 6000

6A–43

ENGINE MECHANICAL

6. Remove oil pump assembly.

Refer to removal procedure for Oil Pump in this

manual.

7. Remove cylinder body side bolts.

8. Remove oil gallery.

9. Remove flywheel.

10. Remove rear oil seal retainer.

Refer to removal procedure for Rear Oil Seal in this

manual.

11. Remove connecting rod caps.

12. Remove crankshaft main bearing caps.

13. Remove crankshaft and main bearings.

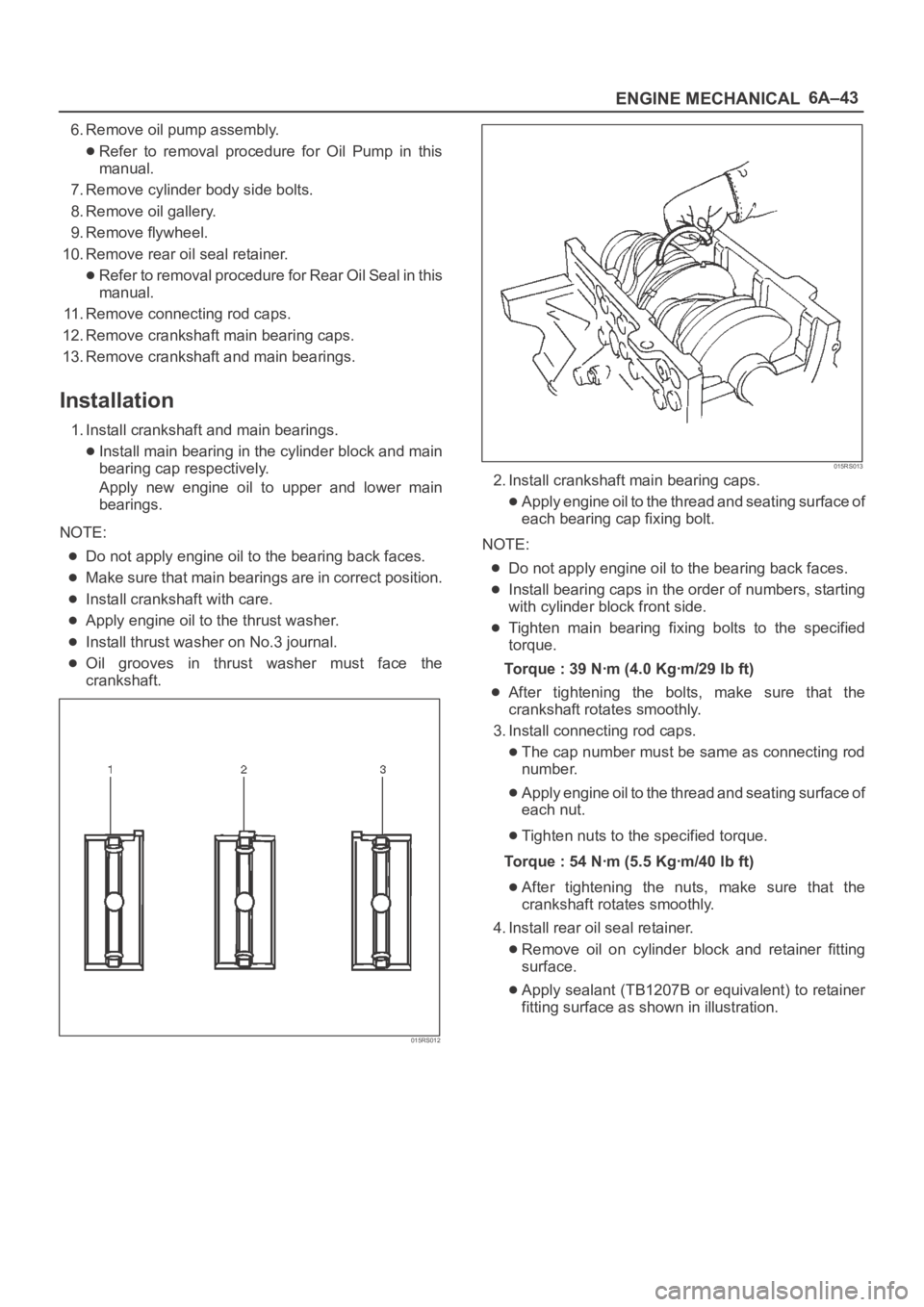

Installation

1. Install crankshaft and main bearings.

Install main bearing in the cylinder block and main

bearing cap respectively.

Apply new engine oil to upper and lower main

bearings.

NOTE:

Do not apply engine oil to the bearing back faces.

Make sure that main bearings are in correct position.

Install crankshaft with care.

Apply engine oil to the thrust washer.

Install thrust washer on No.3 journal.

Oil grooves in thrust washer must face the

crankshaft.

015RS012

015RS013

2. Install crankshaft main bearing caps.

Apply engine oil to the thread and seating surface of

each bearing cap fixing bolt.

NOTE:

Do not apply engine oil to the bearing back faces.

Install bearing caps in the order of numbers, starting

with cylinder block front side.

Tighten main bearing fixing bolts to the specified

torque.

Torque : 39 Nꞏm (4.0 Kgꞏm/29 lb ft)

After tightening the bolts, make sure that the

crankshaft rotates smoothly.

3. Install connecting rod caps.

The cap number must be same as connecting rod

number.

Apply engine oil to the thread and seating surface of

each nut.

Tighten nuts to the specified torque.

Torque : 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

After tightening the nuts, make sure that the

crankshaft rotates smoothly.

4. Install rear oil seal retainer.

Remove oil on cylinder block and retainer fitting

surface.

Apply sealant (TB1207B or equivalent) to retainer

fitting surface as shown in illustration.

Page 1008 of 6000

6A–52

ENGINE MECHANICAL

Cylinder Head

Cylinder Head and Associated Parts

011RW008

Legend

(1) Spark Plug

(2) Cylinder Head Bolt

(3) Camshaft Drive Gear Pulley Fixing Bolt

(4) Camshaft Drive Gear Pulley

(5) Camshaft Bracket Fixing Bolt

(6) Camshaft Bracket

(7) Camshaft Exhaust(8) Camshaft Intake

(9) Retainer Fixing Bolt

(10) Retainer Assembly

(11) Tappet with Shim

(12) Split Collar

(13) Valve Spring and Spring Upper Seat

(14) Valve

Disassembly

NOTE:

During disassembly, be sure that the valve train

components are kept together and identified so that

they can be reinstalled in their original locations.

Before removing the cylinder head from the engine

and before disassembling the valve mechanism,

perform a compression test and note the results.

1. Remove camshaft drive gear pulley fixing bolt (3),

then pulley (4).