catalytic converter OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1442 of 6000

6E–325 ENGINE DRIVEABILITY AND EMISSIONS

Spark Plug Gap Check

Check the gap of all spark plugs before installation.

Use a round wire feeler gauge to ensure an accurate

check.

Plugs installed with the wrong gap can cause poor

engine performance and excessive emissions.

Installation Procedure

NOTE: The plug must thread smoothly into the cylinder

head and be fully seated. Use a thread chaser if

necessary to clean the threads in the cylinder head.

Cross-threading or failure to fully seat the spark plug can

cause plug overheating, exhaust blow-by gas, or thread

damage. Do not overtighten the spark plugs. Over

tightening can cause aluminum threads to strip.

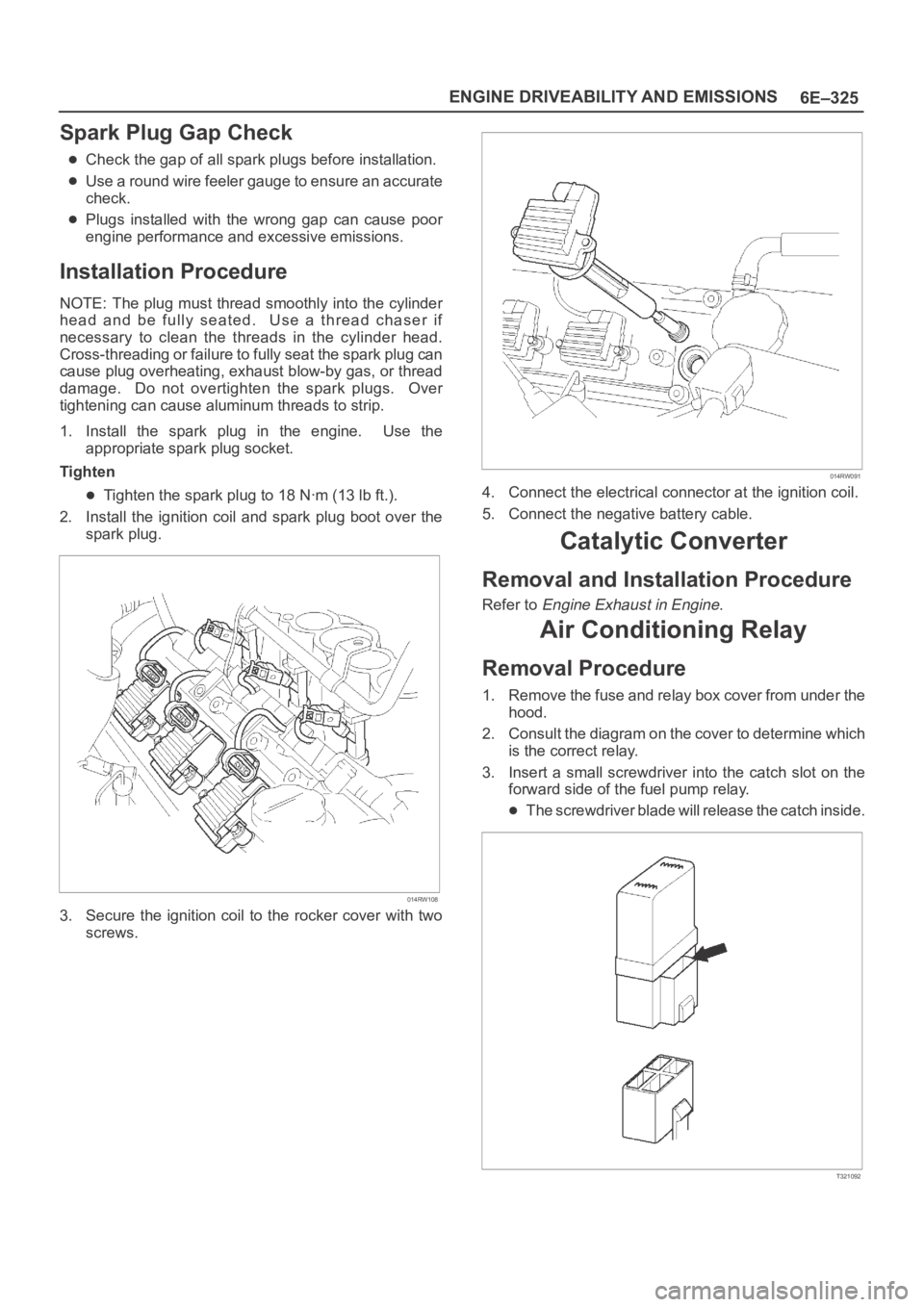

1. Install the spark plug in the engine. Use the

appropriate spark plug socket.

Tighten

Tighten the spark plug to 18 Nꞏm (13 lb ft.).

2. Install the ignition coil and spark plug boot over the

spark plug.

014RW108

3. Secure the ignition coil to the rocker cover with two

screws.

014RW091

4. Connect the electrical connector at the ignition coil.

5. Connect the negative battery cable.

Catalytic Converter

Removal and Installation Procedure

Refer to Engine Exhaust in Engine.

Air Conditioning Relay

Removal Procedure

1. Remove the fuse and relay box cover from under the

hood.

2. Consult the diagram on the cover to determine which

is the correct relay.

3. Insert a small screwdriver into the catch slot on the

forward side of the fuel pump relay.

The screwdriver blade will release the catch inside.

T321092

Page 1459 of 6000

6E–342

ENGINE DRIVEABILITY AND EMISSIONS

PCM to calculate true sequential multiport fuel injection

(SFI). Loss of this signal will set a DTC P0341. If the CMP

signal is lost while the engine is running, the fuel injection

system will shift to a calculated sequential fuel injection

based on the last fuel injection pulse, and the engine will

continue to run. The engine can be restarted and will run

in the calculated sequential mode as long as the fault is

present, with a 1-in-6 chance of being correct.

Clear Flood Mode

Clear a flooded engine by pushing the accelerator pedal

down all the way. The PCM then de-energizes the fuel

injectors. The PCM holds the fuel injectors de-energized

as long as the throttle remains above 80% and the engine

speed is below 800 RPM. If the throttle position becomes

less than 80%, the PCM again begins to pulse the

injectors “ON” and “OFF,” allowing fuel into the cylinders.

Deceleration Mode

The PCM reduces the amount of fuel injected when it

detects a decrease in the throttle position and the air flow.

When deceleration is very fast, the PCM may cut off fuel

completely for short periods.

Engine Speed/Vehicle Speed/Fuel Disable

Mode

The PCM monitors engine speed. It turns off the fuel

injectors when the engine speed increase above 6400

RPM. The fuel injectors are turned back on when engine

speed decreases below 6150 RPM.

Fuel Cutoff Mode

No fuel is delivered by the fuel injectors when the ignition

is “OFF.” This prevents engine run-on. In addition, the

PCM suspends fuel delivery if no reference pulses are

detected (engine not running) to prevent engine flooding.

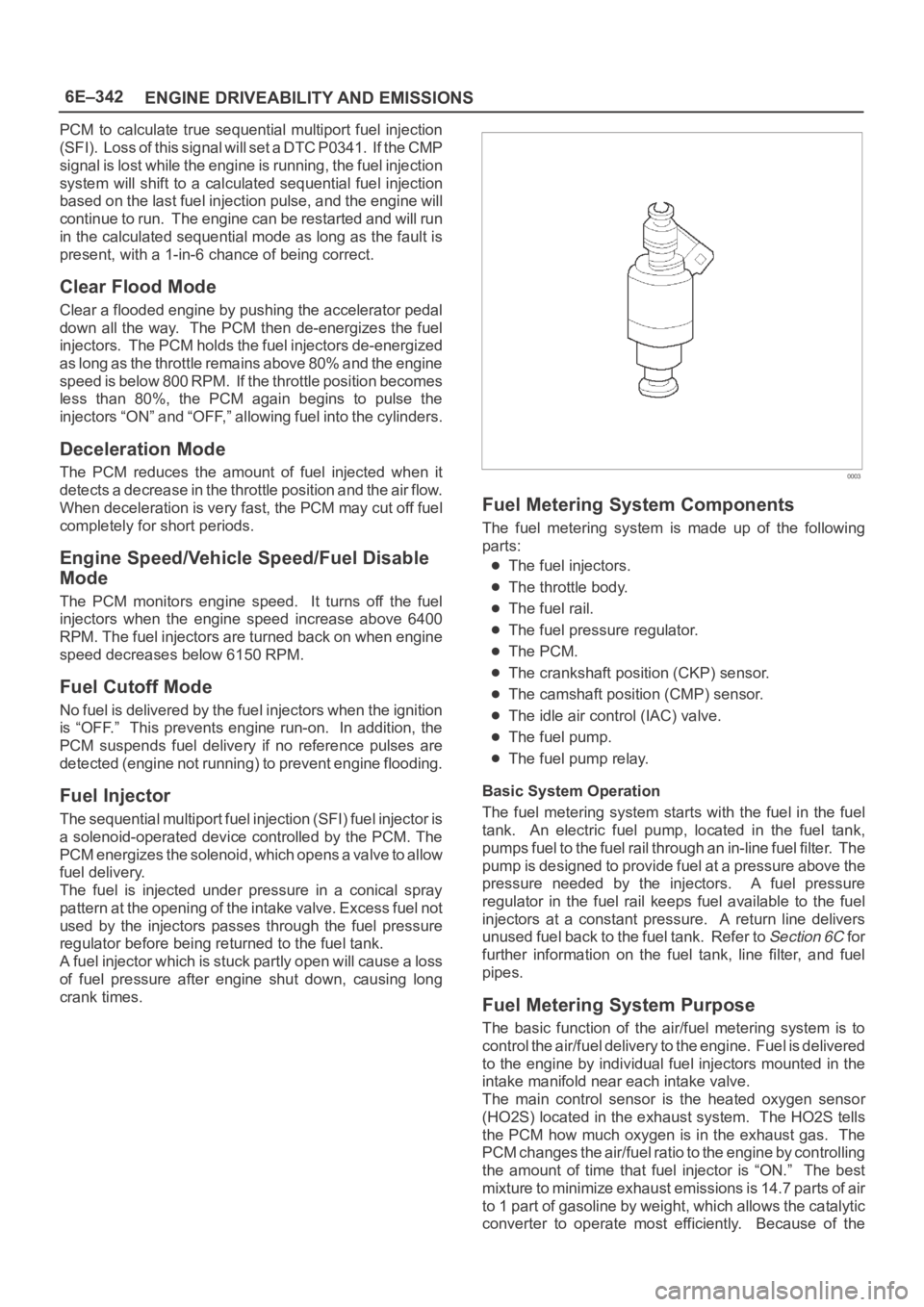

Fuel Injector

The sequential multiport fuel injection (SFI) fuel injector is

a solenoid-operated device controlled by the PCM. The

PCM energizes the solenoid, which opens a valve to allow

fuel delivery.

The fuel is injected under pressure in a conical spray

pattern at the opening of the intake valve. Excess fuel not

used by the injectors passes through the fuel pressure

regulator before being returned to the fuel tank.

A fuel injector which is stuck partly open will cause a loss

of fuel pressure after engine shut down, causing long

crank times.

0003

Fuel Metering System Components

The fuel metering system is made up of the following

parts:

The fuel injectors.

The throttle body.

The fuel rail.

The fuel pressure regulator.

The PCM.

The crankshaft position (CKP) sensor.

The camshaft position (CMP) sensor.

The idle air control (IAC) valve.

The fuel pump.

The fuel pump relay.

Basic System Operation

The fuel metering system starts with the fuel in the fuel

tank. An electric fuel pump, located in the fuel tank,

pumps fuel to the fuel rail through an in-line fuel filter. The

pump is designed to provide fuel at a pressure above the

pressure needed by the injectors. A fuel pressure

regulator in the fuel rail keeps fuel available to the fuel

injectors at a constant pressure. A return line delivers

unused fuel back to the fuel tank. Refer to

Section 6C f o r

further information on the fuel tank, line filter, and fuel

pipes.

Fuel Metering System Purpose

The basic function of the air/fuel metering system is to

control the air/fuel delivery to the engine. Fuel is delivered

to the engine by individual fuel injectors mounted in the

intake manifold near each intake valve.

The main control sensor is the heated oxygen sensor

(HO2S) located in the exhaust system. The HO2S tells

the PCM how much oxygen is in the exhaust gas. The

PCM changes the air/fuel ratio to the engine by controlling

the amount of time that fuel injector is “ON.” The best

mixture to minimize exhaust emissions is 14.7 parts of air

to 1 part of gasoline by weight, which allows the catalytic

converter to operate most efficiently. Because of the

Page 1472 of 6000

6F–1 ENGINE EXHAUST

ENGINE

ENGINE EXHAUST

CONTENTS

Service Precaution 6F–1. . . . . . . . . . . . . . . . . . . . . .

General Description 6F–2. . . . . . . . . . . . . . . . . . . . .

Front Exhaust Pipe 6F–4. . . . . . . . . . . . . . . . . . . . . .

Front Exhaust Pipe and Associated Parts 6F–4.

Removal 6F–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6F–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Three Way Catalytic Converter 6F–5. . . . . . . . . . . .

Removal 6F–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6F–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust Silencer 6F–6. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Silencer and Associated Parts 6F–6. . .

Removal 6F–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6F–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Exhaust pipe 6F–7. . . . . . . . . . . . . . . . . . . . . . .

Rear Exhaust pipe and Associated Parts 6F–7.

Removal 6F–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6F–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6F–8. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1473 of 6000

6F–2ENGINE EXHAUST

General Description

General export with three way catalytic converter

model

150RW060

General export with out three way catalytic

converter model

150RW059

Page 1474 of 6000

6F–3 ENGINE EXHAUST

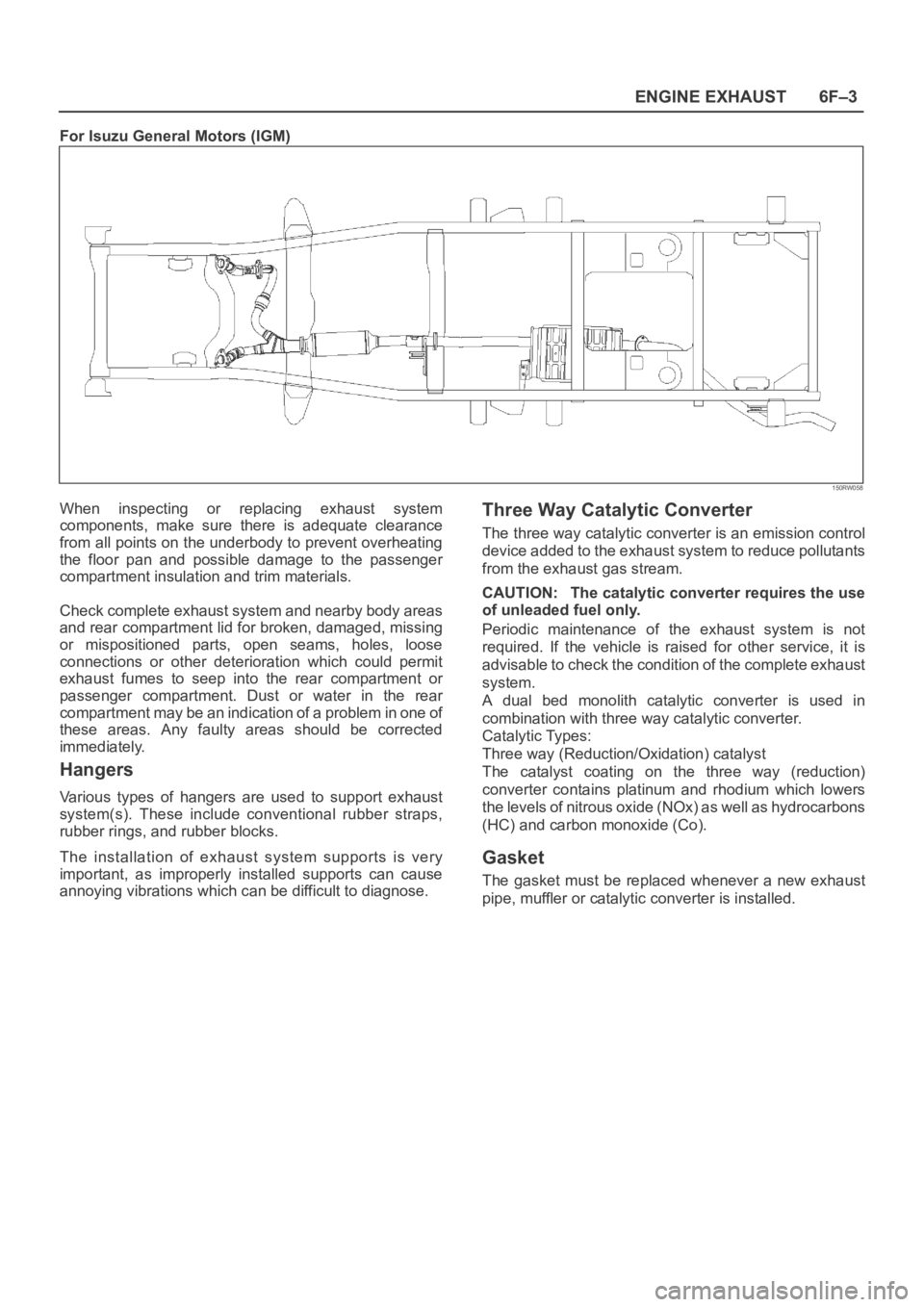

For Isuzu General Motors (IGM)

150RW058

When inspecting or replacing exhaust system

components, make sure there is adequate clearance

from all points on the underbody to prevent overheating

the floor pan and possible damage to the passenger

compartment insulation and trim materials.

Check complete exhaust system and nearby body areas

and rear compartment lid for broken, damaged, missing

or mispositioned parts, open seams, holes, loose

connections or other deterioration which could permit

exhaust fumes to seep into the rear compartment or

passenger compartment. Dust or water in the rear

compartment may be an indication of a problem in one of

these areas. Any faulty areas should be corrected

immediately.

Hangers

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps,

rubber rings, and rubber blocks.

The installation of exhaust system supports is very

important, as improperly installed supports can cause

annoying vibrations which can be difficult to diagnose.

Three Way Catalytic Converter

The three way catalytic converter is an emission control

device added to the exhaust system to reduce pollutants

from the exhaust gas stream.

CAUTION: The catalytic converter requires the use

of unleaded fuel only.

Periodic maintenance of the exhaust system is not

required. If the vehicle is raised for other service, it is

advisable to check the condition of the complete exhaust

system.

A dual bed monolith catalytic converter is used in

combination with three way catalytic converter.

Catalytic Types:

Three way (Reduction/Oxidation) catalyst

The catalyst coating on the three way (reduction)

converter contains platinum and rhodium which lowers

the levels of nitrous oxide (NOx) as well as hydrocarbons

(HC) and carbon monoxide (Co).

Gasket

The gasket must be replaced whenever a new exhaust

pipe, muffler or catalytic converter is installed.

Page 1476 of 6000

6F–5 ENGINE EXHAUST

Three Way Catalytic Converter

Removal

1. Disconnect battery ground cable.

2. Raise the vehicle and support with suitable safety

stands.

3. Remove three way exhaust pipe fixing bolts and nuts.

150RW065

Installation

1. Install three way catalytic converter between three

way exhaust pipe and silencer.

2. Tighten nuts to the specified torque.

Torque

Nuts : 43 Nꞏm (4.4 Kgꞏm/32 lb ft)

Page 2073 of 6000

6E–180

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Surges and/or Chuggles Symptom

StepNo Ye s Va l u e ( s ) Action

101. Check the exhaust system for possible restriction:

Inspect the exhaust system for damaged or

collapsed pipes.

Inspect the muffler for heat distress or possible

internal failure.

Check for a possible plugged catalytic

converter by checking the exhaust system

back pressure. Refer to

Restricted Exhaust

System Check

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

111. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records buffer

All electrical connections within a suspected

circuit and/or system.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 2074 of 6000

6E–181 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

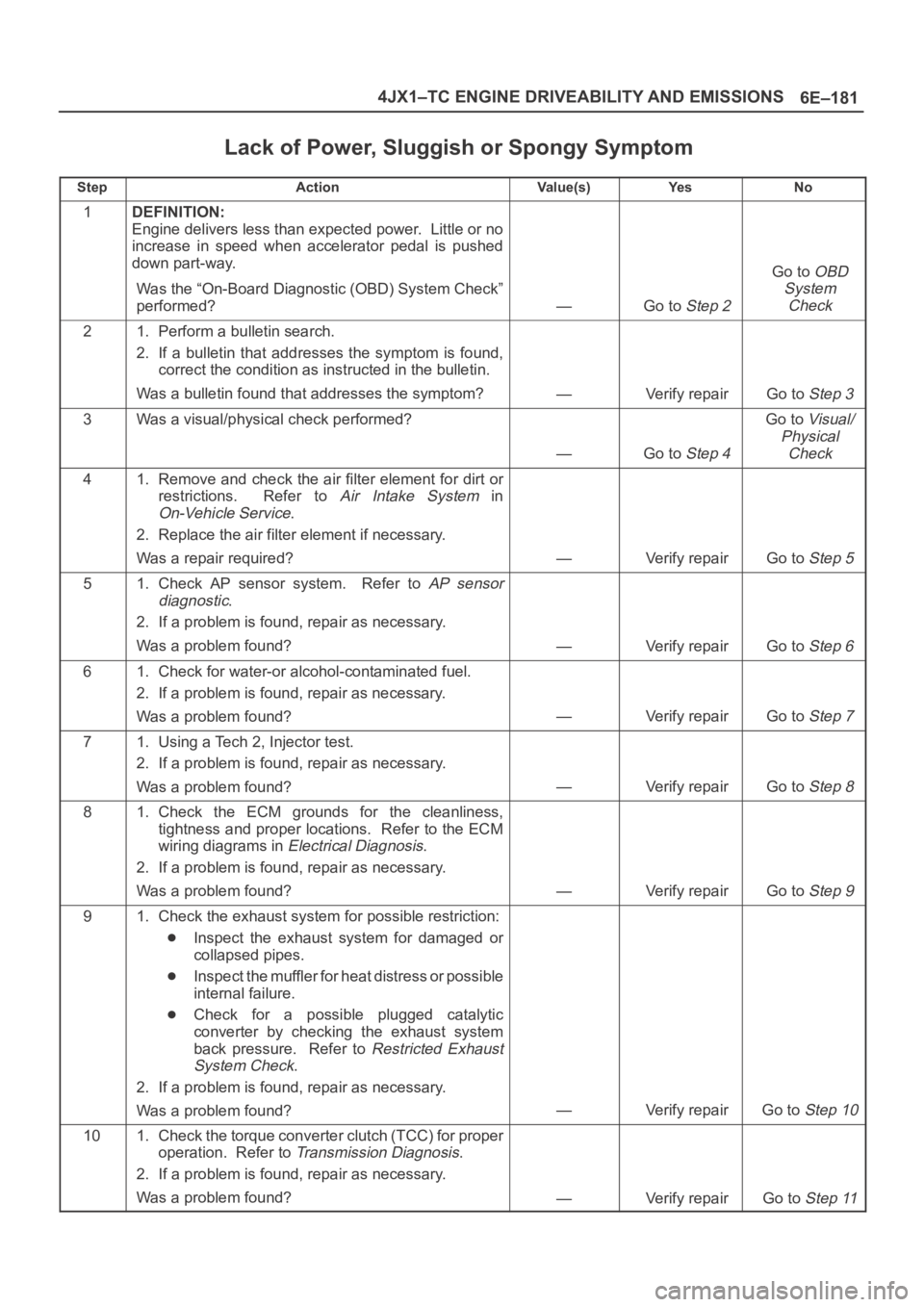

Lack of Power, Sluggish or Spongy Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Engine delivers less than expected power. Little or no

increase in speed when accelerator pedal is pushed

down part-way.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to Visual/

Physical

Check

41. Remove and check the air filter element for dirt or

restrictions. Refer to

Air Intake System in

On-Vehicle Service.

2. Replace the air filter element if necessary.

Was a repair required?

—Verify repairGo to Step 5

51. Check AP sensor system. Refer to AP sensor

diagnostic

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

61. Check for water-or alcohol-contaminated fuel.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Using a Tech 2, Injector test.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check the ECM grounds for the cleanliness,

tightness and proper locations. Refer to the ECM

wiring diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check the exhaust system for possible restriction:

Inspect the exhaust system for damaged or

collapsed pipes.

Inspect the muffler for heat distress or possible

internal failure.

Check for a possible plugged catalytic

converter by checking the exhaust system

back pressure. Refer to

Restricted Exhaust

System Check

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

101. Check the torque converter clutch (TCC) for proper

operation. Refer to

Transmission Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

Page 2324 of 6000

7B–6MANUAL TRANSMISSION

Removal

NOTE: Before remove the transmission and transfer

assembly from the vehicle, change the transfer mode to

2WD using push button on dash panel.

1. Remove engine hood.

2. Disconnect battery ground cable.

3. Remove the gear control lever knob.

4. Remove the front console assembly.

5. Remove the grommet assembly.

6. Remove the transmission control lever and transfer

control lever.

235RW014

7. Raise and support the vehicle with suitable jack

stand.

8. Remove transfer protector.

9. Remove the rear propeller shaft.

NOTE: Apply alignment marks on the flange at the both

front and rear side.

(4JX1)

401RW060

10. Remove the front propeller shaft.

NOTE: Apply alignment marks on the flange at both the

front and rear sides.

401RS003

11. Disconnect two oxygen sensor connectors from the

transmission harness (6VE1).

12.Remove the front and 3 way exhaust pipe (6VE1).

Remove the exhaust pipe with catalytic converter

(4JX1).

(4JX1)

150RW041

Page 2334 of 6000

7B–16MANUAL TRANSMISSION

19. Connect the backup lamp switch, 4WD indicator

switch, and 1-2 indicator switch harness connectors.

826RW023

20. Install the front and 3 way exhaust pipe (6VE1).

Install the exhaust pipe with catalytic converter

(4JX1).

Torque:

Exhaust pipe to exhaust manifold:

67 Nꞏm (6.8 kgꞏm/49 Ib ft)

Exhaust pipe flange bolt:

43 Nꞏm (4.4 kgꞏm/32 Ib ft)

(4JX1)

150RW041

21. Connect two oxygen sensor connectors to the

transmission harness (6VE1).

22. Install the front propeller shaft and tighten the fixing

bolts and nuts specified torque.

Torque: 63 Nꞏm (6.4 kgꞏm/46 Ib ft)

23. Install the rear propeller shaft and tighten the fixing

bolts and nuts specified torque.

Torque: 63 Nꞏm (6.4 kgꞏm/46 Ib ft)24. Install transfer protector and tighten the fixing bolts

specified torque.

Torque: 37 Nꞏm (3.8 kgꞏm/27 Ib ft)

25. Install the transmission control lever and transfer

control lever.

235RW014

26. Install the grommet assembly.

27. Install the front console assembly.

28. Install the gear control lever knob.

29. Connect battery ground cable.

30. Install engine hood.