differential OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4041 of 6000

4A2B–34DIFFERENTIAL (REAR 244mm)

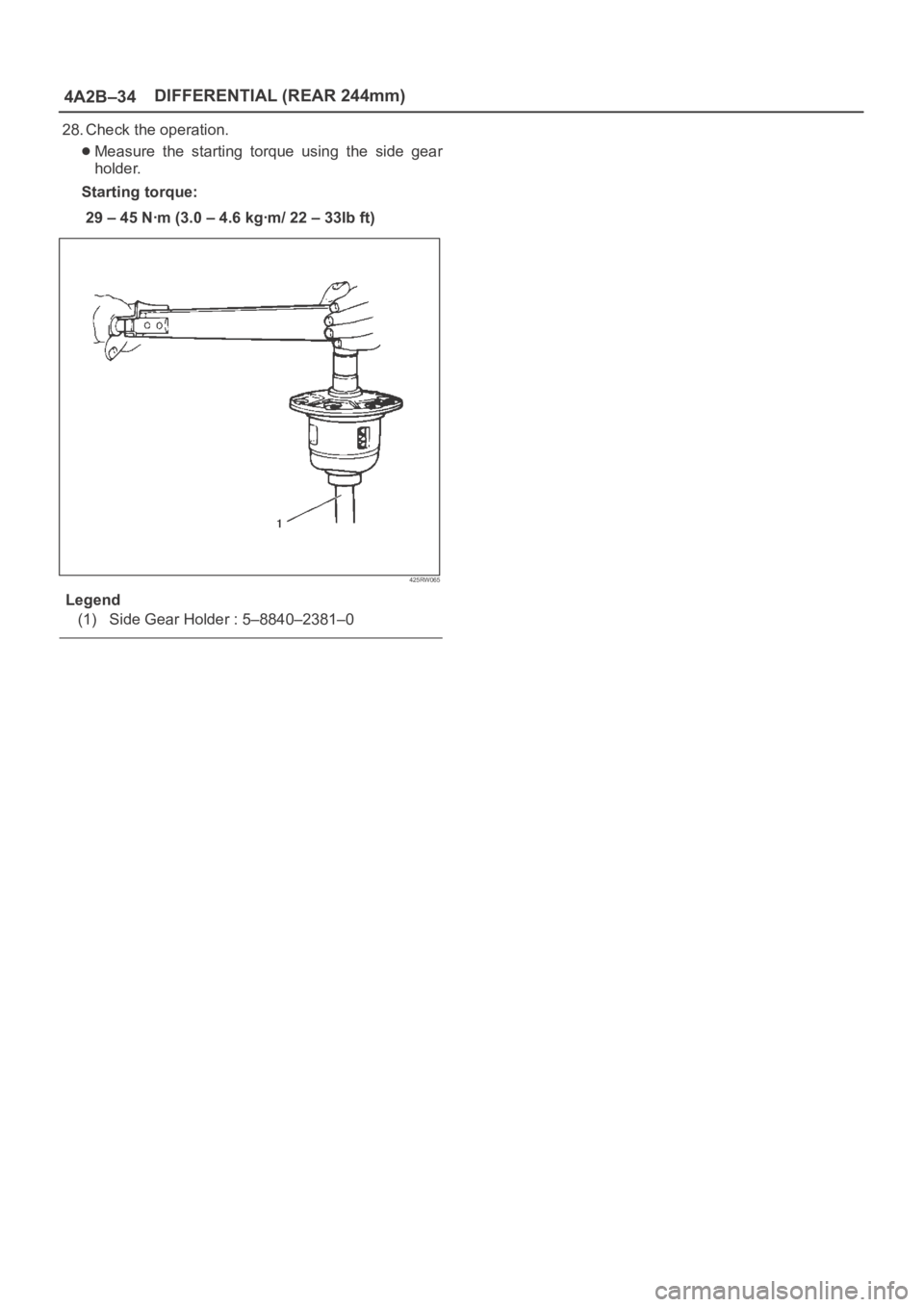

28. Check the operation.

Measure the starting torque using the side gear

holder.

Starting torque:

29–45Nꞏm(3.0–4.6kgꞏm/22–33Ibft)

425RW065

Legend

(1) Side Gear Holder : 5–8840–2381–0

Page 4042 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–35

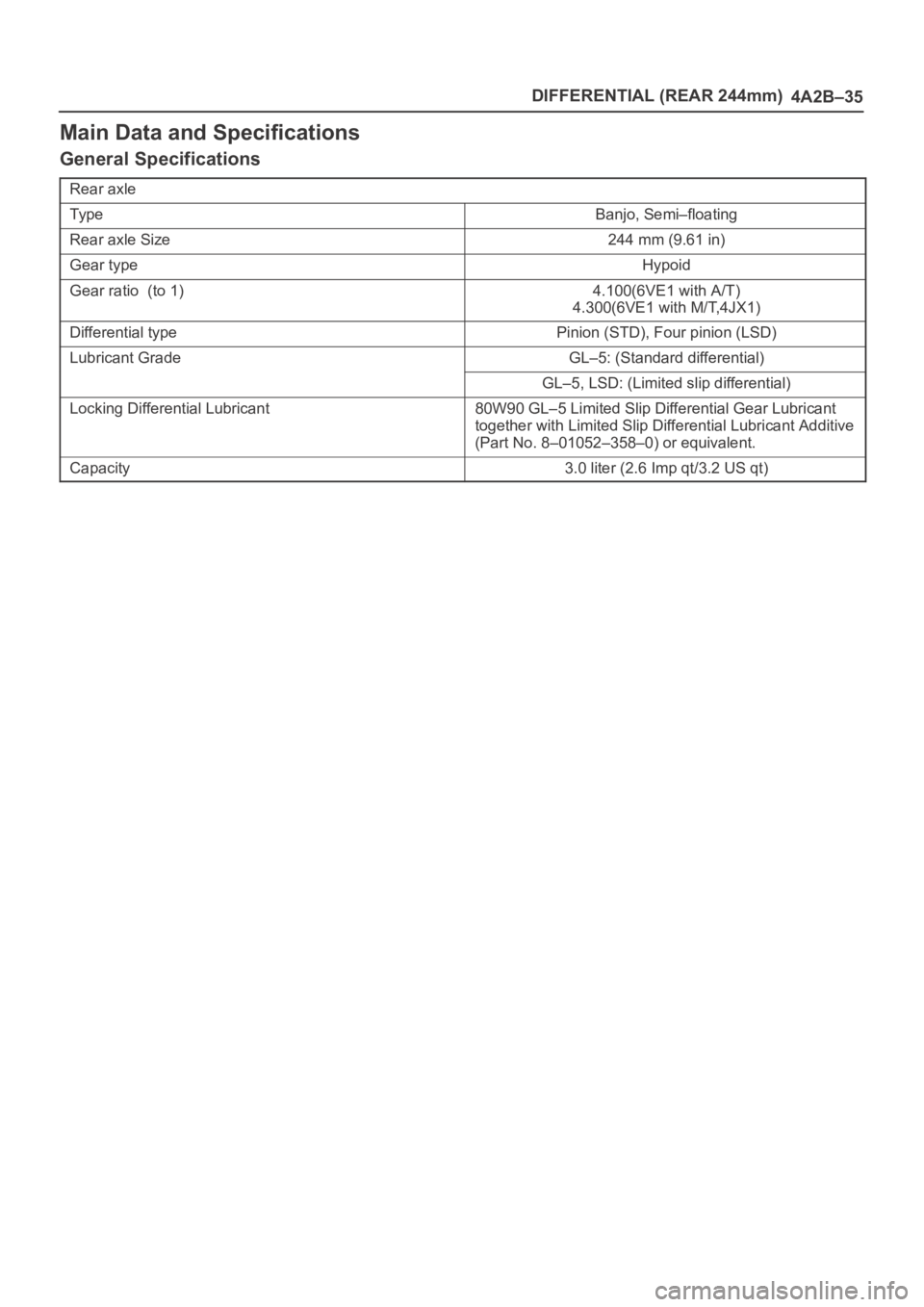

Main Data and Specifications

General Specifications

Rear axle

Ty p eBanjo, Semi–floating

Rear axle Size244 mm (9.61 in)

Gear typeHypoid

Gear ratio (to 1)4.100(6VE1 with A/T)

4.300(6VE1 with M/T,4JX1)

Differential typePinion (STD), Four pinion (LSD)

Lubricant GradeGL–5: (Standard differential)

GL–5, LSD: (Limited slip differential)

Locking Differential Lubricant80W90 GL–5 Limited Slip Differential Gear Lubricant

together with Limited Slip Differential Lubricant Additive

(Part No. 8–01052–358–0) or equivalent.

Capacity3.0 liter (2.6 Imp qt/3.2 US qt)

Page 4043 of 6000

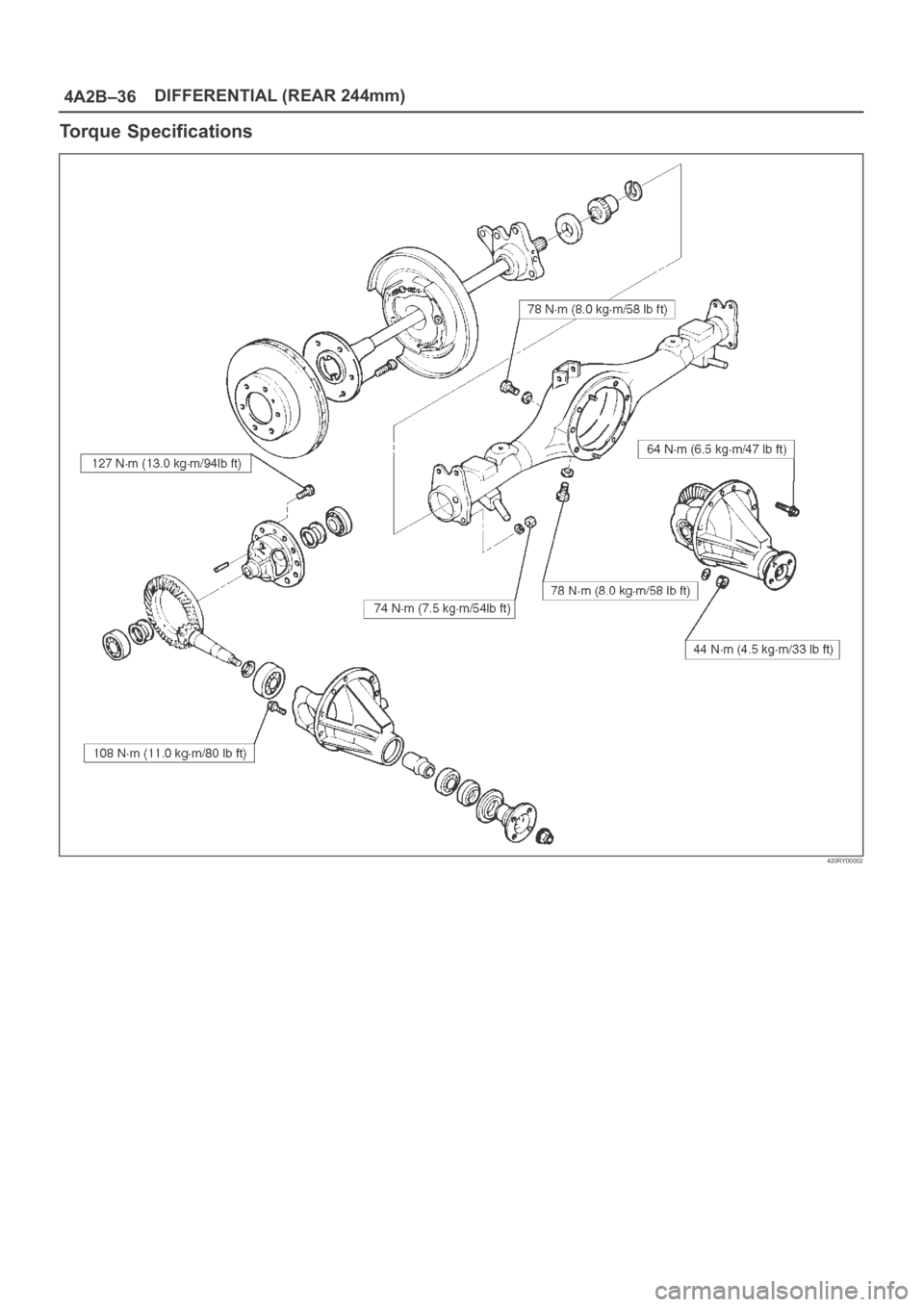

4A2B–36DIFFERENTIAL (REAR 244mm)

Torque Specifications

420RY00002

Page 4044 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–37

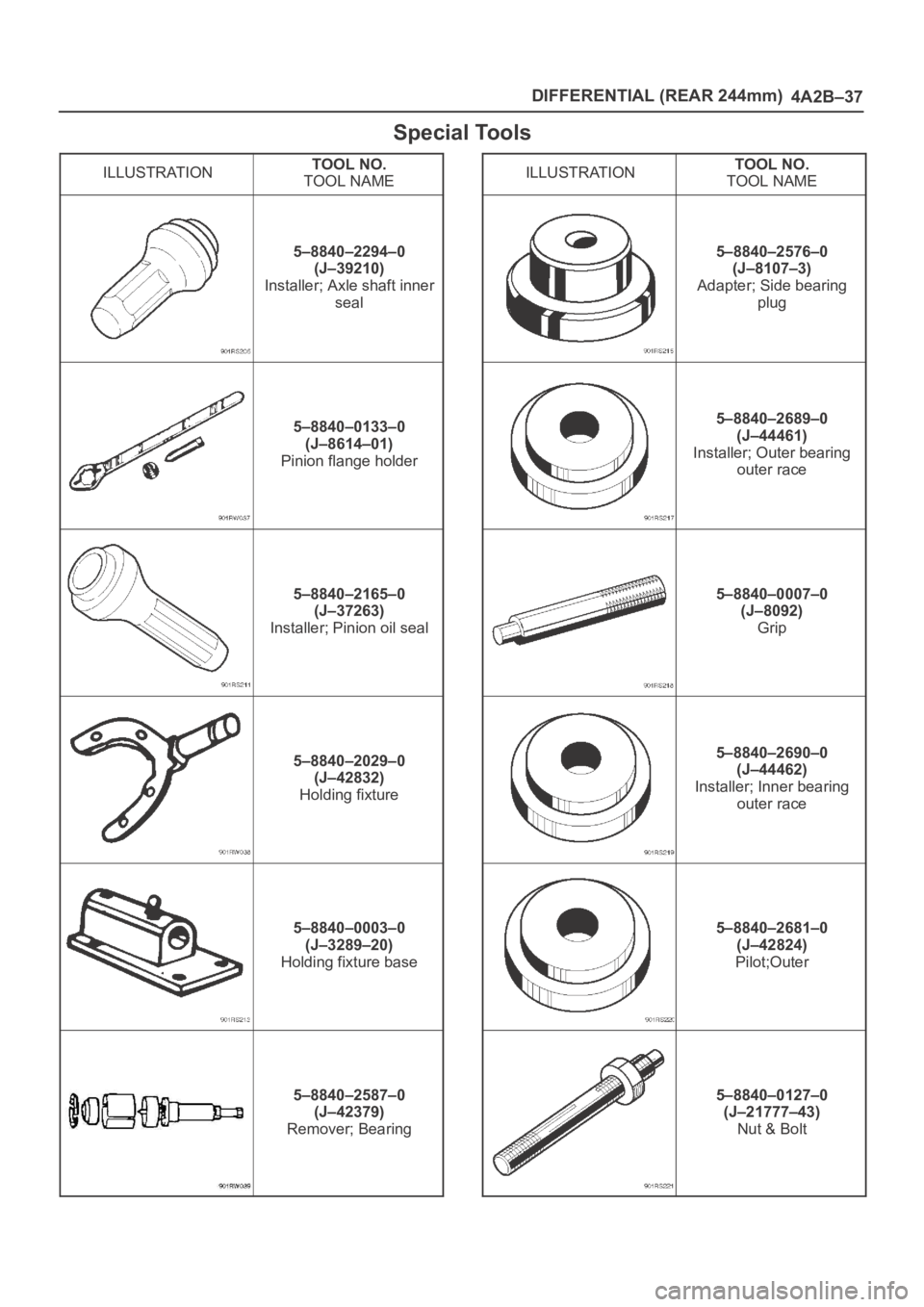

Special Tools

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2294–0

(J–39210)

Installer; Axle shaft inner

seal

5–8840–0133–0

(J–8614–01)

Pinion flange holder

5–8840–2165–0

(J–37263)

Installer; Pinion oil seal

5–8840–2029–0

(J–42832)

Holding fixture

5–8840–0003–0

(J–3289–20)

Holding fixture base

5–8840–2587–0

(J–42379)

Remover; Bearing

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2576–0

(J–8107–3)

Adapter; Side bearing

plug

5–8840–2689–0

(J–44461)

Installer; Outer bearing

outer race

5–8840–0007–0

(J–8092)

Grip

5–8840–2690–0

(J–44462)

Installer; Inner bearing

outer race

5–8840–2681–0

(J–42824)

Pilot;Outer

5–8840–0127–0

(J–21777–43)

Nut & Bolt

Page 4045 of 6000

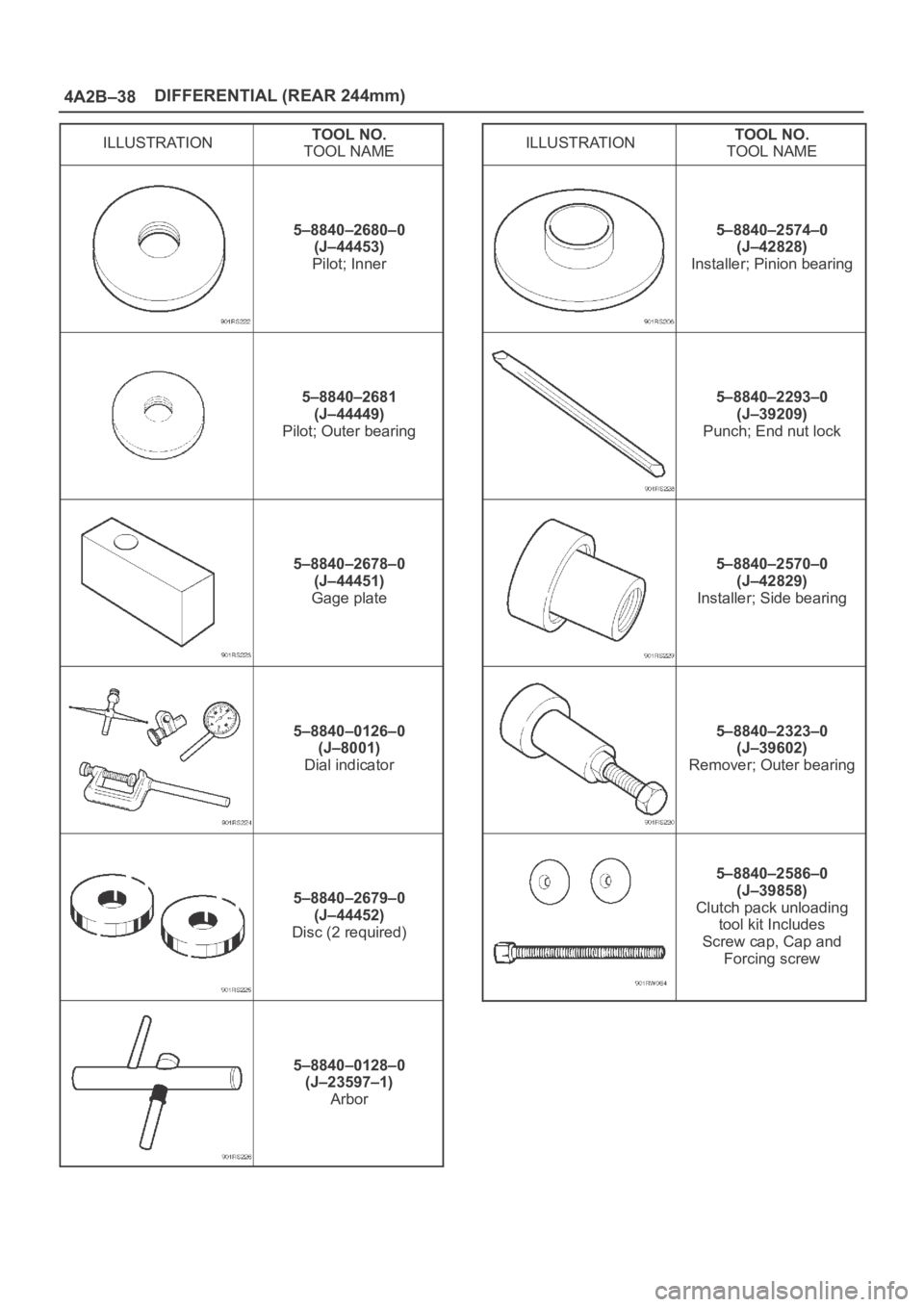

4A2B–38DIFFERENTIAL (REAR 244mm)

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2680–0

(J–44453)

Pilot; Inner

5–8840–2681

(J–44449)

Pilot; Outer bearing

5–8840–2678–0

(J–44451)

Gage plate

5–8840–0126–0

(J–8001)

Dial indicator

5–8840–2679–0

(J–44452)

Disc (2 required)

5–8840–0128–0

(J–23597–1)

Arbor

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2574–0

(J–42828)

Installer; Pinion bearing

5–8840–2293–0

(J–39209)

Punch; End nut lock

5–8840–2570–0

(J–42829)

Installer; Side bearing

5–8840–2323–0

(J–39602)

Remover; Outer bearing

5–8840–2586–0

(J–39858)

Clutch pack unloading

tool kit Includes

Screw cap, Cap and

Forcing screw

Page 4197 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–114

Diagnosis from Symptom

Troubles that are not indicated by the warning lamp are

listed in the table below. These troubles are caused by

the faults that cannot be detected by the self-diagnostic

function of the control unit.

If this type of trouble is observed, interview the customer

and conduct test runs to reproduce the trouble,

cross-check the reported trouble with the listed

phenomena, and diagnose and analyze the trouble on the

item by item basis.

PhenomenaMajor causeCorrective action

1The tight corner braking is

observed when the vehicle is

subject to full steering.The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

failed.

Check and recondition the

vehicle according to Chart 1.

2Even if the 4WD AUTO SW is

select to the 4WD position, the

4WD mode is not active, resulting

in remarkable rear wheel spin.The transfer or wiring is

imperfect.

The shift on the fly system is

failed.

Check and recondition the

vehicle according to Chart 2.

3When the 4WD AUTO SW is

selected to the 4WD position,

the drive resistance of the 4WD

system is too large to get

sufficient running speed.

Noised drive line.

The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

failed.

Check and recondition the

vehicle according to Chart 1.

4The shift on the fly system (front

axle) generates gear noises.The wiring is imperfect.

The shift on the fly system is

failed.

Check and recondition the

vehicle according to Chart 3.

5The braking distance gets long

even when the ABS is active.The wiring is imperfect.

The ABS is failed.

Check and recondition the

vehicle according to Chart 4.

Page 4199 of 6000

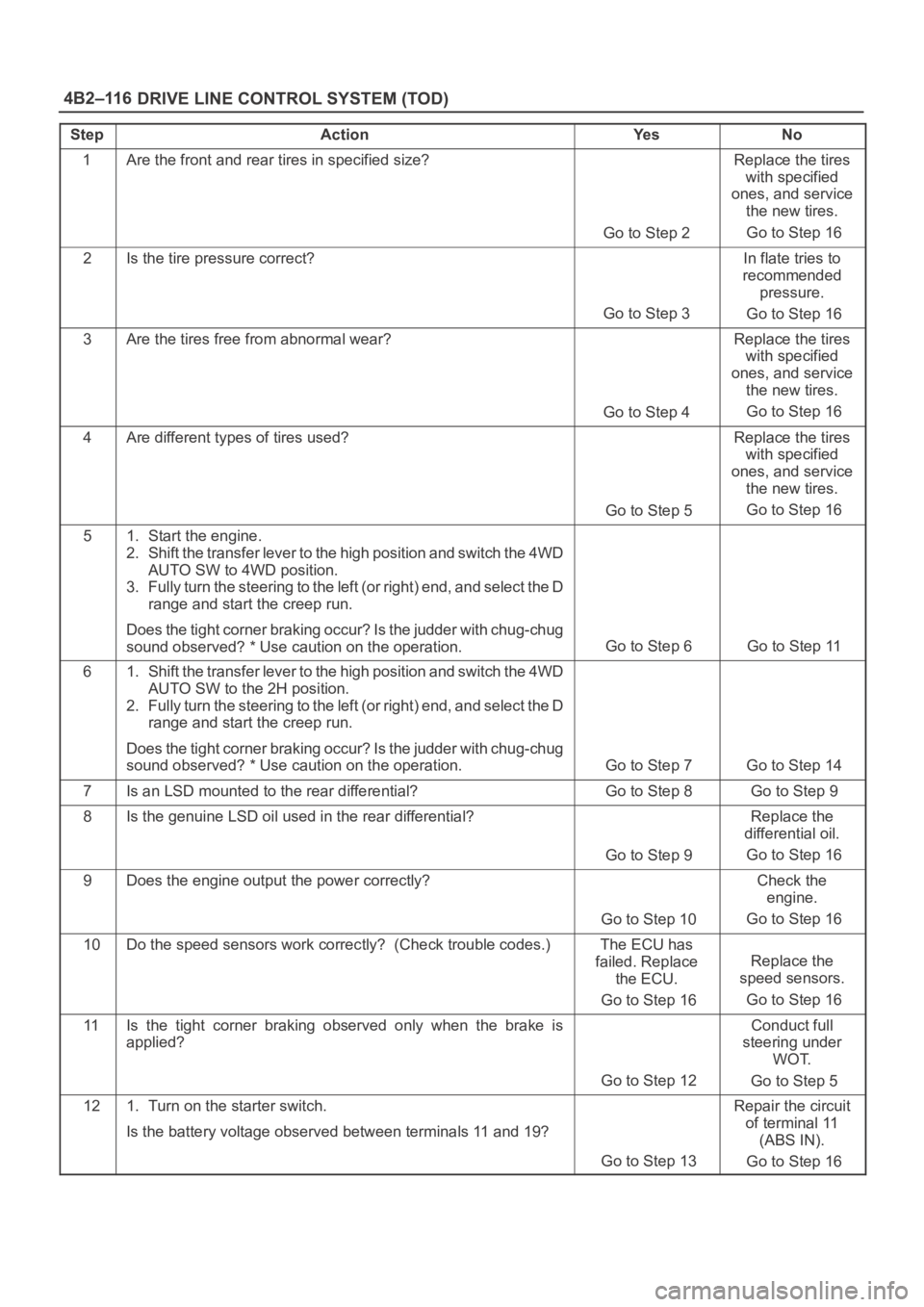

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–116

StepActionYe sNo

1Are the front and rear tires in specified size?

Go to Step 2

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

2Is the tire pressure correct?

Go to Step 3

In flate tries to

recommended

pressure.

Go to Step 16

3Are the tires free from abnormal wear?

Go to Step 4

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

4Are different types of tires used?

Go to Step 5

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

51. Start the engine.

2. Shift the transfer lever to the high position and switch the 4WD

AUTO SW to 4WD position.

3. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 6 Go to Step 11

61. Shift the transfer lever to the high position and switch the 4WD

AUTO SW to the 2H position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 7 Go to Step 14

7Is an LSD mounted to the rear differential? Go to Step 8 Go to Step 9

8Is the genuine LSD oil used in the rear differential?

Go to Step 9

Replace the

differential oil.

Go to Step 16

9Does the engine output the power correctly?

Go to Step 10

Check the

engine.

Go to Step 16

10Do the speed sensors work correctly? (Check trouble codes.)The ECU has

failed. Replace

the ECU.

Go to Step 16

Replace the

speed sensors.

Go to Step 16

11Is the tight corner braking observed only when the brake is

applied?

Go to Step 12

Conduct full

steering under

WOT.

Go to Step 5

121. Turn on the starter switch.

Is the battery voltage observed between terminals 11 and 19?

Go to Step 13

Repair the circuit

of terminal 11

(ABS IN).

Go to Step 16

Page 4209 of 6000

4C–3 DRIVE SHAFT SYSTEM

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 4229 of 6000

4C–23 DRIVE SHAFT SYSTEM

Front Axle Drive Shaft

Front Axle Drive Shaft and Associated Parts

This illustration is based on the model equipped with shift on the fly system.

412RW003

Legend

(1) Axle Case and Differential

(2) DOJ Case Assembly

(3) Snap Ring

(4) Bearing

(5) Snap Ring

(6) Oil Seal

(7) Bracket

(8) DOJ Case

(9) Circlip

(10) Bolt

(11) Drive Shaft Joint Assembly

(12) Snap Ring(13) Spacer

(14) Ball

(15) Snap Ring

(16) Ball Retainer

(17) Ball Guide

(18) Band

(19) Bellows

(20) Band

(21) Band

(22) Bellows

(23) Band

(24) BJ Shaft

(25) Dust Seal

Page 4239 of 6000

4C–33 DRIVE SHAFT SYSTEM

412RS037

Reassembly

1. Install the new oil seal which has been immersed in

differential gear oil, by using an oil seal installer

5–8840–2407–0 and grip 5–8840–0007–0.

412RS043

2. Force a new needle bearing into inner shaft by using a

installer 5–8840–2408–0 and grip 5–8840–0007–0.

412RS051

3. Place a new snap ring(internal) in inner shaft.

Force a new inner shaft bearing into the inner shaft by

using a installer 5–8840–2197–0 and press.

412RS044

4. Install snap ring(external).

NOTE: Be careful not to damage the inner shaft.

5. Clean the housing contact surface of the front axle

case and insert inner shaft assembly into the front

axle case.