coolant level OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 967 of 6000

6A–11

ENGINE MECHANICAL

Condition CorrectionPossible cause

Engine overheatingLevel of Engine Coolant too lowReplenish

Fan clutch defectiveReplace

Incorrect fan installedReplace

Thermostat defectiveReplace

Engine Coolant pump defectiveCorrect or replace

Radiator cloggedClean or replace

Radiator filler cap defectiveReplace

Level of oil in engine crankcase too

low or wrong engine oilChange or replenish

Resistance in exhaust system

increasedClean exhaust system or replace

defective parts

Throttle Position Sensor adjustment

incorrectReplace with Throttle Valve ASM

Throttle Position Sensor circuit open

or shortedCorrect or replace

Cylinder head gasket damagedReplace

Engine overcoolingThermostat defectiveReplace (Use a thermostat set to

open at 82

C (180F))

Engine lacks compression————Refer to Hard Start

OthersTire inflation pressure abnormalAdjust to recommended pressures

Brake dragAdjust

Clutch slippingAdjust or replace

Level of oil in engine crankcase too

highCorrect level of engine oil

Exhaust Gas Recirculation Valve

defectiveReplace

Engine Noisy

Abnormal engine noise often consists of various noises

originating in rotating parts, sliding parts and othermoving parts of the engine. It is, therefore, advisable to

locate the source of noise systematically.

Condition

Possible causeCorrection

Noise from crank journals or from

crank bearings

(Faulty crank journals and crankOil clearance increased due to worn

crank journals or crank bearingsReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

yj

bearings usually make dull noise that

becomes more evident when

accelerating)Crankshaft out of roundReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

Crank bearing seizedCrank bearing seized. Replace crank

bearings and crankshaft or regrind

crankshaft and install the undersize

bearing

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with defectivebearing by listening for abnormal noise that stops when

spark plug is shorted out.

Page 995 of 6000

6A–39

ENGINE MECHANICAL

Valve Stem Oil Controller , Valve Spring and Valve Guide

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

Drain engine coolant.

3. Remove cylinder head assembly.

Refer to removal procedure for Cylinder Head in

this manual.

4. Remove camshaft.

Refer to removal procedure for Camshaft in this

manual.

5. Remove tappets with shim.

NOTE: Do not damage shim surface.

6. Remove valve springs using 5–8840–2446–0 valve

spring compressor and 5–8840–2547–0 valve spring

compressor adapter then remove upper valve spring

seat and lower seat.

014RW042

7. Remove oil controller using 5–8840–0623–0 oil

controller remover, remove each valve stem oil

controller.

8. Remove valve guide using 5–8840–2549–0 valve

guide replacer.

Installation

1. Install valve guide using 5–8840–2442–0 valve guide

installer.

2. Install oil controller using 5–8840–0624–0 oil

controller installer.

3. Install lower valve spring seat, valve spring and upper

valve spring seat then put split collars on the upper

spring seat, using 5–8840–2446–0 valve spring

compressor and 5–8840–2547–0 valve spring

compressor adapter to install the split collars.

014RW042

4. Install tappet with shim.

5. Install camshaft assembly.

Refer to installation procedure for Camshaft in this

manual.

6. Install cylinder head assembly.

Refer to installation procedure for Cylinder Head in

this manual.

7. Fill engine oil until full level.

8. Fill engine coolant.

Page 1058 of 6000

ENGINE COOLING6B–5

Diagnosis

Engine Cooling Trouble

ConditionPossible causeCorrection

Engine overheatingLow Engine Coolant levelReplenish

Incorrect fan installedReplace

Thermo meter unit faultyReplace

Faulty thermostatReplace

Faulty Engine Coolant temperature

sensorRepair or replace

Clogged radiatorClean or replace

Faulty radiator capReplace

Low engine oil level or use of

improper engine oilReplenish or change oil

Clogged exhaust systemClean exhaust system or replace

faulty parts

Faulty Throttle Position sensorReplace throttle valve assembly

Open or shorted Throttle Position

sensor circuitRepair or replace

Damaged cylinder head gasketReplace

Engine overcoolingFaulty thermostatReplace

Engine slow to warm–upFaulty thermostatReplace

Thermo unit faultyReplace

Page 1059 of 6000

6B–6

ENGINE COOLING

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order. The

engine coolant (EC) level should be between the “MIN”

and “MAX” lines of reserve tank when the engine is cold.

If low, check for leakage and add EC up to the “MAX” line.

There should not be any excessive deposit of rust or

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

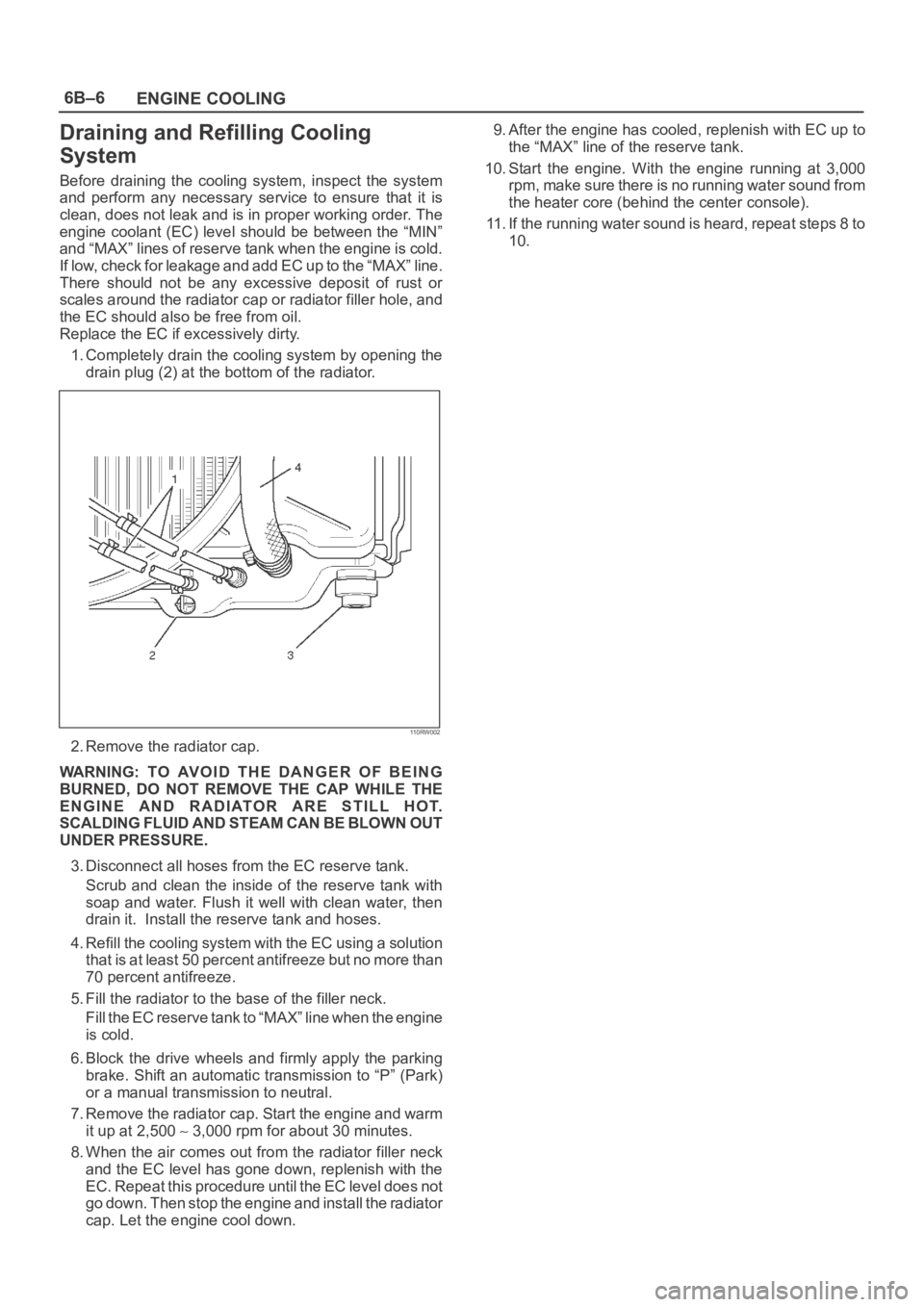

1. Completely drain the cooling system by opening the

drain plug (2) at the bottom of the radiator.

110RW002

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING

BURNED, DO NOT REMOVE THE CAP WHILE THE

ENGINE AND RADIATOR ARE STILL HOT.

SCALDING FLUID AND STEAM CAN BE BLOWN OUT

UNDER PRESSURE.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4. Refill the cooling system with the EC using a solution

that is at least 50 percent antifreeze but no more than

70 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the EC reserve tank to “MAX” line when the engine

is cold.

6. Block the drive wheels and firmly apply the parking

brake. Shift an automatic transmission to “P” (Park)

or a manual transmission to neutral.

7. Remove the radiator cap. Start the engine and warm

it up at 2,500

3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck

and the EC level has gone down, replenish with the

EC. Repeat this procedure until the EC level does not

go down. Then stop the engine and install the radiator

cap. Let the engine cool down.9. After the engine has cooled, replenish with EC up to

the “MAX” line of the reserve tank.

10. Start the engine. With the engine running at 3,000

rpm, make sure there is no running water sound from

the heater core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to

10.

Page 1064 of 6000

ENGINE COOLING6B–11

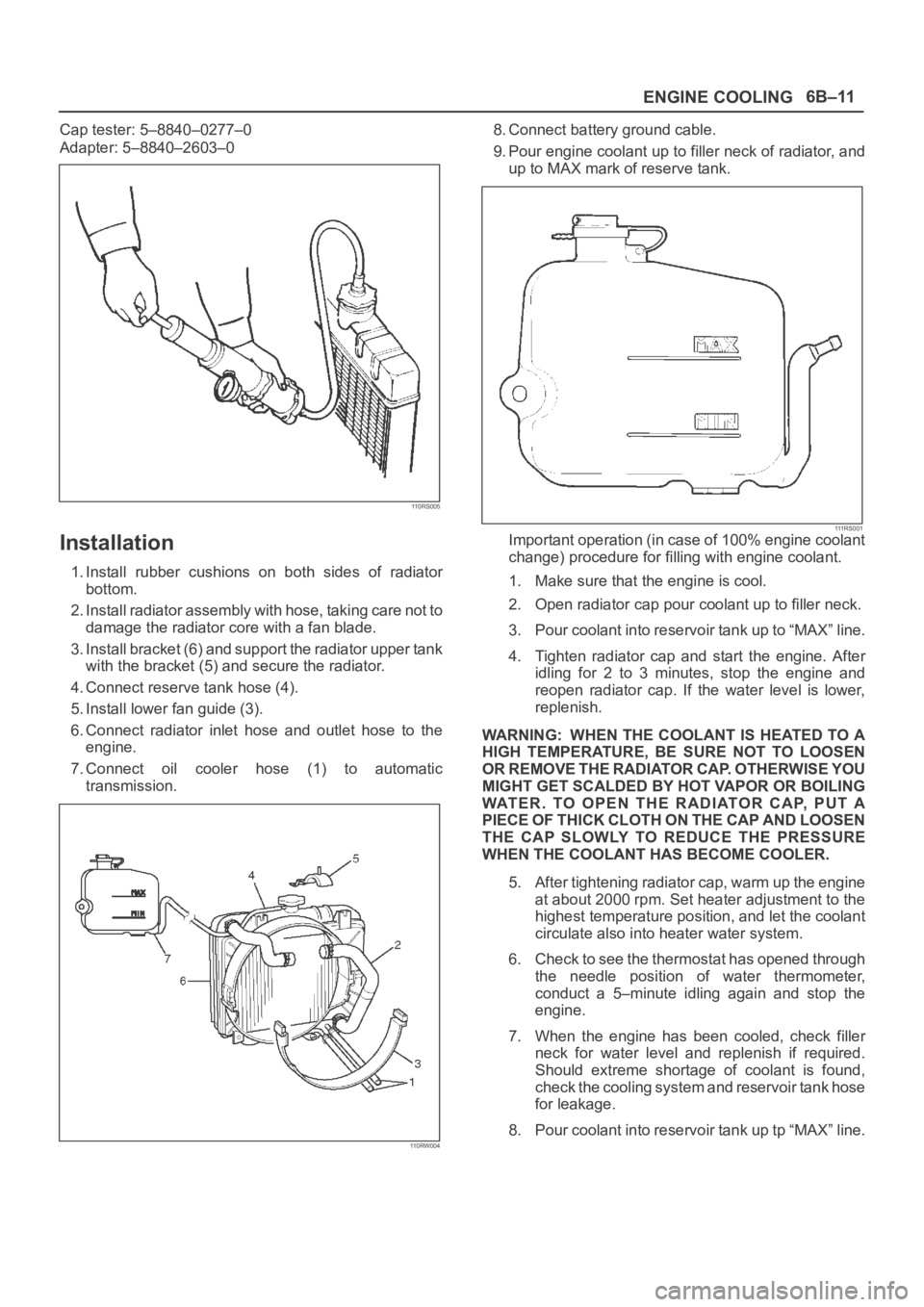

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

110RS005

Installation

1. Install rubber cushions on both sides of radiator

bottom.

2. Install radiator assembly with hose, taking care not to

damage the radiator core with a fan blade.

3. Install bracket (6) and support the radiator upper tank

with the bracket (5) and secure the radiator.

4. Connect reserve tank hose (4).

5. Install lower fan guide (3).

6. Connect radiator inlet hose and outlet hose to the

engine.

7. Connect oil cooler hose (1) to automatic

transmission.

110RW004

8. Connect battery ground cable.

9. Pour engine coolant up to filler neck of radiator, and

up to MAX mark of reserve tank.

111 R S 0 0 1Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

1. Make sure that the engine is cool.

2. Open radiator cap pour coolant up to filler neck.

3. Pour coolant into reservoir tank up to “MAX” line.

4. Tighten radiator cap and start the engine. After

idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.

WARNING: WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIATOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY HOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

5. After tightening radiator cap, warm up the engine

at about 2000 rpm. Set heater adjustment to the

highest temperature position, and let the coolant

circulate also into heater water system.

6. Check to see the thermostat has opened through

the needle position of water thermometer,

conduct a 5–minute idling again and stop the

engine.

7. When the engine has been cooled, check filler

neck for water level and replenish if required.

Should extreme shortage of coolant is found,

check the cooling system and reservoir tank hose

for leakage.

8. Pour coolant into reservoir tank up tp “MAX” line.

Page 1156 of 6000

6E–39 ENGINE DRIVEABILITY AND EMISSIONS

The data displayed on the other Tech 2 will appear the

same, with some exceptions. Some Tech 2s will only be

able to display certain vehicle parameters as values that

are a coded representation of the true or actual value. For

more information on this system of coding, refer to

Decimal/Binary/Hexadecimal Conversions. On this

vehicle Tech 2 displays the actual values for vehicle

parameters. It will not be necessary to perform any

conversions from coded values to actual values.

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The diagnostic test has passed during the current

ignition cycle.

The fault identified by the diagnostic test is not

currently active.

W h e n a d i a g n o s t i c t e s t r e p o r t s a fail result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The fault identified by the diagnostic test is currently

active.

The fault has been active during this ignition cycle.

The operating conditions at the time of the failure.

Remember, a fuel trim DTC may be triggered by a list of

vehicle faults. Make use of all information available (other

DTCs stored, rich or lean condition, etc.) when

diagnosing a fuel trim fault.

Comprehensive Component Monitor

Diagnostic Operation

Input Components:

Input components are monitored for circuit continuity and

out-of-range values. This includes rationality checking.

Rationality checking refers to indicating a fault when the

signal from a sensor does not seem reasonable, i.e.

Throttle Position (TP) sensor that indicates high throttle

position at low engine loads or MAP voltage. Input

components may include, but are not limited to the

following sensors:

Vehicle Speed Sensor (VSS)

Crankshaft Position (CKP) sensor

Knock Sensor (KS)

Throttle Position (TP) sensor

Engine Coolant Temperature (ECT) sensor

Camshaft Position (CMP) sensor

Manifold Absolute Pressure (MAP) sensor

Mass Air Flow (MAF) sensorIn addition to the circuit continuity and rationality check,

the ECT sensor is monitored for its ability to achieve a

steady state temperature to enable closed loop fuel

control.

Output Components:

Output components are diagnosed for proper response to

control module commands. Components where

functional monitoring is not feasible will be monitored for

circuit continuity and out-of-range values if applicable.

Output components to be monitored include, but are not

limited to, the following circuits:

Idle Air Control (IAC) Motor

Electronic Transmission controls

A/C relays

Cooling fan relay

VSS output

MIL control

Cruise control inhibit

Refer to PCM and Sensors in General Descriptions.

Passive and Active Diagnostic Tests

A passive test is a diagnostic test which simply monitors a

vehicle system or component. Conversely, an active test,

actually takes some sort of action when performing

diagnostic functions, often in response to a failed passive

test. For example, the EGR diagnostic active test will

force the EGR valve open during closed throttle decel

and/or force the EGR valve closed during a steady state.

Either action should result in a change in manifold

pressure.

Intrusive Diagnostic Tests

This is any on-board test run by the Diagnostic

Management System which may have an effect on

vehicle performance or emission levels.

Warm-Up Cycle

A warm-up cycle means that engine at temperature must

reach a minimum of 70

C (160F) and rise at least 22C

(40

F) over the course of a trip.

Freeze Frame

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emissions-related fault is

stored in memory and when the MIL is commanded on.

These data can help to identify the cause of a fault. Refer

to

Storing And Erasing Freeze Fame Data for more

detailed information.

Failure Records

Failure Records data is an enhancement of the OBD

Freeze Frame feature. Failure Records store the same

vehicle information as does Freeze Frame, but it will store

that information for any fault which is stored in on-board

memory, while Freeze Frame stores information only for

emission-related faults that command the MIL on.

Page 1158 of 6000

6E–41 ENGINE DRIVEABILITY AND EMISSIONS

If the MIL was set by either a fuel trim or misfire-related

DTC, additional requirements must be met. In addition to

the requirements stated in the previous paragraph, these

requirements are as follows:

The diagnostic tests that are passed must occur with

375 RPM of the RPM data stored at the time the last

test failed.

Plus or minus ten (10) percent of the engine load that

was stored at the time the last failed.

Similar engine temperature conditions (warmed up or

warming up ) as those stored at the time the last test

failed.

Meeting these requirements ensures that the fault which

turned on the MIL has been corrected.

The MIL (“Check Engine” lamp) is on the instrument

panel and has the following function:

It informs the driver that a fault affects vehicle emission

levels has occurred and that the vehicle should be

taken for service as soon as possible.

As a bulb and system check, the MIL will come “ON”

with the key “ON” and the engine not running. When

the engine is started, the MIL will turn “OFF.”

When the MIL remains “ON” while the engine is

running, or when a malfunction is suspected due to a

driveability or emissions problem, a Powertrain

On-Board Diagnostic (OBD ll) System Check must be

performed. The procedures for these checks are given

in On-Board Diagnostic (OBD) System Check. These

checks will expose faults which may not be detected if

other diagnostics are performed first.

DTC Types

Each DTC is directly related to a diagnostic test. The

Diagnostic Management System sets DTC based on the

failure of the tests during a trip or trips. Certain tests must

fail two (2) consecutive trips before the DTC is set. The

following are the four (4) types of DTCs and the

characteristics of those codes:

Ty p e A

Emissions related

Requests illumination of the MIL of the first trip with a

fail

Stores a History DTC on the first trip with a fail

Stores a Freeze Frame (if empty)

Stores a Fail Record

Updates the Fail Record each time the diagnostic

test fails

Ty p e B

Emissions related

“Armed” after one (1) trip with a fail

“Disarmed” after one (1) trip with a pass

Requests illumination of the MIL on the second

consecutive trip

with a fail

Stores a History DTC on the second consecutive trip

with a fail (The DTC will be armed after the first fail)

Stores a Freeze Frame on the second consecutive

trip with a fail (if empty)

Stores a Fail Record when the first test fails (not

dependent on

consecutive trip fails)

Updates the Fail Record each time the diagnostic

test fails

Type C (if the vehicle is so equipped)

Non-Emissions related

Requests illumination of the Service Lamp or the

service message on the Drive Information Center

(DIC) on the

first trip with a fail

Stores a History DTC on the first trip with a fail

Does not store a Freeze Frame

Stores Fail Record when test fails

Updates the Fail Record each time the diagnostic

test fails

Type D (Ty p e D non-emissions related are not utilized

on certain vehicle applications).

Non-Emissions related

Dose not request illumination of any lamp

Stores a History DTC on the first trip with a fail

Does not store a Freeze Frame

Stores Fail Record when test fails

Updates the Fail Record each time the diagnostic

test fails

IMPORTANT:Only four Fail Records can be stored.

Each Fail Record is for a different DTC. It is possible that

there will not be Fail Records for every DTC if multiple

DTCs are set.

Storing and Erasing Freeze Frame Data and Failure

Records

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Data from these faults take precedence over data

associated with any other fault. The Freeze Frame data

will not be erased unless the associated history DTC is

cleared.

Each time a diagnostic test reports a failure, the current

engine operating conditions are recorded in the

Failure

Records

buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed

typically

include the following parameters:

Air Fuel Ratio

Air Flow Rate

Fuel Trim

Engine Speed

Engine Load

Engine Coolant Temperature

Vehicle Speed

TP Angle

MAP/BARO

Injector Base Pulse Width

Loop Status

Page 1182 of 6000

6E–65 ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor Diagnosis

The Tech 2 has two data displays available for diagnosing

the knock sensor (KS) system. The two displays are

described as follows:

“Knock Retard” indicates the number of degrees that

the spark timing is being retarded due to a knock

condition.

“KS Noise Channel” indicates the current voltage level

being monitored on the noise channel.

DTCs P0325 and P0327 are designed to diagnose the KS

module, the knock sensor, and the related wiring. The

problems encountered with the KS system should set a

DTC. However, if no DTC was set but the KS system is

suspect because of a detonation complaint, refer to

Detonation/Spark Knock in Symptoms.

Powertrain Control Module (PCM)

Diagnosis

To read and clear diagnostic trouble codes, use a Tech 2.

IMPORTANT:Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the PCM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition “OFF” and disconnecting the battery power

from the PCM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the PCM will cause

all diagnostic information in the PCM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re-run.

Since the PCM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the PCM connections

or the PCM is the cause of a problem, and the PCM is

replaced, but this does not correct the problem, one of the

following may be the reason:

There is a problem with the PCM terminal connections.

The terminals may have to be removed from the

connector in order to check them properly.

The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the

Symptoms p o r t i o n o f

the manual and make a careful physical inspection of

all component and wiring associated with the affected

system.

There is a shorted solenoid, relay coil, or harness.

S o l e n o i d s a n d r e l a y s a r e t u r n e d “ O N ” a n d “ O F F ” b y t h e

PCM using internal electronic switches called drivers.

A shorted solenoid, relay coil, or harness will not

damage the PCM but will cause the solenoid or relay to

be inoperative.

Multiple PCM Information Sensor

DTCS Set

Circuit Description

The powertrain control module (PCM) monitors various

sensors to determine the engine operating conditions.

The PCM controls fuel delivery, spark advance,

transmission operation, and emission control device

operation based on the sensor inputs.The PCM provides a sensor ground to all of the sensors.

The PCM applies 5 volts through a pull-up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5-volt supply

and the resistor:

The engine coolant temperature (ETC) sensor

The intake air temperature (IAT) sensor

The transmission fluid temperature (TFT) sensor

The PCM provides the following sensors with a 5-volt

reference and a sensor ground signal:

The exhaust gas recirculating (EGR) pintle position

sensor

The throttle position (TP) sensor

The manifold absolute pressure (MAP) sensor

The PCM monitors the separate feedback signals from

these sensors in order to determine their operating

status.

Diagnostic Aids

IMPORTANT:Be sure to inspect PCM and engine

grounds for being secure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

P0108

P0113

P0118

P0123

P0560

P0712

P0406

IMPORTANT:If a sensor input circuit has been shorted

to voltage, ensure that the sensor is not damaged. A

damaged sensor will continue to indicate a high or low

voltage after the affected circuit has been repaired. If the

sensor has been damaged, replace it.

An open in the sensor ground circuit between the PCM

and the splice will cause one or more of the following

DTCs to be set:

P0108

P0113

P0118

P0123

P0712

P0406

A short to ground in the 5-volt reference A or B circuit will

cause one or more of the following DTCs to be set:

P0107

P0122

In the 5-volt reference circuit A, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0122

In the 5-volt reference circuit B, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0107

Check for the following conditions:

Page 1392 of 6000

6E–275 ENGINE DRIVEABILITY AND EMISSIONS

Poor Fuel Economy Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Fuel economy, as measured by an actual road test, is

noticeably lower than expected. Also, economy is

noticeably lower than it was on this vehicle at one time,

as previously shown by an actual road test.

(Non-standard tires will cause odometer readings to be

incorrect, and that may cause fuel economy to appear

poor when it is actually normal.)

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

4Check owner’s driving habits.

Is the A/C “ON” full time (defroster mode “ON”)?

Are tires at the correct pressure?

Are excessively heavy loads being carried?

Is acceleration too much, too often?

Was a problem found?

—Go to Step 5Go to Step 6

5Review the items in Step 4 with the customer and

advise as necessary.

Is the action complete?

—System OK—

61. Visually/physically check: Vacuum hoses for splits,

kinks, and improper connections and routing as

shown on the “Vehicle Emission Control

Information” label.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Remove and check the air filter element for dirt or for

restrictions. Refer to

Air Intake System.

2. Replace the air filter element if necessary.

Was a repair required?

—Verify repairGo to Step 8

81. Remove spark plugs and check for wet plugs,

cracks, wear, improper gap, burned electrodes, or

heavy deposits. Refer to

Spark Plug Replacement.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check for low engine coolant level. Refer to Engine

Cooling

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

Page 1454 of 6000

6E–337 ENGINE DRIVEABILITY AND EMISSIONS

0018

Knock Sensor

Insufficient gasoline octane levels may cause detonation

in some engines. Detonation is an uncontrolled explosion

(burn) in the combustion chamber. This uncontrolled

explosion results from a flame front opposite that of the

normal flame front produced by the spark plug. The

rattling sound normally associated with detonation is the

result of two or more opposing pressures (flame fronts)

colliding within the combustion chamber. Light

detonation is sometimes considered normal, but heavy

detonation could result in engine damage.

A knock sensor system is used to control detonation. This

system is designed to retard spark timing up to 20

degrees to reduce detonation in the engine. This allows

the engine to use maximum spark advance to improve

driveability and fuel economy.

The knock sensor system has two major components:

The knock sensor (KS) module.

The knock sensor.

The knock sensor, mounted in the engine block near the

cylinders, detects abnormal vibration in the engine. The

sensor produces an AC output signal of about 10

millivolts. The signal amplitude and frequency are

dependent on the amount of knock being experienced.

The signal voltage increases with the severity of the

knock. This signal voltage is input to the PCM. The PCM

then retards the ignition control (IC) spark timing based

on the KS signal being received.

The PCM determines whether knock is occurring by

comparing the signal level on the KS circuit with the

voltage level on the noise channel. The noise channel

allows the PCM to reject any false knock signal by

indicating the amount of normal engine mechanical noise

present. Normal engine noise varies depending on the

engine speed and load. If the voltage level on the KS

noise channel circuit is below the range considered

normal, DTC P0327 will set, indicating a fault in the KScircuit or the knock sensor. If the PCM determines that an

abnormal minimum or maximum noise level is being

experienced, DTC P0325 will set.

The PCM contains a knock sensor (KS) module. The KS

module contains the circuitry which allows the PCM to

utilize the KS signal and diagnose the KS sensor and the

KS circuitry. If the KS module is missing or faulty, a

continuous knock condition will be indicated, and the

PCM will set DTC P0325.

Although it is a plug-in device, the KS module is not

replaceable. If the KS module is faulty, the entire PCM

must be replaced.

0009

Linear Exhaust Gas Recirculation (EGR)

Control

The PCM monitors the exhaust gas recirculation (EGR)

actual position and adjusts the pintle position accordingly.

The PCM uses information from the following sensors to

control the pintle position:

Engine coolant temperature (ECT) sensor.

Throttle position (TP) sensor.

Mass air flow (MAF) sensor.

Mass Air Flow (MAF) Sensor

The mass air flow (MAF) sensor measures the difference

between the volume and the quantity of air that enters the

engine. “Volume” means the size of the space to be filled.

“Quantity” means the number of air molecules that will fit

into the space. This information is important to the PCM

because heavier, denser air will hold more fuel than

lighter, thinner air. The PCM adjusts the air/fuel ratio as

needed depending on the MAF value. Tech 2 reads the

MAF value and displays it in terms of grams per second

(gm/s). At idle, Tech 2 should read between 4-7 gm/s on a

fully warmed up engine. Values should change quickly on

acceleration. Values should remain stable at any given