charging OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1093 of 6000

6D3–2STARTING AND CHARGING SYSTEM

Starting System

General Description

Cranking Circuit

The cranking system consists of a battery, starter, starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion

shaft. When the starter switch is turned on, the contacts of

magnetic switch are closed, and the armature rotates. At

the same time, the plunger is attracted, and the pinion is

pushed forward by the shift lever to mesh with the ring

gear.

Then, the ring gear runs to start the engine. When the

engine starts and the starter switch is turned off, the

plunger returns, the pinion is disengaged from the ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

Page 1094 of 6000

6D3–3 STARTING AND CHARGING SYSTEM

C06RW005

Page 1095 of 6000

6D3–4STARTING AND CHARGING SYSTEM

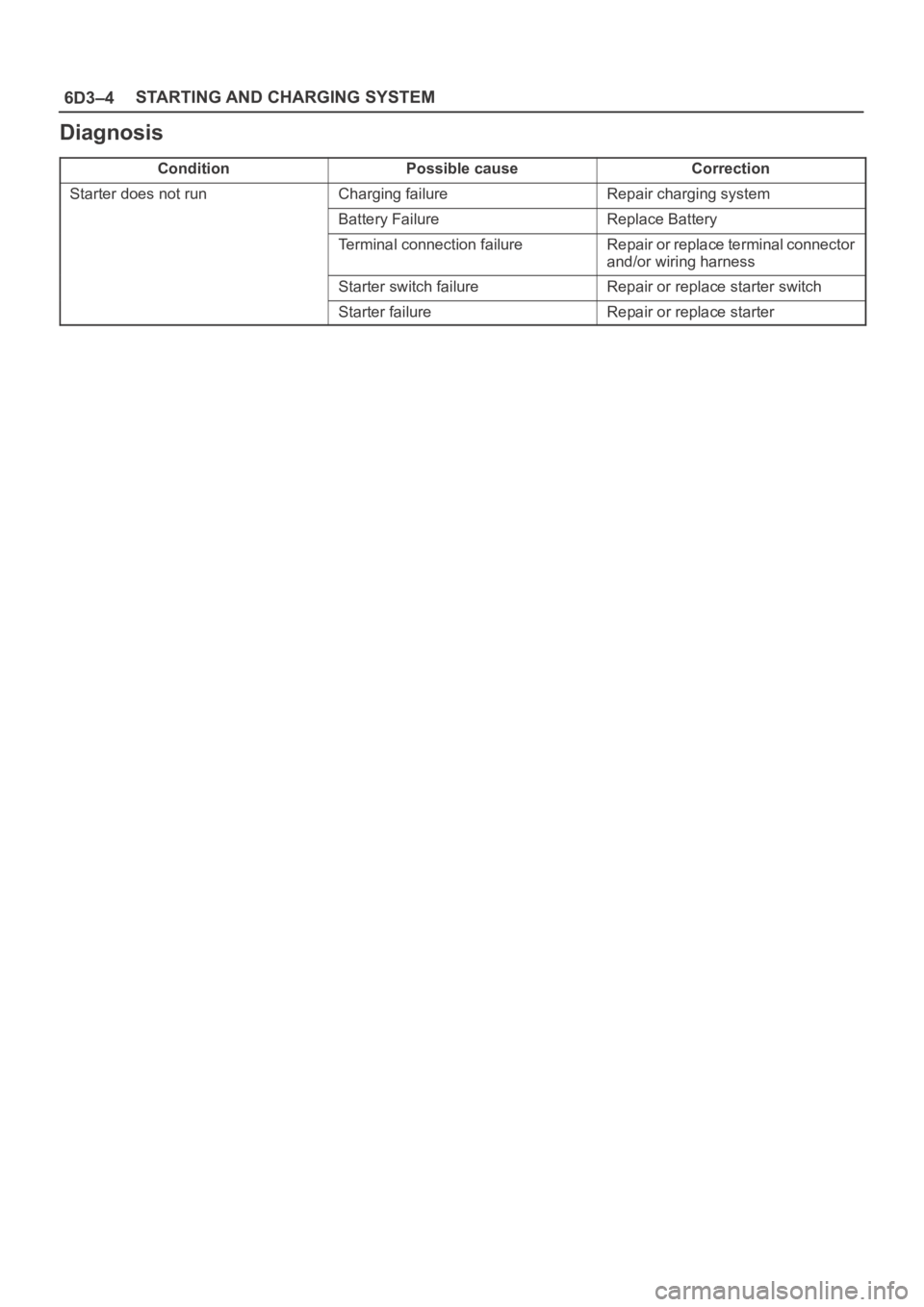

Diagnosis

ConditionPossible causeCorrection

Starter does not runCharging failureRepair charging system

Battery FailureReplace Battery

Terminal connection failureRepair or replace terminal connector

and/or wiring harness

Starter switch failureRepair or replace starter switch

Starter failureRepair or replace starter

Page 1096 of 6000

6D3–5 STARTING AND CHARGING SYSTEM

Starter

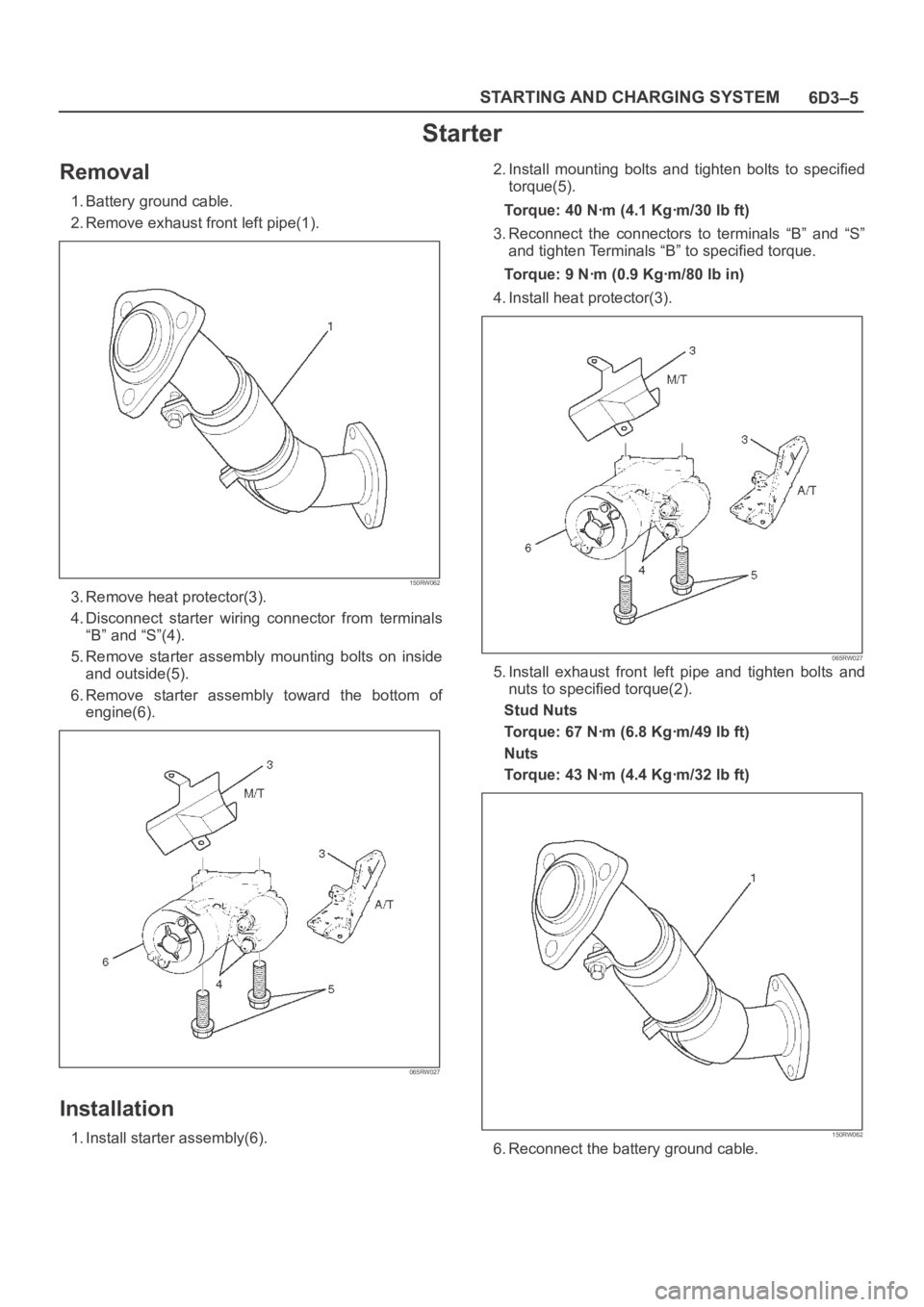

Removal

1. Battery ground cable.

2. Remove exhaust front left pipe(1).

150RW062

3. Remove heat protector(3).

4. Disconnect starter wiring connector from terminals

“B” and “S”(4).

5. Remove starter assembly mounting bolts on inside

and outside(5).

6. Remove starter assembly toward the bottom of

engine(6).

065RW027

Installation

1. Install starter assembly(6).2. Install mounting bolts and tighten bolts to specified

torque(5).

Torque: 40 Nꞏm (4.1 Kgꞏm/30 lb ft)

3. Reconnect the connectors to terminals “B” and “S”

and tighten Terminals “B” to specified torque.

Torque: 9 Nꞏm (0.9 Kgꞏm/80 lb in)

4. Install heat protector(3).

065RW027

5. Install exhaust front left pipe and tighten bolts and

nuts to specified torque(2).

Stud Nuts

Torque: 67 Nꞏm (6.8 Kgꞏm/49 lb ft)

Nuts

Torque: 43 Nꞏm (4.4 Kgꞏm/32 lb ft)

150RW062

6. Reconnect the battery ground cable.

Page 1097 of 6000

6D3–6STARTING AND CHARGING SYSTEM

Disassembled View

065RW002

Legend

(1) Bolt (2 pcs)

(2) Ball Bearing

(3) Pinion

(4) Shift Lever

(5) Dust Cover

(6) Torsion Spring

(7) Dust Cover

(8) Magnetic Switch

(9) Nut

(10) Gear Case

(11) Bearing Cover

(12) E–Ring

(13) Thrust Washer (2)(14) Center Bracket

(15) Pinion Shaft

(16) Planet Gear (3)

(17) Internal Gear

(18) Center Bracket (A)

(19) Yoke Assembly

(20) Armature

(21) Brush

(22) Brush Holder

(23) Thrust Washer

(24) Rear Cover

(25) Screw (2 pcs)

(26) Through Bolt (2 pcs)

Page 1098 of 6000

6D3–7 STARTING AND CHARGING SYSTEM

Disassembly

1. Loosen the nut(1) on terminal “M” of magnetic switch

and disconnect the connector cable.

2. Remove bolt (2 pcs) (2).

065RW003

3. Remove magnetic switch(5).

4. Remove dust cover(4).

5. Remove torsion spring bolts, then the magnetic

switch assembly.

6. Remove torsion spring(3) from magnetic switch

assembly(5).

065RW004

7. Remove screw (2 pcs) (8).

8. Remove through bolt (2 pcs) (7).9. Remove screws and through bolts, then the rear

cover(9) then remove thrust washer(10).

10. Remove brush holder(6).

065RW005

11. Raise a brush spring to detach brushes (4 pcs) from

the commutator face and pull off the brush holder(12)

and brush(11).

065RW006

12. Remove yoke assembly(14).

13. Remove armature(15).

14. Pull off the yoke assembly, then remove armature,

washer and center bracket.(A) (13).

Page 1099 of 6000

6D3–8STARTING AND CHARGING SYSTEM

NOTE: In disassembling the yoke assembly, hold the

armature and pull off slowly the yoke assembly. Because

of strong magnetic force, avoid placing a metallic part

near armature.

065RW007

15. Remove dust cover(17).

16. Remove a dust cover and shift lever(16) from the gear

case.

065RW008

17. Remove ball bearing(19).

18. Remove bearing cover(20).

19. Remove a ball bearing and bearing cover from the

gear case(18).

065RW021

20. Internal gear(21).

21. Remove internal gear and planet gear(3) (22).

065RW009

Page 1100 of 6000

6D3–9 STARTING AND CHARGING SYSTEM

22. Remove an E–ring(23) from the pinion shaft using a

flat blade screwdriver.

065RW010

23. Holding the pinion shaft, push pinion toward the

center bracket. and turn the pinion clockwise or

counterclockwise by one tooth of spline, then pull off

the pinion.

24. Remove thrust washer(24).

25. Remove center bracket

26. Remove pinion shaft.

065RW011

Inspection and Repair

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

Armature

Measure the outer diameter of commutator, and replace

with a new one if it is out of the limit.

Standard: 33.0 mm (1.30 in)

Limit: 32.0 mm (1.26 in)

065RS014Check for continuity between commutator and segment.

Replace commutator if there is no continuity (i.e.,

disconnected).

065RS015

Page 1101 of 6000

6D3–10STARTING AND CHARGING SYSTEM

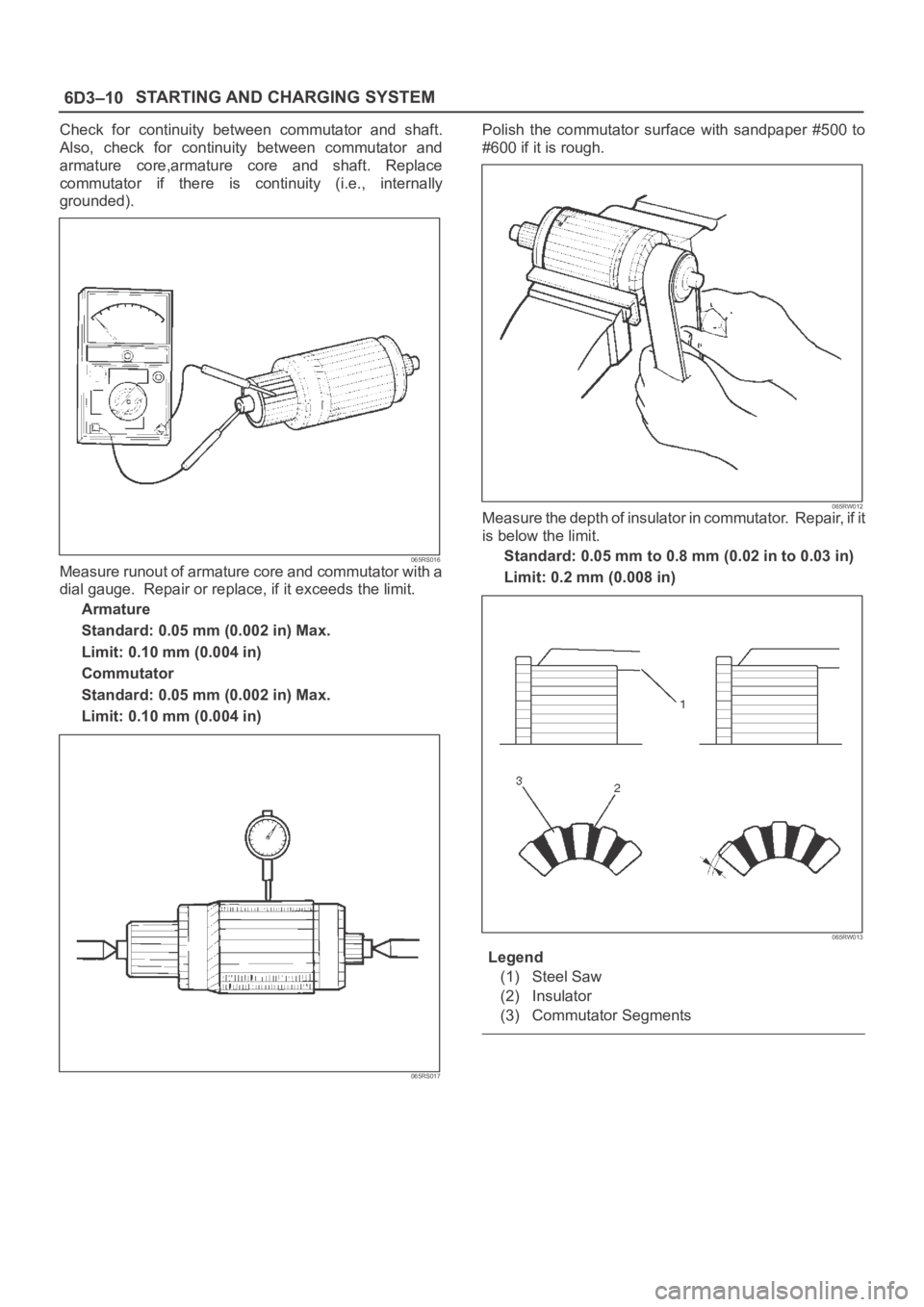

Check for continuity between commutator and shaft.

Also, check for continuity between commutator and

armature core,armature core and shaft. Replace

commutator if there is continuity (i.e., internally

grounded).

065RS016Measure runout of armature core and commutator with a

dial gauge. Repair or replace, if it exceeds the limit.

Armature

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.10 mm (0.004 in)

Commutator

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.10 mm (0.004 in)

065RS017

Polish the commutator surface with sandpaper #500 to

#600 if it is rough.

065RW012Measure the depth of insulator in commutator. Repair, if it

is below the limit.

Standard: 0.05 mm to 0.8 mm (0.02 in to 0.03 in)

Limit: 0.2 mm (0.008 in)

065RW013

Legend

(1) Steel Saw

(2) Insulator

(3) Commutator Segments

Page 1102 of 6000

6D3–11 STARTING AND CHARGING SYSTEM

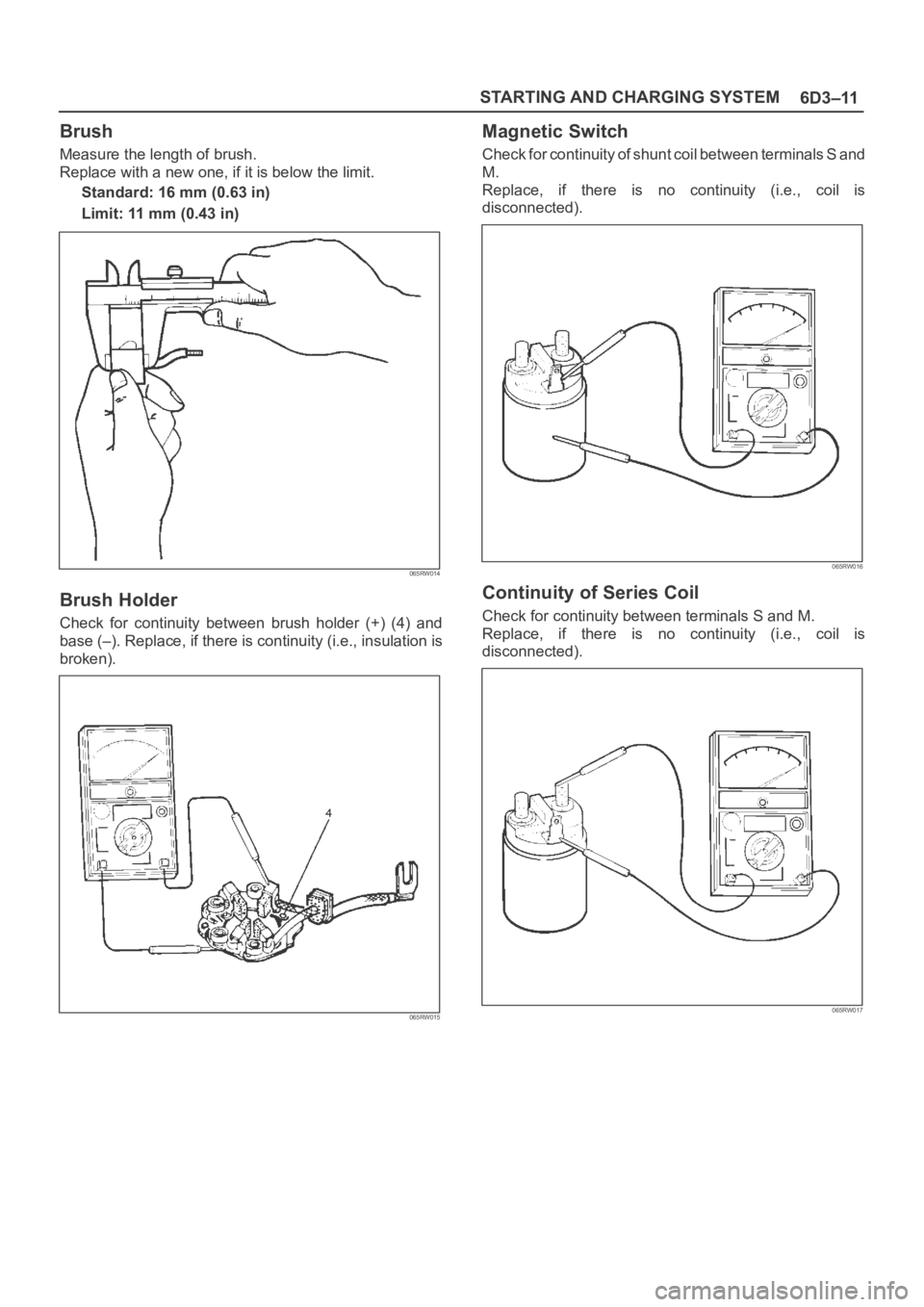

Brush

Measure the length of brush.

Replace with a new one, if it is below the limit.

Standard: 16 mm (0.63 in)

Limit: 11 mm (0.43 in)

065RW014

Brush Holder

Check for continuity between brush holder (+) (4) and

base (–). Replace, if there is continuity (i.e., insulation is

broken).

065RW015

Magnetic Switch

Check for continuity of shunt coil between terminals S and

M.

Replace, if there is no continuity (i.e., coil is

disconnected).

065RW016

Continuity of Series Coil

Check for continuity between terminals S and M.

Replace, if there is no continuity (i.e., coil is

disconnected).

065RW017