parking brake OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2164 of 6000

7A–10

AUTOMATIC TRANSMISSION (4L30–E)

Checking Transmission Fluid Level

and Condition

Checking fluid level and condition (color and odor) at

regular intervals will provide early diagnosis information

about the transmission. This information may be used to

correct a condition that, if not detected early, could result

in major transmission repairs.

IMPORTANT:When new, automatic transmission fluid

is red in color. As the vehicle is driven, the transmission

fluid will begin to look darker in color. The color may

eventually appear light brown.

A dark brown color with burnt odor may indicate

excessive fluid deterioration and signal a need for fluid

change.

Fluid Level

When adding or changing fluid, use only DEXRON –III.

Refer to Maintenance and Lubrication in General

Information section for maintenance information and

servicing interval.

CAUTION: DO NOT OVERFILL.

Overfilling will cause foaming, loss of fluid, abnor-

mal shifting and possible damage to the transmis-

sion.

1. Park the vehicle on level ground and apply the parking

brake firmly.

2. Check fluid level with engine running at idle.

NOTE: Be sure that transmission fluid temperature is

below 30

C (86F).

3. Move the selector lever through all gear ranges.

4. Move the selector lever to “Park”.

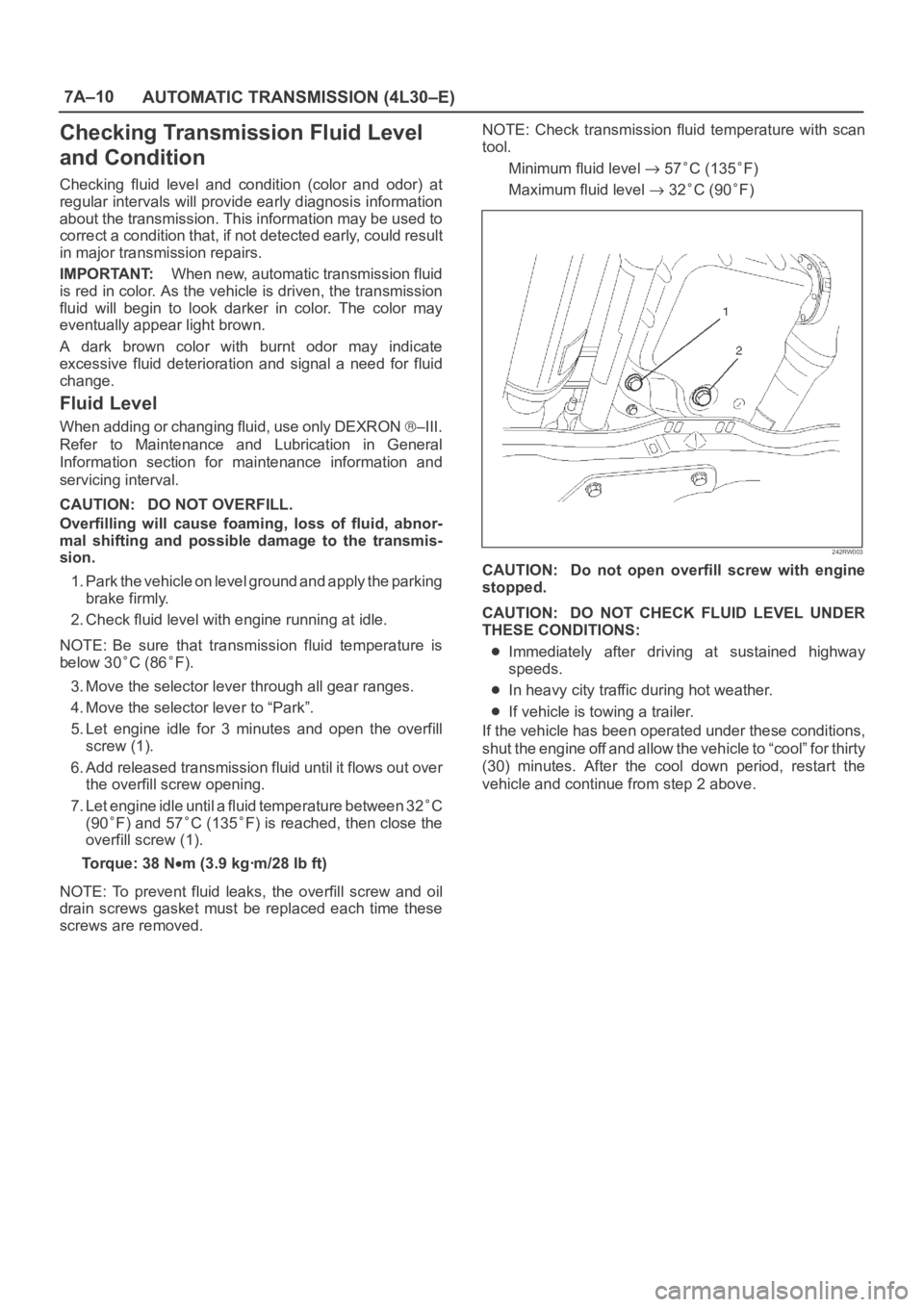

5. Let engine idle for 3 minutes and open the overfill

screw (1).

6. Add released transmission fluid until it flows out over

the overfill screw opening.

7. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached, then close the

overfill screw (1).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.NOTE: Check transmission fluid temperature with scan

tool.

Minimum fluid level

57C (135F)

Maximum fluid level

32C (90F)

242RW003

CAUTION: Do not open overfill screw with engine

stopped.

CAUTION: DO NOT CHECK FLUID LEVEL UNDER

THESE CONDITIONS:

Immediately after driving at sustained highway

speeds.

In heavy city traffic during hot weather.

If vehicle is towing a trailer.

If the vehicle has been operated under these conditions,

shut the engine off and allow the vehicle to “cool” for thirty

(30) minutes. After the cool down period, restart the

vehicle and continue from step 2 above.

Page 2177 of 6000

7A–23 AUTOMATIC TRANSMISSION (4L30–E)

Stall Test

The stall test allows you to check the transmission for

internal abrasion and the one way clutch for slippage.

Torque converter performance can also be evaluated.

The stall test results together with the road test results will

identify transmission components requiring servicing or

adjustment.

Stall Test Procedure:

1. Check the level of the engine coolant, the engine oil,

and the automatic transmission fluid. Replenish if

necessary.

2. Block the wheels and set the parking brake.

3. Connect a tachometer to the engine.

4. Start the engine and allow it to idle until the engine

coolant temperature reaches 70 – 80

C (158 –

176

F).

5. Hold the brake pedal down as far as it will go.

6. Place the selector in the “D” range.

7. Gradually push the accelerator pedal to the floor.

The throttle valve will be fully open.

Note the engine speed at which the tachometer

needle stabilizes.

Stall Speed : 2,100

150 rpm

NOTE: Do not continuously run this test longer than 5

seconds.

8. Release the accelerator pedal.

9. Place the selector in the “N” range.

10. Run the engine at 1,200 rpm for one minute.

This will cool the transmission fluid.

11. Repeat Steps 7 – 10 for the “3”, “2”, “L” and “R”

ranges.

Line Pressure Test

The line pressure test checks oil pump and control valve

pressure regulator valve function. It will also detect oil

leakage.

Line Pressure Test Procedure:

1. Check the level of the engine coolant, the engine oil,

and the automatic transmission fluid.

Replenish if required.

2. Block the wheels and set the parking brake.

3. Remove the pressure detection plug at the left side of

the transmission case.

Set 5–8840–0004–0 pressure gauge and adapter to

the pressure detection plug hole.

241RS001

4. Start the engine and allow it to idle until the engine

coolant temperature reaches 70 – 80

C (158 –

176

F).

5. Hold the brake pedal down as far as it will go.

6. Place the selector in the “D” range.

7. Note the pressure gauge reading with the engine

idling.

8. Gradually push the accelerator pedal to the floor. The

throttle valve will be fully open.

Note the pressure gauge reading with the accelerator

pedal fully depressed.

NOTE: Do not continuously run this test longer than 5

seconds.

9. Release the accelerator pedal.

10. Place the selector in the “N” range.

11. Run the engine at 1,200 rpm for one minute.

This will cool the transmission fluid.

12. Repeat Steps 7 – 11 for the “3”, “2”, “L”, and “R”

ranges.

13. Install a pressure detection plug to the transmission

case, applying recommended thread locking agent

(LOCTITE 242) or its equivalent to thread of plug.

Make sure that thread is cleaned before applying

locking agents.

14. Tighten the pressure detection plug to the specified

torque.

Torque:9–14Nꞏm(0.9–1.4kgꞏm/7–10lbft)

Page 2201 of 6000

7A–47 AUTOMATIC TRANSMISSION (4L30–E)

36. Separate second (40) and third clutch (41)

assemblies.

37. Remove thrust washer (42).

38. Remove reverse clutch plates (43 and 44) and

reverse clutch pressure plate (45).

39. Remove bearing (46) and washer (47).

40. Remove planetary carrier assembly (48).

41. Remove thrust bearing (49).

42. Remove reaction sun gear (50)

43. Remove needle bearing (51).

44. Remove brake drum (52).

45. Remove brake band (53).

46. Remove thrust bearing (54).

242RS003

47. Rotate case to horizontal position, valve body side

facing up.

Remove spring pin (55), using cutting pliers, then

remove parking lock and selector lever assembly

(56).NOTE: Insert wire in the center of the spring pin to

prevent it from collapsing during removal. Be aware of pin

height. Protect machined face of main case.

48. Remove parking lock and range selector lever 17 mm

nut (57).

49. Remove parking lock and range selector lever (56),

and actuator assembly.

50. Remove selector shaft (58).

NOTE: Inspect the shaft for burrs before removing to

prevent damaging seal. If necessary, remove burrs by

lightly sanding with an oilstone.

249RS004

Reassembly

1. Inspect selector shaft seal, and replace it if

necessary.

NOTE: Use a seal installer when replacing the seal.

Install selector shaft.

NOTE: Spring pin groove must be positioned inside the

case.

2. Install spring pin. Be sure the selector shaft can move

freely. Do not push the pin flush with the case surface.

Leave enough height for removal.

3. Install actuator assembly (1).

4. Install parking lock and range selector lever (2) and

new 17 mm nut. Tighten the nut to the specified

torque.

To r q u e : 2 2 N

m (2.2 kgꞏm/16 lb ft)

Page 2245 of 6000

7A–91 AUTOMATIC TRANSMISSION (4L30–E)

(646) Gear Assembly, Input Sun

(647) Race Assembly, Sprag

(648) Ring, Retaining/Sprag

(649) Ring, Retaining

(650) Cage Assembly, Sprag

(651) Bearing, Output Shaft/Input Sun

(652) Washer, Output Shaft/Input Sun

(653) Carrier Assembly, Planetary(658) Gear, Reaction Sun

(659) Drum, Reaction Sun

(664) Band Assembly, Brake

(667) Seal, Ring/Wheel Parking Lock

(668) Wheel, Parking Lock

(672) Wheel, Speed

(673) Ring, Retaining

(675) Bearing, Thrust Assembly

Center Support Assembly

241RS010

Legend

(701) Center Support

(702) Retainer Plate(703) Plug, Lockout

(704) Spring, Overrun Lockout

(705) Valve, Overrun Lockout

Page 2529 of 6000

7C–20CLUTCH

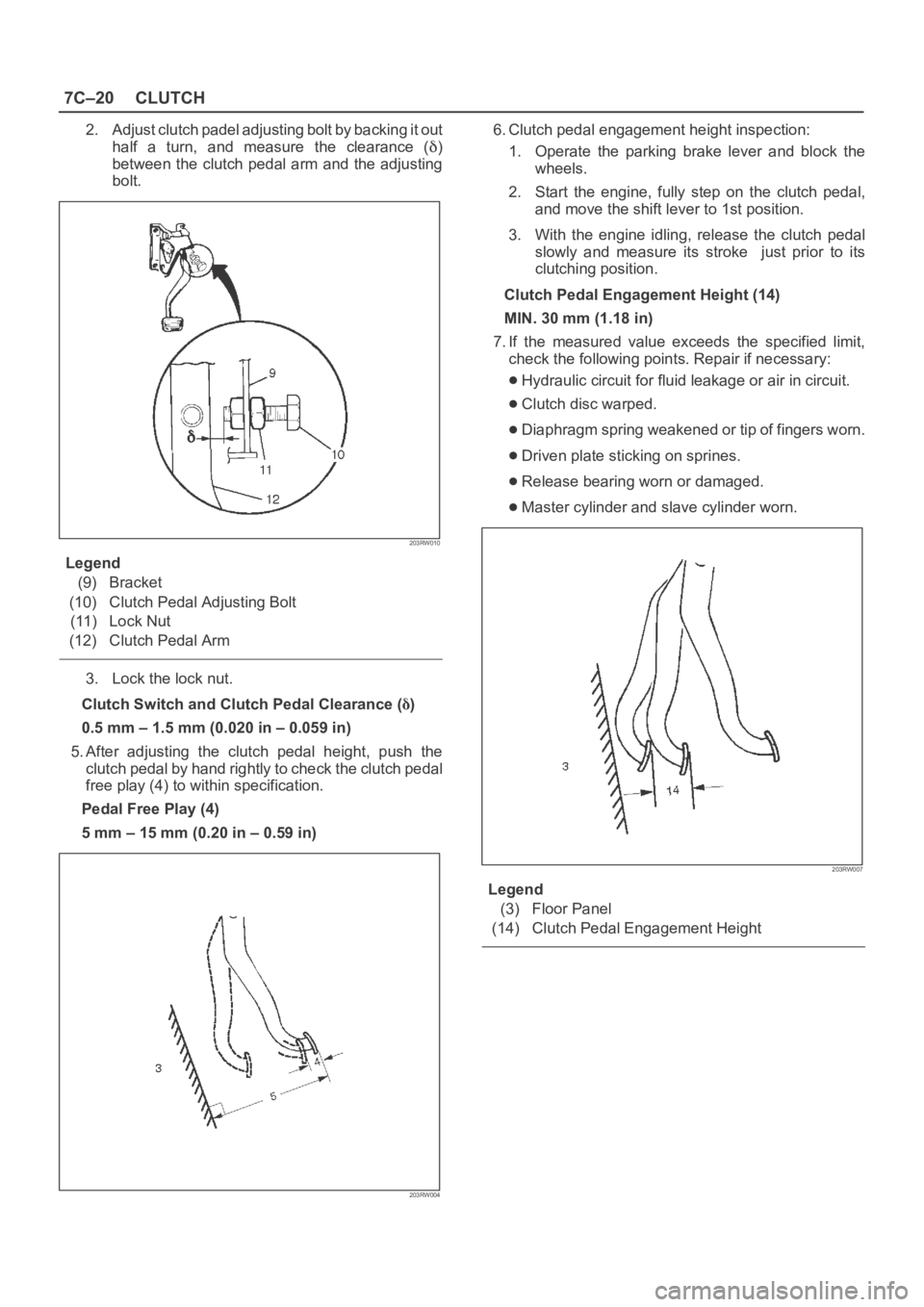

2. Adjust clutch padel adjusting bolt by backing it out

half a turn, and measure the clearance (

)

between the clutch pedal arm and the adjusting

bolt.

203RW010

Legend

(9) Bracket

(10) Clutch Pedal Adjusting Bolt

(11) Lock Nut

(12) Clutch Pedal Arm

3. Lock the lock nut.

Clutch Switch and Clutch Pedal Clearance (

)

0.5 mm – 1.5 mm (0.020 in – 0.059 in)

5. After adjusting the clutch pedal height, push the

clutch pedal by hand rightly to check the clutch pedal

free play (4) to within specification.

Pedal Free Play (4)

5 mm – 15 mm (0.20 in – 0.59 in)

203RW004

6. Clutch pedal engagement height inspection:

1. Operate the parking brake lever and block the

wheels.

2. Start the engine, fully step on the clutch pedal,

and move the shift lever to 1st position.

3. With the engine idling, release the clutch pedal

slowly and measure its stroke just prior to its

clutching position.

Clutch Pedal Engagement Height (14)

MIN. 30 mm (1.18 in)

7. If the measured value exceeds the specified limit,

check the following points. Repair if necessary:

Hydraulic circuit for fluid leakage or air in circuit.

Clutch disc warped.

Diaphragm spring weakened or tip of fingers worn.

Driven plate sticking on sprines.

Release bearing worn or damaged.

Master cylinder and slave cylinder worn.

203RW007

Legend

(3) Floor Panel

(14) Clutch Pedal Engagement Height

Page 2892 of 6000

0.5

L/W

3.0

B/Y

0.85

L/WC-4 10A

ELEC. IGN.

STARTER SW

(IG1)BATT.(+)

STOPLIGHT

SHIFT LOCK

SOLENOIDPARKING POSITION

DETECTING SW 1

B-32

0.85

G/W

0.85

G/W

0.85

G/Y

0.85

G/Y0.85

G/W

0.85

G/Y

42B-32B-32

B-32

6

0.5

B

2.0

B

BODY-LH

B-2

2.0

B

BODY-CTR

B-26

2.0

B

BODY-RH

B-18 AC GENERATOR

(L)5.0

W

C-14 15A

STOP, A/T CONT

5B-3213

H-15

0.85

W/G

STOPLIGHT

SW

1B-14

7

H-32

B-14

24 1

(W/O CRUISE

CONTROL)BRAKE

SW

B-13

B-13

(W/ CRUISE

CONTROL)

SHIFT LOCK CONTROLLER

D08RW659

Page 2894 of 6000

0.5

L/W

3.0

B/Y

0.5

L/WC-4 10A

ELEC. IGN.

STARTER SW

(IG1)BATT.(+)

STOPLIGHT

SHIFT LOCK

SOLENOIDPARKING POSITION

DETECTING SW 1

B-32

0.85

G/W

0.85

G/W

0.85

G/Y

0.85

G/Y0.85

G/W

0.85

G/Y

42B-32B-32

B-32

6

0.5

B

2.0

B

BODY-CTR

B-26

AC GENERATOR

(L)5.0

W

C-14 15A

STOP, A/T CONT

5B-3211

H-15

0.85

W/G

STOPLIGHT

SW

1B-14

7

H-32

B-14

24 1

(W/O CRUISE

CONTROL)BRAKE

SW

B-13

B-13

(W/ CRUISE

CONTROL)

SHIFT LOCK CONTROLLER

D08RW956

Page 3006 of 6000

D08RW725

G

H

FE

16

14 CRUISE

SETCRUISE

MAINAIR BAG ABS 4WD BRAKEEHCU:ELECTRONIC HYDRAULIC CONTROL UNIT

OIL

PRESSURE

CRUISE

CONTROL

UNIT(14)0.5

B/OI-9

H-2617

15

CRUISE

CONTROL

UNIT(13) 0.5

GR/LI-9

H-2624

2

SDM

(7) 0.5

W/RI-9

H-6216

2

EHCU

(16)

OIL PRESSURE

SWBRAKE

FLUID

SWPARKING

BRAKE

SW

0.5

YI-10

H-1618

19

4WD

CONTROL

UNIT(19)/

FRT

AXLESW(2)

OR

4WDSW(1)0.5

LGI-9

H-2722

22

12

1 0.5

LB

0.5

LB0.5

B/P

0.5

B0.5

B/P0.5

B/P

0.5

LBI-9

H-9

H-6

E-14

1

8 9

213

1

FENDER-RH0.5

B/PI-9

H-16

C-15

C-39 C-15H-26

B-27

METER

Page 3012 of 6000

D08RW733

G

FE

18

14 CRUISE

SETCRUISE

MAINAIR BAG ABS BRAKEEHCU:ELECTRONIC HYDRAULIC CONTROL UNIT

OIL

PRESSURE

CRUISE

CONTROL

UNIT(14)0.5

B/OI-9

H-2619

15

CRUISE

CONTROL

UNIT(13) 0.5

GR/LI-9

H-262

2

SDM

(7) 0.5

W/RI-9

H-6216

2

EHCU

(16)

OIL PRESSURE

SWBRAKE

FLUID

SWPARKING

BRAKE

SW

0.5

YI-10

H-1620

22

12

1 0.5

LB

0.5

LB0.5

B/P

0.5

B0.5

B/P0.5

B/P

0.5

LBI-9

H-9

H-6

E-17

1

8 9

213

1

FENDER-RH0.5

B/PI-9

H-16

C-15

C-39 C-15H-26

B-27

METER

Page 3018 of 6000

D08RW737

BRAKE EHCU:ELECTRONIC HYDRAULIC CONTROL UNIT

SEDIMENTER 4WD

BRAKE

FLUID

SWPARKING

BRAKE

SW

18

19

4WD

CONTROL

UNIT(19)

FRT AXLE

SW(2)4WD

SW(1)0.5

LG

0.5

LG 0.5

LG 0.5

LGI-9

H-2723

7

2 0.5

V

0.3

V0.5

B/P

0.85

B/P

0.5

B0.5

B/P0.5

B/P I-9

H-9

H-674

1

8 9

213

1

FENDER-RH0.5

B/PI-9

H-16

C-15

C-39 C-15FUEL

FILTER

SW

0.5

B1

2

FENDER-L HC-16 C-67

VACUUM

SW

1

C-68H-26

B-27

METER