oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1076 of 6000

6C–9

ENGINE FUEL

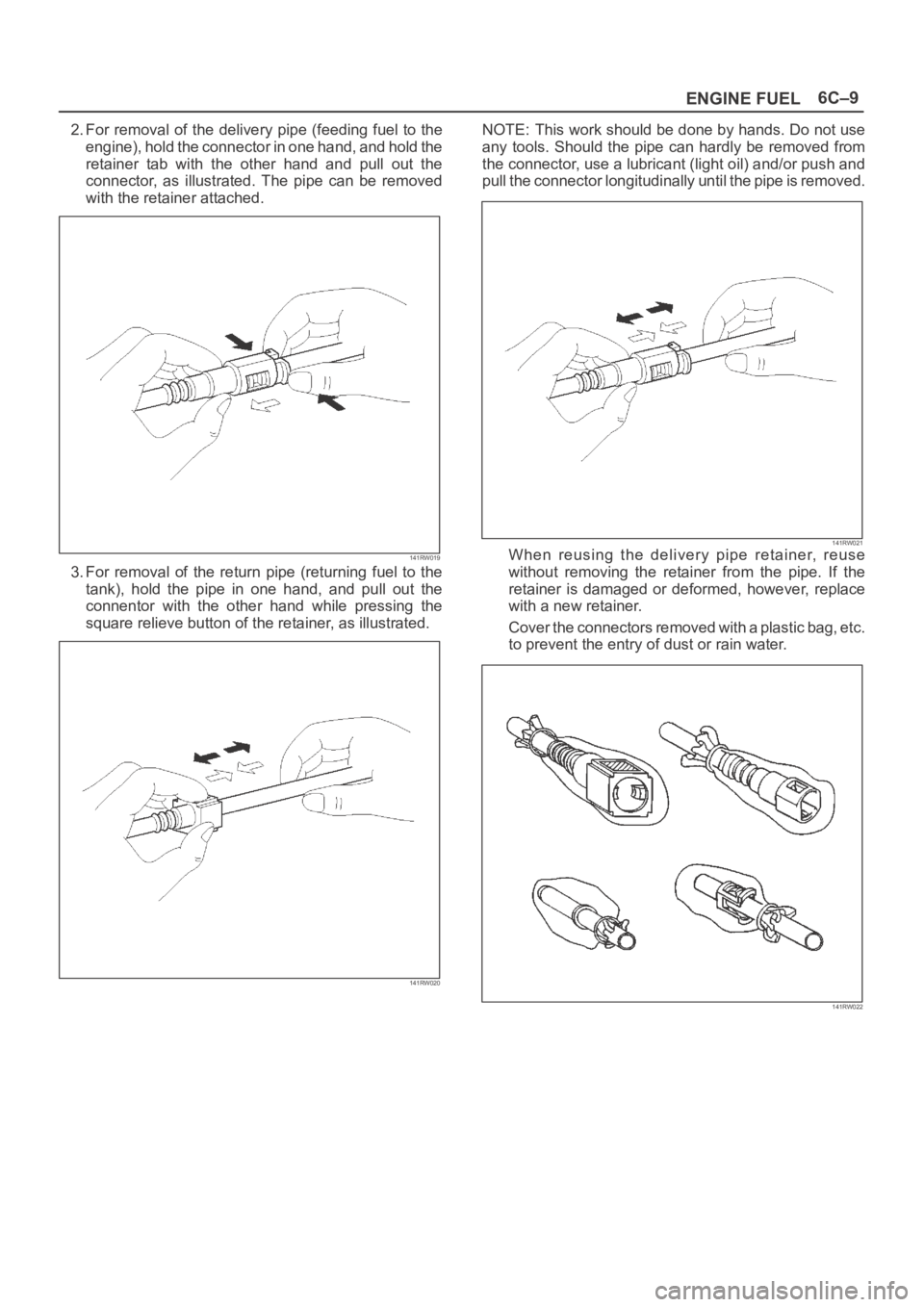

2. For removal of the delivery pipe (feeding fuel to the

engine), hold the connector in one hand, and hold the

retainer tab with the other hand and pull out the

connector, as illustrated. The pipe can be removed

with the retainer attached.

141RW019

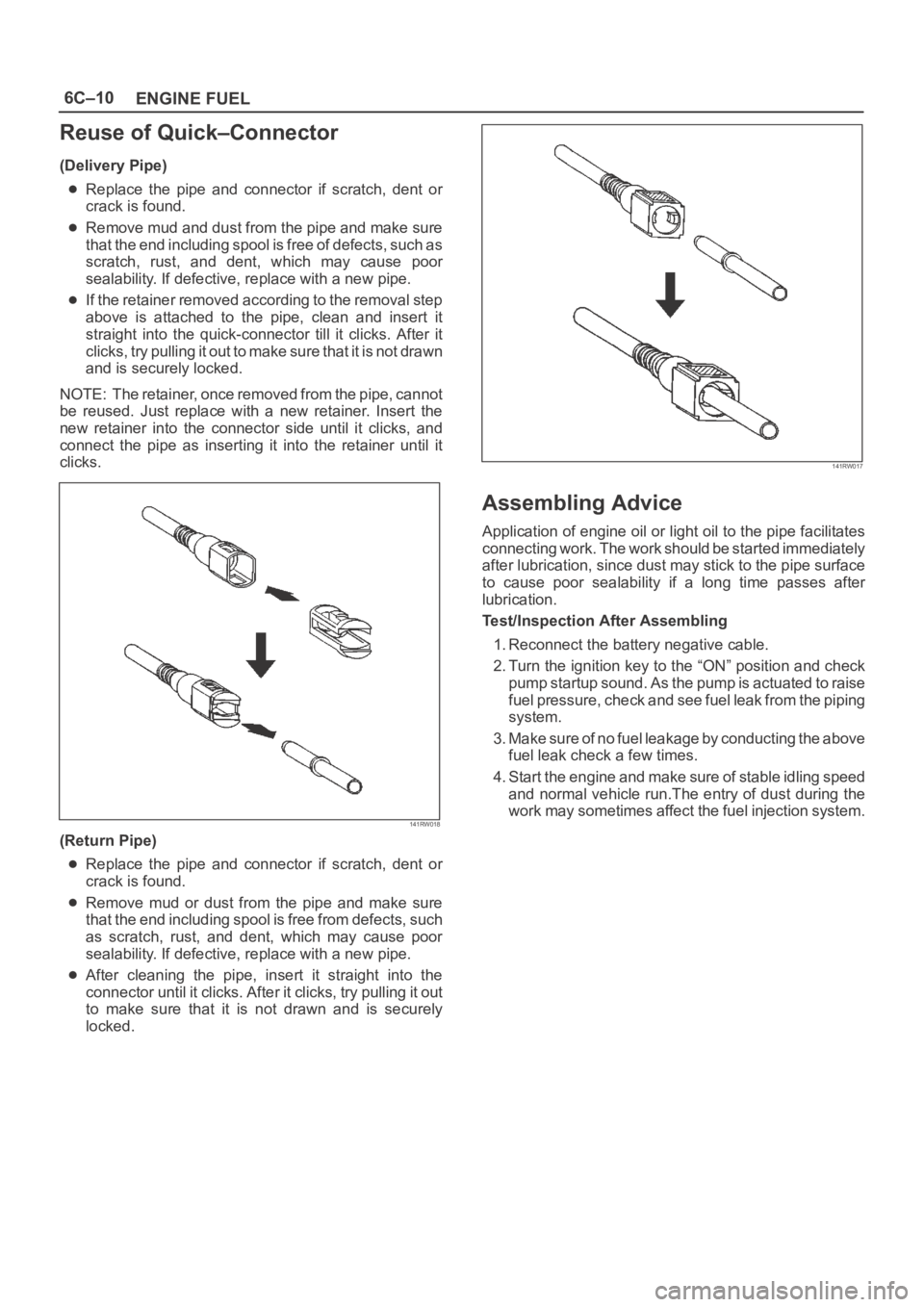

3. For removal of the return pipe (returning fuel to the

tank), hold the pipe in one hand, and pull out the

connentor with the other hand while pressing the

square relieve button of the retainer, as illustrated.

141RW020

NOTE: This work should be done by hands. Do not use

any tools. Should the pipe can hardly be removed from

the connector, use a lubricant (light oil) and/or push and

pull the connector longitudinally until the pipe is removed.

141RW021When reusing the delivery pipe retainer, reuse

without removing the retainer from the pipe. If the

retainer is damaged or deformed, however, replace

with a new retainer.

Cover the connectors removed with a plastic bag, etc.

to prevent the entry of dust or rain water.

141RW022

Page 1077 of 6000

6C–10

ENGINE FUEL

Reuse of Quick–Connector

(Delivery Pipe)

Replace the pipe and connector if scratch, dent or

crack is found.

Remove mud and dust from the pipe and make sure

that the end including spool is free of defects, such as

scratch, rust, and dent, which may cause poor

sealability. If defective, replace with a new pipe.

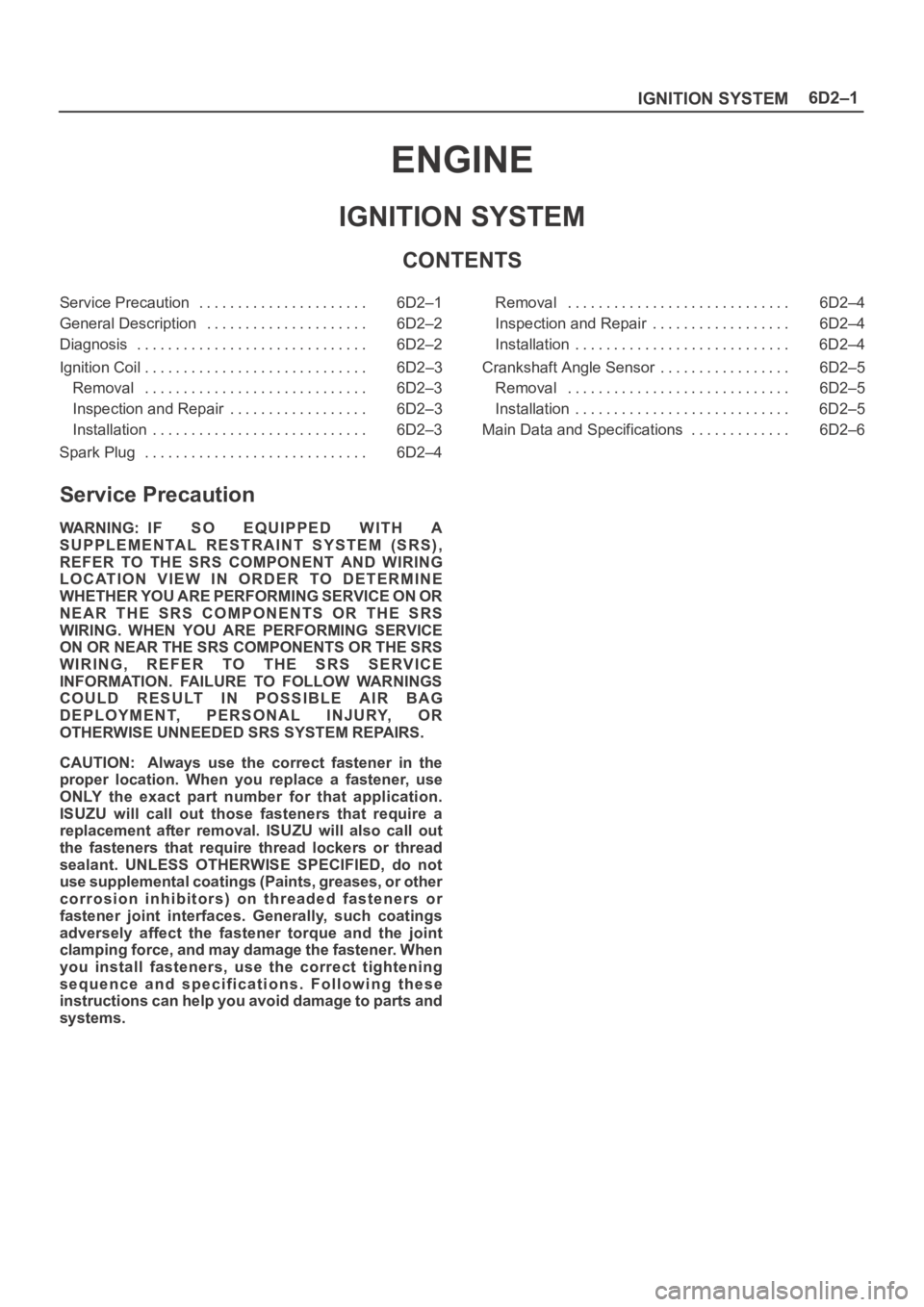

If the retainer removed according to the removal step

above is attached to the pipe, clean and insert it

straight into the quick-connector till it clicks. After it

clicks, try pulling it out to make sure that it is not drawn

and is securely locked.

NOTE: The retainer, once removed from the pipe, cannot

be reused. Just replace with a new retainer. Insert the

new retainer into the connector side until it clicks, and

connect the pipe as inserting it into the retainer until it

clicks.

141RW018

(Return Pipe)

Replace the pipe and connector if scratch, dent or

crack is found.

Remove mud or dust from the pipe and make sure

that the end including spool is free from defects, such

as scratch, rust, and dent, which may cause poor

sealability. If defective, replace with a new pipe.

After cleaning the pipe, insert it straight into the

connector until it clicks. After it clicks, try pulling it out

to make sure that it is not drawn and is securely

locked.

141RW017

Assembling Advice

Application of engine oil or light oil to the pipe facilitates

connecting work. The work should be started immediately

after lubrication, since dust may stick to the pipe surface

to cause poor sealability if a long time passes after

lubrication.

Test/Inspection After Assembling

1. Reconnect the battery negative cable.

2. Turn the ignition key to the “ON” position and check

pump startup sound. As the pump is actuated to raise

fuel pressure, check and see fuel leak from the piping

system.

3. Make sure of no fuel leakage by conducting the above

fuel leak check a few times.

4. Start the engine and make sure of stable idling speed

and normal vehicle run.The entry of dust during the

work may sometimes affect the fuel injection system.

Page 1086 of 6000

6D2–1

IGNITION SYSTEM

ENGINE

IGNITION SYSTEM

CONTENTS

Service Precaution 6D2–1. . . . . . . . . . . . . . . . . . . . . .

General Description 6D2–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 6D2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Coil 6D2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D2–3. . . . . . . . . . . . . . . . . .

Installation 6D2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 6D2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Removal 6D2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D2–4. . . . . . . . . . . . . . . . . .

Installation 6D2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Angle Sensor 6D2–5. . . . . . . . . . . . . . . . .

Removal 6D2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D2–6. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1087 of 6000

6D2–2

IGNITION SYSTEM

General Description

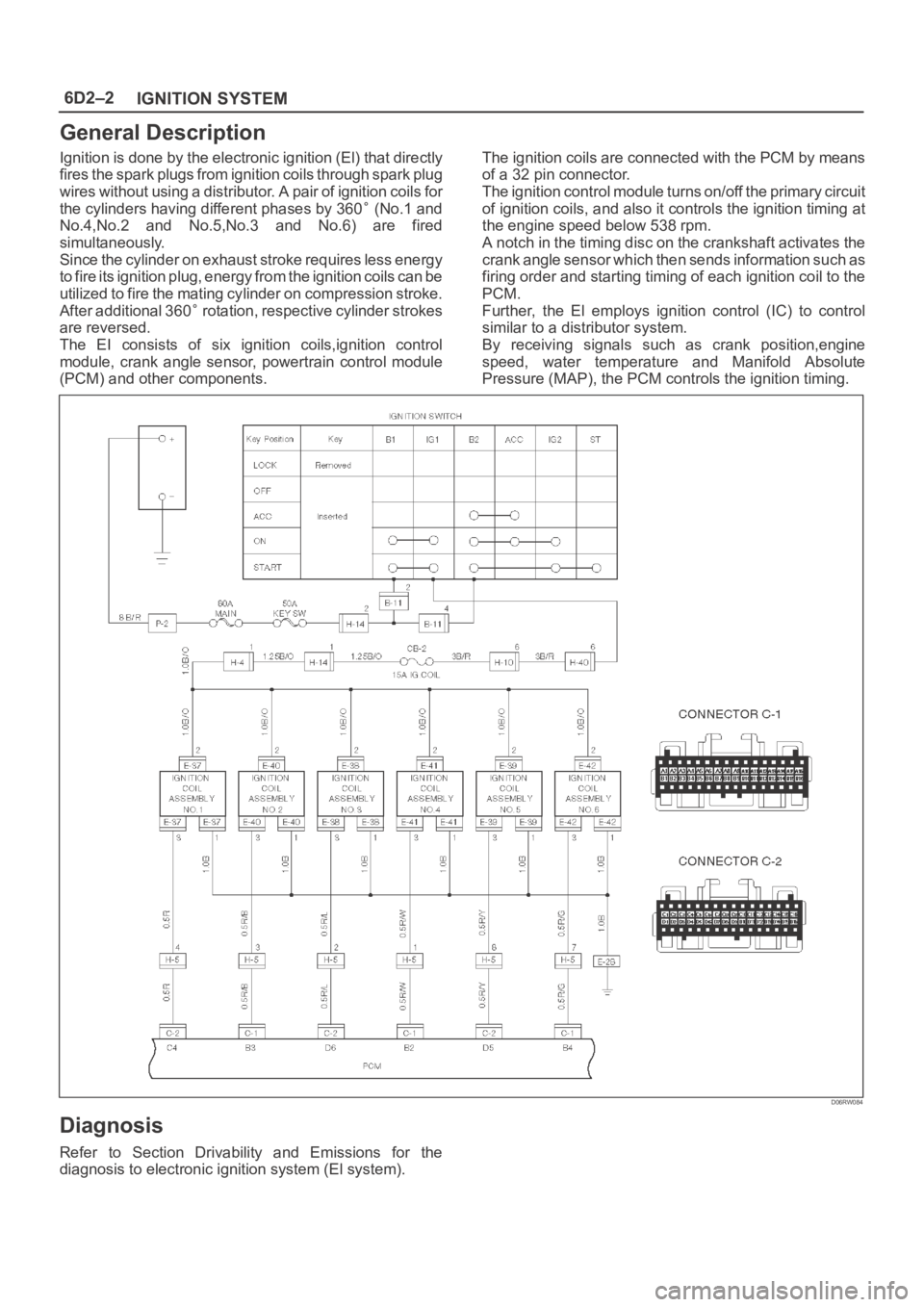

Ignition is done by the electronic ignition (El) that directly

fires the spark plugs from ignition coils through spark plug

wires without using a distributor. A pair of ignition coils for

the cylinders having different phases by 360

(No.1 and

No.4,No.2 and No.5,No.3 and No.6) are fired

simultaneously.

Since the cylinder on exhaust stroke requires less energy

to fire its ignition plug, energy from the ignition coils can be

utilized to fire the mating cylinder on compression stroke.

After additional 360

rotation, respective cylinder strokes

are reversed.

The EI consists of six ignition coils,ignition control

module, crank angle sensor, powertrain control module

(PCM) and other components.The ignition coils are connected with the PCM by means

of a 32 pin connector.

The ignition control module turns on/off the primary circuit

of ignition coils, and also it controls the ignition timing at

the engine speed below 538 rpm.

A notch in the timing disc on the crankshaft activates the

crank angle sensor which then sends information such as

firing order and starting timing of each ignition coil to the

PCM.

Further, the El employs ignition control (IC) to control

similar to a distributor system.

By receiving signals such as crank position,engine

speed, water temperature and Manifold Absolute

Pressure (MAP), the PCM controls the ignition timing.

D06RW084

Diagnosis

Refer to Section Drivability and Emissions for the

diagnosis to electronic ignition system (El system).

Page 1088 of 6000

6D2–3

IGNITION SYSTEM

Ignition Coil

Removal

1. Disconnect battery ground cable.

2. Ignition coil connector and ignition coil.

Disconnect three connector from ignition coil.

Remove harness bracket bolt on cylinder head

cover.

Remove fixing bolts on ignition coil.

060RW121

Legend

(1) Ignition Coil Connector

(2) Bolt

(3) Ignition Coil Assembly

Inspection and Repair

Check the ignition coil assembly for insulation. Check

terminals for corrosion or damage, and replace as

necessary.

Measuring resistance of ignition coil assembly.

Terminal No.

Limit

1 to 2Without 0 ohm or infinity

maximum ohm.

1 to 3Same as above

2 to 3Same as above

Measure resistance of ignition coil assembly, and replace

the ignition coil assembly if its value exceeds the

standard.

060RW006

Installation

1. Install the ignition coil assembly (3).

Connect ignition coil connector (1) and ignition coil

(3), then tighten bolt (2) to the specified torque.

Torque: 4 Nꞏm (0.4 Kgꞏm/35 lb in)

060RW121

2. Connect battery ground cable.

Page 1089 of 6000

6D2–4

IGNITION SYSTEM

Spark Plug

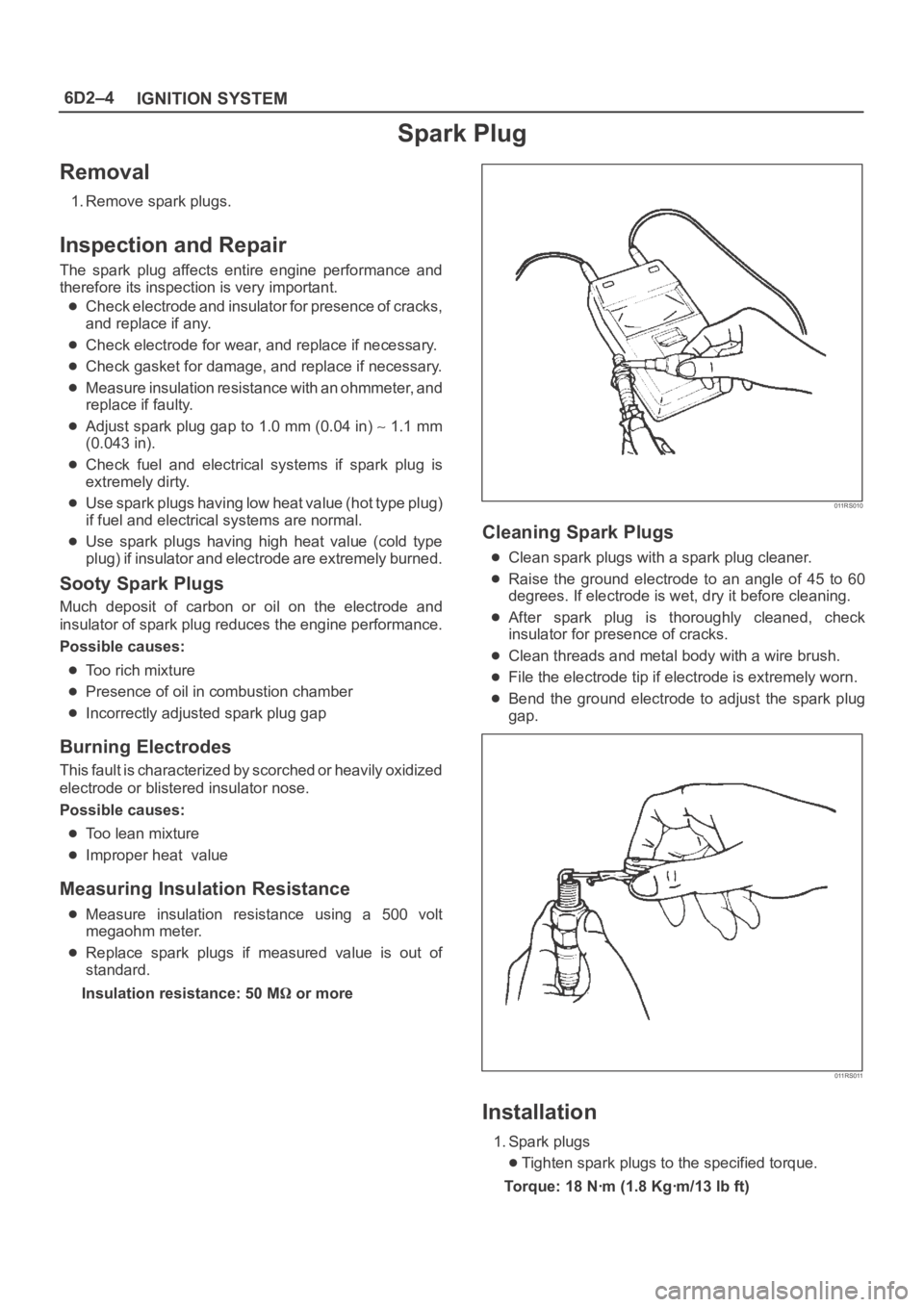

Removal

1. Remove spark plugs.

Inspection and Repair

The spark plug affects entire engine performance and

therefore its inspection is very important.

Check electrode and insulator for presence of cracks,

and replace if any.

Check electrode for wear, and replace if necessary.

Check gasket for damage, and replace if necessary.

Measure insulation resistance with an ohmmeter, and

replace if faulty.

Adjust spark plug gap to 1.0 mm (0.04 in) 1.1 mm

(0.043 in).

Check fuel and electrical systems if spark plug is

extremely dirty.

Use spark plugs having low heat value (hot type plug)

if fuel and electrical systems are normal.

Use spark plugs having high heat value (cold type

plug) if insulator and electrode are extremely burned.

Sooty Spark Plugs

Much deposit of carbon or oil on the electrode and

insulator of spark plug reduces the engine performance.

Possible causes:

Too rich mixture

Presence of oil in combustion chamber

Incorrectly adjusted spark plug gap

Burning Electrodes

This fault is characterized by scorched or heavily oxidized

electrode or blistered insulator nose.

Possible causes:

Too lean mixture

Improper heat value

Measuring Insulation Resistance

Measure insulation resistance using a 500 volt

megaohm meter.

Replace spark plugs if measured value is out of

standard.

Insulation resistance: 50 M

or more

011RS010

Cleaning Spark Plugs

Clean spark plugs with a spark plug cleaner.

Raise the ground electrode to an angle of 45 to 60

degrees. If electrode is wet, dry it before cleaning.

After spark plug is thoroughly cleaned, check

insulator for presence of cracks.

Clean threads and metal body with a wire brush.

File the electrode tip if electrode is extremely worn.

Bend the ground electrode to adjust the spark plug

gap.

011RS011

Installation

1. Spark plugs

Tighten spark plugs to the specified torque.

Torque: 18 Nꞏm (1.8 Kgꞏm/13 lb ft)

Page 1090 of 6000

6D2–5

IGNITION SYSTEM

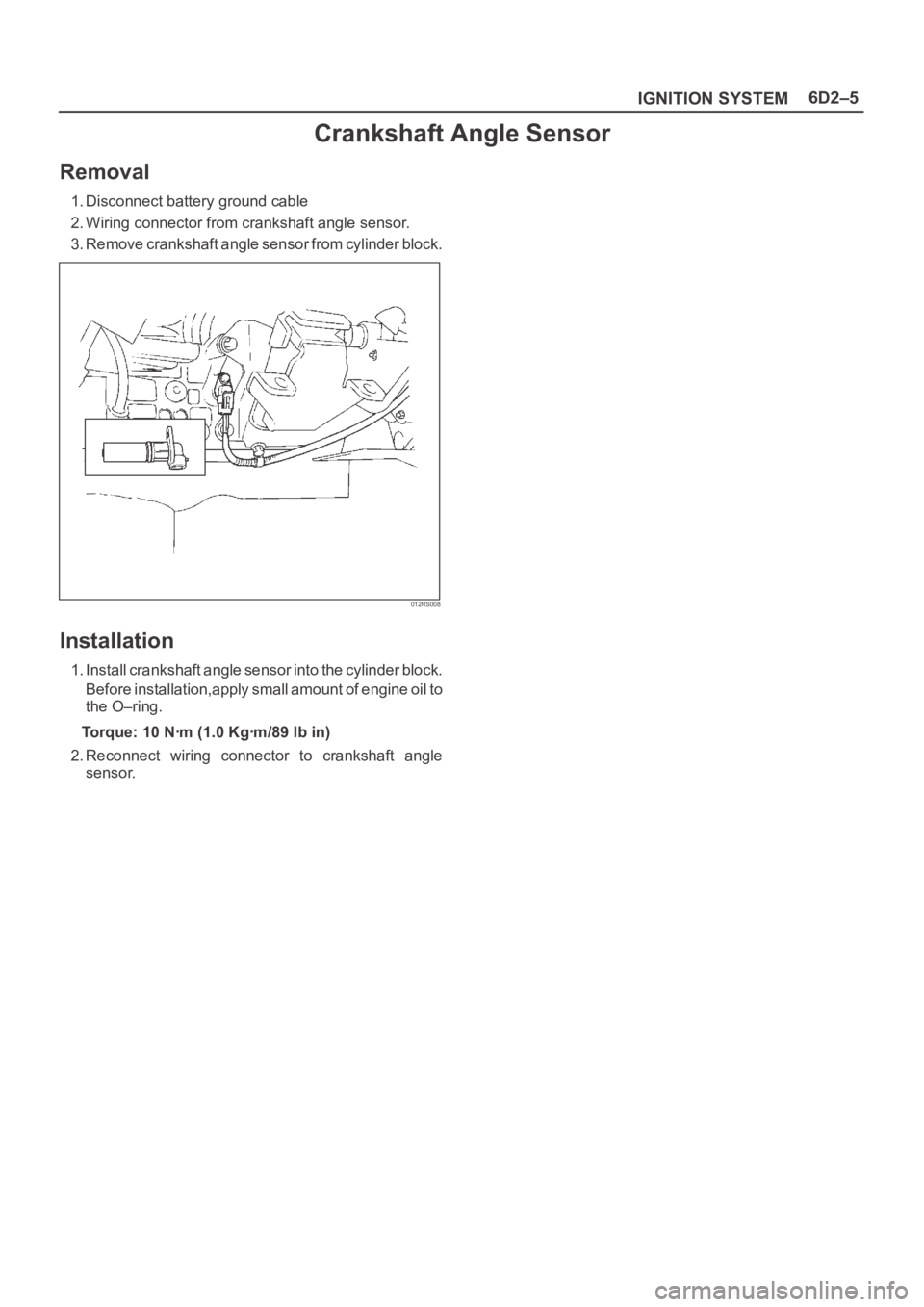

Crankshaft Angle Sensor

Removal

1. Disconnect battery ground cable

2. Wiring connector from crankshaft angle sensor.

3. Remove crankshaft angle sensor from cylinder block.

012RS008

Installation

1. Install crankshaft angle sensor into the cylinder block.

Before installation,apply small amount of engine oil to

the O–ring.

Torque: 10 Nꞏm (1.0 Kgꞏm/89 lb in)

2. Reconnect wiring connector to crankshaft angle

sensor.

Page 1102 of 6000

6D3–11 STARTING AND CHARGING SYSTEM

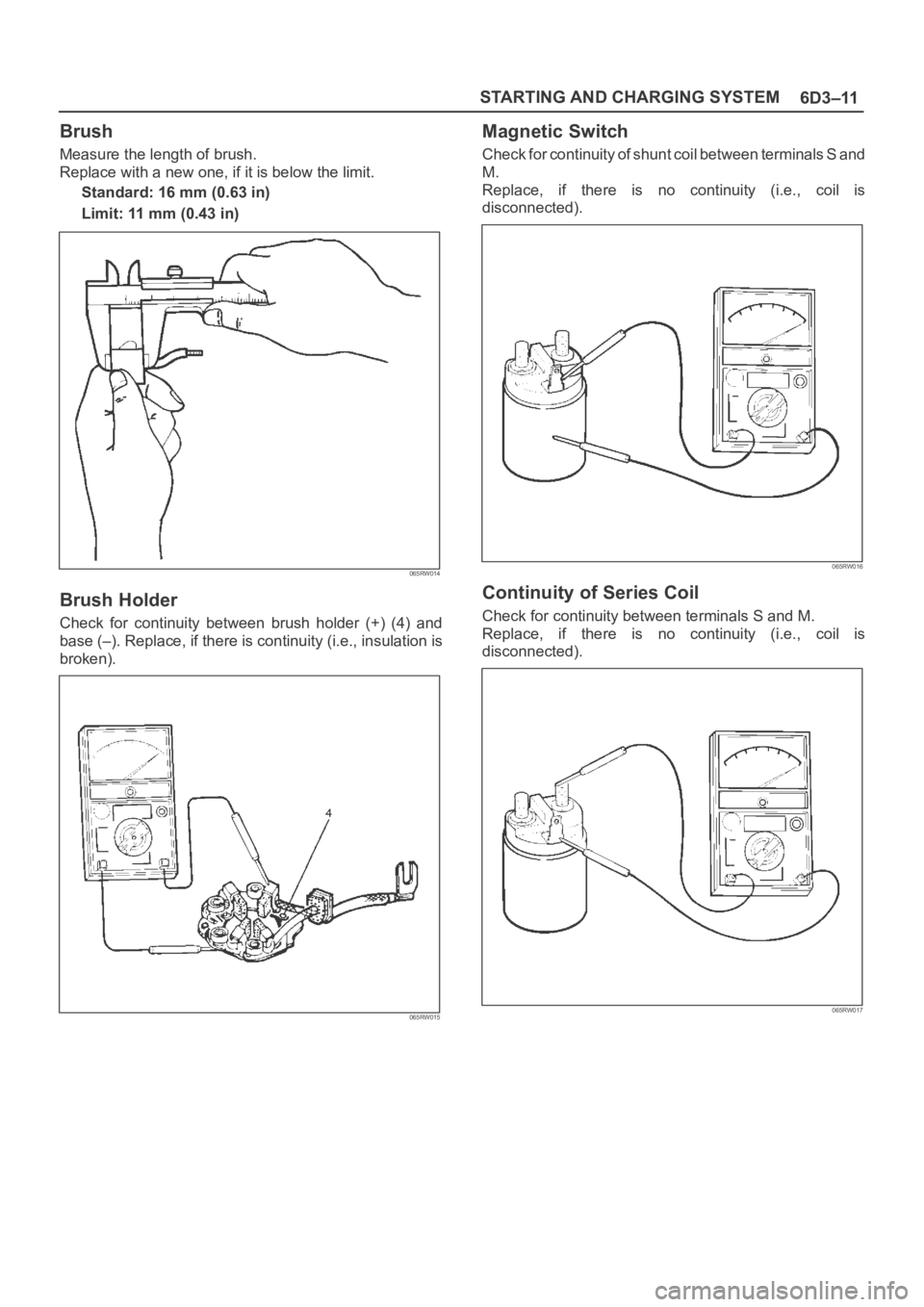

Brush

Measure the length of brush.

Replace with a new one, if it is below the limit.

Standard: 16 mm (0.63 in)

Limit: 11 mm (0.43 in)

065RW014

Brush Holder

Check for continuity between brush holder (+) (4) and

base (–). Replace, if there is continuity (i.e., insulation is

broken).

065RW015

Magnetic Switch

Check for continuity of shunt coil between terminals S and

M.

Replace, if there is no continuity (i.e., coil is

disconnected).

065RW016

Continuity of Series Coil

Check for continuity between terminals S and M.

Replace, if there is no continuity (i.e., coil is

disconnected).

065RW017

Page 1109 of 6000

6D3–18STARTING AND CHARGING SYSTEM

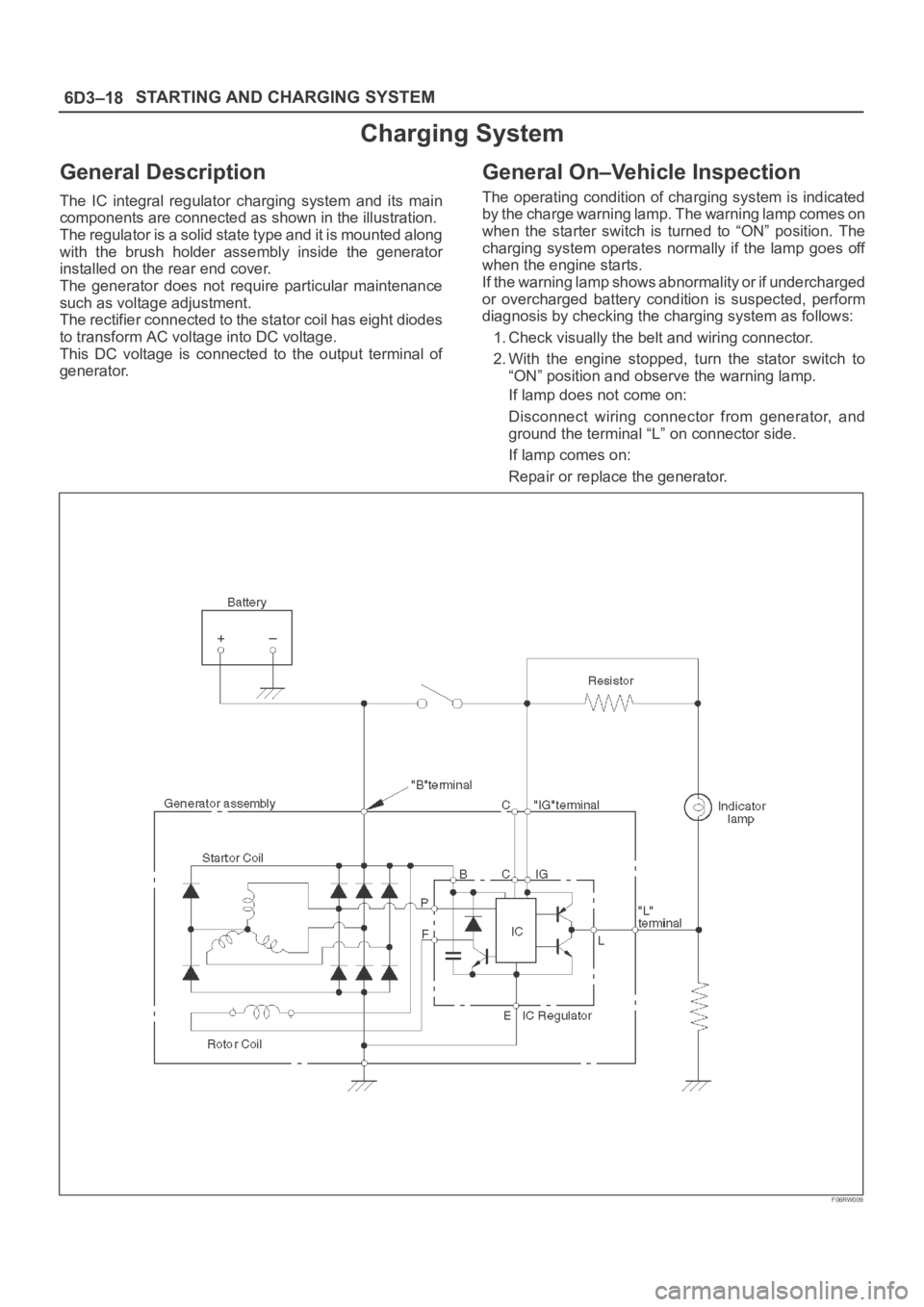

Charging System

General Description

The IC integral regulator charging system and its main

components are connected as shown in the illustration.

The regulator is a solid state type and it is mounted along

with the brush holder assembly inside the generator

installed on the rear end cover.

The generator does not require particular maintenance

such as voltage adjustment.

The rectifier connected to the stator coil has eight diodes

to transform AC voltage into DC voltage.

This DC voltage is connected to the output terminal of

generator.

General On–Vehicle Inspection

The operating condition of charging system is indicated

by the charge warning lamp. The warning lamp comes on

when the starter switch is turned to “ON” position. The

charging system operates normally if the lamp goes off

when the engine starts.

If the warning lamp shows abnormality or if undercharged

or overcharged battery condition is suspected, perform

diagnosis by checking the charging system as follows:

1. Check visually the belt and wiring connector.

2. With the engine stopped, turn the stator switch to

“ON” position and observe the warning lamp.

If lamp does not come on:

Disconnect wiring connector from generator, and

ground the terminal “L” on connector side.

If lamp comes on:

Repair or replace the generator.

F06RW009

Page 1115 of 6000

6D3–24STARTING AND CHARGING SYSTEM

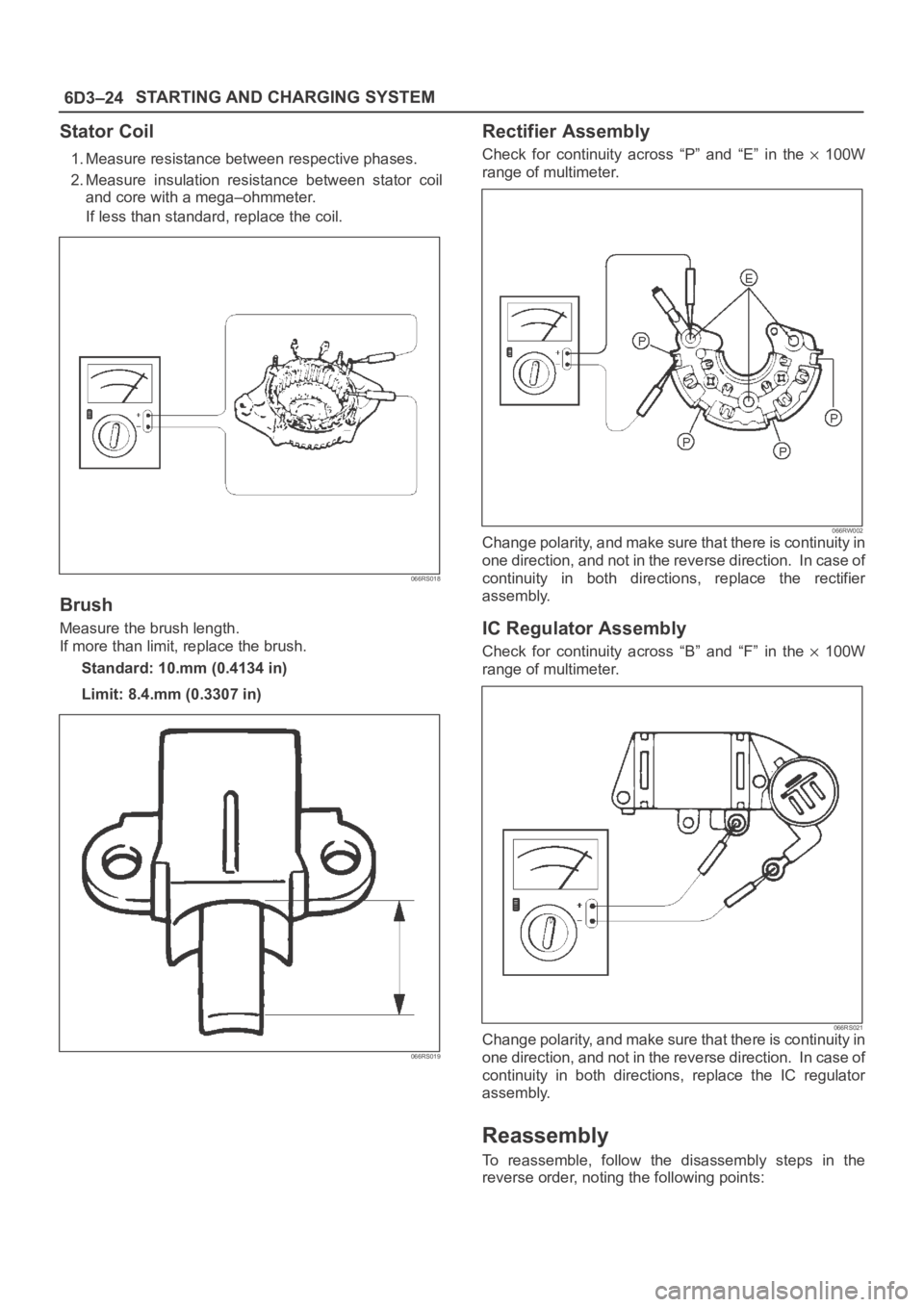

Stator Coil

1. Measure resistance between respective phases.

2. Measure insulation resistance between stator coil

and core with a mega–ohmmeter.

If less than standard, replace the coil.

066RS018

Brush

Measure the brush length.

If more than limit, replace the brush.

Standard: 10.mm (0.4134 in)

Limit: 8.4.mm (0.3307 in)

066RS019

Rectifier Assembly

Check for continuity across “P” and “E” in the 100W

range of multimeter.

066RW002Change polarity, and make sure that there is continuity in

one direction, and not in the reverse direction. In case of

continuity in both directions, replace the rectifier

assembly.

IC Regulator Assembly

Check for continuity across “B” and “F” in the 100W

range of multimeter.

066RS021Change polarity, and make sure that there is continuity in

one direction, and not in the reverse direction. In case of

continuity in both directions, replace the IC regulator

assembly.

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points: